Non-toxic anticorrosive mildew-proof nano coating as well as preparation and application methods thereof

A nano-coating, anti-corrosion and anti-mildew technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as health hazards, achieve low cost, easy operation, and avoid incomplete processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

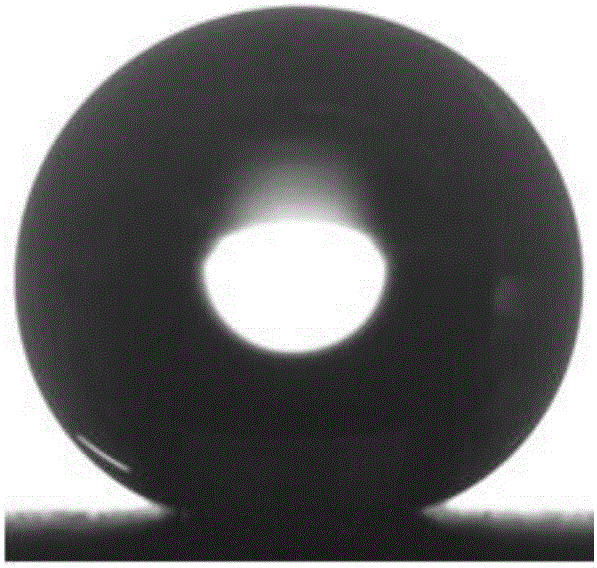

[0033] Add the ammonia solution to the deionized water solution and adjust the pH value to 8-11, take 100g of the solution, add 60g of tetraethyl orthosilicate dropwise, stir mechanically for 20min, then add 1g of perfluorooctanoic acid dropwise, continue mechanically stirring for 24h, then add 20g Water-based FEVE resin, continue to mechanically stir for 1 hour to obtain a nano-coating, brush the paint on the surface of the wood board and dry it in a 60°C oven for 4 hours to obtain a nano-superhydrophobic coating. figure 1 It is the picture of the water contact angle of the coating, the water contact angle is 158.6°, and the rolling angle is 6.2°.

Embodiment 2

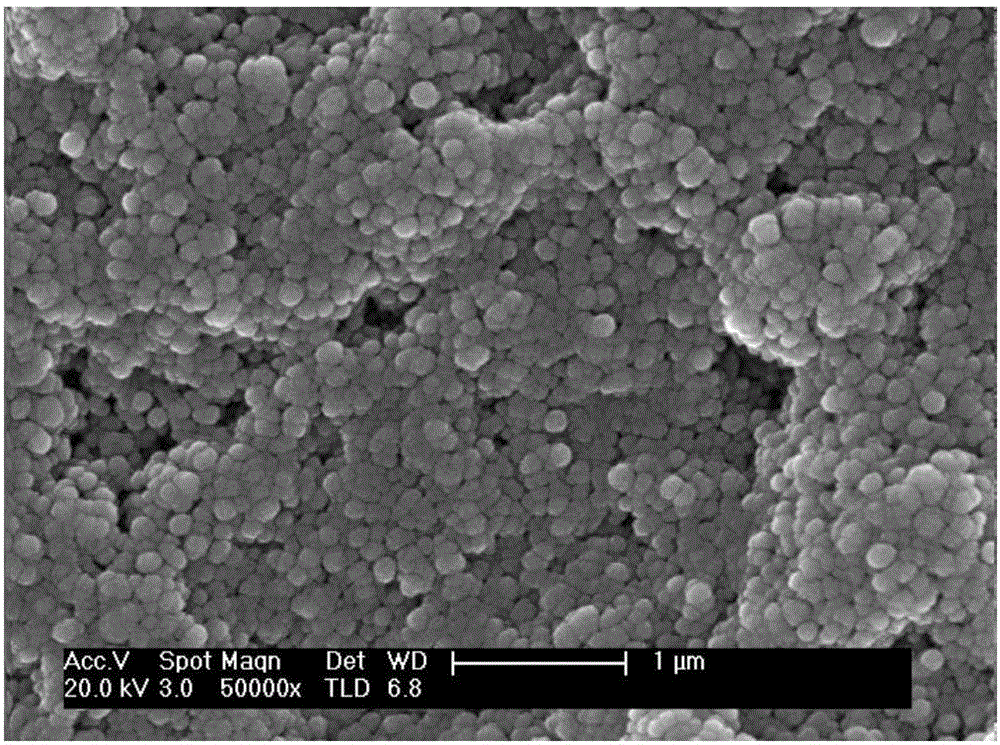

[0035] Add the acetic acid solution to the deionized water solution and adjust the pH value to 4-6, take 1000g of the solution, add 60g of tetraethyl orthosilicate dropwise, stir mechanically for 30min, then add 1g of isobutyltrimethoxysilane dropwise, continue Add 20g of water-based FEVE resin after mechanical stirring for 12 hours, and then continue mechanical stirring for 1 hour to obtain a nano-coating, spray the coating on the surface of the copper sheet and dry it in the natural environment for 12 hours to obtain a nano-superhydrophobic coating. figure 2 Scanning electron micrograph of the coating.

Embodiment 3

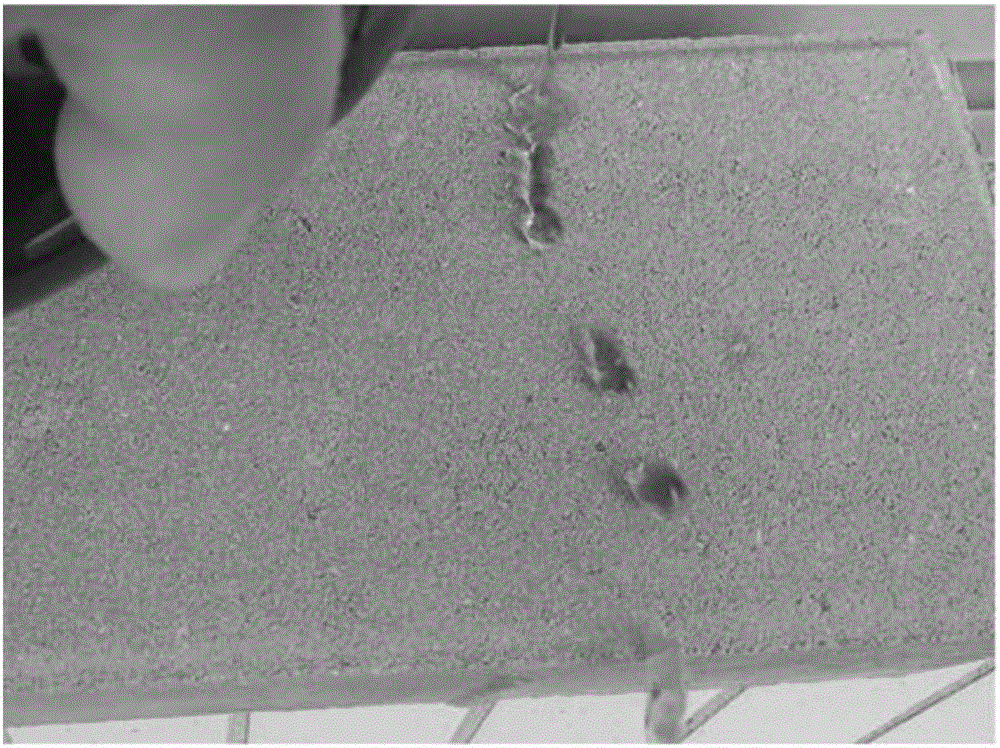

[0037] Add the hydrochloric acid solution to the deionized water solution and adjust the pH value to 4-6, take 500g of the solution, add 60g of tetraethyl orthosilicate dropwise, stir mechanically for 10min, then add 1g of methyltriethoxysilane dropwise, continue Add 20g of water-based FEVE resin after mechanical stirring for 48 hours, and then continue mechanical stirring for 2 hours to obtain a nano-coating. Spray the coating on the surface of the floor tiles and dry it in an oven at 80°C for 1 hour to obtain a nano-superhydrophobic coating. Put it in an outdoor environment After 1 year, its surface remains clean without any traces of corrosion and mildew, and it still maintains excellent superhydrophobicity, image 3 The optical photo and its superhydrophobicity after being placed outdoors for one year.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com