Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Improve softness," patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fibrous structures and methods for making same

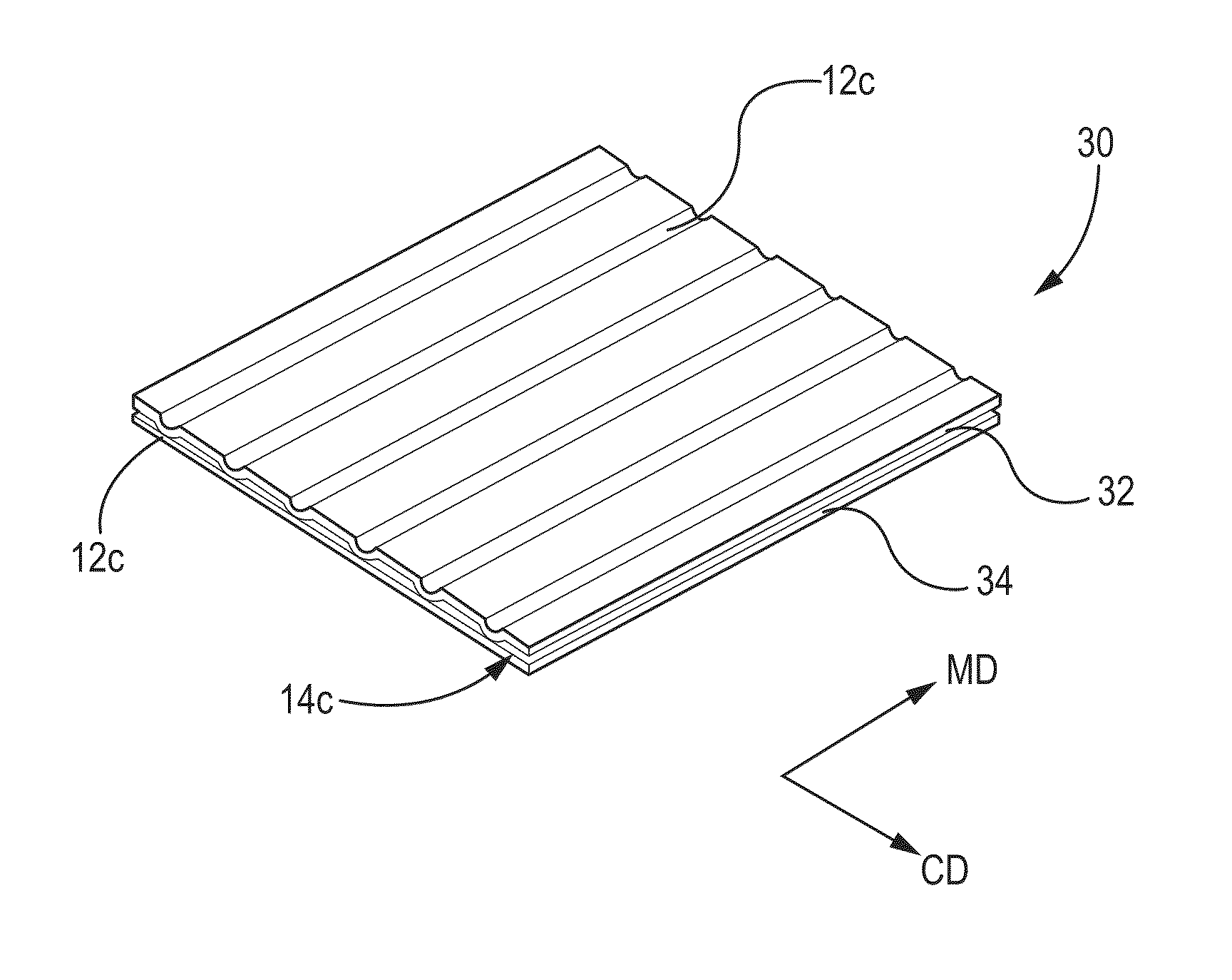

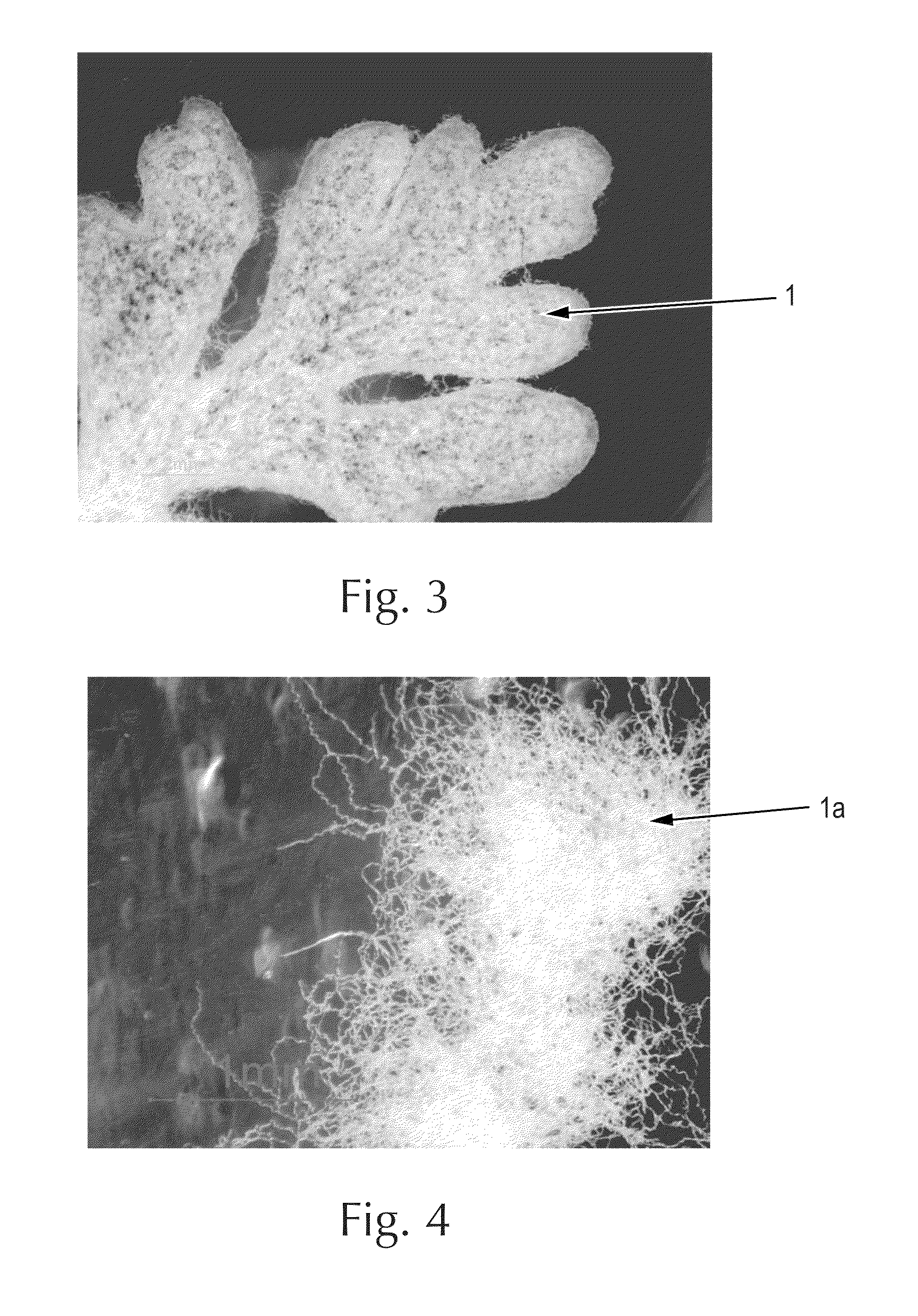

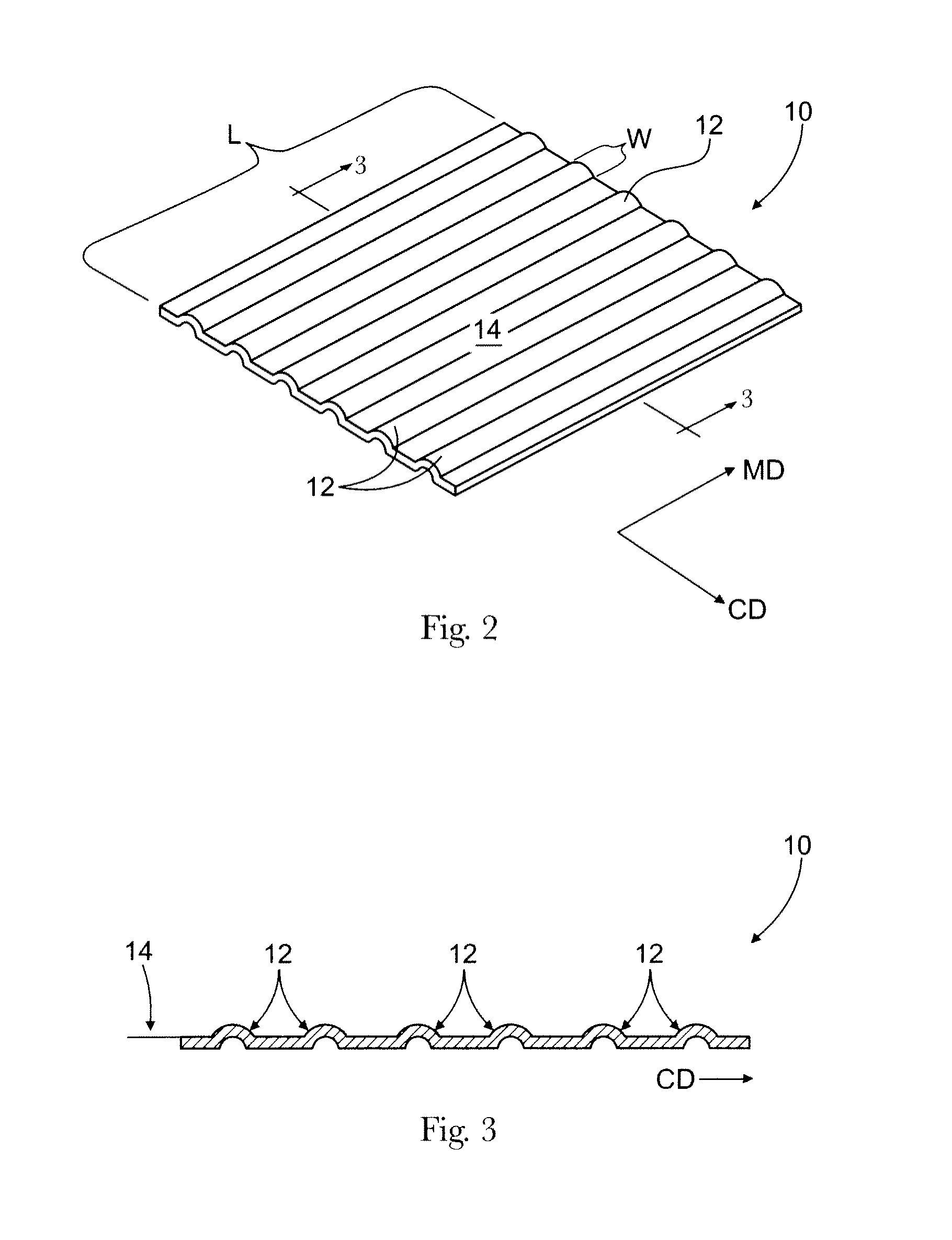

ActiveUS20130319625A1Improve softnessIncrease in numberNon-fibrous pulp additionNatural cellulose pulp/paperFiber structureMaterials science

Fibrous structures that exhibit a Free Fiber End Count greater than the Free Fiber End Count of known fibrous structures in the range of free fiber end lengths of from about 0.10 mm to about 0.75 mm as determined by the Free Fiber End Test Method, and sanitary tissue products comprising same and methods for making same are provided.

Owner:THE PROCTER & GAMBNE CO

Fibrous structures and methods for making same

InactiveUS20100040825A1Improve softnessIncrease in numberNatural cellulose pulp/paperMechanical working/deformationFiber structureMaterials science

Owner:THE PROCTER & GAMBNE CO

Soft-pellet creep feed and preparation method thereof

ActiveCN103416591AImprove palatabilityEliminate lossAnimal feeding stuffAdditive ingredientBlood plasma

The invention discloses a soft-pellet creep feed and a preparation method thereof, and belongs to the field of feed formulation design and feed processing techniques. The preparation method comprises the following steps: mixing and bacillus subtilis and pickled vegetables fermentation liquor, performing fermentation in sequence to form fermented soybean meal and rice which are taken as main raw materials; adding steam fish meal, blood plasma powder, soybean meal and the like in a matched manner; utilizing a soft pelletizer to prepare pellet materials through ultramicro smashing; utilizing a syrup spray device to uniformly spray syrup on the surfaces of the pellet materials. The creep feed provided by the invention is full and balanced in nutrition, is easy to digest and intake, has stable quality, and is subjected to multiple fermentation. Moreover, feed inducing performance, soft protection performance and nutrition full value performance are improved, as a process of combining a soft manufacturing system and the syrup spray system is adopted; the incidence of hardening of medium-sized pellet feed during the preservation process is reduced; compared with a dry pellet feed, the loss of nutritional ingredient during the granulating heating and drying process is avoided, and the palatability of soft pellet feed is kept well.

Owner:LIAONING WELLHOPE AGRI TECH

Double-layer composite production method for plastic film sheet material on blowfilm machine and equipment thereof

ActiveCN101220181AImprove softnessIncrease die temperatureFlat articlesLow-density polyethylenePlastic film

The invention relates to the field of fine chemical products, in particular to a producing method of double-layer composition of plastic film sheet on a plastic film blowing machine. The invention pertains to a plastic film sheet, the compositions of which are 5-65 percent of low density polyethylene and 95-35 percent of acetic acid. Difference of the producing method of the invention with the existing plastic film is that: the temperature of a die head of the plastic film blowing machine is 150 to 170 DEG C, which causes that the plastic film blown in drum shape can be directly compacted into bundles without cutting, namely, two layers of film are hot pressed into one layer. The invention has the advantages that: the tenderness of the plastic film is increased by changing the compounding formula of the plastic film, and the viscidity of the film is also increased by enhancing the temperature of the die head; the originally separated two layers of film are closely compacted into a whole; due to the invention, the modification to the existing device is little, and the production cost is lowered. By using a small scale device for producing thick plastic film sheet, machine consumptions in production process can also be reduced and the cost is prevented from increasing due to the composing by glue and environment pollution.

Owner:福州永鑫塑料包装用品有限公司

Flexible bulletproof stab-resistant material and preparing method thereof

ActiveCN110103556AImprove softnessComfortable bulletproof and stabproof effectLamination ancillary operationsProtective equipmentCeramic particleFiber

The invention discloses a flexible bulletproof stab-resistant material and a preparing method thereof. The flexible bulletproof stab-resistant material includes a basic layer and a passivation layer,the basic layer includes fabric, a thermoplastic elastic material which penetrates into the fabric after being subjected to hot melting penetrates into one side of the fabric, and shear thickening fluid is dispersed in the portion, where the thermoplastic elastic material does not penetrate, of the fabric; the passivation layer is prepared by smearing a mixed liquid of ceramic particles and thermosetting resin to the side, containing the thermoplastic elastic material, of the fabric and conducting curing, and protective membranes cover the basic layer and the passivation layer through vacuuming. The preparing method is used for preparing the flexible bulletproof stab-resistant material. By the adoption of the preparing method, the flexibility of the bulletproof stab-resistant material is greatly improved, and light, comfortable, bulletproof and stab-resistant effects are provided.

Owner:山东三达科技发展有限公司

High-quality disposable paper cup and preparation method thereof

PendingCN107411473AImprove softnessImprove antioxidant capacityStarch dervative coatingsPaper coatingAnti bacterialChemistry

The invention discloses a high-quality disposable paper cup and a preparation method thereof. It is made of the following substances in parts by weight: 30-35 parts of bagasse, 40-50 parts of reed, 20-25 parts of Chinese herbal medicine residue, 3-5 parts of modified Atmospheric powder, 8-10 parts of corn starch, 15-20 parts of surface spraying agent; the preparation method has the following steps: (1) pulping, (2) pulping, (3) copying, (4) surface treatment, ( 5) Make a cup. The raw materials of the disposable paper cup of the present invention are easy to obtain and convenient to obtain, and can be completely degraded under natural conditions, which not only solves the problem of environmental pollution, but also reasonably turns waste from traditional Chinese medicine into treasure, saving waste treatment costs for the factory. The paper cup has Good water resistance, heat resistance, certain antibacterial function, low cost, simple manufacture, and good promotion value.

Owner:安徽鑫科生物环保有限公司

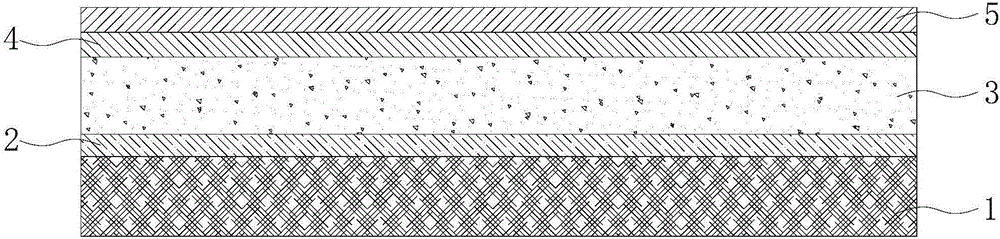

Modified chlorinated polyethylene waterproof roll and method for preparing same

InactiveCN101718078AImprove softnessHigh tensile strength at breakBridge structural detailsPlasticizerNational standard

The invention relates to a waterproof roll, in particular to a modified chlorinated polyethylene waterproof roll and a method for preparing the same, which solve the problems that the conventional waterproof roll cannot meet various performance indexes of products and the cost of formula is too high. The modified chlorinated polyethylene waterproof roll is prepared from an ethylene-octene copolymer, chlorinated polyethylene, linear high-pressure polyethylene, a filling reinforcing agent, a softening plasticizer, a phenolic antioxidant, a heat stabilizer, a lubricant and a light stabilizer. The method comprises the following steps of mixing and stirring various raw materials; pelleting the mixture by using a plastic mixing mill, a double roller and a pelletizer; putting granules into a single-screw extruder to extrude and then molding the granules through a die; and putting the molding materials into a three-roller cooling embossing machine to press the waterproof roll. The waterproof roll not only maintains specific flexibility, elongation and resilience of rubber, but also maintains higher tensile breaking strength of LLDPE; the waterproof roll has the advantages of good flexibility, flatness and evenness of the whole sheet, excellent ageing-resistance performance, physical performance and processing performance, and low production cost; and the performance indexes exceed national standards and relative standards of the Ministry of Railways.

Owner:SHANXI SIFANG HENGTAI WATERPROOF MATERIALS

Flexibility-enhanced polyurethane

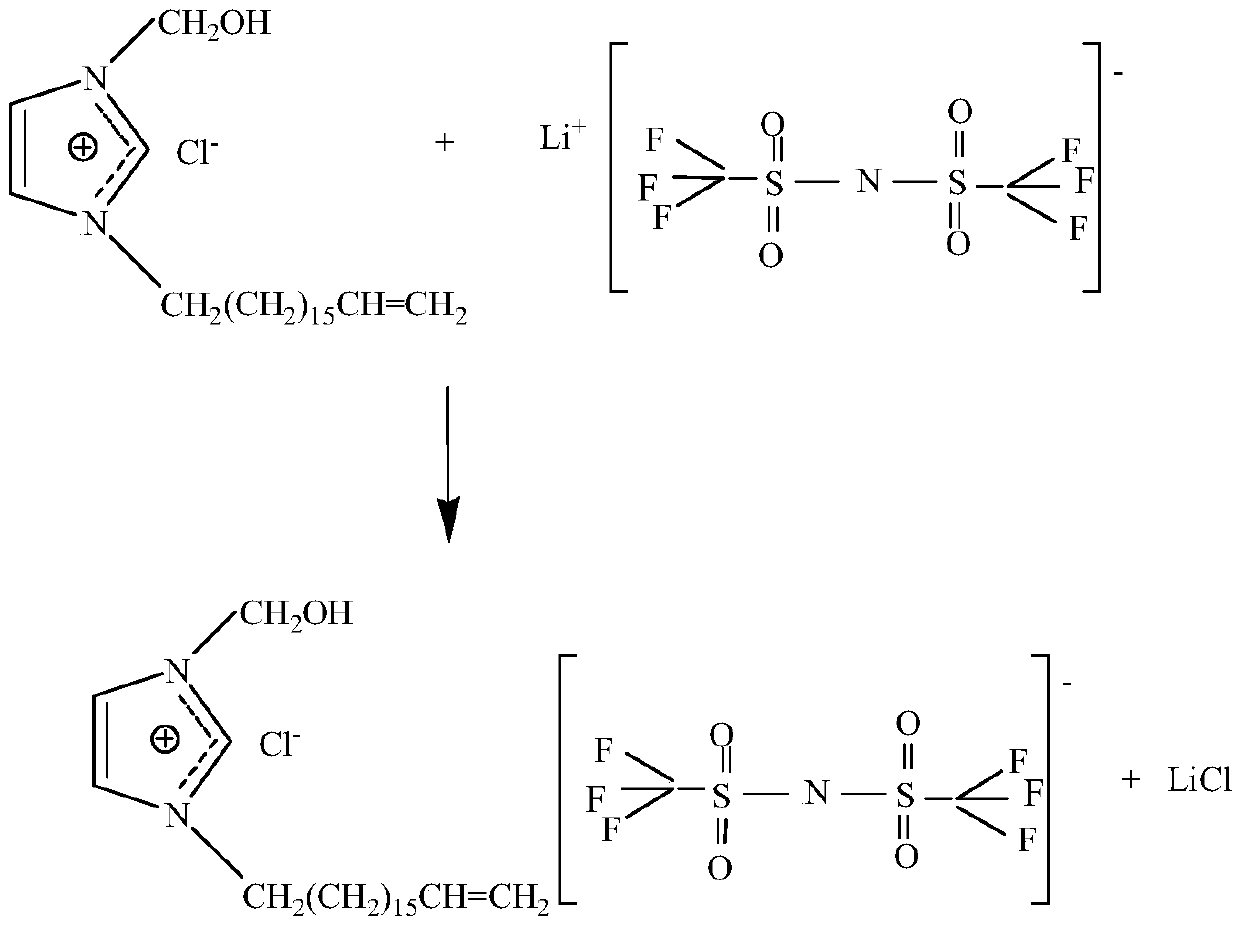

ActiveCN109897517AGood film-forming performanceImprove softnessFireproof paintsPolyurea/polyurethane coatingsPrepolymerPolymer chemistry

The invention provides a flexibility-enhanced polyurethane. A preparation method of the flexibility-enhanced polyurethane comprises the following reaction steps: 1, preparation of an ionic liquid polymer with a dihydroxy group; 2, preparation of an ionic liquid polymer modified polyurethane prepolymer; and 3, preparation of the flexibility-enhanced polyurethane. The modified polyurethane preparedby the preparation method has the advantages of high flexibility, good film forming property, strong mechanical properties, high thermal stability, high chemical stability, high tensile strength, difficult shedding or explosion, energy saving, environmental protection and wide application range.

Owner:广州精点高分子材料制品有限公司

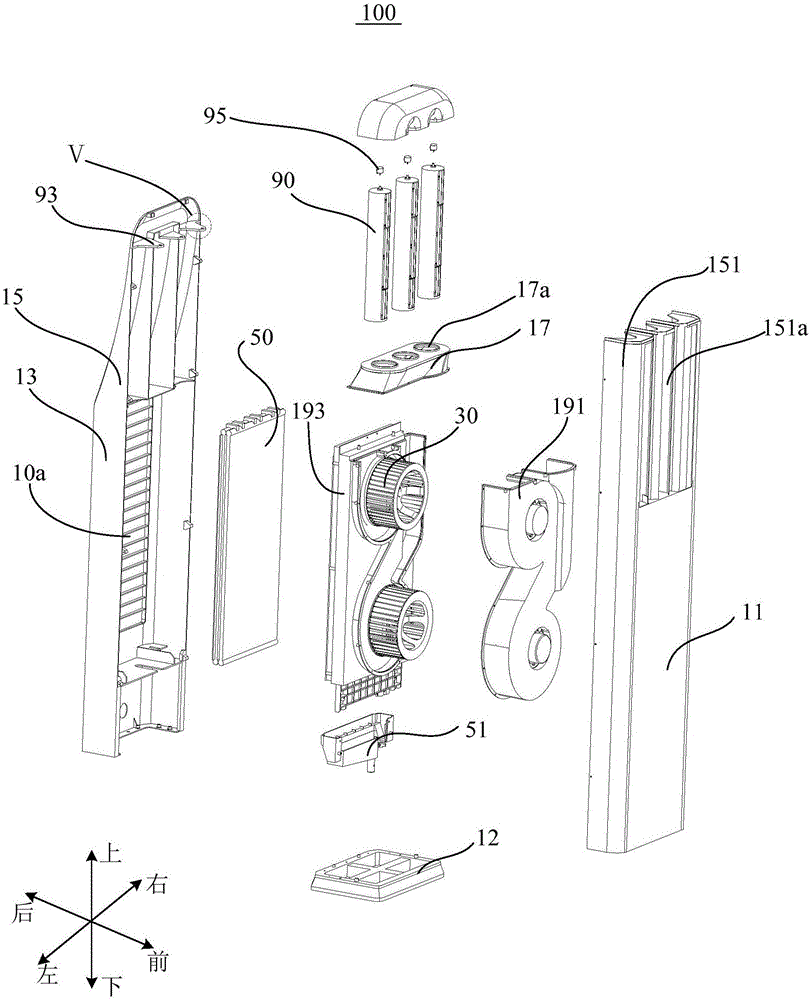

Cabinet air conditioner, air conditioner and exhaust control method of cabinet air conditioner

ActiveCN106225089ALarge air volumeFast flowMechanical apparatusSpace heating and ventilation safety systemsPlate heat exchangerEngineering

The invention discloses a cabinet air conditioner, an air conditioner and an exhaust control method of the cabinet air conditioner. The cabinet air conditioner comprises a shell; an air flue is formed in the shell; a plate heat exchanger is arranged in the air flue, and is fixed in the shell; an exhaust device is fixed on the shell, and includes three exhaust structures transversely spaced; the three exhaust devices are all communicated with the air flue; air holes are formed between two adjacent exhaust structures, and penetrate through the shell in the front-back direction; an intake structure is fixed on the shell, and is communicated with the air flue; the plate heat exchanger faces to the intake structure; and air enters the air flue by the intake structure for heat exchange by the plate heat exchanger, and is blown out by the exhaust structure. The exhaust quantity and the exhaust mode of the cabinet air conditioner can be effectively adjusted, so that the indoor air temperature effectively and quickly reaches the set temperature.

Owner:WUHU MATY AIR CONDITIONING EQUIP CO LTD +1

Preparation and construction method of machine-sprayed phosphogypsum lightweight plastering mortar

The invention discloses a preparation and construction method of machine-sprayed phosphogypsum lightweight plastering mortar. The machine-sprayed phosphogypsum lightweight plastering mortar is prepared from the following components in parts by weight: 75-85 parts of phosphogypsum, 10-15 parts of fine aggregate, 1-6 parts of an inert admixture, 4-8 parts of lightweight aggregate, 0.1-0.2 part of aretarder, 0.1-0.25 part of a water-retaining agent, 0.05-0.1 part of an anti-sagging agent, 0.1-0.3 part of an enhancer, 0.2-0.8 part of a fiber and 0-2 parts of a brightener. According to the preparation and construction method, phosphorus building gypsum (mainly composed of calcium sulfate hemihydrate) modified from solid waste slag phosphogypsum generated when phosphorite is treated with sulfuric acid in the process of phosphoric acid production is used as the main raw materials to prepare the machine-sprayed plastering gypsum mortar, the raw material cost is lowered, the construction efficiency and the construction quality are improved, the purpose of turning waste into treasure is achieved, great economic and social benefits are achieved, and the machine-sprayed phosphogypsum lightweight plastering mortar has a broad application prospect in construction engineering.

Owner:CHINA WEST CONSTR ACAD OF BUILDING MATERIALS CO LTD +2

Cabinet air conditioner, air conditioner and air outlet control method of cabinet air conditioner

ActiveCN106440032ALarge air volumeFast flowMechanical apparatusSpace heating and ventilation safety systemsDrive motorFlue

The invention discloses a cabinet air conditioner, an air conditioner and an air outlet control method of the cabinet air conditioner. The cabinet air conditioner comprises a shell and an air outlet device. An air flue is formed in the shell. The air outlet device is fixed to the shell and comprises three air outlet structures transversely arranged at intervals. The three air outlet structures communicate with the air flue, a wind tunnel is formed between air outlets of every two adjacent air outlet structures, and the wind tunnels penetrate the shell in the front and back direction. Each air outlet structure comprises an air outlet frame communicating with the air flue, wherein a shaft table is arranged on the air outlet frame. Drive motors are fixedly arranged on the shell, the shaft tables are in transmission connection with output shafts of the drive motors, and the air outlet frames are driven to rotate relative to the shell. According to the technical scheme, the air outlet volume and the air outlet mode of the cabinet air conditioner can be effectively adjusted, and the temperature of indoor air effectively and rapidly reaches the set temperature.

Owner:WUHU MATY AIR CONDITIONING EQUIP CO LTD +1

Making method of super soft cotton woven fabric

PendingCN110409090AImprove softnessSave steam energyFabric breaking/softeningSucessive textile treatmentsWoven fabricYarn

The invention discloses a making method of a super soft cotton woven fabric. The process comprises the steps of weaving, pretreatment, mercerizing, dyeing, air washing, setting softening, pre-shrinking and inspection; firstly, cotton yarn is woven into a cotton fabric; pre-treating is conducted on the fabric, and after cloth is discharged, first wet cropping is conducted; then mercerizing is conducted; then dyeing is conducted, and after the cloth is discharged, second wet cropping is conducted; then the fabric is subjected to air washing in a softening machine; a combined softener prepared from polyurethane and a silicone oil softener is adopted for performing setting softening on the fabric completing air washing; the fabric completing setting softening is pre-shrinked, and then the processing of the fabric is completed; finally, the finished woven fabric product is inspected. According to the making method, the cotton woven fabric which is super soft, boneless and fluffy in hand feeling can be made, and after repeated washing, the good softness can still be maintained.

Owner:SHENZHEN PURCOTTON TECH

Waterproof rolled material and preparation method thereof

InactiveCN101845169AImprove softnessHigh tensile strength at breakFlat articlesPlasticizerAntioxidant

The invention relates to a waterproof rolled material, in particular to a modified chlorinated polyethylene waterproof rolled material and a preparation method thereof, which solve the problems that the traditional waterproof rolled material can not completely satisfy each performance index of a product and the formula cost is overhigh. The waterproof rolled material is prepared from an ethylene-octylene copolymer, chlorinated polyethylene, linear high-pressure polyethylene, a filler intensifier, a softener plasticizer, a phenol antioxidant, a heat stabilizer, a lubricant and a light stabilizer, and the preparation method thereof comprises the following steps: mixing and stirring various raw materials; granulating by sequentially adopting a plastic refining machine, a double-roll machine and a grain cutting machine; adding grain materials into a single-screw extruding machine for extrusion and molding through a mould; and adding the molded material into a three-roll cooling embossing machine for rolling to obtain the waterproof rolled material. Not only the peculiar softness, the elongation percentage and the rebound resilience of rubber are reserved, but also the higher breaking tensile strength of an LLDPE is reserved, the integral sheet material has good softness, flatness and evenness, the performance index exceeds a national standard and the related standard of a railway ministry, all the ageing-resistant performance, the physical performance and the processing performance are more excellent, and the production cost is low.

Owner:SHANXI SIFANG HENGTAI WATERPROOF MATERIALS

Edge cutting woven label and preparation method thereof

The invention relates to a preparation method of an edge cutting woven label. The preparation method comprises the following steps: treating weft yarns, wherein the weft yarns adopt mixed yarns of polyester yarns and cotton yarns; setting the compactness of label tissues to be 4200-5800; weaving: weaving conventional warp yarns and weft yarns according to the label tissues, so as to obtain a woven label pre-finished product; cutting: cutting the woven label pre-finished product to obtain an edge cutting woven label pre-finished product; pre-treating: carrying out pre-shrinking and loosening treatment on the edge cutting woven label pre-finished product; shearing and folding: shearing and folding the pre-treated edge cutting woven label pre-finished product, wherein a shearing and folding process is as follows: the temperature of a hot cutter is 240 DEG C to 280 DEG C and the shearing frequency is 150-250 times / min. The edge cutting woven label prepared by the preparation method of the edge cutting woven label, provided by the invention, has a soft edge and small irritation on skins and is not easy to wrinkle and bulge; and the blanching shrinkage rate, water-washing shrinkage rate and hot drying shrinkage rate of the woven label are low and the quality of the woven label is high.

Owner:GUANGDONG ESQUEL TEXTILES

Colorful fiber

InactiveCN102605500AImprove softnessGood flexibilityConjugated synthetic polymer artificial filamentsYarnSolubilityWater soluble

The invention discloses a high-softness colorful fiber which is manufactured by drawing, false twisting and stranding a plurality of single-silk fibers with different colors, wherein the single-silk fiber comprises single-color polybutylene terephthalate accounting for 60-90% of the total weight and water-solubility polyester accounting for 10-40% of the total weight, wherein the content of the master batch in the single-color polybutylene terephthalate is between 0.1% to 50%; the cross section of the single-silk fiber is an island type; the single-color polybutylene terephthalate is an island component; and the water-solubility polyester is an island component. The colorful fiber has the advantages that the water-solubility polyester is dissolved into alkaline water after the colorful fiber is dissolved by water through after treatment; and finally the single-silk fiber degree of the single-silk fiber can reach 0.04dtex, so that the colorful fiber can have high softness.

Owner:张家港保税区长江塑化有限公司

Bidirectional high-shrink sanded home textile fabric

The invention relates to bidirectional high-shrink sanded home textile fabric. The bidirectional high-shrink sanded home textile fabric is characterized in that a processing technology specifically includes preparing a warp yarn consisting of cotton 21S and a high-shrink polyester filament 100 D / 48F in a ratio of 1:1 and a weft yarn consisting of cotton 21S and a high-shrink polyester filament 100 D / 48F in a ratio of 1:1. The bidirectional high-shrink sanded home textile fabric has the advantages of practicality, novelty, high performance cost and capability of enriching bedding quilt covers.

Owner:JIANGSU YUEDA HOME TEXTILE

Soft environment-friendly polyolefin cable material

The invention provides a soft environment-friendly polyolefin cable material prepared from the following raw materials in parts by weight: 20-30 parts of a PE resin powder, 40-50 parts of EVA, 10-15 parts of a POE elastomer, 4-5 parts of ACR resin, 20-30 parts of magnesium hydroxide, 20-30 parts of aluminum hydroxide, 10-20 parts of a talcum powder, 4-5 parts of molybdenum trioxide, 2-3 parts of iron oxide, 8-10 parts of tributyl citrate, 1-2 parts of an antioxidant 1010, 20-30 parts of triethyl O-acetylcitrate, 1-2 parts of pentaerythritol, 1-2 parts of melamine cyanurate, 1-2 parts of polytetrafluoroethylene, 1-2 parts of stearic acid, 1-2 parts of paraffin, and 8-10 parts of a modified filler. The cable material has high softness degree and excellent mechanical properties, and can meet use in communication cables, weak electric cables and other industries having higher demands on the cable softness degree.

Owner:河北润丰塑料制品有限公司

Laundry detergent

InactiveCN105647670AImprove softnessProtect the skin of the handsInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsProteaseNonionic surfactant

The invention discloses a laundry detergent. The laundry detergent is prepared from, by weight, 2-4 parts of caustic soda flakes, 5-8 parts of a soapberry extracting solution, 0.3-1 part of tea tree oil, 0.3-1 part of protective softener, 0.1-1 part of protease, 0.1-2 parts of sodium citrate, 3-6 parts of a nonionic surfactant and 2-5 parts of ethyl alcohol, and finally deionized water is added till the number of weight parts is 100. The laundry detergent contains the soapberry extracting solution which contains saponin, and saponin, the caustic soda flakes and the nonionic surfactant are used in cooperation so that dirt in clothes can be effectively removed. Besides, the protective softener can improve softness of the clothes, a protective film is formed on the surface of skin of a user, and skin of the hands is protected. The tea tree oil and ethyl alcohol can protect the skin and also have a good bacterium inhibition effect.

Owner:DONGGUAN PINPAI IND INVESTMENT

Preparation method of butyronitrile false foaming anti-skid gloves

The invention relates to a preparation method of butyronitrile false foaming anti-skid gloves. The method comprises the step that paraffin oil plasticizer poor in compatibility with butyronitrile latex is added in the butyronitrile latex, wherein the additive amount of the paraffin oil plasticizer is 2.4%-12.2% of butyronitrile latex by mass. Accordingly, on one hand, the advantage of the plasticizer capable of increasing the softness, oil resistance and abrasion resistance of rubber products is applied; on the other hand, by means of the advantage of being poor in compatibility with butyronitrile, the paraffin oil plasticizer forms the certain occupying effect in butyronitrile glue, in the heating prevulcanization process, separation or bleeding is conducted, pit-shaped structures in different degrees are formed on the glove glue surfaces, the roughness of the glove glue surfaces is increased to a certain extent, and the grasp anti-skid property of the gloves is enhanced. Due to the fact that the pit-shaped structures have the advantage of increasing the softness of the butyronitrile gloves, the pit-shaped structures are different from communicated foaming holes formed by foamingglue, the water resistance and oil resistance cannot be weakened, and the gloves are false foaming butyl rubber gloves approximating foaming but not virtually foaming.

Owner:SHANDONG XINGYU GLOVES

High-pressure-resistant water-base foamed raincoat leather

InactiveCN106087459AReasonable structureImprove softnessOvergarmentsTextiles and paperHollow formEnvironmentally friendly

The invention discloses high-pressure-resistant water-base foamed raincoat leather. The raincoat leather comprises base cloth and a high-pressure-resistant resin layer coating one surface of the base cloth, wherein high-pressure-resistant resin layer comprises a water-based PU bottom layer, a water-based foamed resin intermediate layer, a water-based resin upper layer and an anti-UV water-based resin surface layer which are sequentially connected from bottom to top. According to the high-pressure-resistant water-based foamed raincoat leather, a waterproof gas-permeable surface layer is a four-layer structure formed by the water-based PU bottom layer, the water-based foamed resin intermediate layer, the water-based resin upper layer and the anti-UV water-based resin surface layer, is safe and environmentally friendly and has bending resistance, high softness and tensile strength and relative high gas permeability and water resistance; the water-base foamed resin intermediate layer is of a hollow formed structure and is light, so that the leather feel and the water pressure resistance are provided; by adding a mixture of nano-TiO2 powder and nano-ZnO powder to the surface layer, the foamed raincoat leather has the effects of resisting ultraviolet light, protecting leather, blocking sunshine and resisting ageing, and the service life is prolonged.

Owner:浙江嘉科新材料科技有限公司

Limb supporting device for gynecological examination

InactiveCN112716734ARelieve fatigueImprove comfortOperating tablesMedical transportObstetric examinationEngineering

Disclosed is a limb supporting device for gynecological examination. The limb supporting device comprises a moving plate, a telescopic rod, a supporting plate and a supporting frame, a supporting ring is welded to one side of the moving plate, a lifting rod is installed in the supporting ring in a penetrating mode, and the telescopic rod is installed at the top of the moving plate through a bolt; a supporting plate is installed at the top of the telescopic rod through a bolt, a first bearing seat is installed at the top of the supporting plate through a bolt, a first pushing rod is movably connected to the top of the first bearing seat, and a back supporting plate is movably connected to the top end of the first pushing rod through a second bearing seat; and the top connecting piece of the supporting plate is connected with a second pushing rod. The angle of the leg supporting plate is adjusted, the thigh of a patient is supported, the thigh of the patient is prevented from being in a suspended state all the time when the body of the patient is detected, leg fatigue of the patient can be relieved to a large extent, comfort of the patient is improved, and a doctor can conveniently examine the lower half body of the patient.

Owner:张利峰

Jute spinning method

The invention discloses a jute spinning method. The key points of the technical scheme comprise the following steps of softening jute; and combing, sizing and performing wet-spinning, wherein the softening solution used in the softening step comprises the following components in percentage by weight: 1.5 percent of emulsifier, 23.5 percent of linen softening oil, and 75 percent of water. By using the method, the spinnability of jute fibers can be improved, the difference ratio of fiber lengths can be reduced, the strength of the jute fibers can be improved, the requirement of spinning production of high-count pure jute yarn can be met, and the high-count pure jute yarn of between 6 and 12Nm can be produced.

Owner:郴州湘南麻业有限公司

Fresh antibacterial tissue and preparation method thereof

PendingCN111395037APaper texture is smooth and delicateImprove softnessCosmetic preparationsNatural cellulose pulp/paperBiotechnologyStaphylococcus bacteria

The invention provides a fresh antibacterial tissue. The fresh antibacterial tissue is prepared from the following raw materials in percentage by weight: 0.3 to 0.5 percent of a moisturizing factor, 1.2 to 2.0 percent of antibacterial essential oil, 0.05 to 0.07 percent of a dispersing agent, 0.2 to 0.4 percent of a wet strength agent, 0.03 to 0.05 percent of a defoaming agent and the balance of wood pulp fibers. Compared with the prior art, the fresh antibacterial tissue provided by the invention is smooth and fine in paper touch, fresh, mild and non-irritant, can moisten and care the skin, and has an antibacterial effect on escherichia coli, staphylococcus aureus and the like. In addition, the preparation method of the fresh antibacterial tissue provided by the invention is simple to operate, low in cost and easy for large-scale production, and has a good application prospect.

Owner:安徽霏羽纸业有限公司

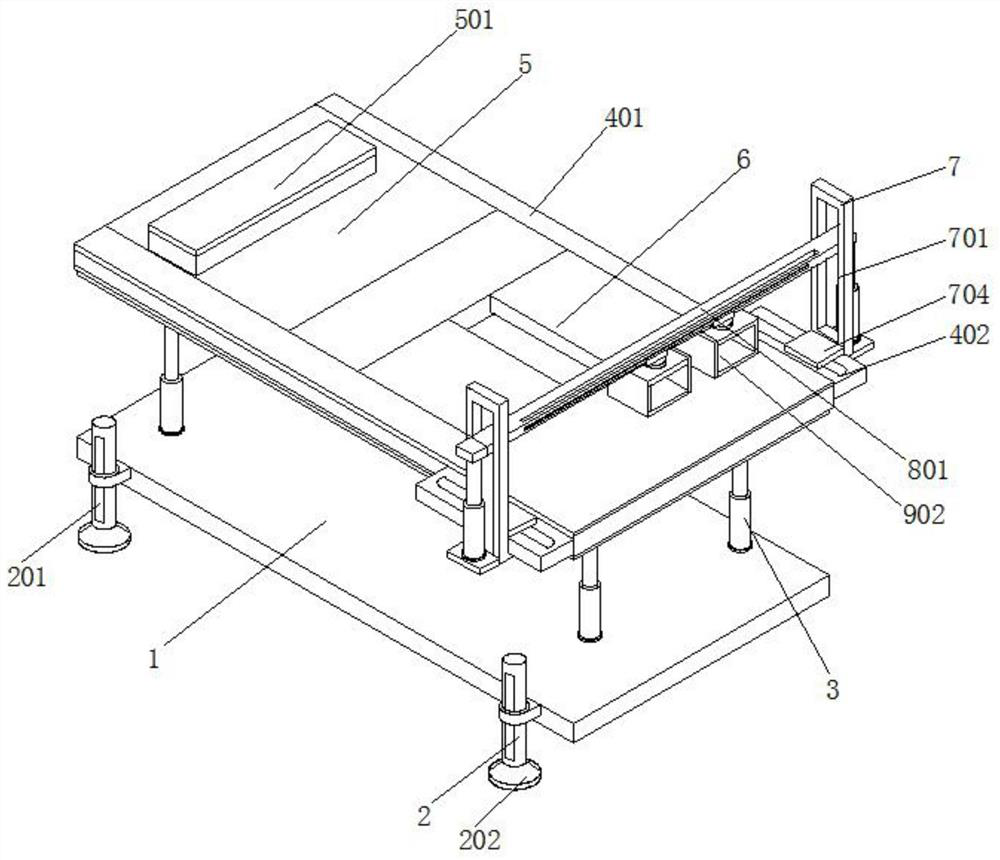

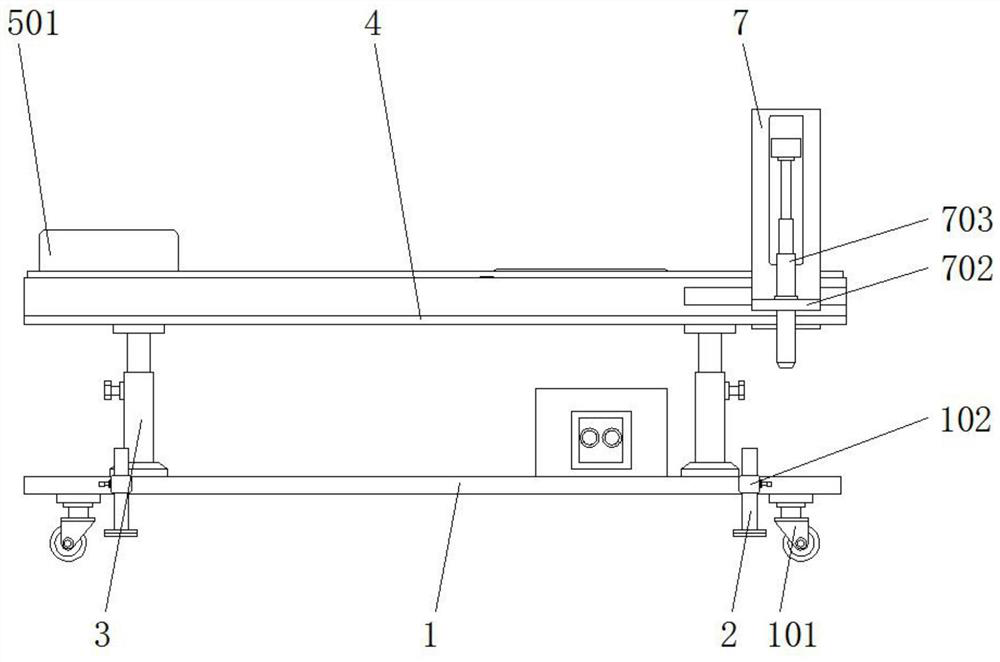

Efficient embossing and disinfecting integrated napkin machine

PendingCN112046088AImprove softnessGood embossing effectMechanical working/deformationPaper after-treatmentPhysicsLiquid water

The invention discloses an efficient embossing and disinfecting integrated napkin machine which comprises a base, a bobbin paper roller, a humidifying mechanism, an embossing mechanism, a hot pressingmechanism, a disinfecting mechanism, a folding mechanism and a paper cutting mechanism. The bobbin paper roller is rotationally installed at one end of the base, the embossing mechanism is located onone side of the bobbin paper roller, the humidifying mechanism is located above the embossing mechanism, the hot pressing mechanism is located on one side of the embossing mechanism, the disinfectingmechanism is located on one side of the hot pressing mechanism, the folding mechanism is located on one side of the disinfecting mechanism, the paper cutting mechanism is located on one side of the folding mechanism, and the embossing mechanism comprises an embossing box. By arranging the humidifying mechanism, an ultrasonic atomization piece in a water tank works to scatter liquid water moleculestructures to generate naturally flowing water mist, and the water mist is conveyed into an atomization pipe through an atomization conveying pipe and an atomization conveying pump and blown to the surface of paper to be embossed in the embossing machine through an atomization outlet. The softness of the paper is improved, the good embossing effect is guaranteed, and the embossing efficiency is improved.

Owner:东莞市旭利日用品有限公司

Preparation method of comfortable polyurethane elastic fiber

ActiveCN108251912AImprove softnessLow modulusMonocomponent synthetic polymer artificial filamentArtifical filament manufactureIsocyanateDiamine

The invention discloses a preparation method of comfortable polyurethane elastic fiber. The preparation method of the comfortable polyurethane elastic fiber comprises the following steps: 1, mixing achemical foaming agent and an organic solvent to obtain chemical foaming agent dispersing liquid; 2, mixing polyether polyol and diisocyanate to prepare a -NCO end-capped polyurethane formic ester prepolymer, adding an organic solvent and completely dissolving to obtain a prepolymer solution; 3, performing chain extension on the prepolymer solution and diamine to obtain a polyurethane stock solution; 4, adding the chemical foaming agent dispersing liquid into the polyurethane stock solution, adding a spandex aid, curing and defoaming to obtain a spinning solution; and heating and curing the spinning solution in a high-temperature processional road by a wet spinning system to form tows and performing winding molding to obtain the comfortable polyurethane elastic fiber. The decomposition temperature of the selected chemical foaming agent is high, the softness and the air permeability of the polyurethane elastic fiber can be improved, the modulus of the polyurethane elastic fiber is reduced and the comfortable wearing effect is achieved.

Owner:ZHEJIANG HUAFENG SPANDEX

Storage method capable of quickening white liquor aging

InactiveCN107557258AEasy to storePlay a role in filtration and purificationAlcoholic beverage preparationPressure riseVacuum pumping

The invention discloses a storage method capable of quickening white liquor aging. The storage method is characterized by comprising the following steps: (1) filtering, distilling white liquor for a second time until alcoholic strength is greater than 52 degrees, and adding active carbon into liquor to perform ultrasonic oscillation; (2) performing low-temperature ionization, pouring filtered white liquor into a sealed ionization slot to perform low-temperature ionization; (3) performing negative-oxygen treatment, pouring ionized white liquor into the sealed tank, using a guide tube for introducing negative oxygen ions into the white liquor to aerate, and performing pressure-rising treatment; (4) performing variable-temperature storage, filling white liquor subjected to negative-oxygen treatment into a wine jar, and sealing the wine jar, separately regulating the temperatures of two storage rooms to 1-3 DEG C and 26-29 DEG C, and separately storing the sealed white liquor in a low-temperature room and a high-temperature room alliteratively; and (3) performing pool storage, i.e., using sticky mud to coat the wine jar until the wine jar is completely covered, repeatedly coating by 2-3 times, performing low-temperature drying, using a vacuum bag to downwards fill liquor from an upper jar hole, sealing, performing vacuum-pumping, and putting the wine jar into the bottom of a waterpool to perform pool storage.

Owner:ANHUI WANGJIABA WINE

Battery protection piece and protection method and battery module

Owner:江西美晨通讯有限公司 +2

Preparation method for soft fabric with high air permeability

InactiveCN108998994AImprove softnessImprove dyeing effectDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsChemistryDyeing

The invention discloses a preparation method for a soft fabric with high air permeability, belonging to the field of fabrics. The preparation method for the soft fabric with high air permeability comprises the following steps: rinsing, dyeing, dye fixation, soaping, washing with clear water, drying and setting. The prepared soft fabric has high air permeability and excellent color fastness to dryrubbing, wet rubbing, washing and soaping.

Owner:FUJIAN FORTUNES TEXTILE PRINTING & DYEING TECH

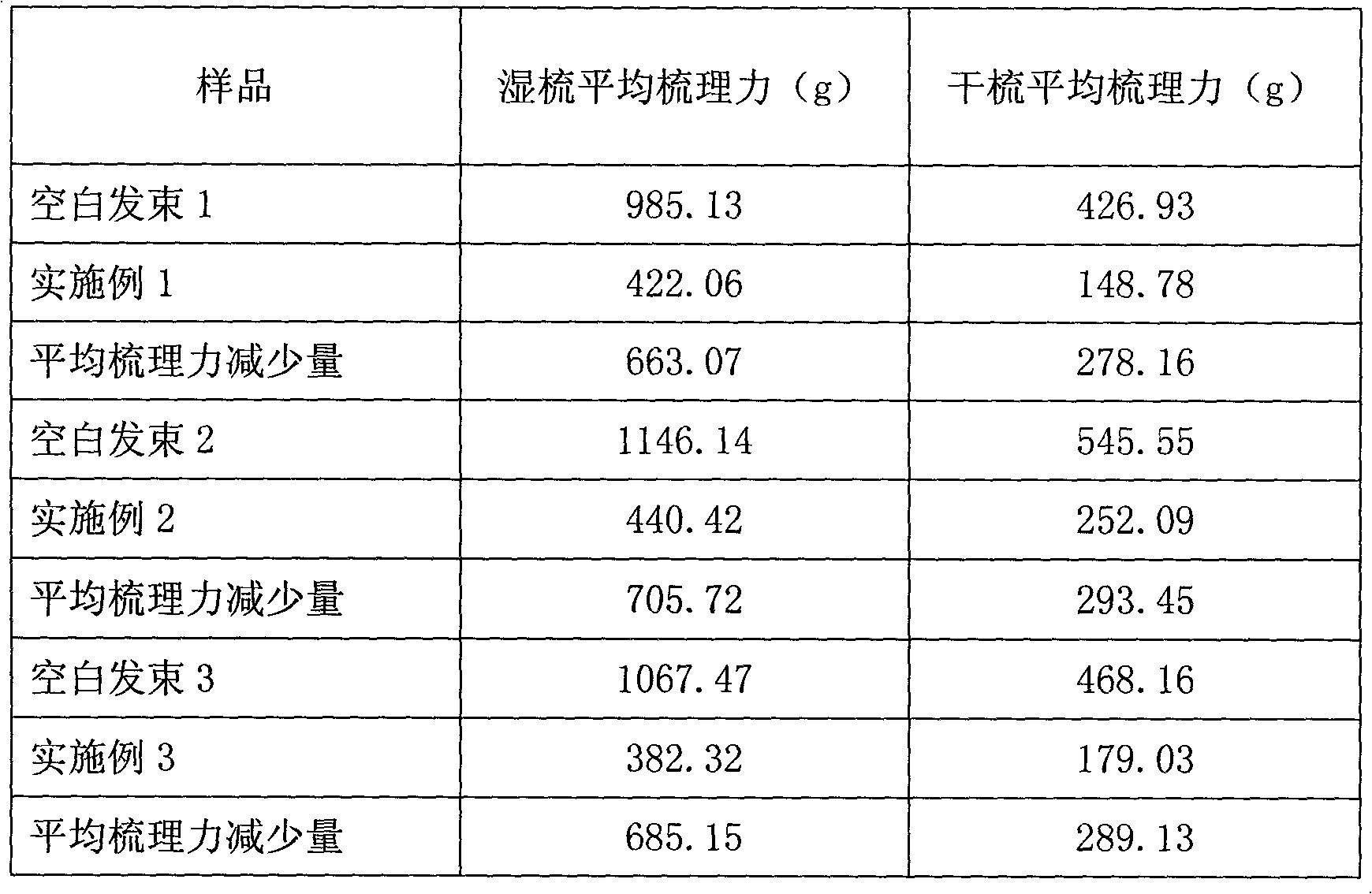

Composition with function of repairing damaged hair and application thereof in hair cosmetics

InactiveCN102697683AImproves density and fullnessImprove softnessCosmetic preparationsHair cosmeticsCeramideFish skin

The invention discloses a composition with a function of repairing damaged hair and application thereof in hair cosmetics. The composition consists of ceramide, deep-sea fish skin hydrolyzed elastin, corn fermentation liquor extract, behenacylpropyl dimethylamine, lactic acid and deionized water. The composition can improve compactness, fullness, strength, humidity and softness of hair, plays a role in repairing the damaged hair, and can be applied to the hair cosmetics.

Owner:GUANGZHOU HENGTUO TRADE

Composite yarns containing artificial cotton fibers and metallic fibers and preparation method of composite yarns

InactiveCN104178861AGood air permeability and moisture absorption performanceImprove softnessYarnYarnFilm coating

The invention discloses composite yarns containing artificial cotton fibers and metallic fibers and a preparation method of the composite yarns. The composite yarns comprise the following materials in parts by weight: 5-40 parts of metallic fibers, and 50-90 parts of artificial cotton fibers. The preparation method comprises the following steps: the metallic fibers are conducted by cleaning treatment and starching film coating treatment; the metallic fibers and other functional fibers are prepared into first cross-blended yarns through procedures of cotton assorting, blowing, cotton carding, drawing, roving, and spun yarn self-spooling; the artificial cotton fibers and other functional fibers are prepared into second cross-blended yarns through procedures of cotton assorting, blowing, cotton carding, drawing, roving, and spun yarn self-spooling; the first cross-blended yarns and the second cross-blended yarn are mixed and combined into three channels in proportion, and prepared into the composite yarns by roving, spinning and spooling. The composite yarns are good in ventilation and moisture absorption performance, and high in softness, integrate various functions, and can meet multifunctional requirements.

Owner:无锡市金蜘蛛复合丝线厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com