Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Good anti-corrosion and anti-mildew effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bamboo mould-resisting corrosion-resisting treatment method

InactiveCN106239672AGood effectStrong color fixationWood treatment detailsReed/straw treatmentColor mixingChemistry

The invention discloses a bamboo mould-resisting corrosion-resisting treatment method. The bamboo mould-resisting corrosion-resisting treatment method comprises the following steps of (1) conducting dipping; (2) conduct high-temperature steaming; (3) conducting secondary steaming, wherein the adopted bamboo filaments, bamboo battens and bamboo chips are dipped in a dipping solution firstly, and then the bamboo filaments, the bamboo battens and the bamboo chips are steamed, oxidized and sterilized through hydrogen peroxide and aqueous alkali. The bamboo treated by the adoption of the bamboo mould-resisting corrosion-resisting treatment method is protected against color mixing and color shading, the color fixation capacity of the bamboo is high, and the effect of bamboo-woven furniture and crafts can be improved. Besides, a good protection function is achieved on the surfaces of the bamboo filaments, the bamboo battens and the bamboo chips, and the bamboo filaments, the bamboo battens and the bamboo chips are good in mould-resisting performance, corrosion-resisting performance and mothproof performance. In addition, the compressive resistance and the flexibility of the bamboo filaments, the bamboo battens and the bamboo chips are improved, and therefore the furniture and crafts in various shapes can be conveniently woven.

Owner:泸州纳溪竹韵贸易有限公司

Incense flake as well as preparation method and using method thereof

InactiveCN107982562AKeep dry and feelFast dryingBiocidePest repellentsOlder peopleAdditive ingredient

The invention relates to the technical field of traditional Chinese medicine products with an incense function, in particular to an incense flake as well as a preparation method and a using method thereof. The incense flake is prepared from raw materials in parts by weight as follows: 1-10 parts of flos caryophyllata, 1-10 parts of pericarpium zanthoxyli, 1-10 parts of radix angelicae, 1-10 partsof flos magnoliae, 1-10 parts of borneol, 1-10 parts of folium artemisiae argyi, 1-10 parts of herba eupatorii, 1-10 parts of ramulus cinnamomi, 1-10 parts of fennel, 1-10 parts of rhizoma acori graminei, 1-10 parts of rhizoma atractylodis, 1-10 parts of herba menthae and 1-10 parts of agastache rugosus. The raw materials of the incense flake are traditional Chinese medicines containing volatile ingredients, are natural and harmless and have mutual compounding effect, so that the functions of the incense flake are improved, the condition of incompatibility of medicinal effects of the traditional Chinese medicines is prevented, and the incense flake has effects of resisting bacteria, cleaning air, repelling mosquitoes, relieving pressure and the like, has faint scent odor and is suitable for most environments for infants, old people, adults and the like.

Owner:深圳市卡加德科技发展有限公司

Reflective and heat-isolation coating and preparation method thereof

InactiveCN107298886AExcellent reflective insulation performanceEnergy savingFireproof paintsAntifouling/underwater paintsIonEmulsion

The invention relates to a reflective and heat-isolation coating and a preparation method thereof. The reflective and heat-isolation coating is characterized by being prepared from the following raw materials in parts by weight: 40 to 60 parts of macromolecular emulsion, 4 to 8 parts of composite hollow microspheres, 10 to 20 parts of rutile type titanium dioxide, 1 to 3 parts of flame-retardant agent, 0.5 to 2 parts of filming additive, 0.1 to 0.5 part of wetting agent, 0.1 to 0.5 part of dispersant, 0.1 to 0.5 part of preservative, 0.05 to 0.2 part of defoaming agent, 0.01 to 0.2 part of thickening agent, and 10 to 20 parts of deionized water, wherein the macromolecular emulsion is a mixed solution of acrylate emulsion and polyurethane emulsion; the composite hollow microspheres comprise hollow glass microspheres, hollow ceramic microspheres, and fly ash hollow microspheres. The reflective and heat-isolation coating has the advantages that the components are scientifically compounded, the usage amount of the coating is small, the use cost is low, the reflective and heat-isolation effects of the coating thin layer are good, the construction is rapid, the anti-cracking property, anti-dirt property and weather-resistant property are good, and the certain flame-retardant function is realized.

Owner:张聪聪

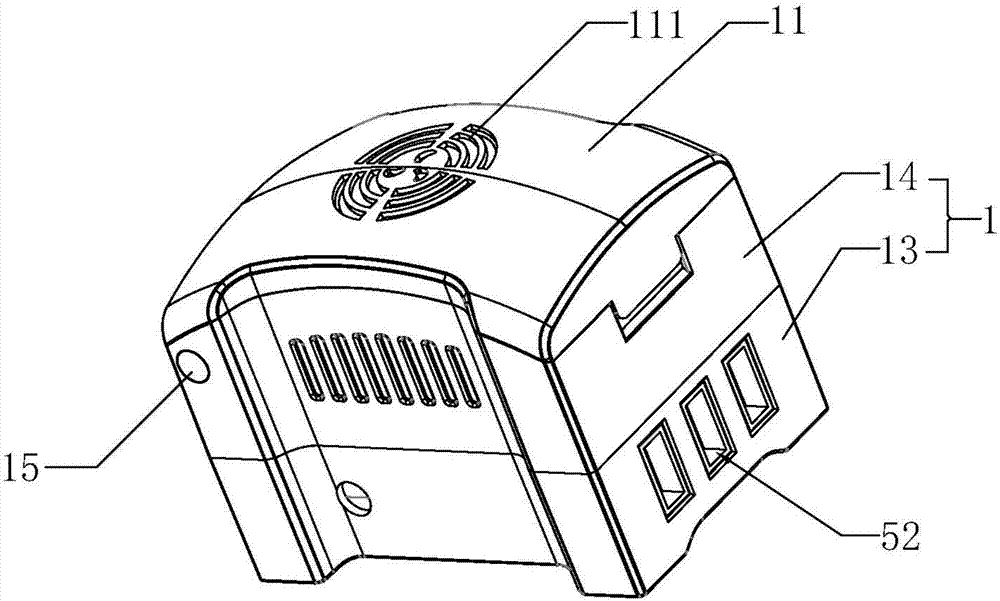

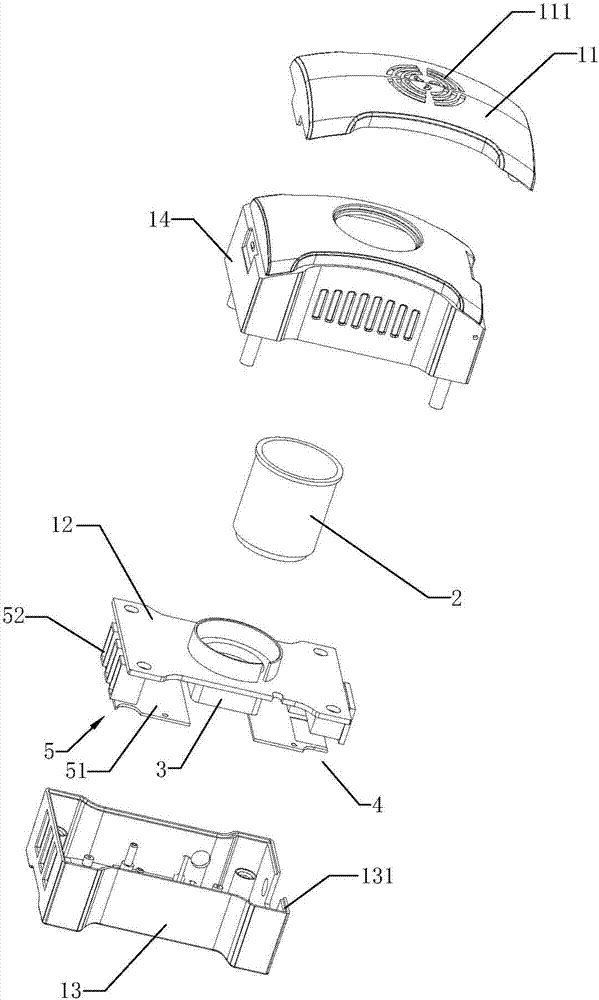

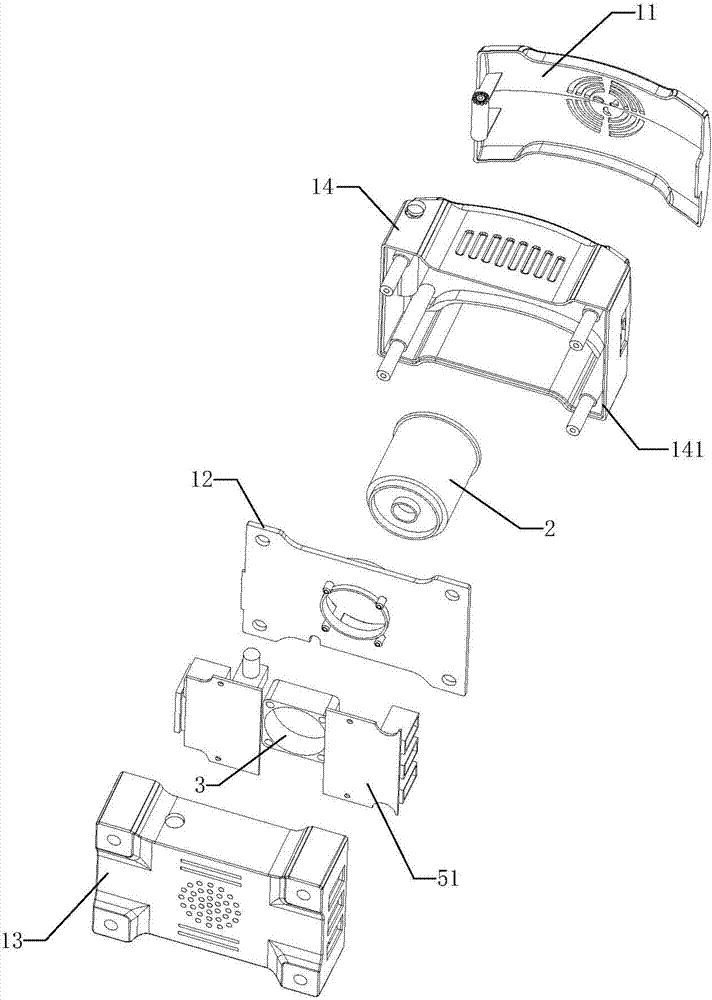

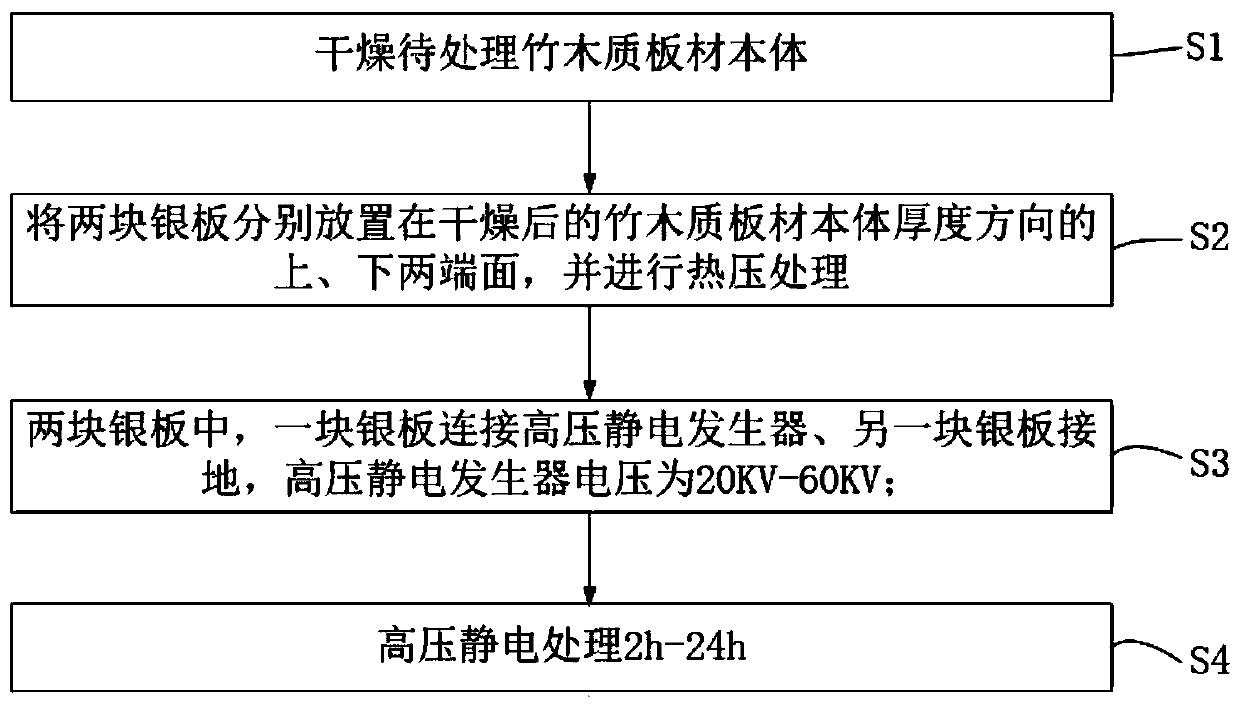

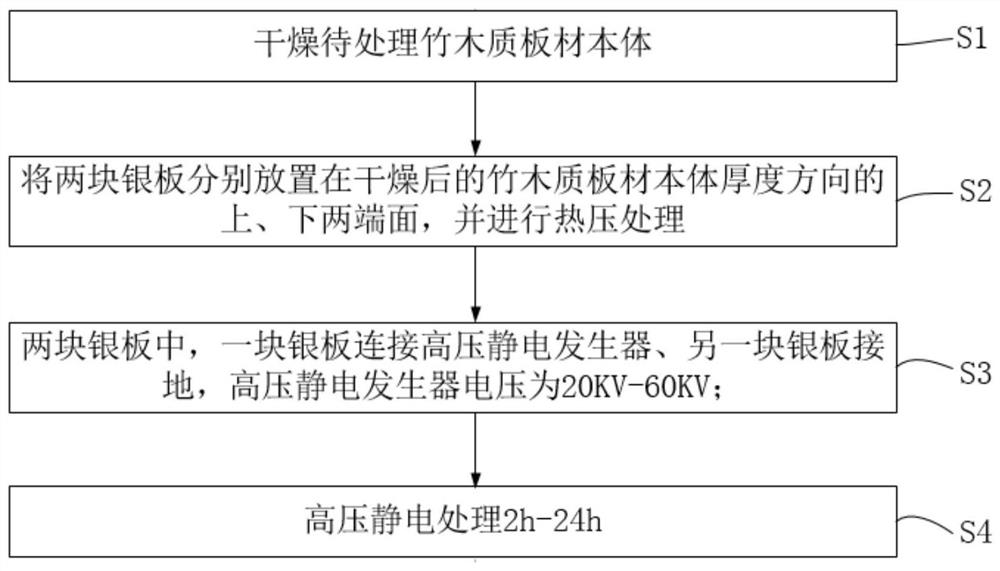

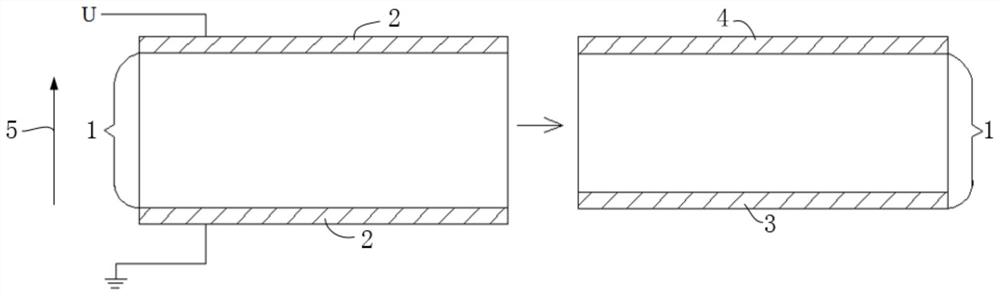

Bamboo material modifying method and bamboo plate

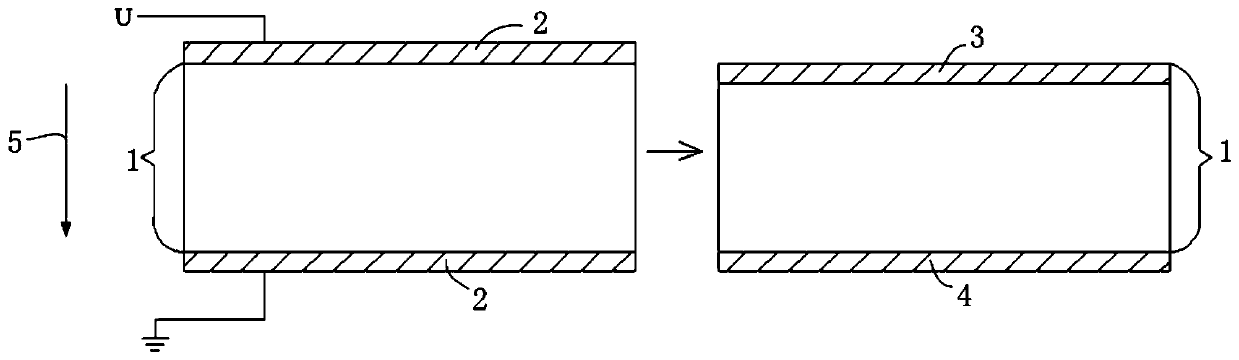

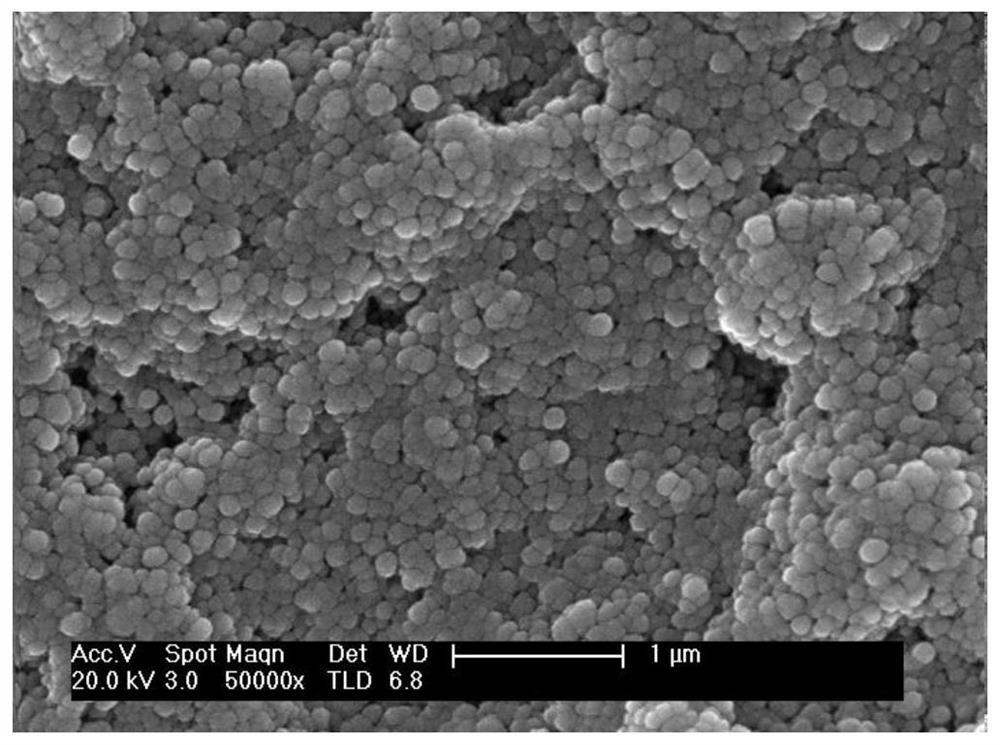

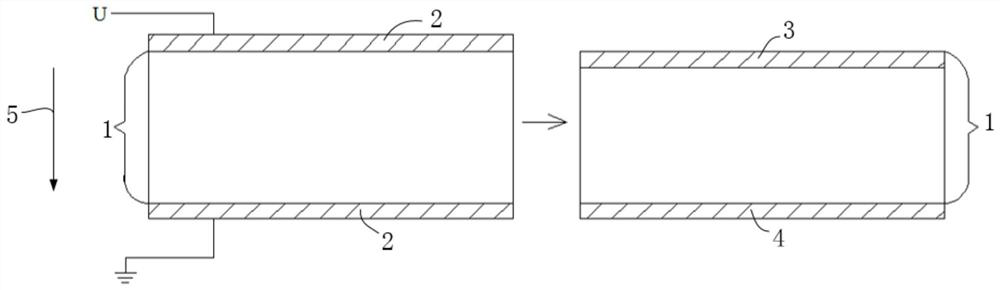

ActiveCN110202649AHigh modification treatment depthModification treatment is easy to operateLamination ancillary operationsElectric wood treatmentSilver plateHigh pressure

The invention discloses a bamboo material modifying method and a bamboo plate and belongs to the field of wood materials. According to the bamboo material modifying method, under the action of a 20-60KV high-voltage electrostatic field, high-voltage electrostatic treatment is carried out on a bamboo plate body with silver plates fitting on the upper and lower end faces. The bamboo plate after modified treatment sequentially comprises a nano-silver element permeation layer, a bamboo plate body, and a nano-silver element deposition layer / nano-silver element permeation layer in the thickness direction of the plate. The bamboo material after high-voltage electrostatic modified treatment has larger anti-corrosive and mildewproof treatment depth; the permeation depth of the nano-silver elementin the plate is 0.05-1mm; and the modified bamboo material is higher in anti-corrosive and mildewproof effect.

Owner:NANJING FORESTRY UNIV

Environmental protection wood flame retardation antiseptic

InactiveCN104858969AImprove flame retardant and smoke suppression performanceBroad-spectrum bactericidal and insecticidal effectWood treatment detailsWood impregnation detailsCarbamatePhosphate

The invention discloses an environmental protection wood flame retardation antiseptic. The flame retardation antiseptic comprises the following ingredients, by weight, 15%-20% of guanylurea phosphate, 4%-6% of zinc borate, 8%-12% of diammonium phosphate, 6%-10% of nanometer titanium dioxide, 1%-4% of ammonium molybdate, 6%-9% of cupric dimethyldithio carbamate, 4%-8% of disodium octoborate tetrahydrate, 1%-3% of dioctyl dimethyl ammonium chloride, 1%-3% of tetradecyl benzyl dimethyl ammonium chloride, 1%-3% of 8-hydroxyquinoline, 0.5%-2% of fatty alcohol polyoxyethylene ether and 20%-50% of water. The beneficial effects are that the flame retardation antiseptic has advantages of high efficiency, no poison and meeting environmental protection requirements, and has advantages of excellent flame retardation smoke inhibition performances, broad-spectrum sterilization and insecticidal effects, excellent anticorrosion and mildew-resistant effects and the like for processing wood. The permeability is good, the leaching resistance is strong and the cost is low.

Owner:王玉燕

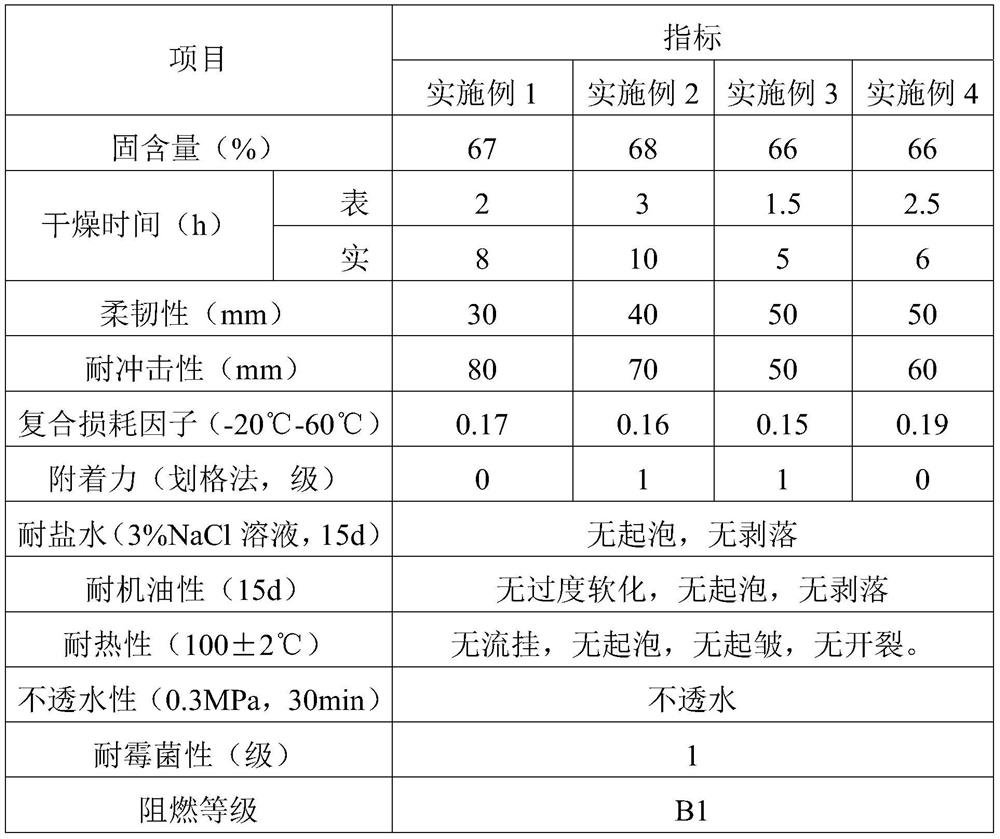

Water-based damping coating, and preparation method and application thereof

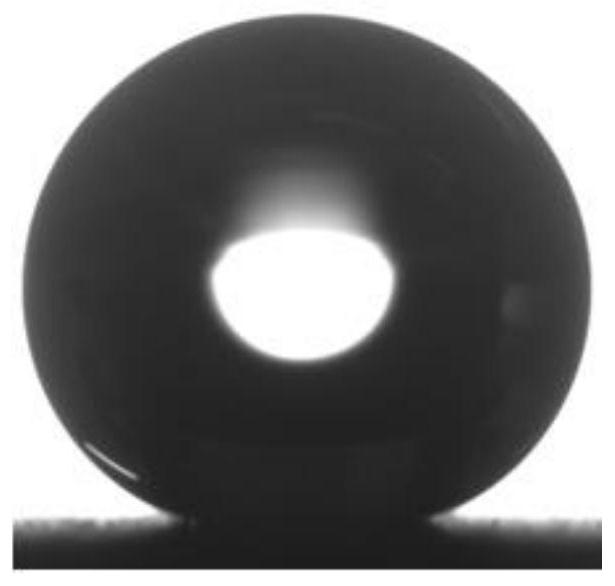

InactiveCN111944372AHigh surface energyHigh activityFireproof paintsAntifouling/underwater paintsEmulsionPhysical chemistry

The invention relates to the technical field of damping coatings, and provides a water-based damping coating, and a preparation method and application thereof. The water-based damping coating comprises a water-based emulsion and an anti-corrosion and anti-mildew agent, wherein the anti-corrosion and anti-mildew agent comprises one or two selected from organic modified nano-silver and nanometer zinc oxide. According to the water-based damping coating disclosed by the invention, organic modified nano-silver and / or nanometer zinc oxide are / is used as the anti-corrosion and anti-mildew agent, so acoating layer has long-term anti-corrosion and anti-mildew properties and environment-friendly characteristics. A traditional anti-corrosion and anti-mildew agent is generally a liquid anti-corrosionand anti-mildew agent which is easy to migrate in a humid environment during usage, and the problems of mould prevention performance loss and pollution are caused; and the traditional anti-corrosionand anti-mildew agent is a toxic substance and easily causes pollution to the environment.

Owner:QINGDAO AIR NEW MATERIALS

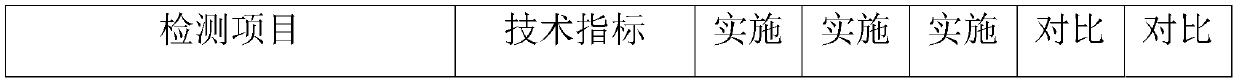

Porcelain-like paint and preparation method thereof

InactiveCN106905793AImprove the decorative effectImprove protectionAntifouling/underwater paintsPaints with biocidesCelluloseEmulsion

The invention discloses a porcelain-like paint and a preparation method thereof, which relates to the technical field of the porcelain-like paint. The porcelain-like paint comprises the following raw materials by parts: 60-80 parts of nanoparticles, 50-60 parts of a modified acrylic resin emulsion, 30-40 parts of modified phosphogypsum powder, 20-30 parts of ceramic powder, 20-30 parts of a refractory material, 2-10 parts of an auxiliary agent, 2-8 parts of a color paste, 2-8 parts of cellulose, and 40-80 parts of deionized water. The preparation method comprises the following steps: 1) preparing the auxiliary agent; 2) preparing the modified acrylic resin emulsion; 3) preparing the modified phosphogypsum powder; 4) preparing a glue solution; and 5) preparing the finished product. The coating has the advantages that the coating is flat and bright, the corrosion-resistant and mildew resistant performances are high, waterproofness is good, age proof performance is good, washability frequency is many, the paint has the advantages of safety and no toxic, and high environmental protection performance, and has good decoration and protection effects for inner walls.

Owner:HEFEI OAKS NEW BUILDING MATERIAL CO LTD

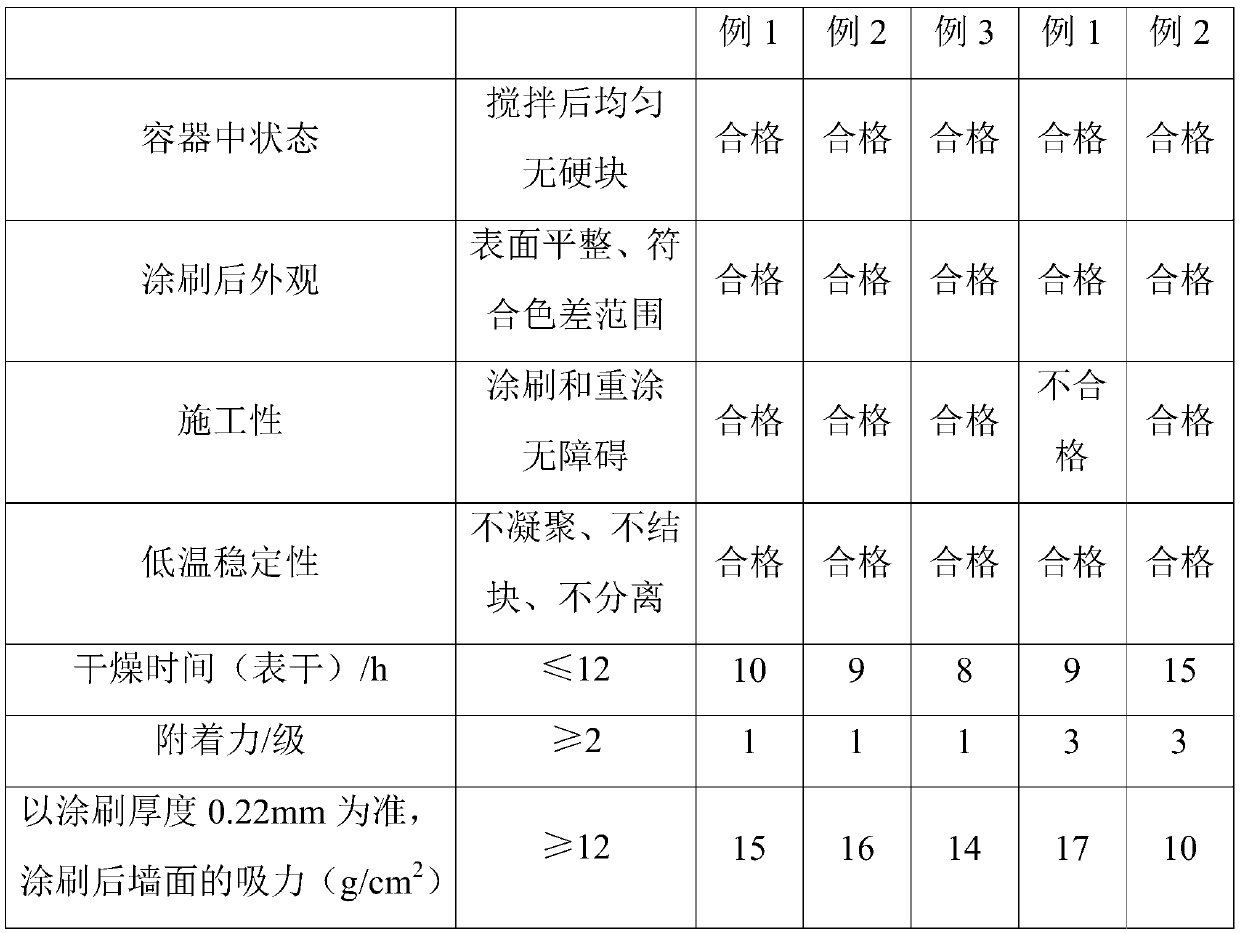

Preparation method of low-VOC anti-cracking environment-friendly building waterproof coating

InactiveCN109054547ALow VOC contentIncrease elasticityAntifouling/underwater paintsPaints with biocidesPolymer scienceBasalt fiber

The invention discloses a preparation method of a low-VOC anti-cracking environment-friendly building waterproof coating. A compound polymer emulsion with the ratio of an environment-friendly pure acrylic emulsion to an environment-friendly VAE emulsion to a non-soap organic silicone rubber emulsion being 7:1:2 is selected. An antibacterial and mildewproof complex inoculant compounded with modified chitosan and beta-cyclodextrin modified silver nano-particles, modified basalt fibers and other effective auxiliaries are added to make synergistic interaction. Thus, the obtained coating has the advantages of low VOC content, good elasticity, high-temperature and low-temperature resistance, excellent anti-cracking and anti-permeability performance, better rheological performance, good anti-corrosion and anti-mildew effect, high strength, better scratch resistance, and the like.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

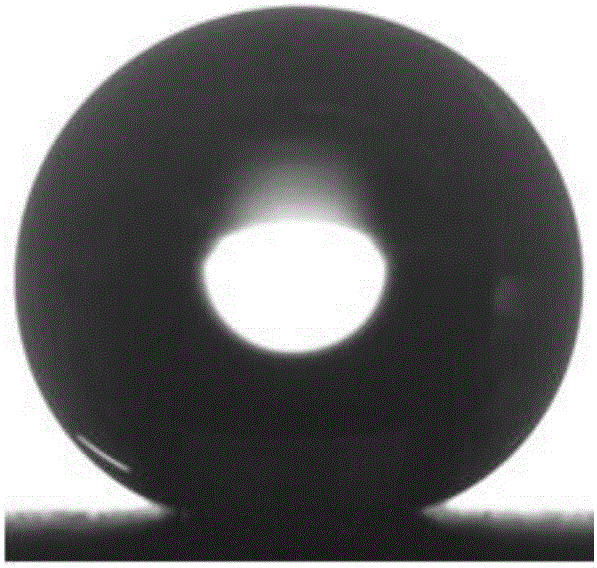

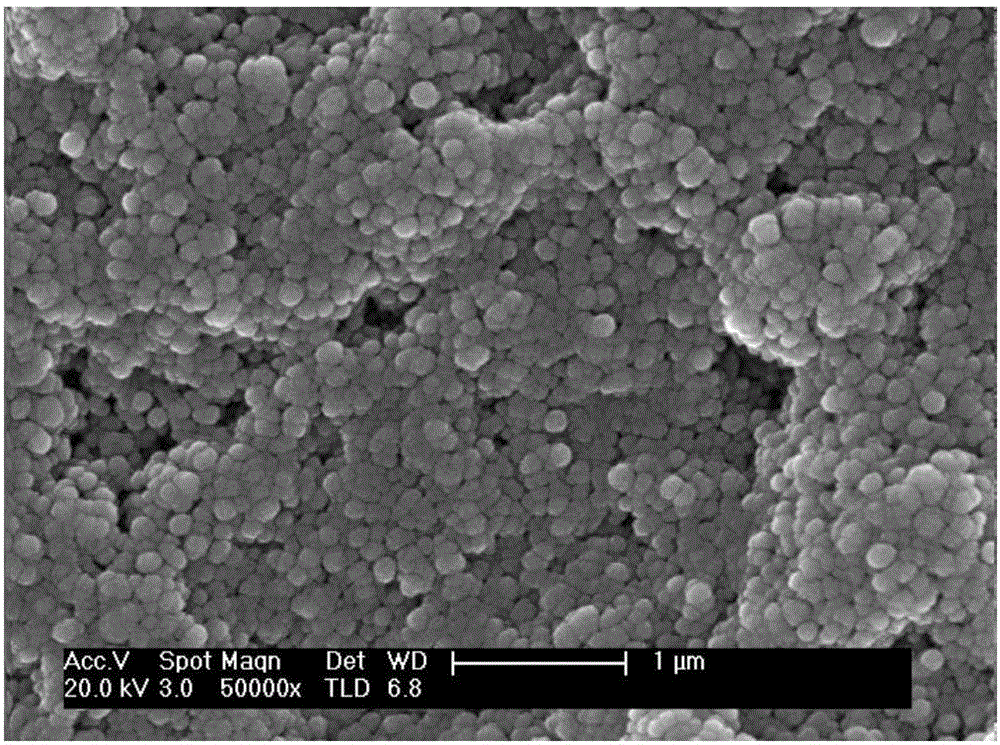

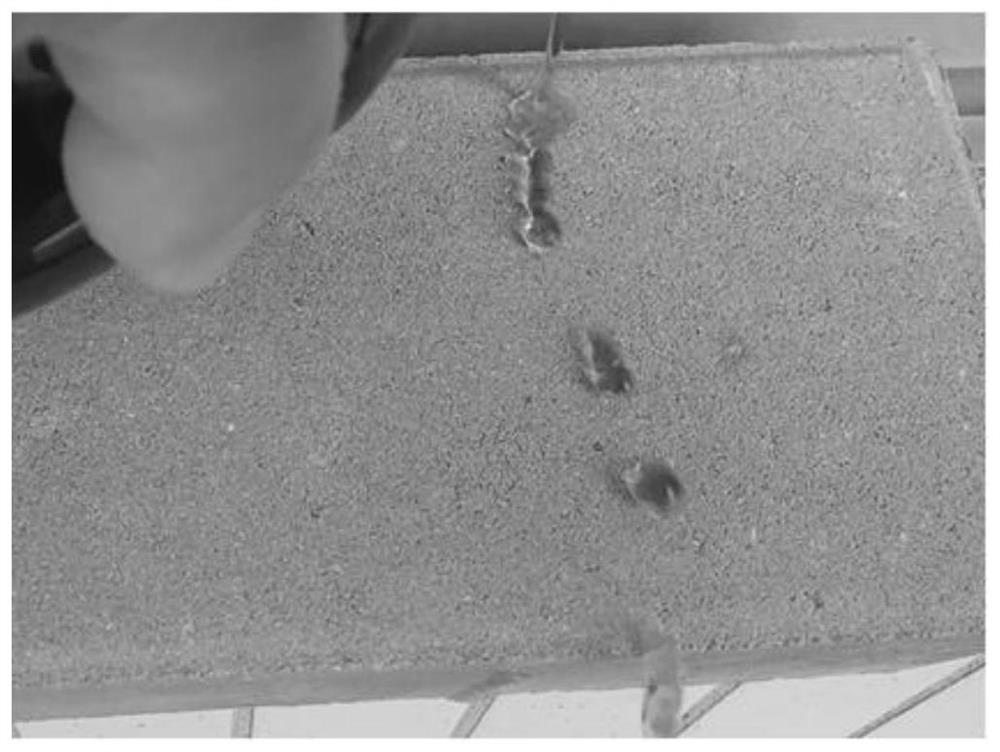

Non-toxic anticorrosive mildew-proof nano coating as well as preparation and application methods thereof

ActiveCN106634563AAvoid residueAvoid processing powerAntifouling/underwater paintsPaints with biocidesToxic materialMildew

The invention relates to a non-toxic anticorrosive mildew-proof nano coating as well as preparation and application methods thereof. The preparation method of the non-toxic anticorrosive mildew-proof nano coating comprises the following steps: adding 6 parts by mass of tetraethyl orthosilicate, 0.1 part by mass of an aqueous hydrophobic treatment agent and 2 parts by mass of aqueous FEVE resin into 10-100 parts by mass of a weak acidic or weak alkaline aqueous solution, and continuously and mechanically stirring to obtain an aqueous super-hydrophobic nano coating. No toxic substance is used and generated in the preparation and application processes of the coating; the coating is non-toxic and environmentally friendly, and can be applied to corrosion prevention and mildew prevention of the surfaces of wood products, bamboo products, clothes, leather products and cement-based materials such as wood support plates and wood boxes for packaging, wood or bamboo cooking utensils, kitchen ware, tea sets, furniture, building wall surfaces and wall corners. The non-toxic anticorrosive mildew-proof nano coating has the characteristics of simple preparation process and equipment, easy operation, low cost and the like, and is suitable for large-scale preparation and industrial production.

Owner:CUBESPACE FURNITURE

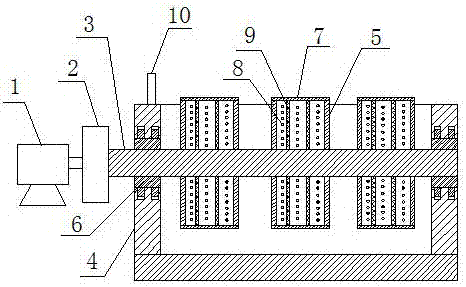

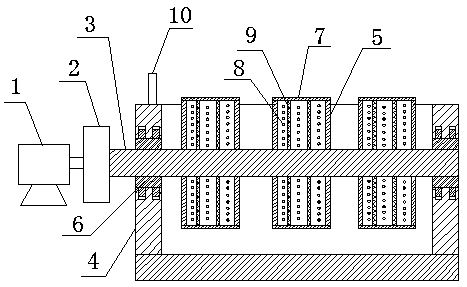

Mildew-proof soaking device for sofa wooden board

The invention discloses a mildew-proof soaking device for a sofa wooden board. The mildew-proof soaking device comprises a motor, a speed reducer, a rotary shaft, a solution placing slot and a plurality of wooden board placing slots, wherein a hole is formed in the solution placing slot; a bearing is arranged in the hole; the rotary shaft passes through the bearing and is connected with the speed reducer outside the solution placing slot; the speed reducer is connected with the motor; the wooden board placing slots are uniformly and symmetrically mounted in the axial direction of the rotary shaft arranged in the solution placing slot; openings are formed in the bottoms of the wooden board placing slots; slot bottom plates are hinged on side walls on the bottom of the wooden board placing slots; and a plurality of water inlets are formed in the side walls of the wooden board placing slots. The mildew-proof soaking device is simple in structure, a mildew-proof solution is placed into the solution placing slot, the mildew-proof solution soaks the rotary shaft, and the motor rotates to slowly rotate the rotary shaft through the speed reducer, so that the wooden board placing slots in the rotary shaft can be alternatively soaked into the mildew-proof solution, and the soaked wooden board is taken out of the mildew-proof solution and is dried in air by blowing via an air blower in an accelerated mode repeatedly by many times, and therefore, the soaked wooden board has better corrosion and mildew resistance.

Owner:宿州市宜美家具有限公司

Method for preparing natural anticorrosive mildew-proof preservative of pickled foods

InactiveCN103734871AGood broad-spectrum antibacterial and bactericidal propertiesGood anti-corrosion and anti-mildew effectFood preservationBiotechnologySodium lactate

The invention discloses a method fro preparing a novel all-natural anticorrosive mildew-proof preservative for foods. The method comprises the following steps: uniformly mixing the following components in parts by weight: 10-20 parts of mixed extract of raw materials such as garlic, shaddock ped and cinnamon bark, 1-3 parts of nisin, 1-3 parts of D-sodium erythorbate, 1-3 parts of sodium lactate, 10-20 parts of ethanol and water, and obtaining a natural anticorrosive mildew-proof preservative of pickled foods. The anticorrosive preservative is safe, non-toxic, good in broad-spectrum bacteriostatic and bactericidal performance and excellent in anticorrosive mildew-proof effects; the preservative has an effect of expelling insects, is readily available in raw materials and simple in production process and is widely applied to corrosion prevention of vegetables pickled in soy sauce, pickled vegetables, pickled Chinese cabbage, pickles, recipe, thick broad-bean sauce and other foods.

Owner:SUZHOU WANTAI VACUUM FIRING FURNACE RES INST

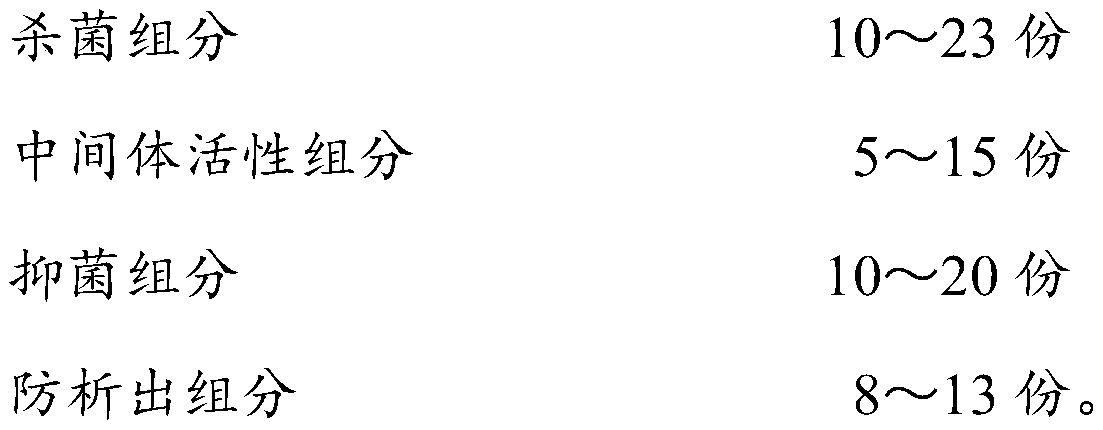

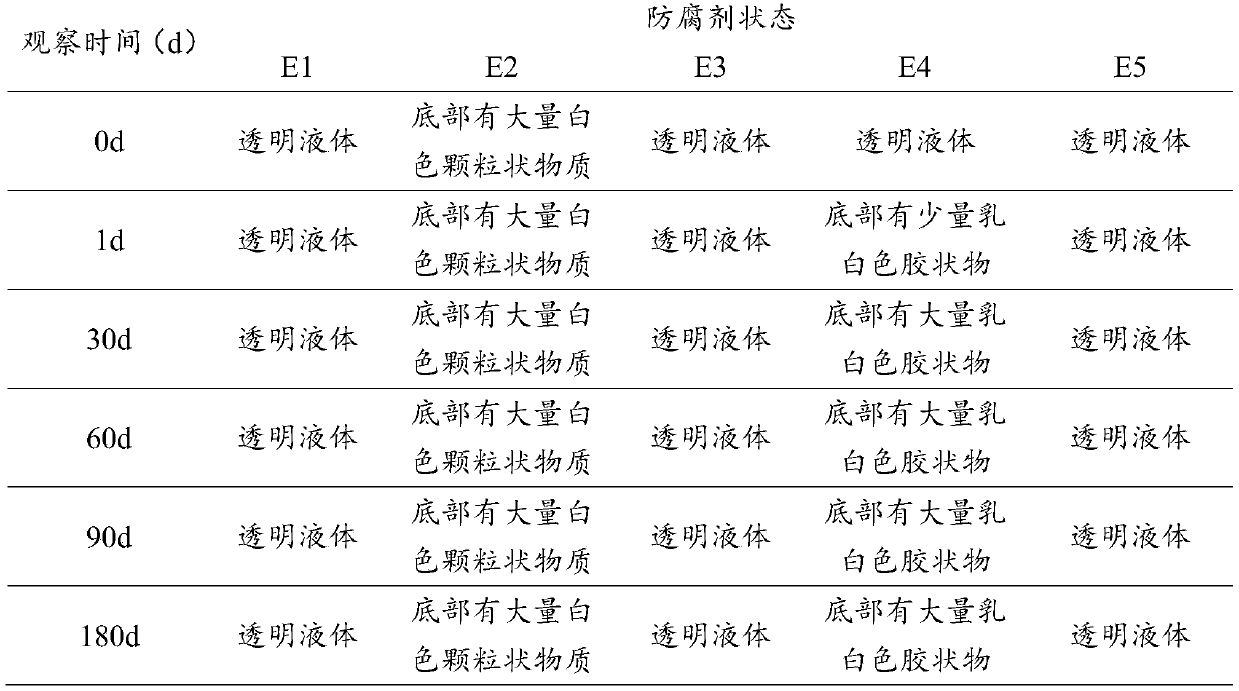

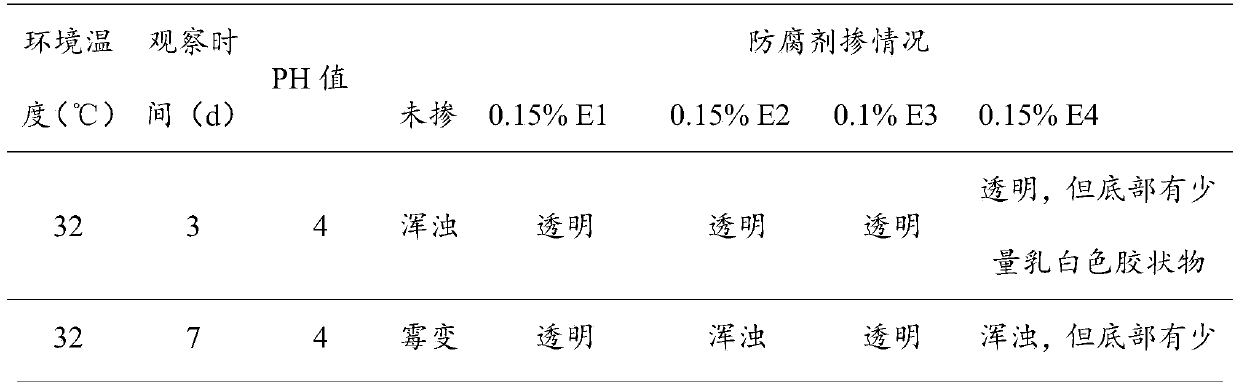

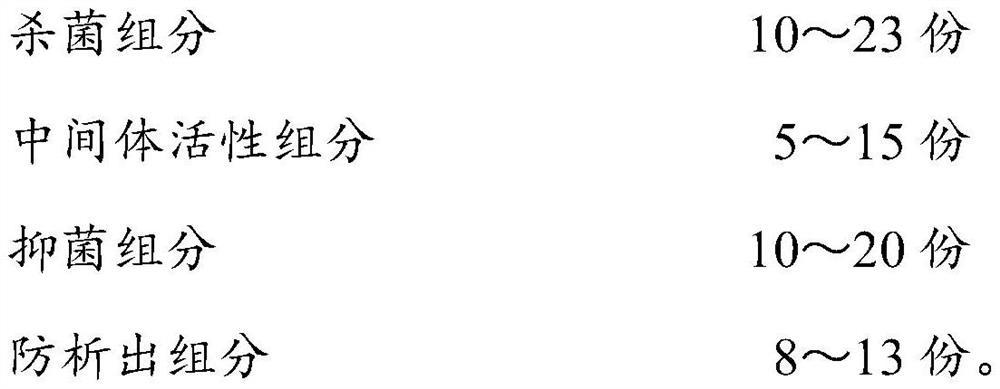

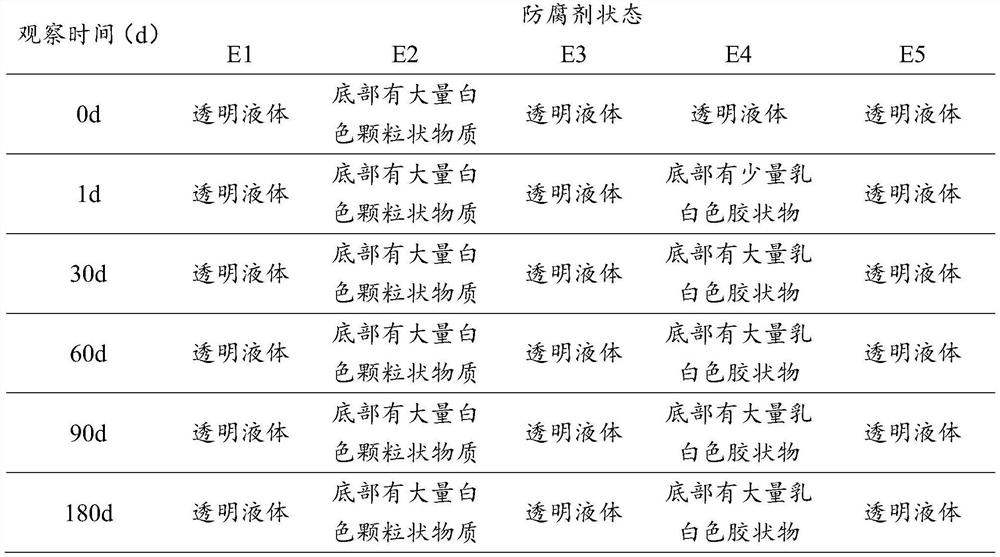

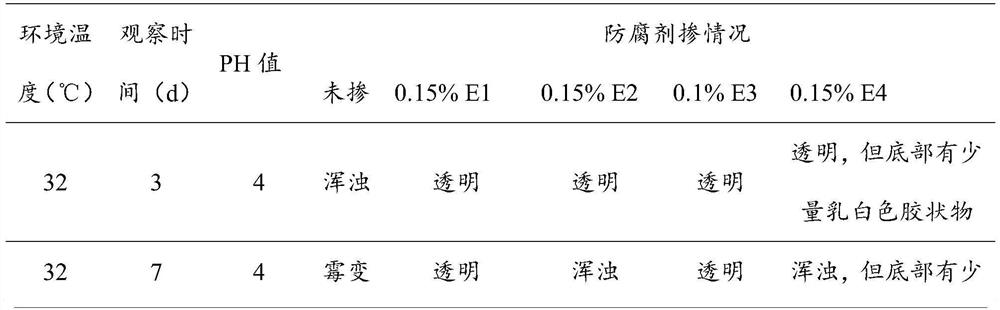

Preservative for concrete admixture and preparation method of preservative

ActiveCN109704625AGood compatibilityGood anti-corrosion and anti-mildew effectMicrobiological growthAdverse effect

The invention relates to a preservative for a concrete admixture and a preparation method of the preservative. Raw materials of the preservative comprise the following components in parts by weight: 10-23 parts of a bactericidal component, 10-20 parts of a bacterium inhibiting component, 5-15 parts of an intermediate active component and 8-13 parts of an anti-precipitation component. The mixing amount of the preservative in the concrete admixture is low; when the preservative is mixed into a water reducer, a slump retaining agent, a wet-mixed mortar additive and the like, layering and precipitation are avoided; the preservative has good compatibility with the concrete admixture and has good anti-corrosion and anti-mildew effects; and growth and reproduction of microorganisms such as saccharomycetes, bacteria and molds can be effectively inhibited. When the pH value of the concrete admixture is 2-7, the preservative has a best sterilization effect. The preservative provided by the invention can be naturally degraded in concrete, and no adverse effect is caused to the environment.

Owner:GUIZHOU KEZHIJIE NEW MATERIAL

Anti-cracking and anti-corrosion concrete and preparation method thereof

PendingCN113387637AAlleviate early crackingOvercoming Maintenance DifficultiesSulfite saltSodium sulfites

The invention discloses anti-cracking and anti-corrosion concrete and a preparation method thereof. The anti-cracking and anti-corrosion concrete comprises the following components in parts by weight: 190-200 parts of water, 230-260 parts of Portland cement, 50-65 parts of fly ash, 55-65 parts of mineral powder, 720-830 parts of medium sand, 1000-1130 parts of stone, 6-10 parts of modified polypropylene fibers, 1-1.5 parts of an air-entraining type waterproof agent, 1-1.5 parts of a micro-expansion type waterproof agent, 10-15 parts of diatom ooze, 1.5-2 parts of a sodium sulfite water reducing agent, and 0.75 kg / m of a water absorbing material. The concrete has the beneficial effects that 20%-40% of the starch grafted acrylate water absorbing material is added in the concrete preparation process, and water is supplemented into the concrete through the water absorbing material, so that the relative humidity in the concrete is always kept at a relatively high level, the early cracking of the concrete caused by insufficient maintenance can be effectively relieved, and the problem of maintenance difficulty caused by special climate conditions in different regions can be solved.

Owner:福建省兴岩建设集团有限公司

Environment-friendly anticorrosion and heat-resisting coating and preparation method thereof

InactiveCN106118384ACause decompositionWon't happenFireproof paintsAnti-corrosive paintsEpoxyAdipate

The present invention relates to an environment-friendly anticorrosion and heat-resistant paint and a preparation method thereof. In parts by weight, it contains the following components: 40-80 parts of epoxy acrylate, 15-25 parts of adipate, 20-40 parts of cyclic Oxygen resin, 10-20 parts of calcium carbonate, 2-4 parts of magnesium hydroxide, 3-5 parts of aluminum hydroxide, 0.5-2.5 parts of stabilizer, 2-8 parts of curing agent, 5-15 parts of surfactant, its preparation The method is to mix the above components evenly; compared with the prior art, the material in the product of the present invention does not produce vinyl chloride monomer, which is safe and harmless. Among them, epoxy acrylate, adipate and epoxy resin are combined The anti-corrosion and anti-mildew effect is better, and the use of calcium carbonate, magnesium hydroxide and aluminum hydroxide can have a good fire prevention effect, stable heat resistance, and will not cause material decomposition due to excessive light or high temperature, and the service life It is longer, and its preparation method is simple to operate, and the input cost is low, which is very suitable for large-scale production.

Owner:桂林市晟博科技服务有限公司

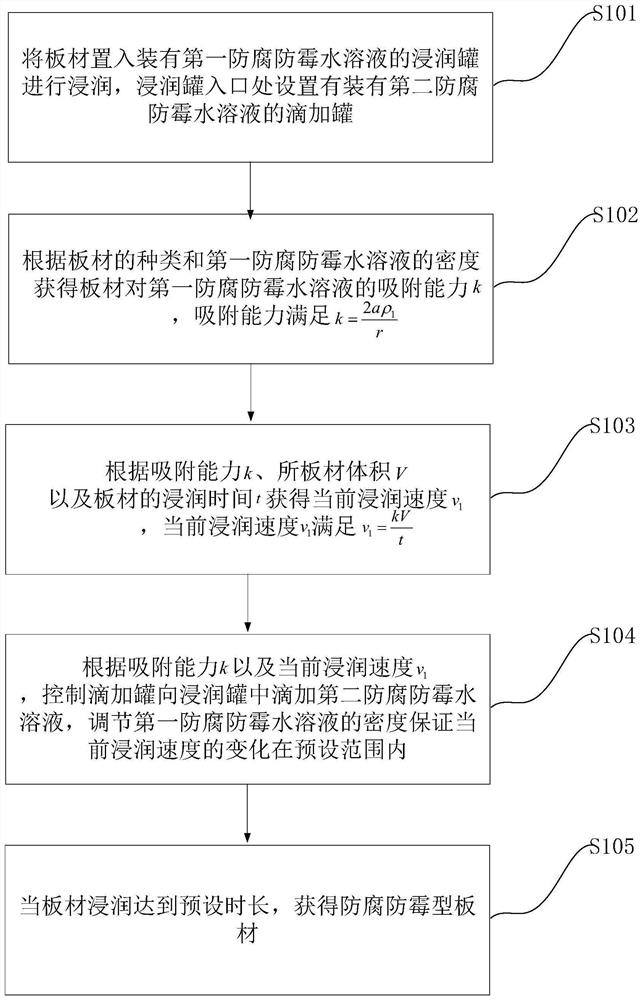

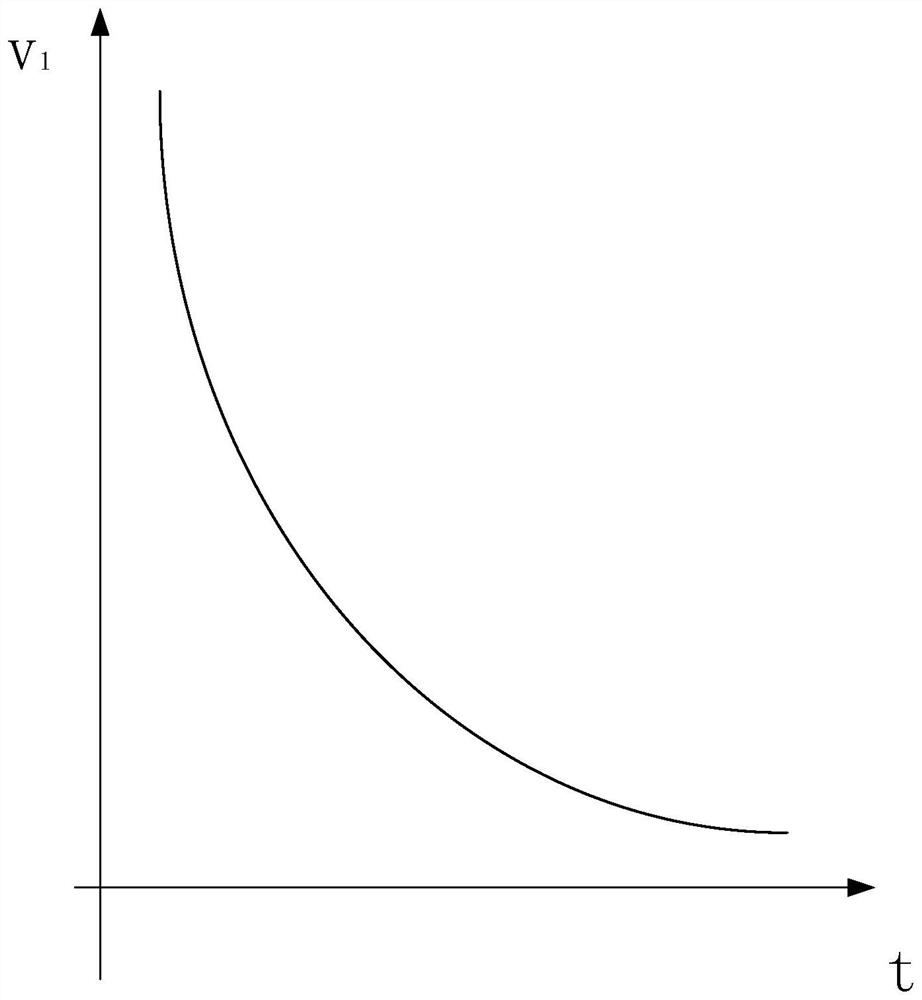

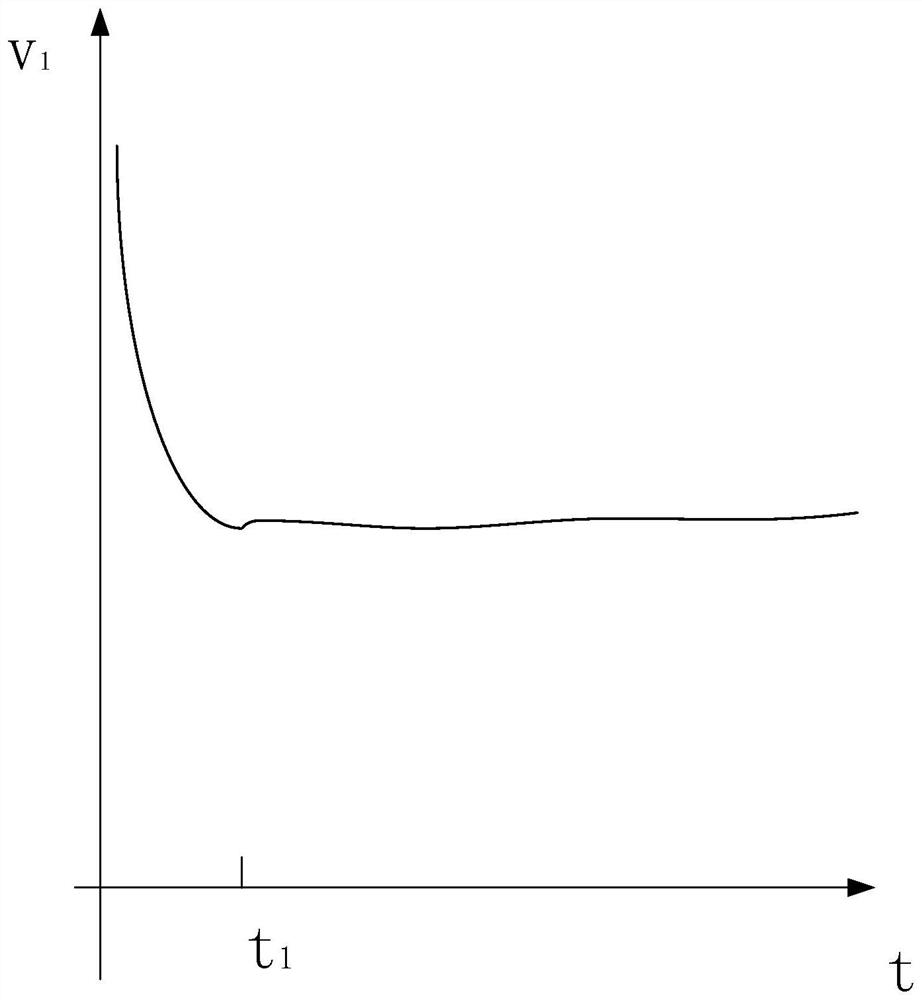

Corrosion-resistant and mildew-resistant plate processing technology

PendingCN113829454ADensity adjustmentGuaranteed DensityWood treatment detailsPretreatment apparatusAqueous solutionCorrosion prevention

The invention discloses a corrosion-resistant and mildew-resistant plate processing technology. The processing technology comprises the steps: placing a plate in an infiltration tank containing a first anti-corrosion and anti-mildew water solution to be infiltrated, wherein a dropwise adding tank containing a second anti-corrosion and anti-mildew water solution is arranged at an inlet of the infiltration tank; obtaining the adsorption capacity of the plate to the first anti-corrosion and anti-mildew aqueous solution according to the type of the plate and the density of the first anti-corrosion and anti-mildew aqueous solution; obtaining the current infiltration speed according to the adsorption capacity, the plate volume V and the infiltration time of the plate; controlling the dropwise adding tank to dropwise add the second anti-corrosion and anti-mildew aqueous solution into the infiltration tank according to the adsorption capacity and the current infiltration speed, and adjusting the density of the first anti-corrosion and anti-mildew aqueous solution to ensure that the change of the current infiltration speed is within a preset range; and when the board is infiltrated for a preset time length, obtaining the corrosion-resistant and mildew-resistant plate. The problem that the infiltration speed of the plate is not uniform in the anti-corrosion and anti-mildew process is solved, and the anti-corrosion and anti-mildew effect and the anti-corrosion and anti-mildew treatment efficiency of the plate are guaranteed.

Owner:FUJIAN BICHENG IND & TRADE CO LTD

A kind of sofa board anti-mildew soaking device

InactiveCN107263644BStrong penetrating powerSimple structureOpen tank impregnationReducerEngineering

The invention discloses a mildew-proof soaking device for a sofa wooden board. The mildew-proof soaking device comprises a motor, a speed reducer, a rotary shaft, a solution placing slot and a plurality of wooden board placing slots, wherein a hole is formed in the solution placing slot; a bearing is arranged in the hole; the rotary shaft passes through the bearing and is connected with the speed reducer outside the solution placing slot; the speed reducer is connected with the motor; the wooden board placing slots are uniformly and symmetrically mounted in the axial direction of the rotary shaft arranged in the solution placing slot; openings are formed in the bottoms of the wooden board placing slots; slot bottom plates are hinged on side walls on the bottom of the wooden board placing slots; and a plurality of water inlets are formed in the side walls of the wooden board placing slots. The mildew-proof soaking device is simple in structure, a mildew-proof solution is placed into the solution placing slot, the mildew-proof solution soaks the rotary shaft, and the motor rotates to slowly rotate the rotary shaft through the speed reducer, so that the wooden board placing slots in the rotary shaft can be alternatively soaked into the mildew-proof solution, and the soaked wooden board is taken out of the mildew-proof solution and is dried in air by blowing via an air blower in an accelerated mode repeatedly by many times, and therefore, the soaked wooden board has better corrosion and mildew resistance.

Owner:宿州市宜美家具有限公司

Iron-based putty powder and preparation method thereof

InactiveCN111019428AColorfulIncrease stickinessAntifouling/underwater paintsPaints with biocidesAdhesiveNickel-zinc ferrite

The invention discloses iron-based putty powder and a preparation method thereof. The iron-based putty powder comprises the following components in percentage by weight: 60-75% of soft magnetic ferrite powder, 3-8% of a water-based adhesive, 0.5-2% of an efficient film forming agent, 0.5-3% of a water-based dispersing agent, 0.2-0.8% of an organic silicon defoaming agent, 0.1-0.8% of a thickeningagent, 5-12% of a curing agent, 1-2% of a cross-linking agent, 8-10% of pearl powder and 3-8% of water, wherein the soft magnetic ferrite powder is at least one selected from ferroferric oxide powder,manganese zinc ferrite powder and nickel zinc ferrite powder. According to the invention, the soft magnetic ferrite powder is used as the main material for preparing the putty powder, so that the prepared iron-based putty powder can achieve the wall brushing effect of general putty powder, and enables the painted wall surface to have magnetism.

Owner:杨振龙

Nano protection process for textiles

InactiveCN109837736AGood anti-corrosion and anti-mildew effectFunction increaseFibre treatmentHeating/cooling textile fabricsIonLong lasting

The invention relates to a nano protection process for textiles, comprising the steps of processing a textile semi-finished gray fabric, softening for setting, and drying for setting. The nano protection process is characterized in that in the step of softening for setting, the gray fabric is soaked with a nano sodium ion liquid for 1-120 min, the fabric is washed and aired after being taken out to obtain a nano sodium anticorrosion textile; the nano sodium ion liquid is made by mixing, by mass, 0.01-5% of an aminosilane hyperbranched compound, a thickener solution, and copper carbonate solution having the mass molar concentration of 0.01-0.5 mol / L. In the step of softening for setting to treat the textile gray fabric, the textile gray fabric is soaked with the nano sodium ion liquid and is dried; the produced textile has evident anticorrosion and mildew-proof effects, long-lasting functions, has the health functions, such as deodorizing, is tolerant to multiple washing and repeated dry washing.

Owner:贾龙平

Antisepticize and mildew preventive of bamboo wood material

InactiveCN100518517CStrong loss resistanceLow hygroscopicityBiocideAnimal repellantsLoss rateSolubility

The invention provides a kind of antisepsis and antifungal agent for bamboo wood materials, which is mainly obtained by adding zinc-containing compounds, copper-containing compounds and cationic surfactants to the substrate; the present invention uses bamboo vinegar, wood vinegar and grass vinegar as main components, Biological (chemical) wood preservatives are prepared by compounding water-insoluble inorganic compounds, and nitrogen-containing compounds of ammonia, ammonium salts or amines can also be added to increase its solubility. The beneficial effects of the invention are mainly reflected in: strong loss resistance (loss rate less than 2%), low hygroscopicity, no blooming phenomenon, low toxicity, good anti-corrosion and anti-mildew effect, and can also be used for discoloration treatment of wood and bamboo.

Owner:ZHEJIANG FORESTRY UNIVERSITY

High-performance sand wall coating and preparation method thereof

ActiveCN107177261BImprove performanceImprove stain resistanceAntifouling/underwater paintsPaints with biocidesPolymer scienceEmulsion

The invention relates to a high-performance sand wall paint and a preparation method thereof, which is characterized in that it comprises the following raw materials in parts by weight: 15-30 parts of base material, 60-80 parts of natural colored sand, and 3-6 parts of film-forming aid , 0.1-0.5 parts of wetting agent, 0.5-2 parts of titanium dioxide, 0.1-0.3 parts of dispersant, 0.1-0.5 parts of anti-corrosion and anti-mold agent, 0.1-0.5 parts of multi-functional additives, 0.05-0.2 parts of defoaming agent, 0.01-0.2 parts of thickener, 10-15 parts of deionized water, the base material includes a mixture of pure acrylic emulsion and styrene-acrylic emulsion, and the weight ratio of pure acrylic emulsion and styrene-acrylic emulsion is 1-2:1. The components of the sand wall-shaped paint of the present invention are scientifically compatible, and the prepared paint has good comprehensive performance, less dosage, low use cost, high strength, compact surface, convenient construction, good stain resistance, high mechanical construction efficiency, and coating decoration The effect is good, the texture is strong, the color is rich, and the imitation stone effect is good.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Preparation method of acidulant special for feeds

InactiveCN107173547ALower pH valueStructural regulationAccessory food factorsFood consumptionNutrients substances

The invention relates to a preparation method of an acidulant special for feeds. The preparation method comprises the following steps of A, performing mixing and stirring; B, performing a condensation reaction on lactic acid to form polylactic acid; C, regulating the PH value with acetic acid; D, performing adsorption and bonding; and E, performing compression, drying and disinfection. According to the preparation method disclosed by the invention, the materials are easy to obtain, the preparation method is simple, the cost is low, the PH value of the gastrointestinal tract is reduced, the enzymic activity of the alimentary tract and the digestibility of nutrient substances are improved, the structure of microorganism microbial population is regulated, the acidulant participates in metabolism in organisms, absorption is more facilitated, the immunity is enhanced, stress is alleviated, the palatability is improved, the food consumption is increased, the regulation is stable, and the acidulant has good anticorrosive and mildewproof effects, and is long in quality guarantee period, free from residues, free from drug resistance and nonhazardous.

Owner:陶圣香

Method for manufacturing integrated bamboo by mildew-proof and anti-corrosion full impregnation treatment of carbonized bamboo strip

InactiveCN109746997ASimple processImproved anti-mold and anti-corrosion effectWood treatment detailsReed/straw treatmentMaterials scienceAnti-corrosion

The invention discloses a method for manufacturing an integrated bamboo by mildew-proof and anti-corrosion full impregnation treatment of a carbonized bamboo strip. The method has the advantages thata technology is simple, mildew-proof and anti-corrosion full impregnation treatment is the same in reality as in appearance, and all surfaces of the optionally cut carbonized bamboo strip can achievethe same mildew-proof and anti-corrosion effects.

Owner:刘生军

Manufacturing method for treatingbamboo board with finish planing bamboo strip through corrosion prevention and mildew proofing successive full-penetration impregnation

InactiveCN109676728ASimple processImproved anti-mold and anti-corrosion effectWood treatment detailsCane mechanical workingMildewMaterials science

The invention discloses a manufacturing method for treating a bamboo board with a finish planing bamboo strip through corrosion prevention and mildew proofing successive full-penetration impregnation.The manufacturing method has the advantages of simple process, consistent full-penetration impregnation mildewproofing and anticorrosion, and being capable of achieving the same mildewproofing and anticorrosion effects after arbitrary cutting.

Owner:蒋健艳

A kind of non-toxic anti-corrosion anti-mildew nano-coating and its preparation and application method

ActiveCN106634563BAvoid residueAvoid processing powerAntifouling/underwater paintsPaints with biocidesSilicic acidEthyl ester

The invention relates to a non-toxic anticorrosive mildew-proof nano coating as well as preparation and application methods thereof. The preparation method of the non-toxic anticorrosive mildew-proof nano coating comprises the following steps: adding 6 parts by mass of tetraethyl orthosilicate, 0.1 part by mass of an aqueous hydrophobic treatment agent and 2 parts by mass of aqueous FEVE resin into 10-100 parts by mass of a weak acidic or weak alkaline aqueous solution, and continuously and mechanically stirring to obtain an aqueous super-hydrophobic nano coating. No toxic substance is used and generated in the preparation and application processes of the coating; the coating is non-toxic and environmentally friendly, and can be applied to corrosion prevention and mildew prevention of the surfaces of wood products, bamboo products, clothes, leather products and cement-based materials such as wood support plates and wood boxes for packaging, wood or bamboo cooking utensils, kitchen ware, tea sets, furniture, building wall surfaces and wall corners. The non-toxic anticorrosive mildew-proof nano coating has the characteristics of simple preparation process and equipment, easy operation, low cost and the like, and is suitable for large-scale preparation and industrial production.

Owner:CUBESPACE FURNITURE

Bamboo batten corrosion-preventing mildew-preventing fully-impregnated treatment method, and bamboo board or integrated bamboo material prepared by method

InactiveCN107443526ASimple processImproved anti-mold and anti-corrosion effectWood treatment detailsReed/straw treatmentMildewHigh pressure

The invention discloses a bamboo batten corrosion-preventing mildew-preventing fully-impregnated treatment method. The bamboo batten corrosion-preventing mildew-preventing fully-impregnated treatment method comprises the following steps: (1) performing corrosion-preventing high-pressure impregnation; (2) placing at normal temperature for the first time; (3) drying for the first time; (4) returning carbon; (5) performing mildew-preventing high-pressure impregnation; (6) placing at normal temperature for the second time; and (7) drying for the second time and reducing the water content of the carbon-returned bamboo batten to be below 10 percent. The bamboo batten impregnated by the method can realize surface and interior consistent fully-impregnated mildew prevention and corrosion prevention, and each surface can achieve the mildew-preventing and corrosion-preventing effect after arbitrary cutting. The invention also discloses a bamboo board or integrated bamboo material which is prepared by gelatinizing, blanking and hot-pressing the bamboo sheet obtained by the fully-impregnated mildew-preventing corrosion-preventing treatment method.

Owner:赖燕丽

Weaving method for Yujin knitted calligraphy and painting

InactiveCN108486725AKeep dryPrevent mildewSpecial ornamental structuresPattern making devicesMildewEngineering

The invention provides a weaving method for Yujin knitted calligraphy and painting. The weaving method comprises picture acquisition, picture processing, color separation design, process design, picking, weaving and post processing. The post processing comprises covering the right side of Yujin knitted calligraphy and painting with an anti-corrosion film, and arranging a dry layer on a reverse layer. Through combination of a knitting technology and a computer technology, the weaving method of the Yujin knitted calligraphy and painting is improved. The weaving method has simple processes, shortens a production period, has high production efficiency and a high yield, realizes mass production and good gloss and is easy to store. The anti-corrosion film coats the right side of Yujin knitted calligraphy and painting through an extrusion coating method and the dry layer is arranged on the reverse layer. Through the double protection, the product has good anti-corrosion and anti-mildew effects and the glossiness and softness of the product are not affected.

Owner:郑州市君友纺织品织造有限公司

Preservative for concrete admixture and preparation method thereof

Owner:GUIZHOU KEZHIJIE NEW MATERIAL

A kind of bamboo wood material modification method and a kind of bamboo wood board

ActiveCN110202649BHigh modification treatment depthModification treatment is easy to operateLamination ancillary operationsElectric wood treatmentSilver NanoMaterials science

The invention discloses a method for modifying bamboo wood materials and a bamboo wood board, belonging to the field of bamboo wood materials. The invention discloses a method for modifying bamboo and wood materials. Under the action of a high-voltage electrostatic field of 20KV to 60KV, high-voltage electrostatic treatment is performed on a bamboo and wood board body with silver plates pasted on its upper and lower ends. The sheet material modified by the present invention sequentially comprises a nano-silver element permeation layer, a bamboo wood plate body, and a nano-silver element deposition layer / nano-silver element permeation layer along the thickness direction of the sheet material. The bamboo wood material modified by high-voltage static electricity in the present invention has a deeper anticorrosion and mildew-proof treatment depth, and the penetration depth of the nano-silver element inside the board is 0.05 mm to 1 mm, and the anti-corrosion and mildew-proof effect of the modified bamboo wood material is more stable .

Owner:NANJING FORESTRY UNIV

Processing technology of nano-sodium anticorrosion textile

InactiveCN109778536AGood anti-corrosion and anti-mildew effectFunction increaseFibre treatmentIonCopper carbonate

The invention relates to a processing technology of a nano-sodium anticorrosion textile. The technology comprises the steps of a processing process for a textile semi-finished product grey fabric, a softening formation process and a drying formation process. The technology is characterized in that in the softening formation process, a nano-sodium ion material solution is adopted for conducting penetration treatment on the grey fabric, the dipping time is 1-120 minutes, the fabric is taken out, washed with water and air-dried, and the nano-sodium anticorrosion textile is obtained; the nano-sodium ion material solution is obtained by mixing an amino silane hyperbranched compound with the mass percentage of 0.01-5% and a thickening agent aqueous solution thereof and a copper carbonate solution with the molality of 0.01-0.5 mol / L. According to the processing technology, in the softening formation process for treating the textile grey fabric, the textile grey fabric is subjected to penetration treatment of the nano-sodium ion material solution, then drying is conducted, and the produced textile has an obvious anticorrosion and anti-mold effect and a durable function, has health and health care functions such as odor removal, and can be washed multiple times and repeatedly dry-washed.

Owner:张胜利

Anti-corrosion and mildew-proof full impregnation treatment for carbonized bamboo strip

InactiveCN109747001ASimple processImproved anti-mold and anti-corrosion effectWood treatment detailsReed/straw treatmentMaterials scienceAnti-corrosion

The invention discloses an anti-corrosion and mildew-proof full impregnation treatment method for a carbonized bamboo strip. The method has the advantages that a technology is simple, anti-corrosion and mildew-proof full impregnation treatment is the same in reality as in appearance, and all surfaces of the optionally cut carbonized bamboo strip can achieve the same anti-corrosion and mildew-proofeffects.

Owner:刘生军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com