Bamboo charcoal-based magnetic composite material and preparation method

A magnetic composite material and composite material technology are applied in the field of bamboo charcoal-based magnetic composite materials, which can solve the problems of complex magnetic adsorbent process, and achieve the effects of being suitable for industrial production and popularization, reducing costs, and having good crystallization performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

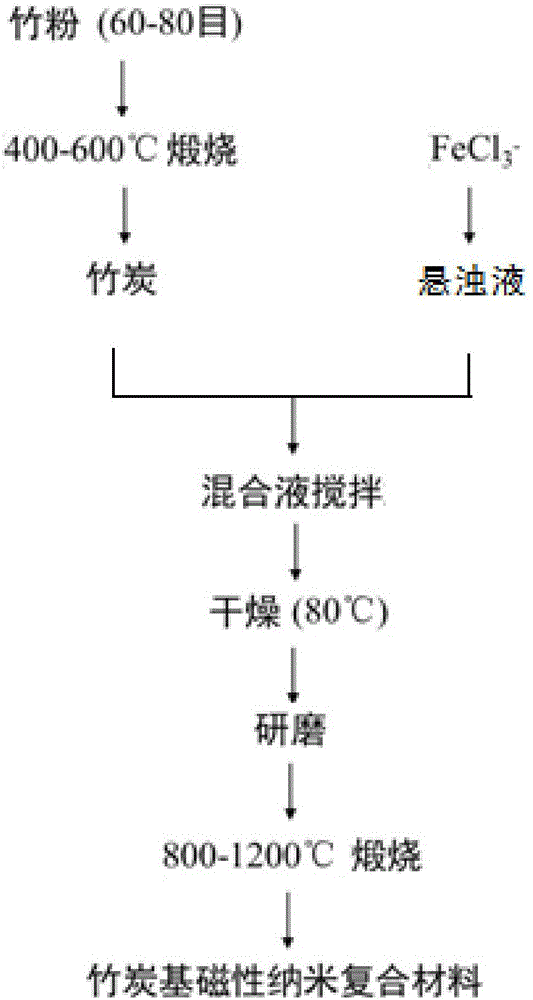

[0041] Such as figure 1 Shown, the bamboo charcoal base / α-Fe described in this embodiment 3 o 4 The magnetic composite material is prepared according to the following steps:

[0042] (1) Divide the bamboo raw material into small sticks of 10mm×5mm×5mm, then use a pulverizer to pulverize and sieve, select a 60-mesh powder sample and dry it at 120°C for 12h; and dry the above-mentioned dried bamboo powder Placed in a tubular calciner, under the protection of argon (the argon flow rate is 300mL / min), the calcining treatment is carried out at a high temperature of 600°C for 1h, and the heating rate of the calcining step is 5°C / min, and the prepared Bamboo charcoal, spare;

[0043] (2) Dissolve 35g of ferric chloride hexahydrate in 65ml of ultrapure water (resistivity 18.2 Ω), and stir evenly under the condition of 150rpm / min to obtain ferric chloride solution for subsequent use;

[0044] (3) Mix 2 g of prepared bamboo charcoal with 20 mL of ferric chloride solution at room tem...

Embodiment 2

[0048] Such as figure 1 As shown, the bamboo charcoal base / α-Fe magnetic composite material described in this embodiment is prepared according to the following steps:

[0049] (1) Divide the bamboo raw material into small sticks of 10mm×5mm×5mm, then use a pulverizer to pulverize and sieve, select a 60-mesh powder sample and dry it at 120°C for 12h; and dry the above-mentioned dried bamboo powder Placed in a tubular calciner, under the protection of argon (the argon flow rate is 300mL / min), the calcining treatment is carried out at a high temperature of 600°C for 1h, and the heating rate of the calcining step is 5°C / min, and the prepared Bamboo charcoal, spare;

[0050] (2) Dissolve 35g of ferric chloride hexahydrate in 65ml of ultrapure water (resistivity 18.2 Ω), and stir evenly under the condition of 150rpm / min to obtain ferric chloride solution for subsequent use;

[0051] (3) Mix 4g of prepared bamboo charcoal with 40mL of ferric chloride solution at room temperature, a...

Embodiment 3

[0055] Such as figure 1 As shown, the bamboo charcoal base / α-Fe magnetic composite material described in this embodiment is prepared according to the following steps:

[0056] (1) Divide the bamboo material into small sticks of 10mm×5mm×5mm, then use a pulverizer to pulverize and sieve, select a 60-80 mesh powder sample and dry it at 120°C for 12 hours; Bamboo powder is placed in a tubular calciner, under argon protection (the argon flow rate is 300mL / min), and is calcined at a high temperature of 600°C for 1h, and the heating rate of the calcining step is 5°C / min, Bamboo charcoal is prepared and set aside;

[0057] (2) Dissolve 40g of ferric chloride hexahydrate in 60ml of ultrapure water (resistivity 18.2 Ω), and stir evenly under the condition of 150rpm / min to obtain ferric chloride solution for subsequent use;

[0058] (3) Mix 4g of prepared bamboo charcoal with 40mL of ferric chloride solution at room temperature, and stir at 350rpm / min for 2h until fully uniform, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com