Diaphragm pyrolysis assisted recovery method for valuable metals in waste lithium battery material

A waste lithium battery, valuable metal technology, applied in the direction of waste collector recycling, lithium carbonate;/acid carbonate, etc., can solve problems such as increasing cost and increasing carbon resource consumption, and achieves easy operation and avoidance. Adding and improving the effect of acid leaching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

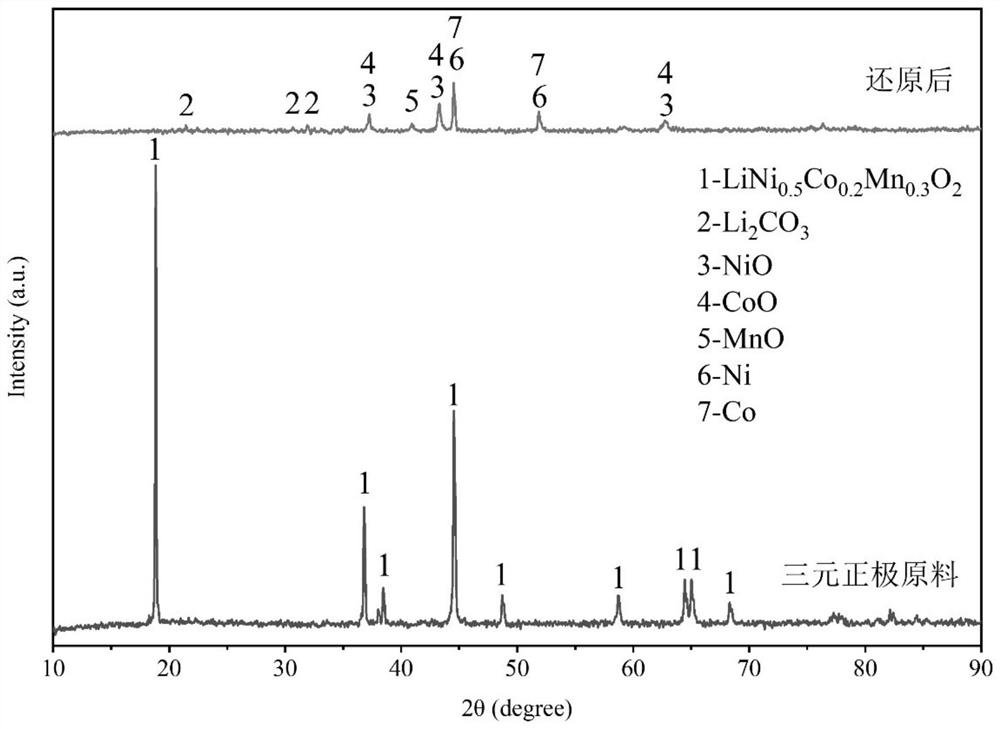

Embodiment 1

[0035] a. Soak the waste lithium-ion battery in a 5% sodium chloride solution for 24 hours to discharge, and then manually disassemble the positive electrode and the diaphragm;

[0036] b. Put the disassembled positive electrode sheet into the universal crusher for crushing, the obtained crushed product is sieved through a 200-mesh sieve, the aluminum sheet is enriched on the sieve, and the positive electrode material under the sieve is placed in a muffle with a temperature of 500 ° C. Oxygen calcination is carried out in the furnace for 2 hours to remove the binder to obtain waste ternary positive electrode powder for reduction roasting; the time for crushing in the universal crusher is 15s.

[0037] c. Cut the obtained diaphragm to 2mm so that it can be mixed evenly with the waste ternary positive electrode powder, and mix the shredded diaphragm with the waste ternary positive electrode powder and put it into the tube furnace; The mass ratio of the positive electrode powder ...

Embodiment 2

[0043] a. Soak the waste lithium-ion battery in a sodium chloride solution with a mass fraction of 5% for 24 hours to discharge, and then manually disassemble the positive electrode and the diaphragm;

[0044] b. Put the disassembled positive electrode sheet into the universal crusher for crushing. The obtained crushed product is sieved through a 200-mesh sieve, and the aluminum sheet is enriched on the sieve. Oxygen calcination is carried out in the furnace for 2 hours to remove the binder to obtain waste ternary positive electrode powder for reduction roasting; the time for crushing in the universal crusher is 18s.

[0045] c. Cut the obtained diaphragm to 2.5mm so that it can be evenly mixed with the waste ternary positive electrode powder, and mix the shredded diaphragm and the waste ternary positive electrode powder evenly into the tube furnace; The mass ratio of the ternary cathode powder is 10%.

[0046] d. The air in the tube furnace is pumped out by a vacuum pump to ...

Embodiment 3

[0051] a. Soak the waste lithium-ion battery in a sodium chloride solution with a mass fraction of 5% for 24 hours to discharge, and then manually disassemble the positive electrode and the diaphragm;

[0052] b. Put the disassembled positive electrode sheet into the universal crusher for crushing. The obtained crushed product is sieved through a 200-mesh sieve, and the aluminum sheet is enriched on the sieve. Oxygen calcination is carried out in the furnace for 2 hours to remove the binder to obtain waste ternary positive electrode powder for reduction roasting; the time for crushing in the universal crusher is 20s.

[0053] c. Cut the obtained diaphragm to 3mm so that it can be mixed evenly with the waste ternary positive electrode powder, and mix the shredded diaphragm and the waste ternary positive electrode powder evenly into the tube furnace; The mass ratio of the positive electrode powder is 12%.

[0054] d. The air in the tube furnace is pumped out by a vacuum pump to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com