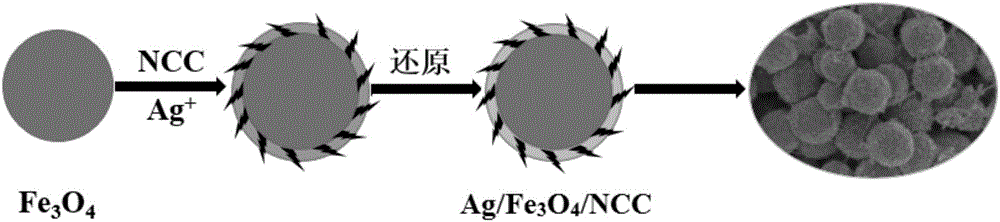

Ag/Fe3O4/nano-cellulose tri-element composite material and preparation method thereof

A nanocellulose and composite material technology, applied in the field of Ag/Fe3O4/nanocellulose ternary composite material and its hydrothermal preparation, can solve the problems of uneven size and distribution of silver particles, inability to recycle, poor antibacterial performance, etc. , to achieve uniform particle size, improved application and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In the preparation method according to the present invention is Fe 3 o 4 The ratio of the weight parts of nanoparticles, silver nitrate and nano cellulose (NCC) is 2~25:10~25:25~60, more preferably the ratio of weight parts is Fe 3 o 4 Nanoparticles: silver nitrate: NCC=2~10:10~20:35~60.

[0034] where Fe 3 o 4 When the amount of nanoparticles is less than 2 parts by weight, Ag / Fe 3 o 4 The photocatalytic properties and superparamagnetism of nanocellulose ternary composites are not ideal; and when Fe 3 o 4 When the amount of nanoparticles is greater than 25 parts by weight, the content of elemental silver is relatively low, and it may be due to Fe 3 o 4 Under the combined influence of the magnetic properties of the nanoparticles themselves and the adhesion of nanocellulose, the prepared Ag / Fe 3 o 4 / The agglomeration phenomenon of the nanocellulose ternary composite material is serious, and it is not easy to disperse, which makes the catalytic performance of ...

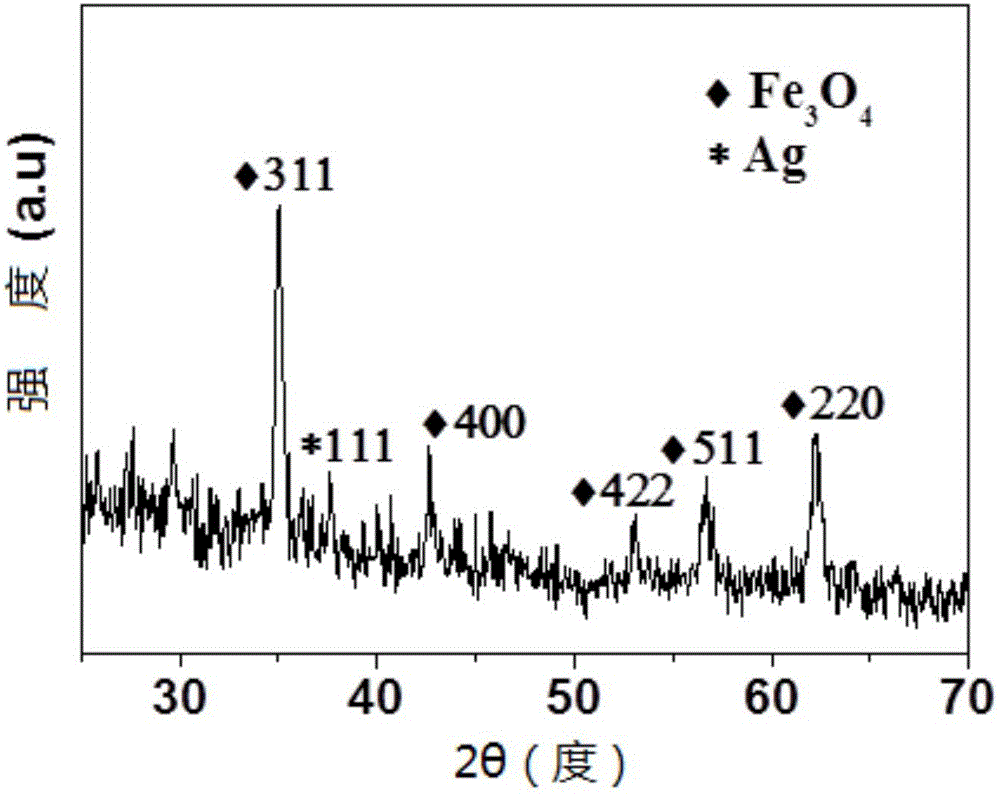

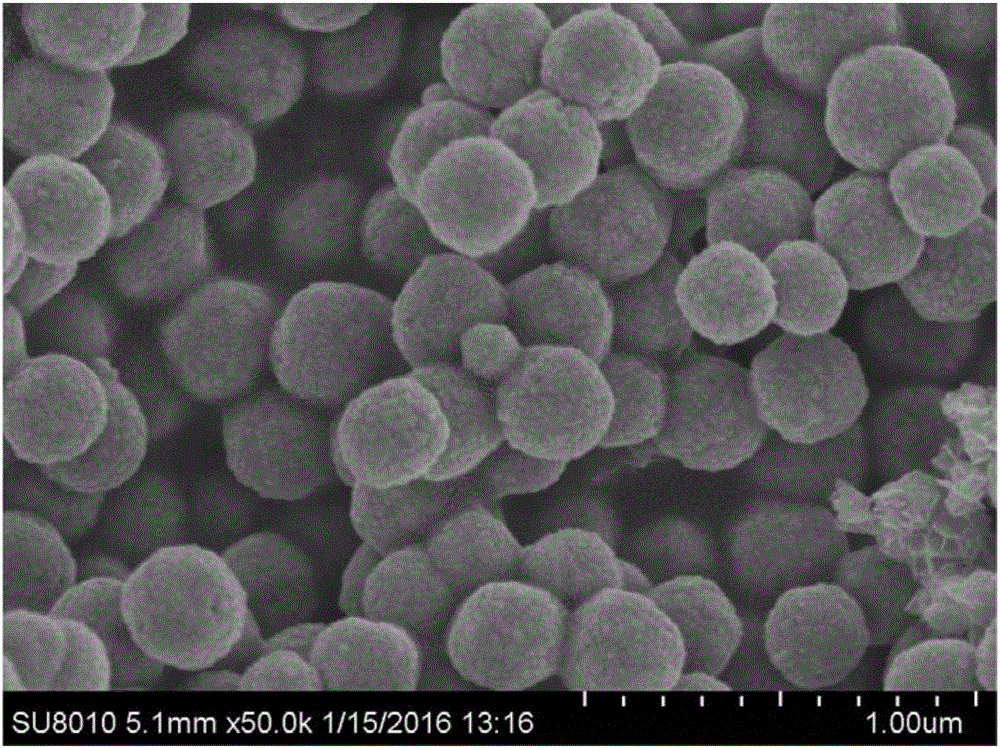

Embodiment 1

[0043] Fe 3 o 4 Preparation of particles: 3.0 g of FeCl 3 ˙6H 2 Sodium acetate (NaAc) of 0 and 12g is dissolved in the ethylene glycol / ethylenediamine mixed solution, and wherein the volume of ethylene glycol and ethylenediamine solvent is respectively 90ml and 10ml, after the mixed solution is mechanically stirred for 30min, a yellow liquid appears , put the yellow liquid into a polytetrafluoroethylene high-pressure reactor (150ml), put it in a muffle furnace and heat up to 200°C, and the reaction time is 2 hours. After the reaction is over, naturally cool to room temperature, and take out the reaction product. And it is centrifuged, washed (deionized water and ethanol washed three times each), and finally the precipitate is centrifuged, and it is dried (at a temperature of 60 ° C for 12 hours) to finally obtain Fe 3 o 4 nanoparticles. like image 3 The SEM photo shown, the obtained Fe 3 o 4 Nanoparticles are spherical Fe with a diameter of about 203nm 3 o 4 particl...

Embodiment 2

[0050] It was performed in the same manner as in Example 1 except for the following differences.

[0051] Take a small amount of prepared Fe 3 o 4 Powder, after adding deionized water, ultrasonically dispersed to obtain a concentration of 2g / L Fe 3 o 4 aqueous solution; take a small amount of AgNO 3 Powder, after adding deionized water, ultrasonically dispersed to obtain AgNO with a concentration of 10g / L 3 Aqueous solution: Take an appropriate amount of nanocellulose, add deionized water and then ultrasonically disperse to obtain an aqueous dispersion with a concentration of 30 g / L. The three solutions were mixed according to a certain ratio (Fe 3 o 4 Aqueous solution: AgNO 3 Aqueous solution: the volume ratio of nanocellulose aqueous dispersion is 10ml:10ml:10ml, wherein Fe 3 o 4 Nanoparticles: AgNO 3 : the weight ratio of nanocellulose is 2:10:30), packs in polytetrafluoroethylene autoclave (50ml), in muffle furnace (Tianjin Zhonghuan Experimental Electric Furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com