Electrode catalyst, composite electrode and preparation process of electrode catalyst

A technology of electrode catalyst and composite electrode, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of high price, difficult processing, and easy falling off of the catalytic layer, and achieve low cost, good catalytic performance, and simple and efficient preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a preparation process of an electrode loaded with a catalyst, and the specific steps are as follows:

[0035] (1) Preparation of electrode substrate;

[0036] The sheet foam metal and alloy are used as the electrode base, the electrode base is soaked in 30%-60% PTFE (polytetrafluoroethylene) solution for 1-24 hours, and then dried at room temperature for 1-24 hours. Put the above materials into a muffle furnace for heat treatment at 300-400°C for 10-40 minutes, take them out and dry them at room temperature. Apply a layer of 30% to 60% PTFE solution evenly on one side of the above materials, and then dry at room temperature for 20 to 40 minutes. Put the above material into a muffle furnace and heat it at 300-400°C for 10-20 minutes, take it out to dry at room temperature, and this side is the gas diffusion layer; sand the other side of the above material until the metal layer is exposed to achieve conductivity, and ultrasonically After cleaning,...

Embodiment 1

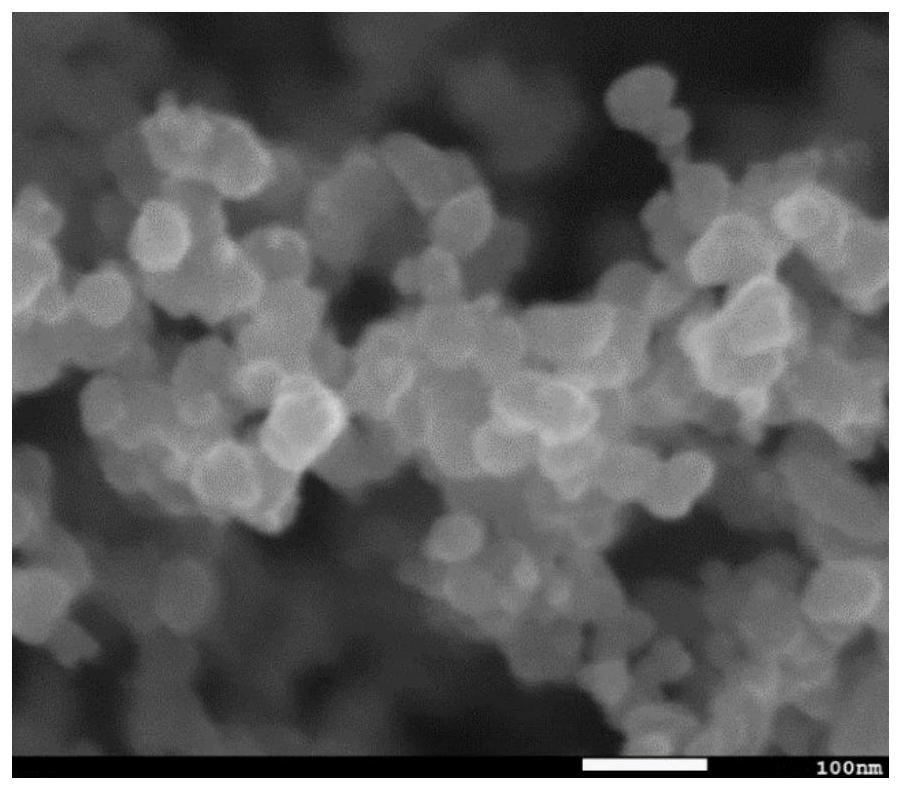

[0053] To prepare the electrode catalyst with flame soot particles loaded on the catalytic layer, the specific preparation steps are as follows:

[0054] (1) Preparation of electrode substrate;

[0055] Soak the titanium foam substrate in 30% PTFE solution for 10 h, and then dry it at room temperature for 12 h. Afterwards, the above materials were put into a muffle furnace for heat treatment at 370° C. for 30 minutes, and then taken out to dry at room temperature. Apply a layer of 60% PTFE solution evenly on one side of the above materials, and then dry at room temperature for 30 minutes. Put the above materials into a muffle furnace for heat treatment at 370°C for 15 minutes, take them out and dry them at room temperature. Polish the other side of the above material with sandpaper until the metal layer leaks out, clean it ultrasonically, and dry it at room temperature to obtain an electrode substrate with an air diffusion layer on one side and a conductive side on the other...

Embodiment 2

[0059] Concrete preparation steps are as follows:

[0060] (1) Preparation of electrode substrate;

[0061] Soak the titanium foam substrate in 30% PTFE solution for 10 h, and then dry it at room temperature for 12 h. Afterwards, the above materials were put into a muffle furnace for heat treatment at 370° C. for 30 minutes, and then taken out to dry at room temperature. Apply a layer of 60% PTFE solution evenly on one side of the above materials, and then dry at room temperature for 30 minutes. Put the above materials into a muffle furnace for heat treatment at 370°C for 15 minutes, take them out and dry them at room temperature. Grind the other side of the above material with sandpaper until the metal layer leaks out, clean it ultrasonically, and dry it at room temperature to obtain an electrode substrate with an air diffusion layer on one side and a conductive electrode on the other side;

[0062] (2) preparation of catalytic layer;

[0063] After the paraffin is melted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com