Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Avoid sharp corners" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

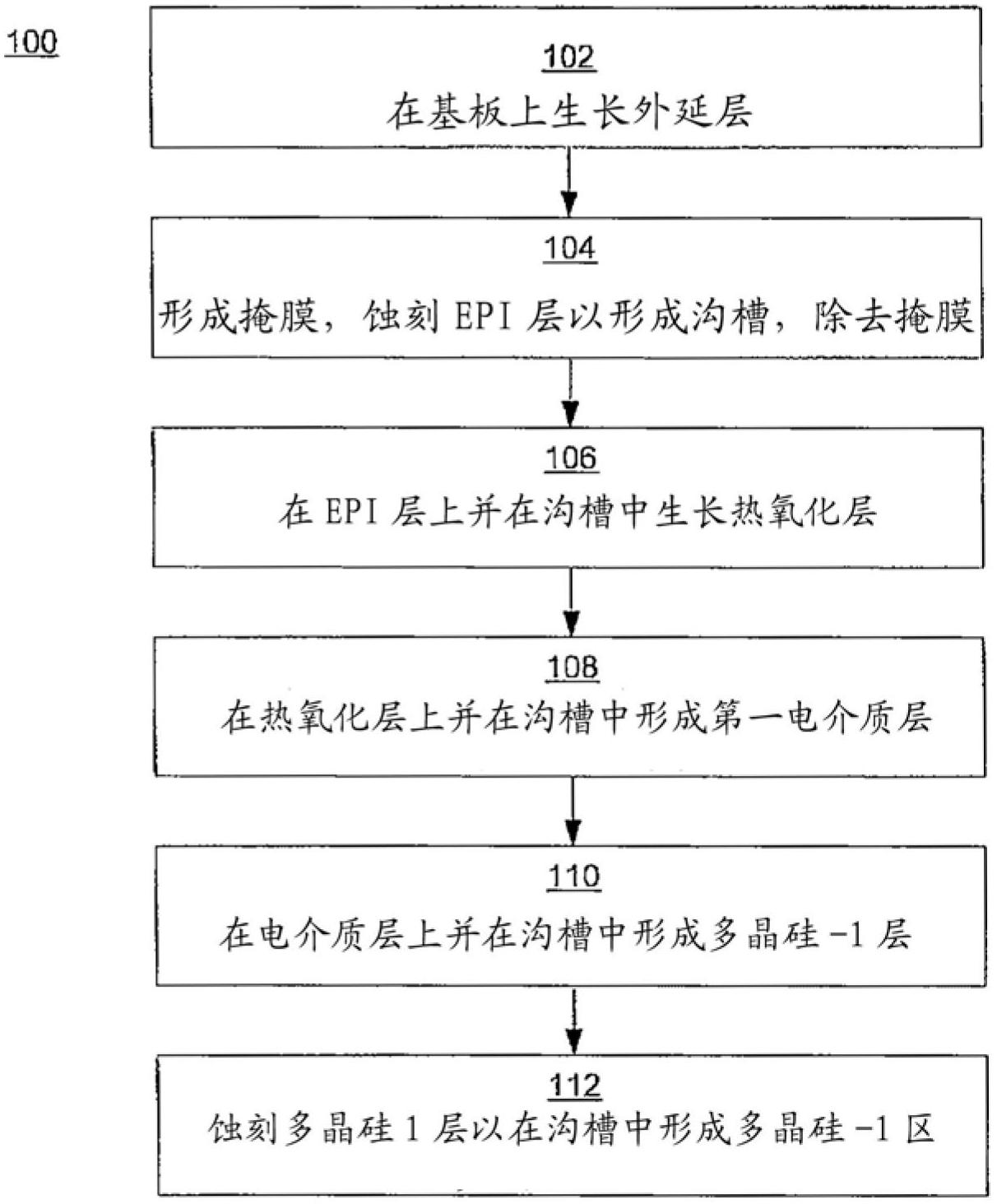

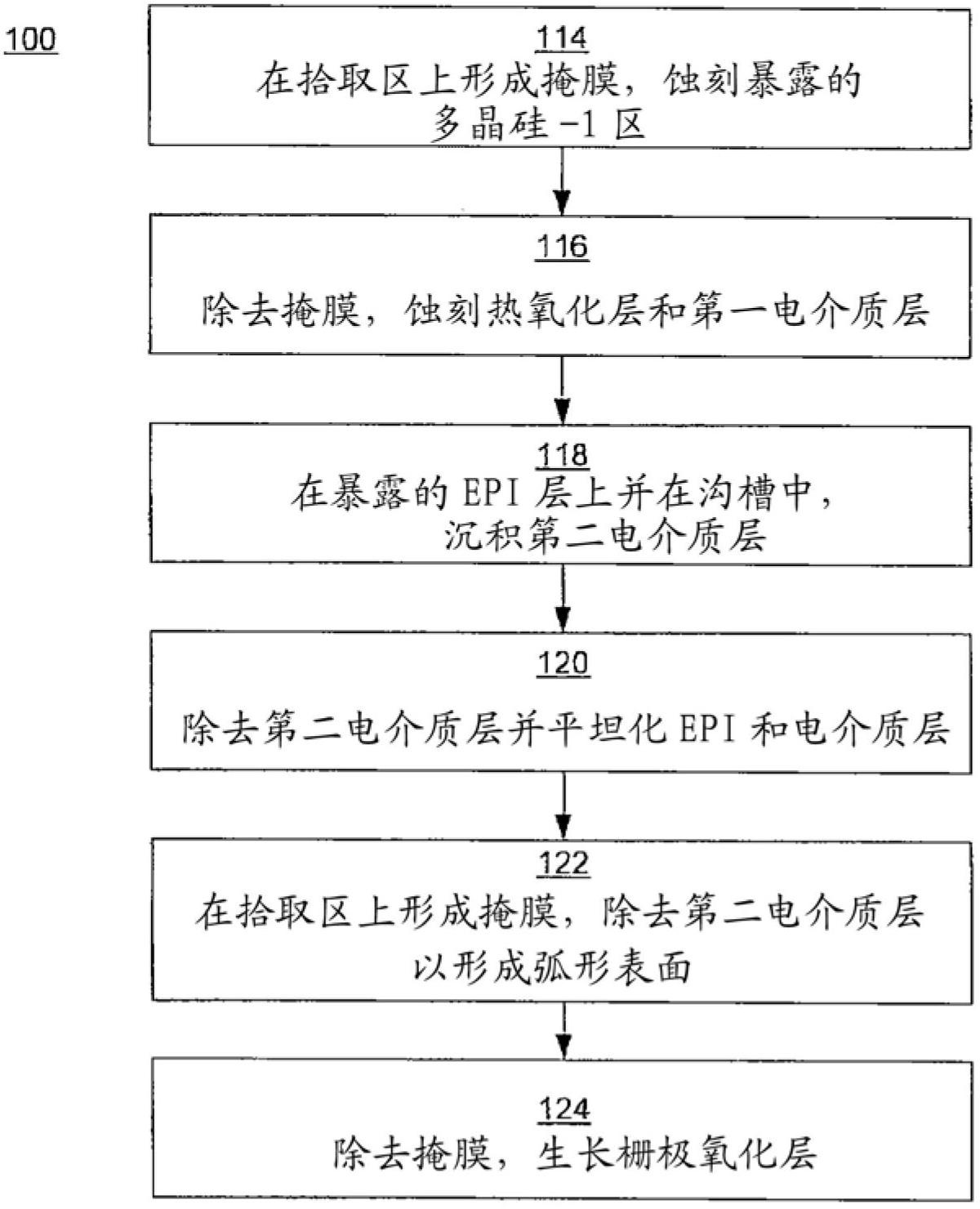

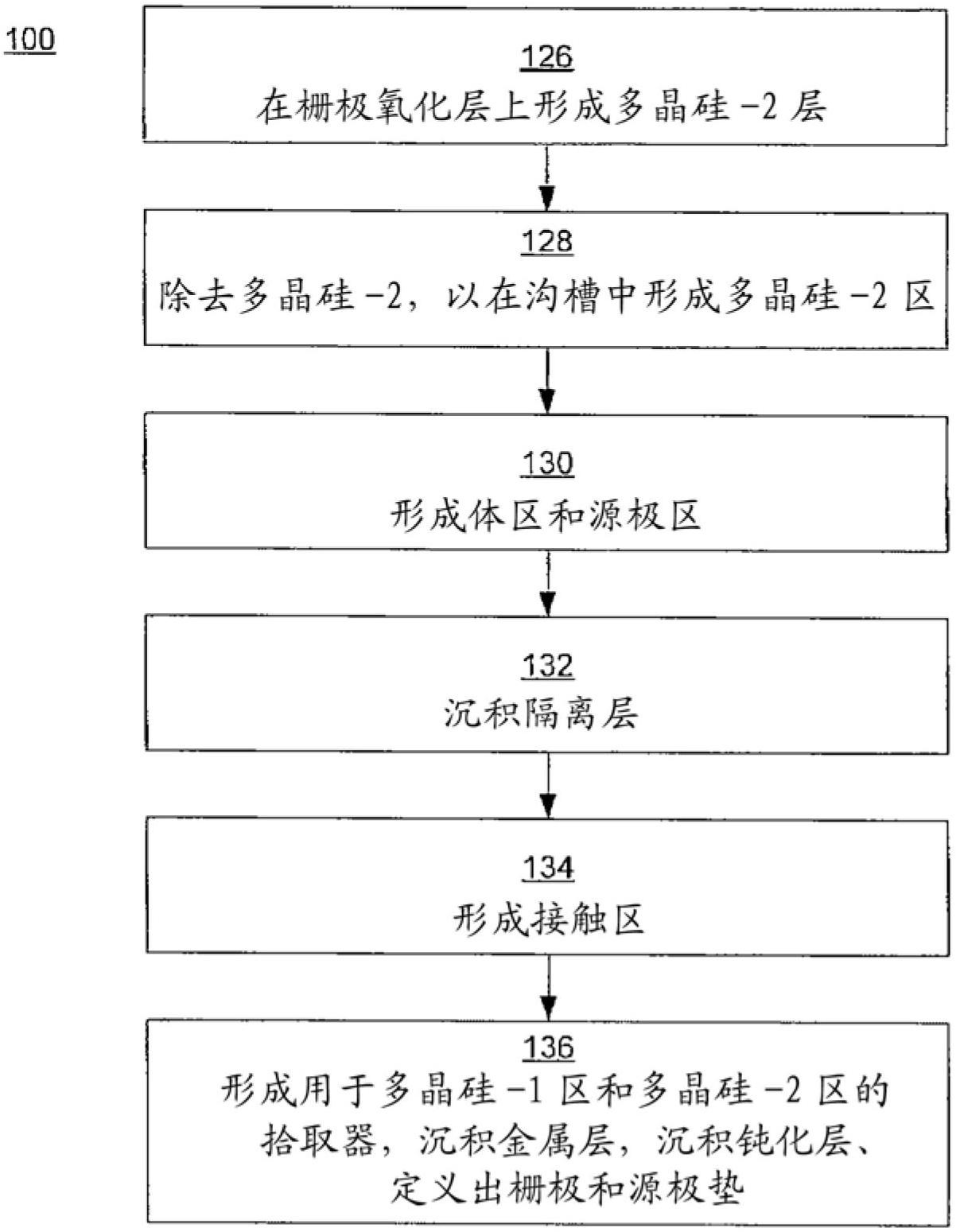

Split gate semiconductor device with curved gate oxide profile

ActiveCN102656696AAvoid the problems of trying to achieve a consistent etch rateAvoid sharp cornersSemiconductor/solid-state device manufacturingSemiconductor devicesGate oxideDielectric layer

Owner:VISHAY SILICONIX LLC

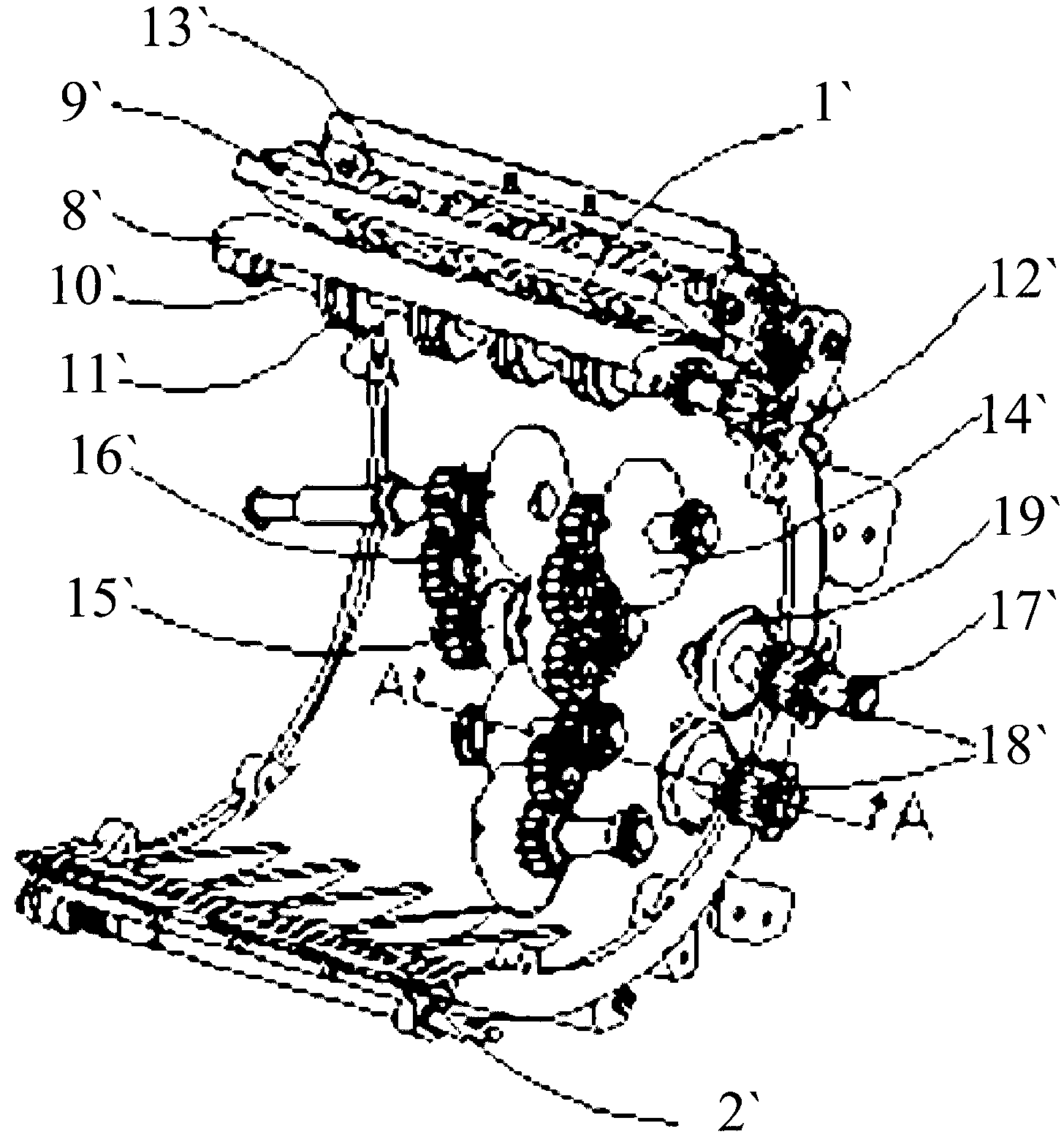

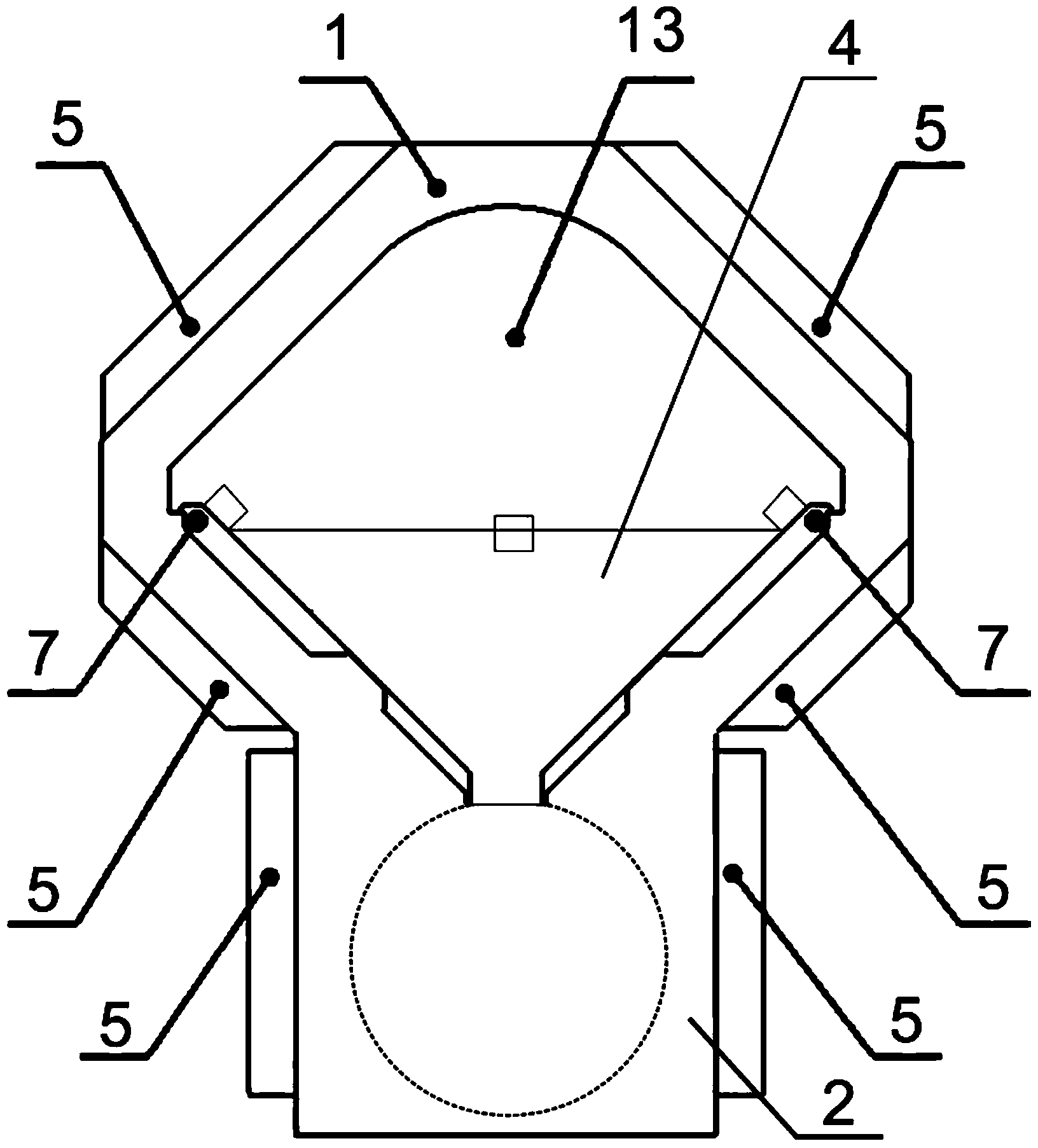

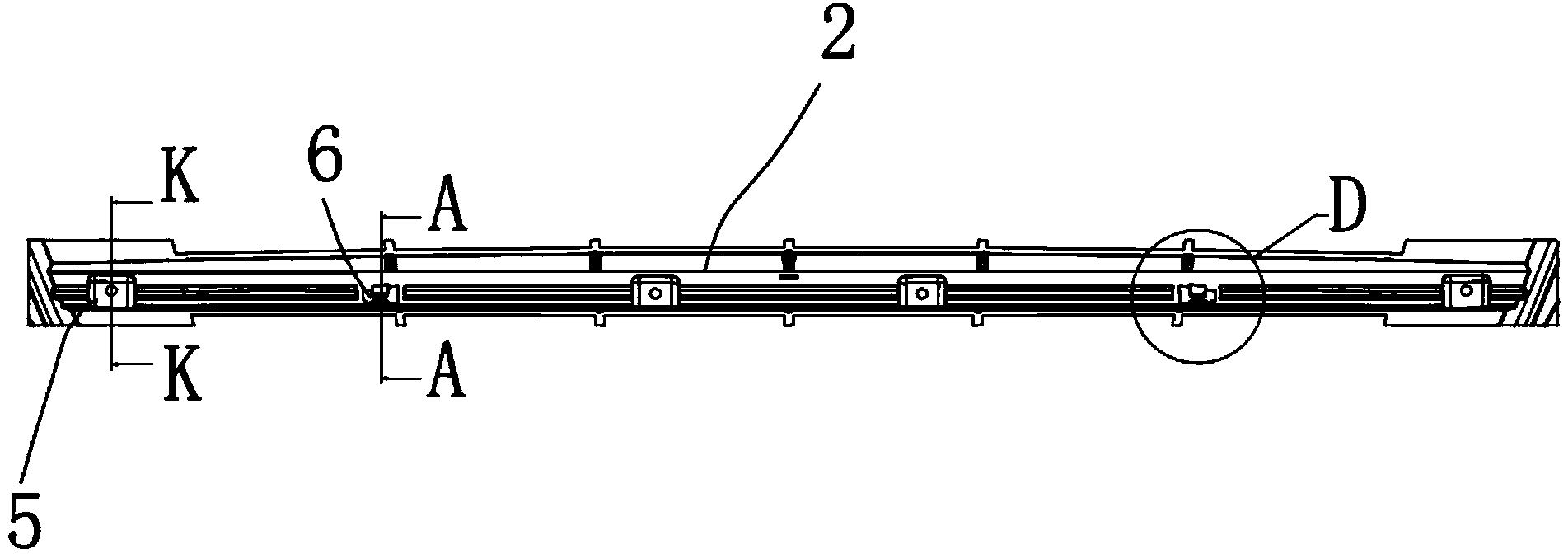

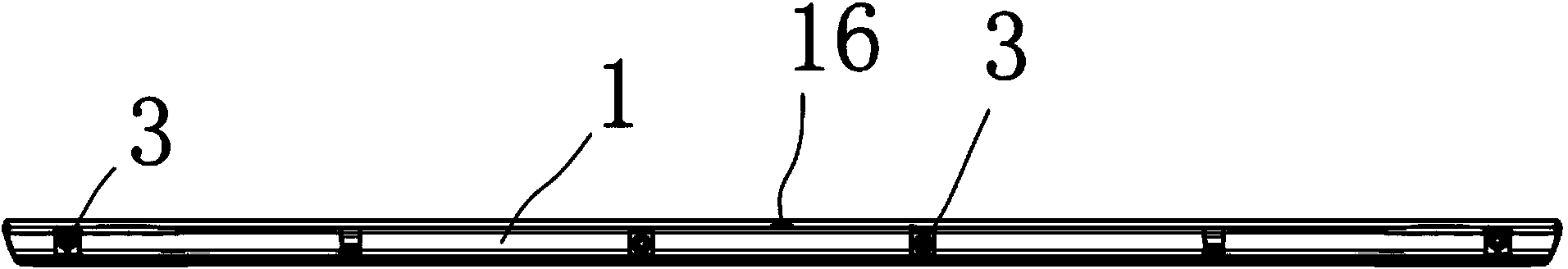

Automatic teller machine and deflection correcting device thereof

ActiveCN103236120AShorten the lengthAchieving direct correctionComplete banking machinesRegistering devicesEngineeringWheel drive

The invention provides a deflection correcting device which comprises a bill operation channel composed of a first channel plate and a second channel plate. Bills pass through the bill operation channel and are gradually delivered by a deflection correcting wheel in the bill operation channel to be close to a standard wall. When the bills are close to the standard wall, the bills are delivered into an adjusting wheel. The adjusting wheel and the deflection correcting wheel drive together to deliver the bills, and rotating line speed of the adjusting wheel is larger than rotating line speed of the deflection correcting wheel. Due to the fact that the delivery direction of the deflection correcting wheel is deflected from the standard wall, the front end of the bill delivery direction is close to the standard wall gradually, at this time, the adjusting wheel with higher line speed corrects the bills, the bills are slowly away from the front end of the standard wall, and the tail ends of the bills are gradually close to the standard wall. When the tail ends of the bills are attached to the standard wall, the bills are delivered continuously and set right gradually. Direct guiding of the deflection correcting wheel on the bills is achieved, and a delivery space during correction of the bills is reduced. The invention further provides an automatic teller machine.

Owner:GRG BAKING EQUIP CO LTD

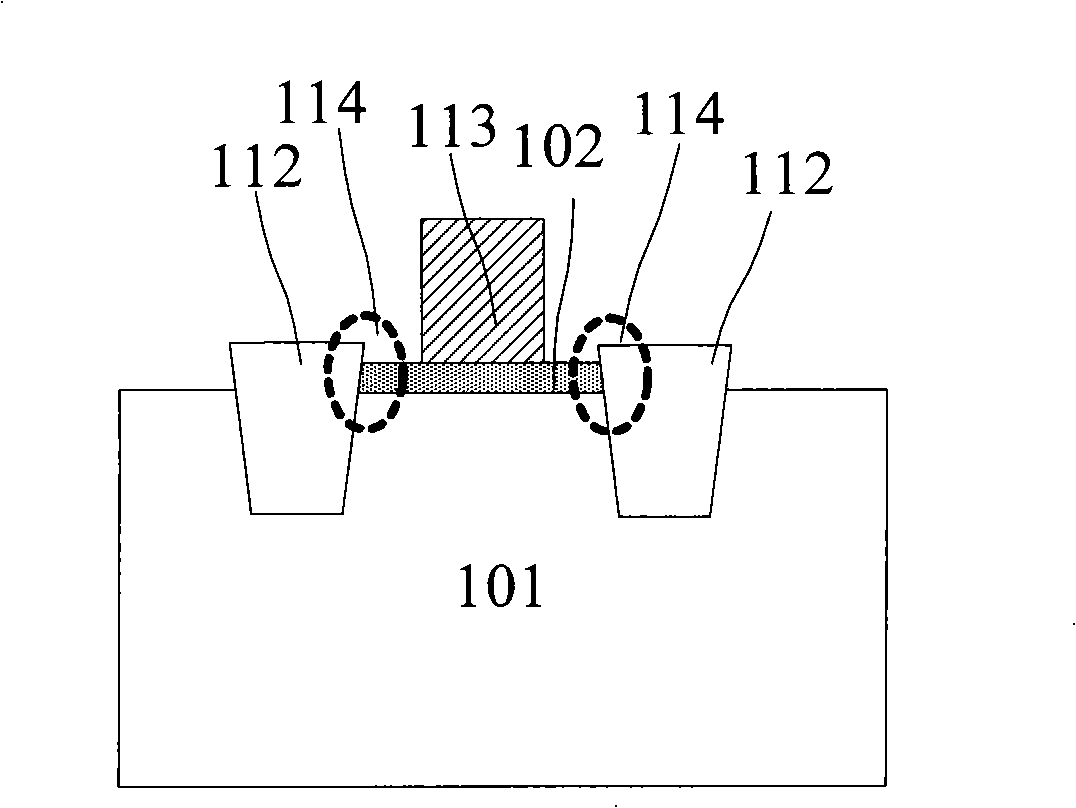

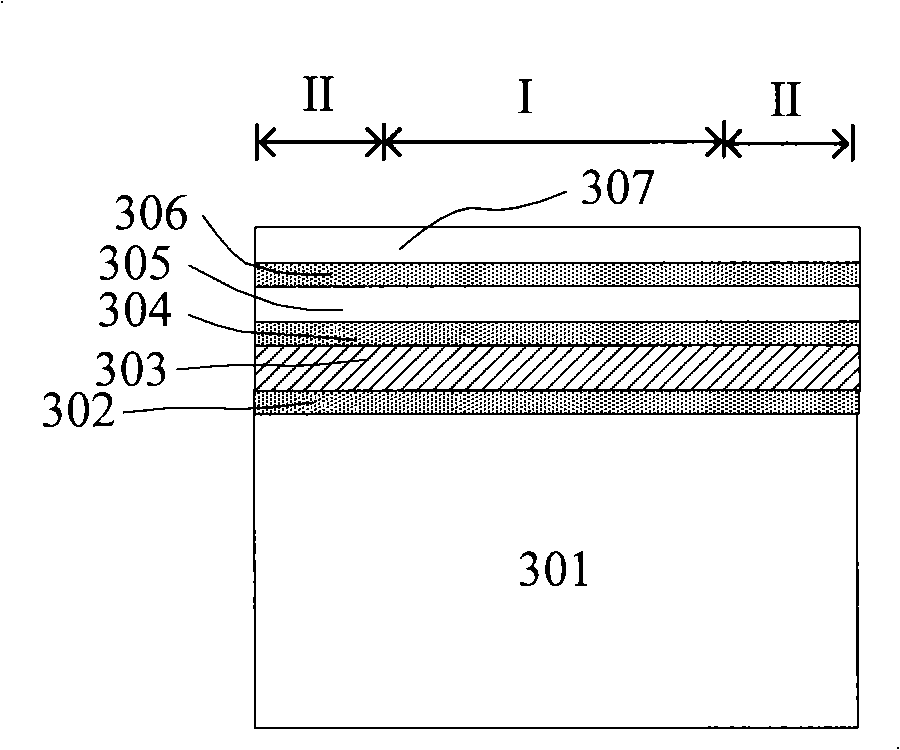

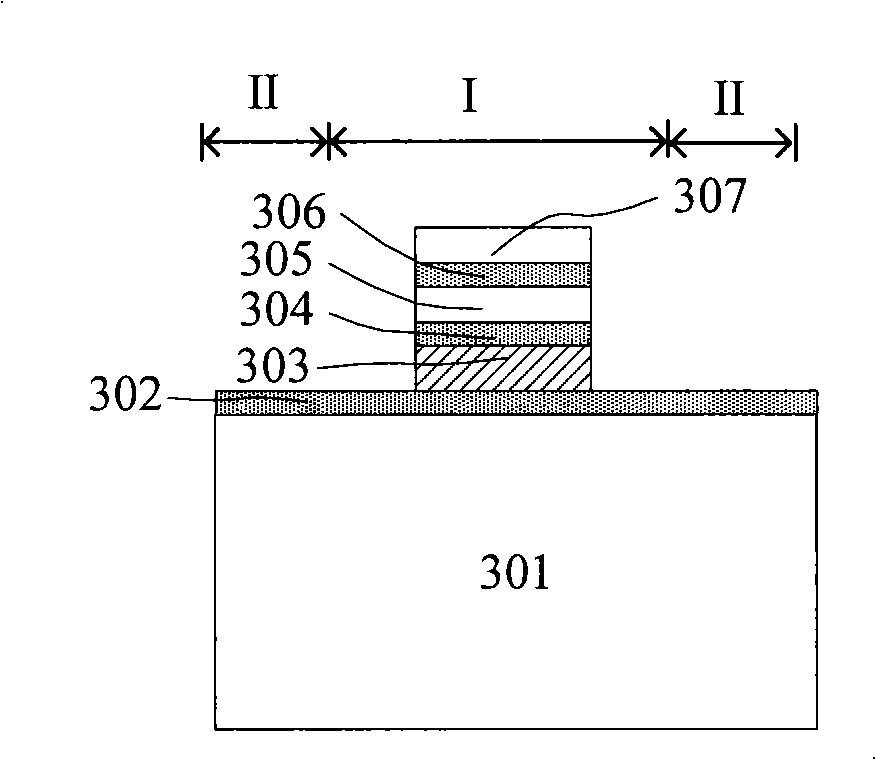

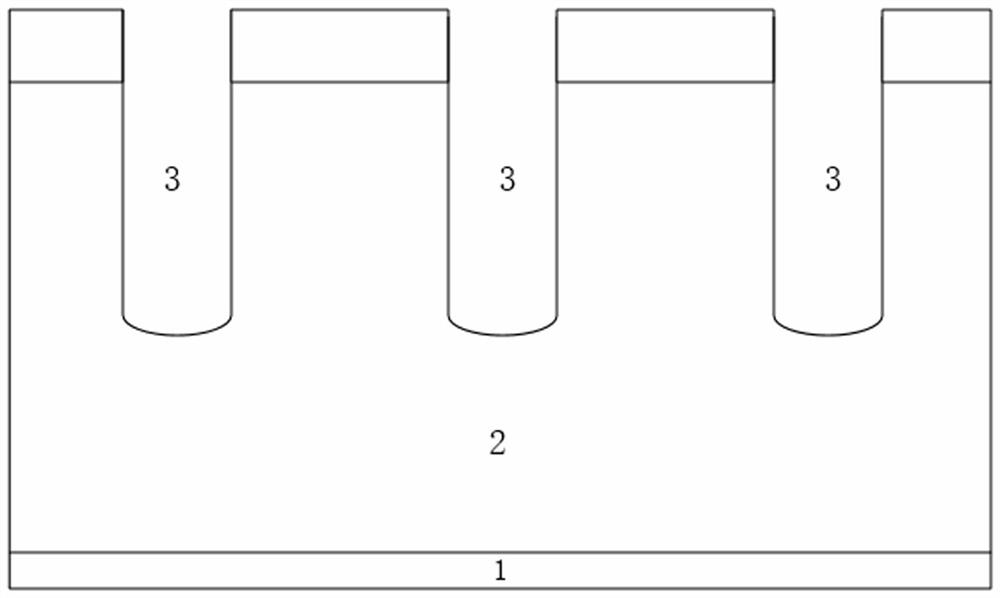

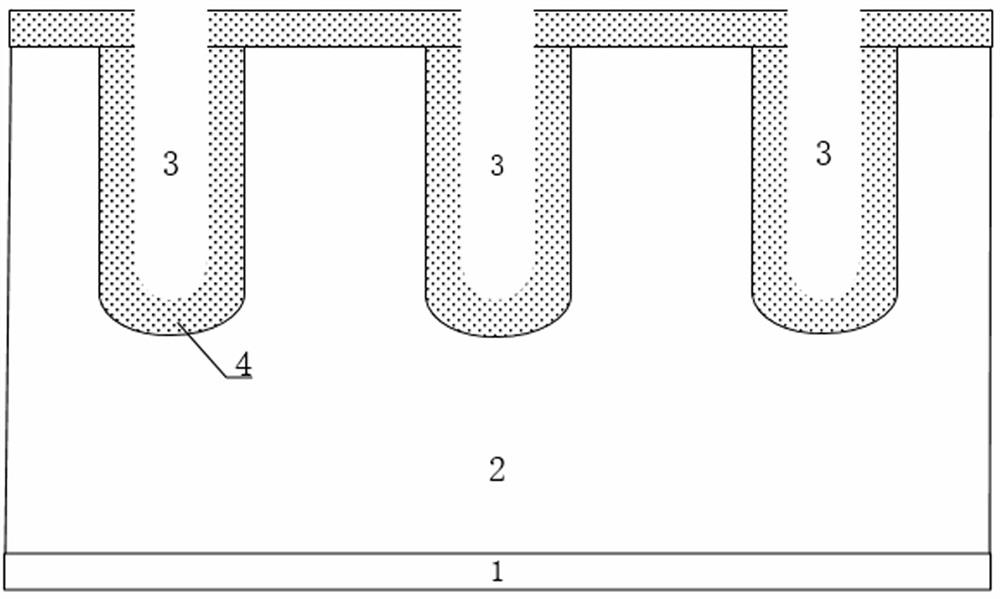

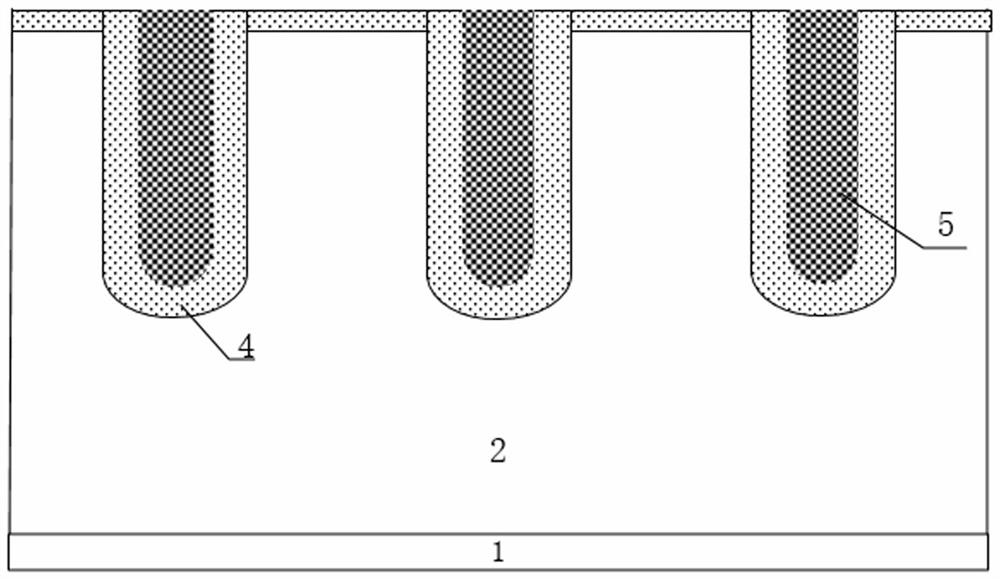

Self-aligning shallow groove isolation structure, memory unit and method for forming the same

ActiveCN101330049AAvoid sharp cornersSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSharp angle

The invention relates to a method for forming a self-aligning shallow groove isolation structure, which comprises the following steps: a side wall is added into a self-aligning shallow groove isolation structure technology for oxidation so as to form a filed oxide layer; then, grooves are formed at an isolation area and are filled by a liner oxide layer and a third insulated layer. By adding the side wall into the self-aligning shallow groove isolation structure technology for oxidation and forming the field oxide layer, a sharp angle formed at the contact place of the self-aligning shallow groove isolation structure and a grid medium layer is avoided. Correspondingly, the invention provides a self-aligning shallow groove isolation structure. The invention also provides a memory unit and a formation method thereof for preventing the forming of a sharp angle at the contact place between the self-aligning shallow groove isolation structure of the areas of the memory unit and peripheral circuits, and the grid medium layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP

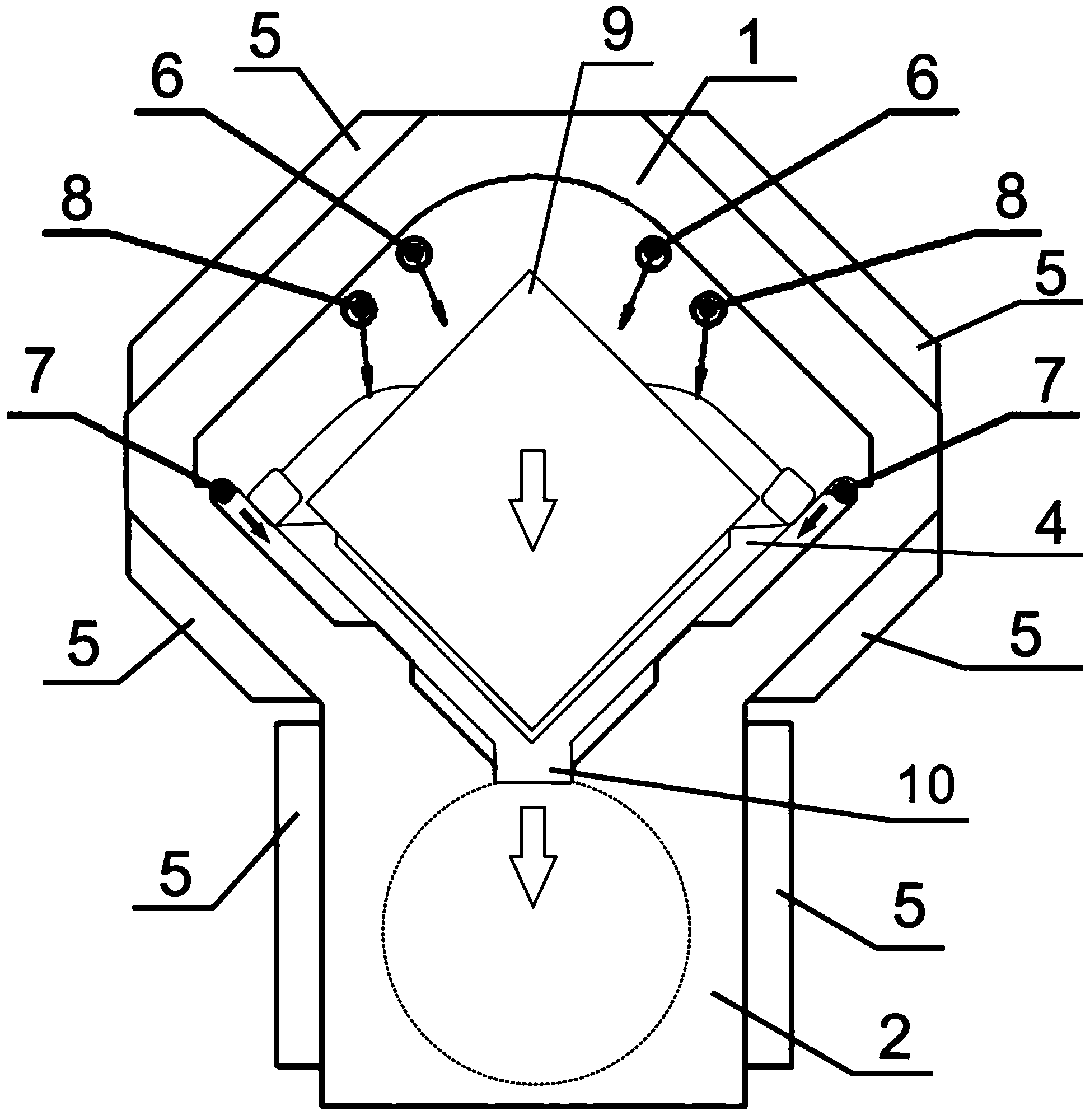

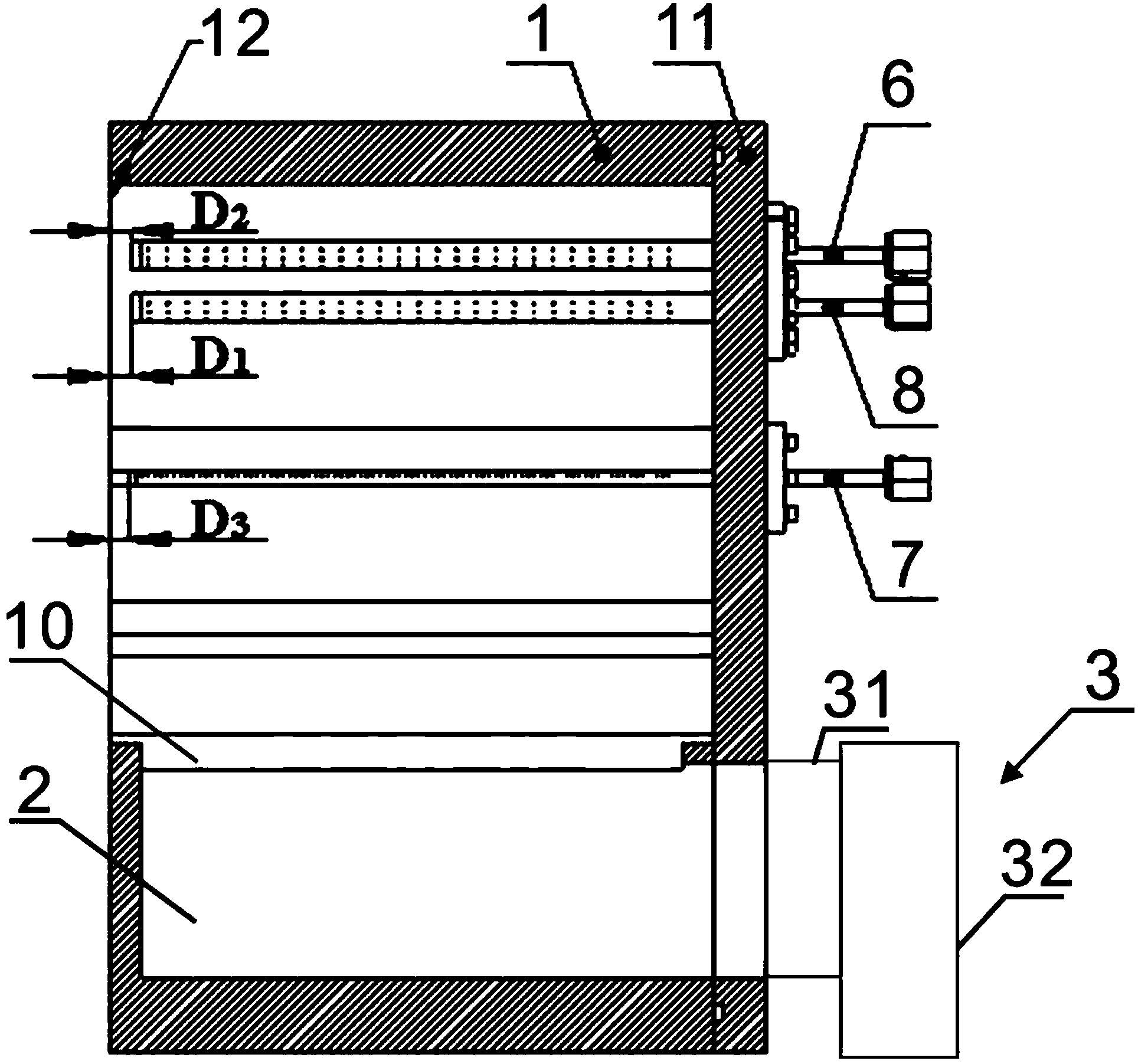

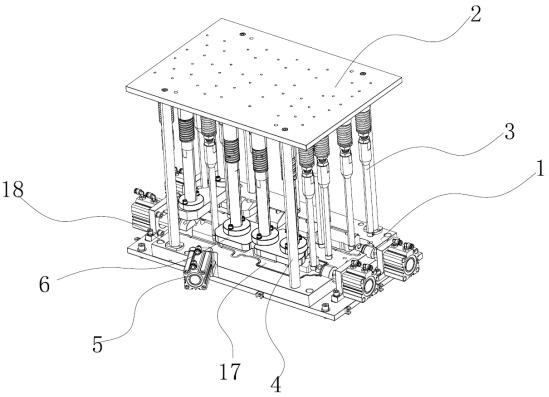

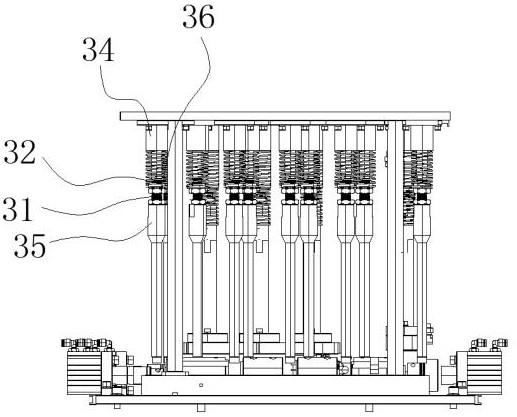

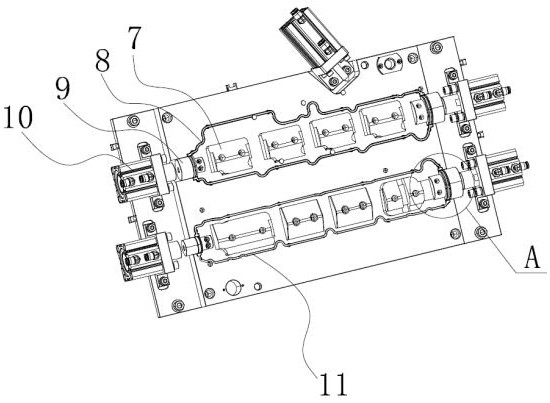

Reaction unit and method for atom layer film deposition

ActiveCN103866288AIncrease production capacityEvenly heatedChemical vapor deposition coatingChemisorptionEngineering

The invention provides a reaction unit and a method for atom layer film deposition, and belongs to the technical field of manufacturing, assembly and processing of solar cells. The reaction unit comprises a reaction deposition chamber, a reaction emptying chamber and a vacuum system connected in sequence, wherein a silicon wafer bearing unit, a heating unit, a precursor feeding unit and a blowing gas charging unit are arranged inside the reaction deposition chamber. According to the method disclosed by the invention, at least two gaseous precursors are fed into a reactor in a pulse alternation manner and chemically adsorbed on a depositing base body for reaction so as to form a deposited film. The reaction unit and the method disclosed by the invention have the advantages of effectively remedying the defects that in the existing reaction unit, the productivity is low, the gaseous reactant precursors are distributed on the surface of the silicon wafer unevenly, temperature gradient exists on the surface of the silicon wafer and the gaseous reactant precursors cannot be discharged completely and the like, greatly improving the productivity and the depositing speed of the silicon wafer of an atom layer film depositing device and effectively improving the deposition quality of the atom layer film.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

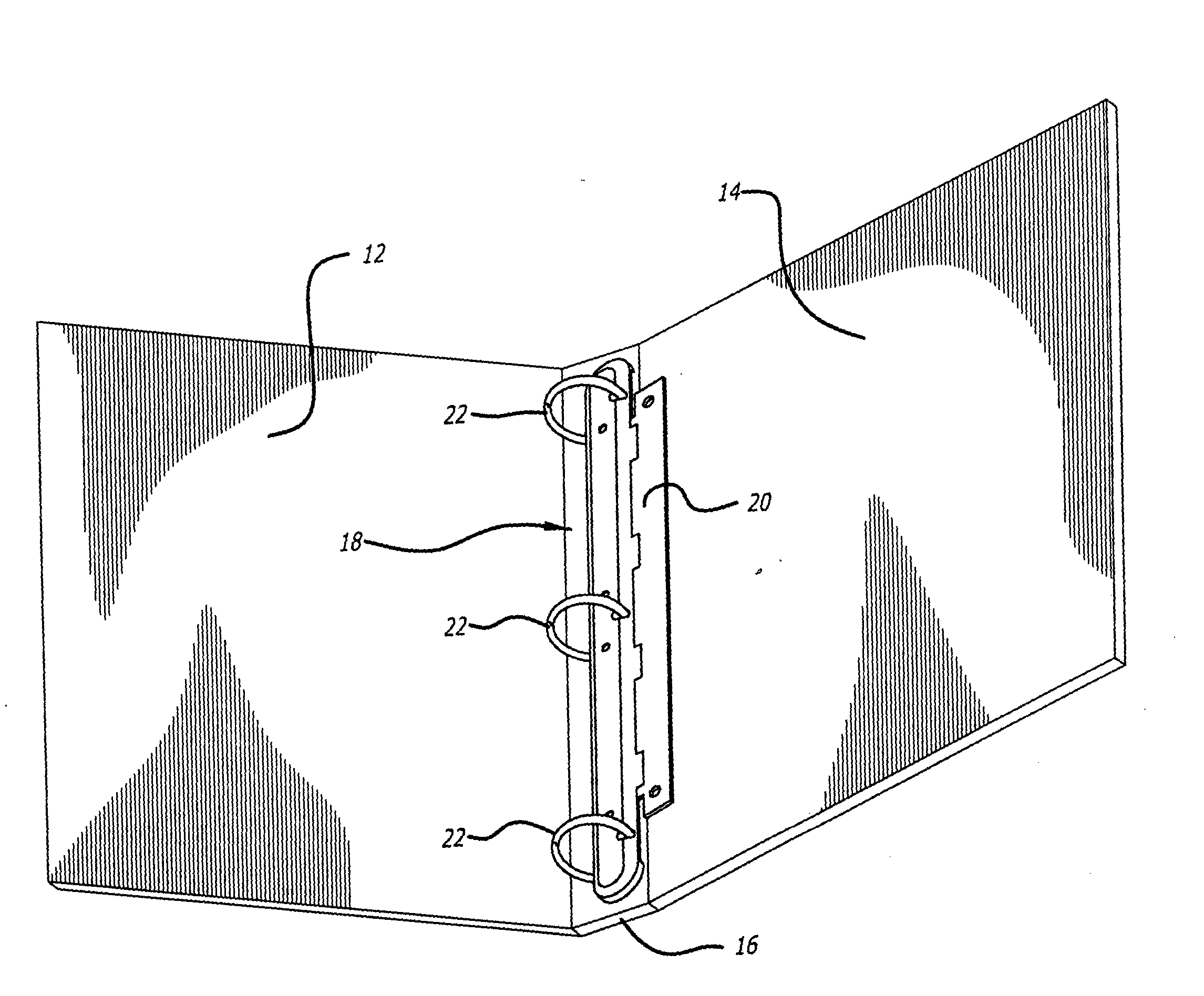

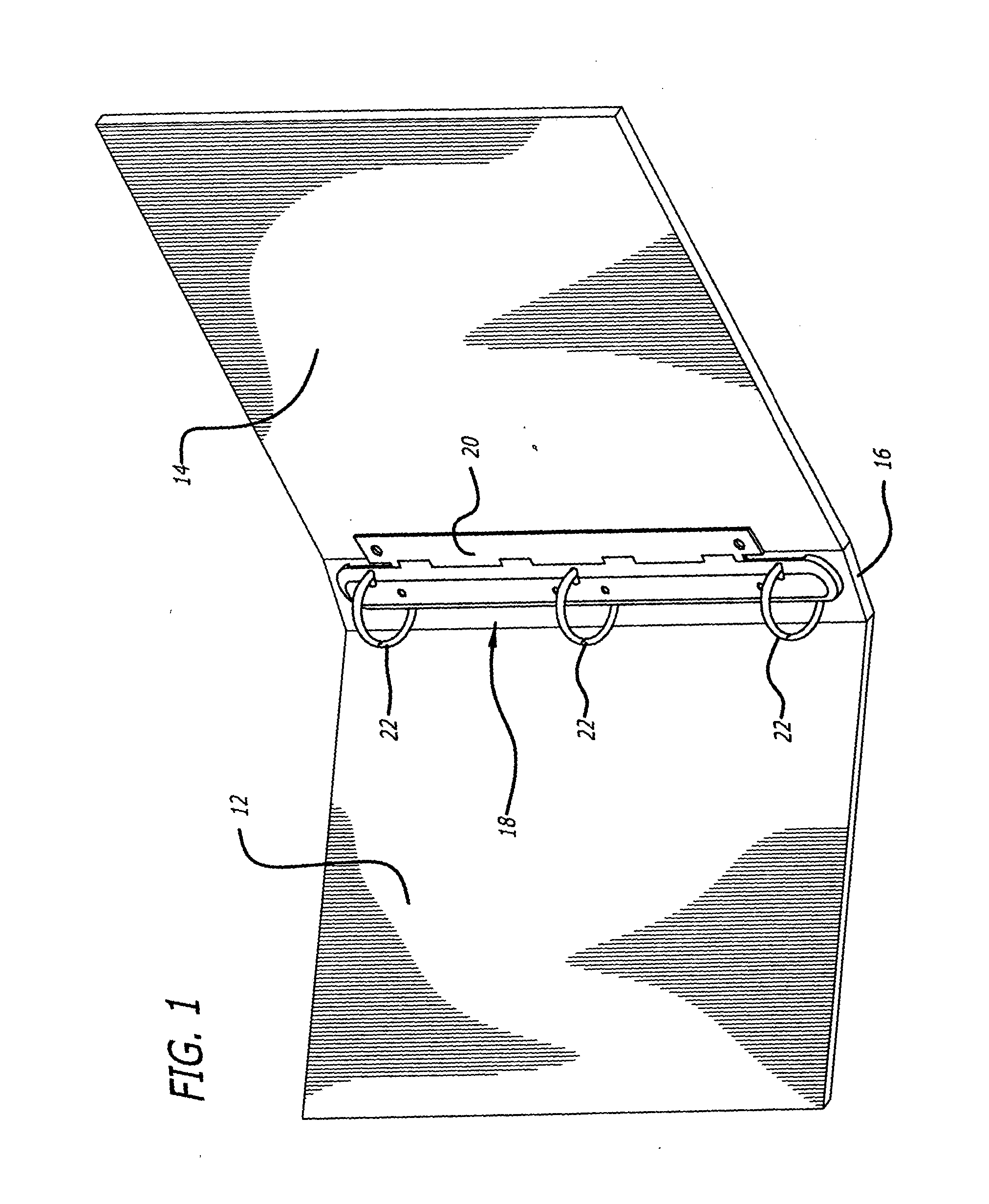

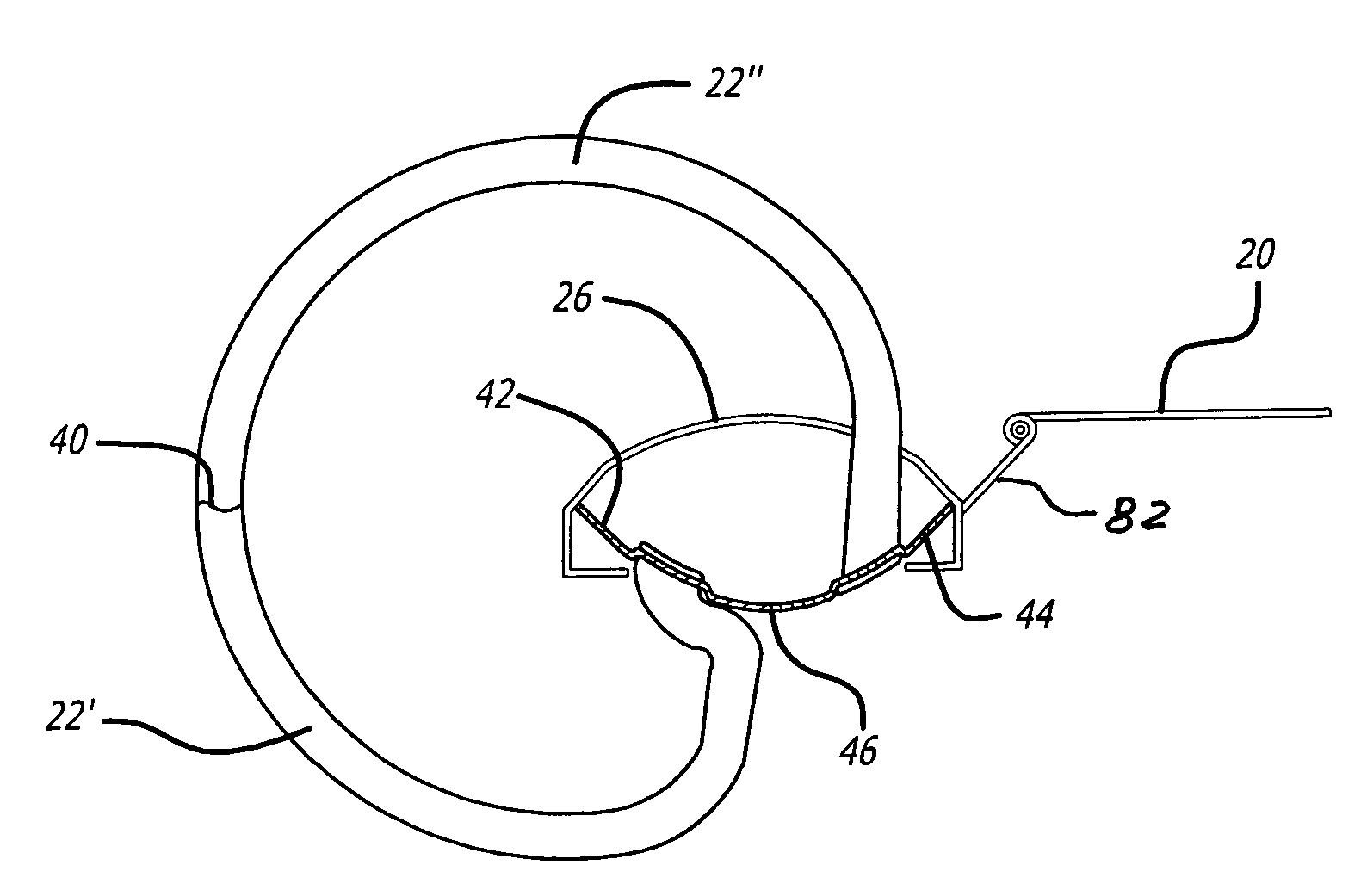

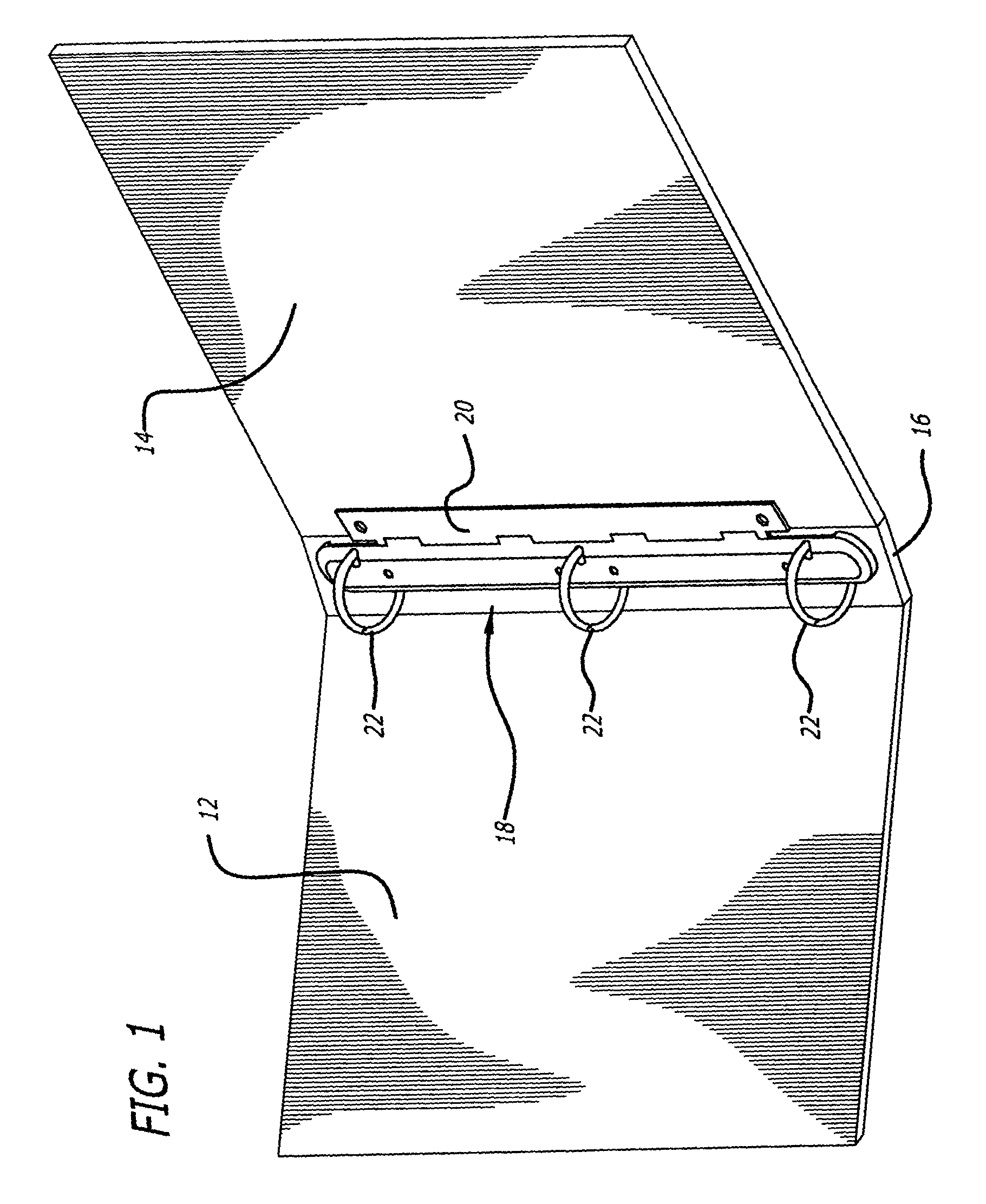

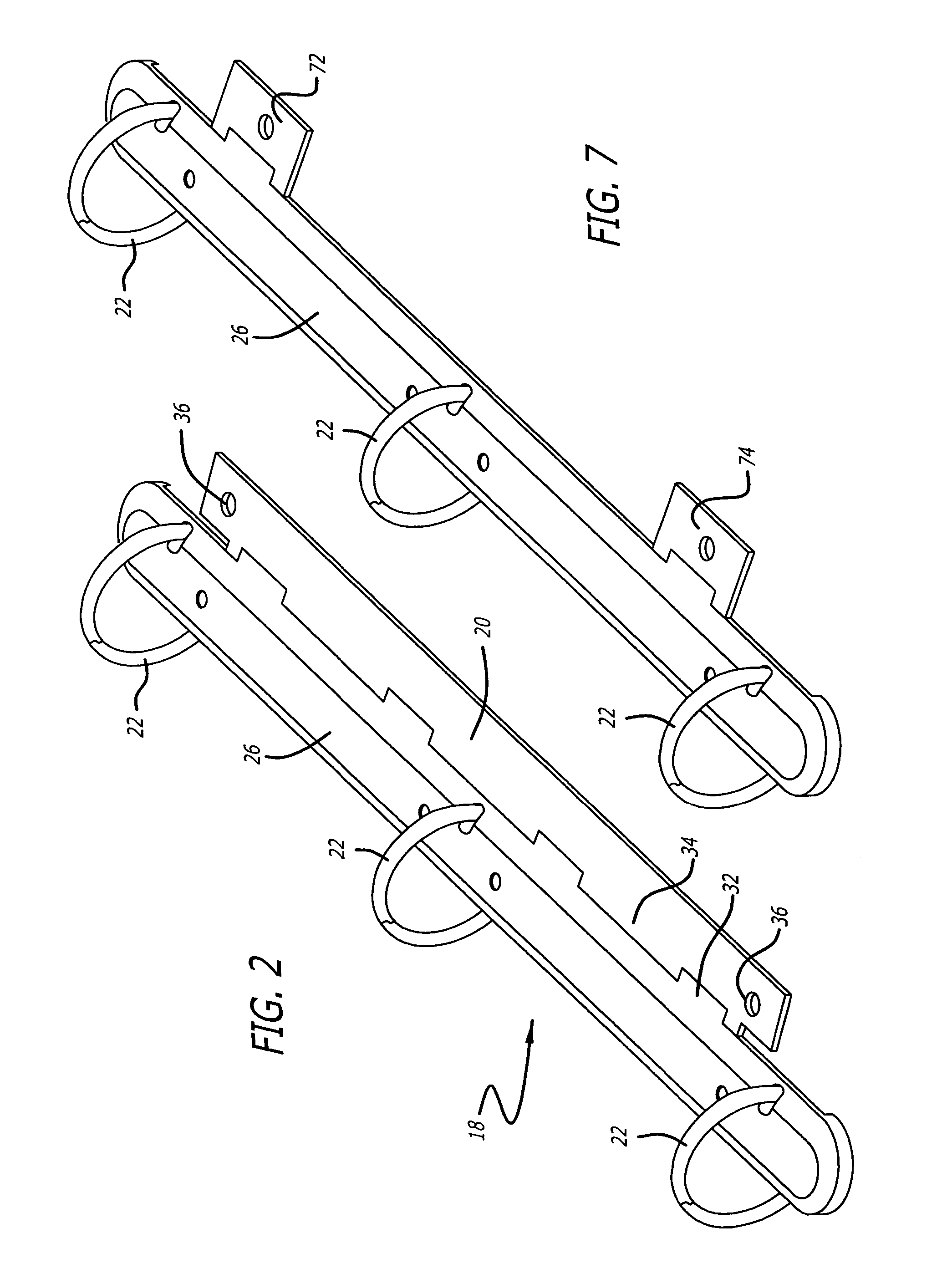

Wrap-around notebook

A wrap-around notebook or binder includes a ring assembly with a shield and a pair of frames forming a bistable construction, and a hinge plate pivotally coupled to the shield with the outer surface of the hinge plate aligned with the outer extent of the shield / frame assembly when the hinge plate is parallel to the plane of the shield. The exposed frame member may be convex, recessed to receive rivet heads, and may be plated. The hinge plate(s) may have curls which interfit with alternate curls from the shield to provide a hinge. The ring assembly may be mounted in the notebook or binder so that the shield side of the ring assembly faces the front cover of the binder. The pivot line between the shield and the hinge plate may be spaced from the shield by a clearance distance. The notebook or binder lies flat on an underlying surface with either the front cover of the rear cover folded under the assembly.

Owner:CCL LABEL INC

Wrap-around notebook

A wrap-around notebook or binder includes a ring assembly with a shield and a pair of frames forming a bistable construction, and a hinge plate pivotally coupled to the shield with the outer surface of the hinge plate aligned with the outer extent of the shield / frame assembly when the hinge plate is parallel to the plane of the shield. The exposed frame member may be convex, recessed to receive rivet heads, and may be plated. The hinge plate(s) may have curls which interfit with alternate curls from the shield to provide a hinge. The ring assembly may be mounted in the notebook or binder so that the shield side of the ring assembly faces the front cover of the binder. The pivot line between the shield and the hinge plate may be spaced from the shield by a clearance distance. The notebook or binder lies flat on an underlying surface with either the front cover of the rear cover folded under the assembly.

Owner:CCL LABEL INC

Method for preparing purple sand slime containing tourmaline iron sand

The invention provides a method for preparing purple sand slime containing tourmaline iron sand. Ore and raw tourmaline scattered in a soft clay ore bed are artificially selected, purple sand ore is stacked in the open air in winter and summer for natural weathering, the weathered raw ore is aired, dried, ground by means of a hard stone mill and smashed into 60-mesh fine powder, 80-mesh fine powder and 120-mesh fine powder, and after the tourmaline ore is smashed and ground and ore powder is screened out by a 140-mesh sieve, water is added, the materials are mixed, evenly stirred and sealed for ageing; vacuum pugging, clay strip pressing, sealing and ageing are repeated for 3-5 times, and the purple sand slime containing the tourmaline iron sand is prepared. The slime prepared through the method is original, pure, free of chemical raw materials and artificial pigment and not likely to crack when purple sand ceramic products are fired, and the manufactured purple sand ceramic products are natural, environmentally friendly, good in quality, natural in texture, fine and smooth in hand feeling, good in light transparency and water color and good in color generation. Meanwhile, the purple sand slime has the effects of improving water quality and promoting blood microcirculation.

Owner:宜兴市帛玉碧砂艺术品有限公司

Automotive radiator grille decorating electroplated bright strip assembling structure

ActiveCN103909880AGuaranteed appearanceSimple processing technologyRadiatorsEngineeringRejection rate

The invention belongs to the technical field of automobile accessories and provides an automotive radiator grille decorating electroplated bright strip assembling structure which comprises a bright strip body and a grille body. Multiple self-tapping screw mounting columns and two clamping claws are arranged on an inner-side mounting face of the bright strip body, locking pieces matched with the self-tapping screw mounting columns and inserting grooves matched with the clamping claws are arranged on the grille body respectively, each inserting groove is composed of an inserting portion and extending connection portions on two sides, the clamping claws and the bright strip body form a whole through the extending connection portions, inserting direction of each inserting portion is uniform with transverse direction of the corresponding inserting groove, and a thickening portion is arranged at a junction between each inserting portion and the corresponding extending connection portion and is of a non-sharp-angled structure. The automotive radiator grille decorating electroplated bright strip assembling structure has the advantages that under the premise that performance is guaranteed, appearance performance of an automotive radiator grille decorating strip is guaranteed, rejection rate of injection molding and electroplating processes is greatly reduced, die processing technique is improved, die service life is prolonged, and wind dryness after the automotive radiator grille decorating electroplated bright strip assembling structure is mounted on an automobile is prevented.

Owner:NINGBO XINTAI MACHINERY

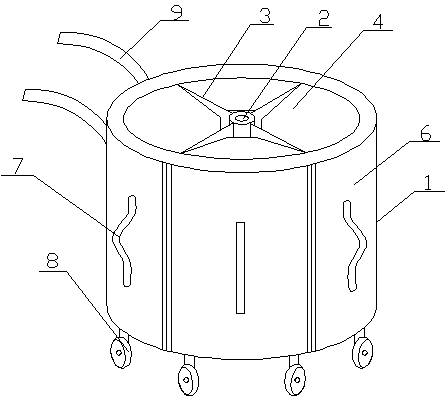

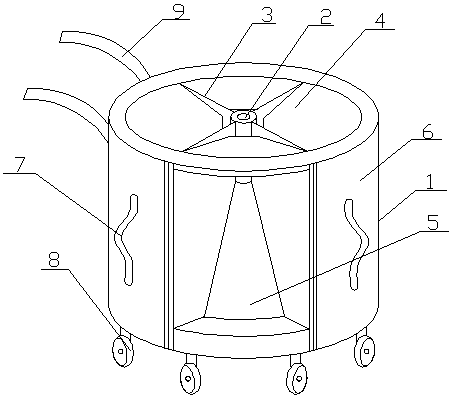

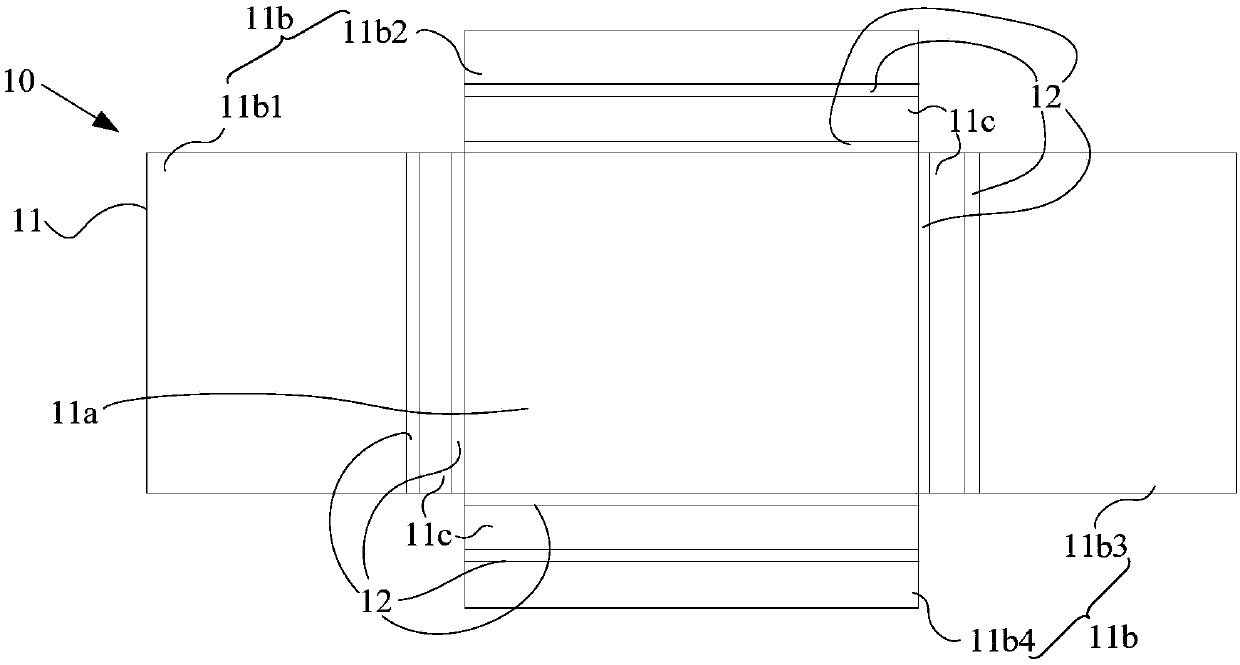

Book pre-sorting device

InactiveCN103433223ASimple structureIngenious ideaSortingHand carts with multiple axesEngineeringWorkload

A book pre-sorting device comprises a body and a central shaft arranged in the body, wherein the body can rotate freely around the central shaft; the body consists of a bottom plate and a side wall; a plurality of partitions are arranged between the central shaft and the side wall; a sorting plate inclined inwards is arranged between every two adjacent partitions; a notch is formed between the end part of each sorting plate and the central shaft; an inclined slide rail is arranged between each sorting plate and the bottom plate; a notch is formed at the top end, corresponding to a position between each sorting plate and the central shaft, of each slide rail; a movable door is arranged on the side wall, corresponding to each sorting plate, of the body; a handle is arranged on each movable door; sterilization and disinfection devices are arranged on inner wall surfaces of the movable doors; and a plurality of casters are arranged at the bottom of the body. The book pre-sorting device is simple in structure and convenient to use, greatly reduces the workload in a book organization process, improves the neat quality of books, and is suitable for popularization and application in various large libraries.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

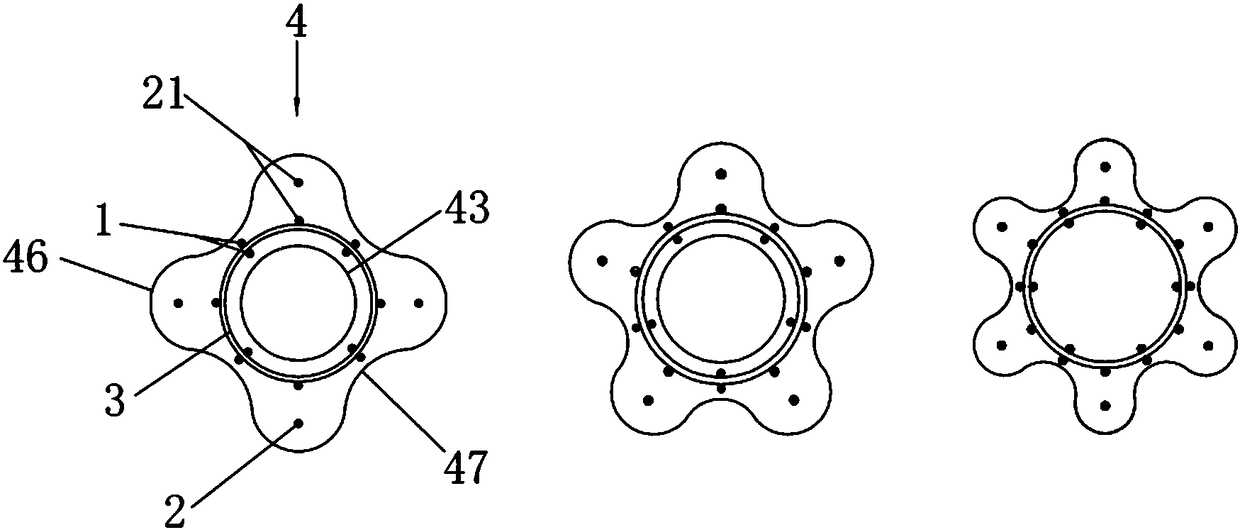

Quincunx concrete pipe pile

PendingCN108221963AImprove stress resistanceImprove tensile propertiesBulkheads/pilesVertical barSymmetry line

The invention provides a quincunx concrete pipe pile. The quincunx concrete pipe pile comprises a pile body and metal plates welded to the upper end and the lower end of the pile body. The pile body comprises a reinforcement cage and concrete filling the reinforcement cage. The cross section of the pile body comprises a hollow inner circle and a quincunx outline. The outline is composed of N convex arcs and N concave arcs at intervals, and the adjacent convex arcs and concave arcs are connected in a streamline mode. The reinforcement cage comprises N pairs of main bars and N reinforcing meshes, and further comprises a plurality of hoops, each pair of main bars are located on the symmetry line of the corresponding concave arcs, each reinforcing mesh is located on the symmetry line of the corresponding convex arcs, the multiple hoops are arranged up and down and are parallel, each hoop is welded and fixed to the N pairs of main bars and the N reinforcing meshes, each reinforcing mesh comprises two vertical bars and a plurality of short bars located between the two vertical bars and used for connecting the two vertical bars, the two vertical bars of each reinforcing mesh are located on the symmetry line of the corresponding convex arcs, are parallel to the main bars, penetrate through the concrete on the pile body in the up and down direction together with the main bars and are welded to a metal plate, and N is a natural number bigger than 3.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

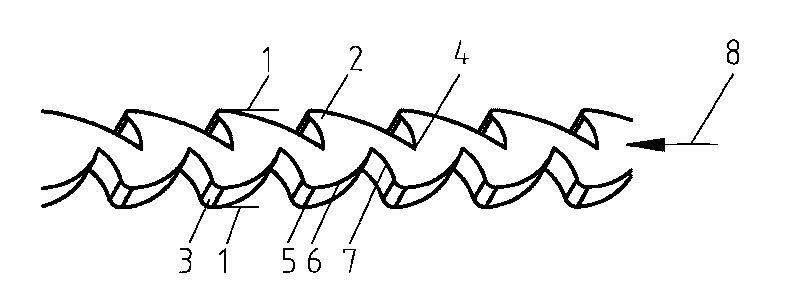

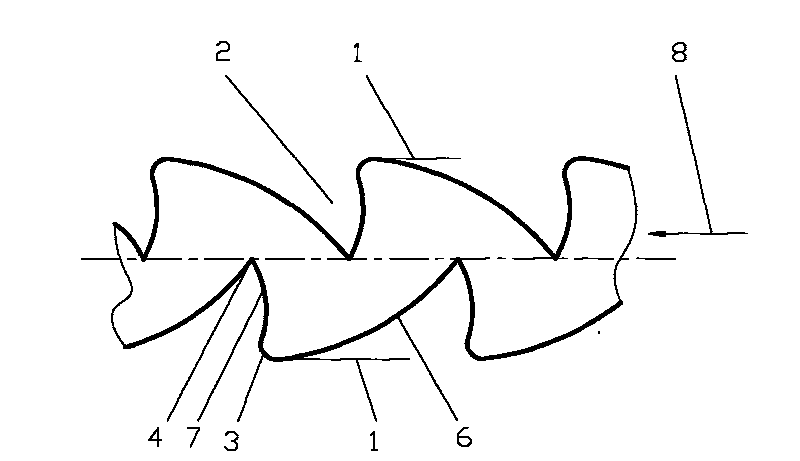

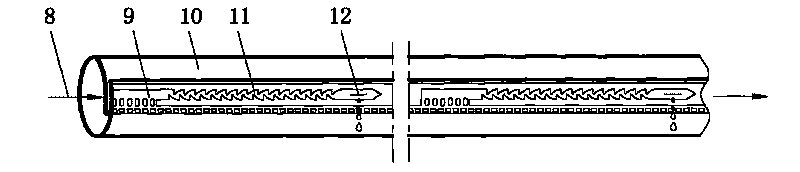

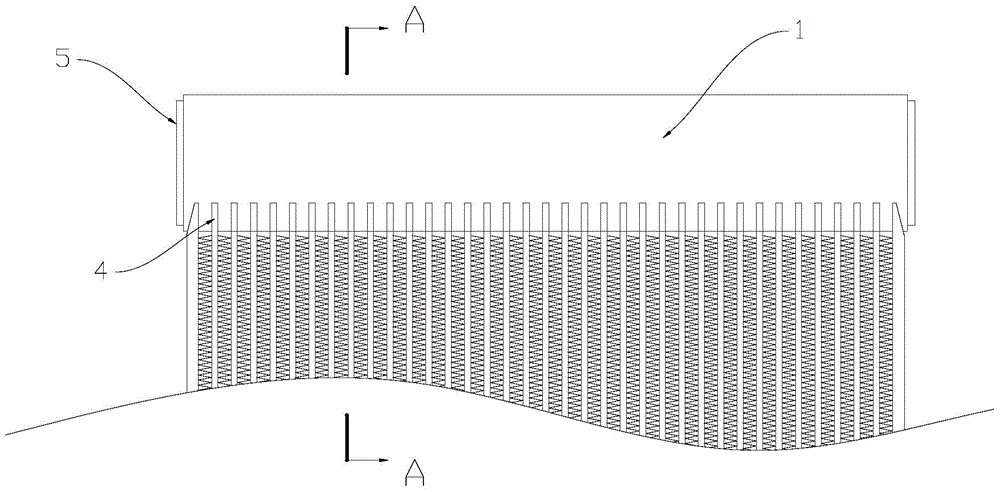

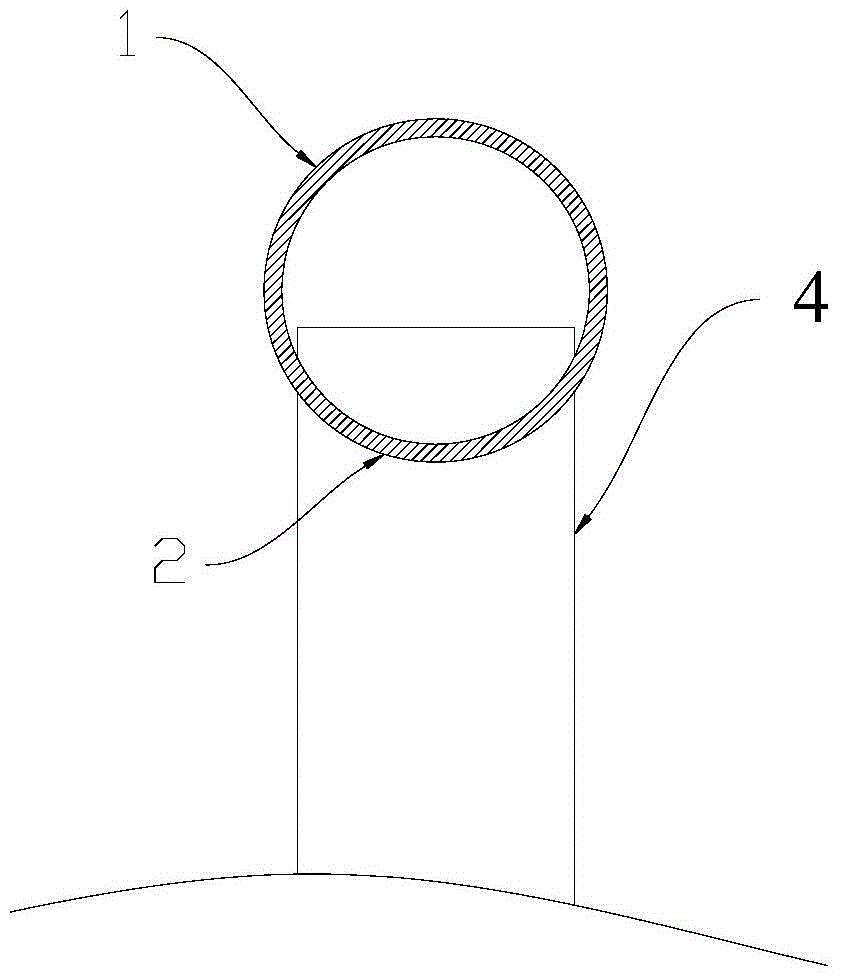

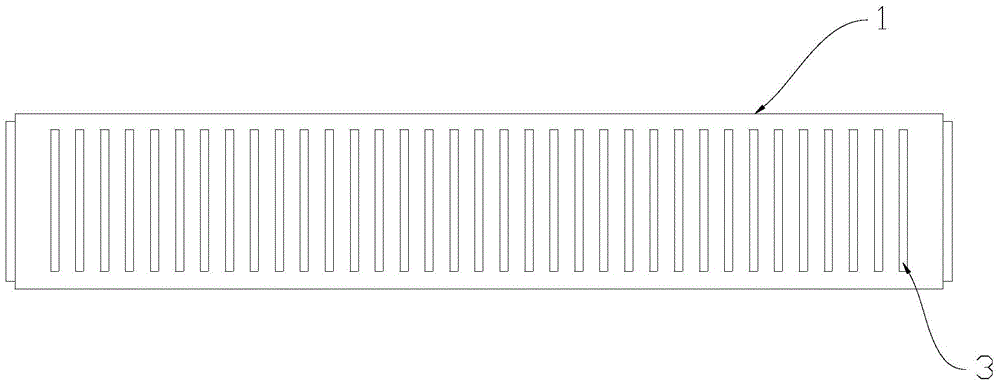

Fishbone drop irrigation douche runner

ActiveCN101712016AImprove hydraulic performanceImprove anti-clogging performanceSpray nozzlesWater flowEngineering

The invention provides a fishbone drop irrigation douche runner, and an upper and lower boundary (1) and a runner depth (5) form a groove-shaped runner; the invention is characterized in that the upper and lower boundary (1) is formed by connection of more than two tooth-shaped angles (2) in sequence; the tooth-shaped angles (2); the tooth-shaped angles (2) of the upper boundary and the lower boundary are in staggered arrangement; the tooth-shaped angle (2) is formed by two circular arcs with different sizes, wherein, the circle center of a bigger circular arc (6) and the bigger circular arc (6) are positioned at the different sides of the central surface of the length direction of the runner; and the circle center of a smaller circular arc (7) and the small circular arc (7) are arranged at the same side of the central surface of the length direction of the runner. The fishbone drop irrigation douche runner of the invention is in a tooth-shaped angle runner structure which is formed by the circular arcs. The structure can lead the water in the runner to generate the function of stronger turbulent flow under a certain pressure; on one hand, the hydraulic performance of the douche can be improved, and the blockage resisting capacity of the douche is enhanced on the other hand.

Owner:HOHAI UNIV

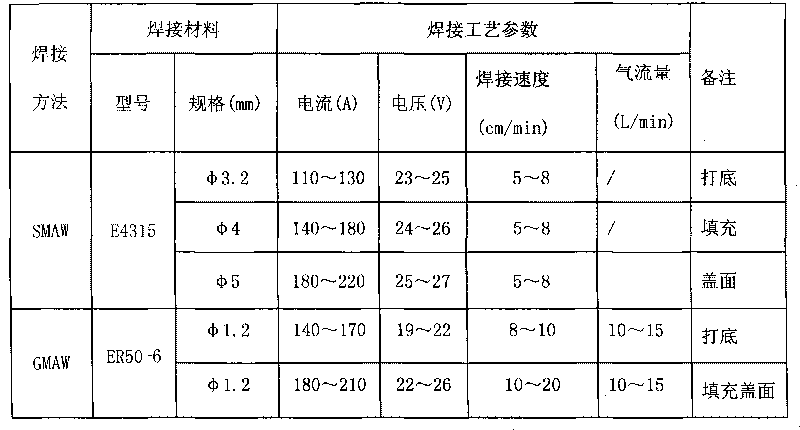

Butt welding construction method of large diameter underground pipelines

InactiveCN101722374ASuitable for welding requirementsAvoid sharp cornersArc welding apparatusWorkpiece edge portionsSteel tubeMiddle line

The invention relates to a pipeline welding technology, in particular to the welding of large diameter pipelines. The invention discloses a butt welding construction method of large diameter underground pipelines, which comprises a plurality of steel pipes to be butted which are buried below the surface, and comprises the following steps of: beveling, assembling and cleaning the butt connector of a steel pipe, welding, and cleaning and detecting, wherein the bevel adopts a V-shaped bevel; the steel pipe is divided into an upper part and a lower part which are symmetrical with each other from a horizontal midline, the bevel of the upper part faces outwards, and the bevel of the lower part faces inwards; for the upper part of the pipeline, a constructor welds the top of the pipeline, and welds the inner part of the pipeline for the lower part of the pipeline; the bevel is cleaned after welding, and appearance and non-destructive inspections are performed. The method not only can improve the butt welding operating efficiency, but also is in favor of ensuring the construction quality and reducing the construction cost.

Owner:SHANGHAI BAOYE GRP CORP

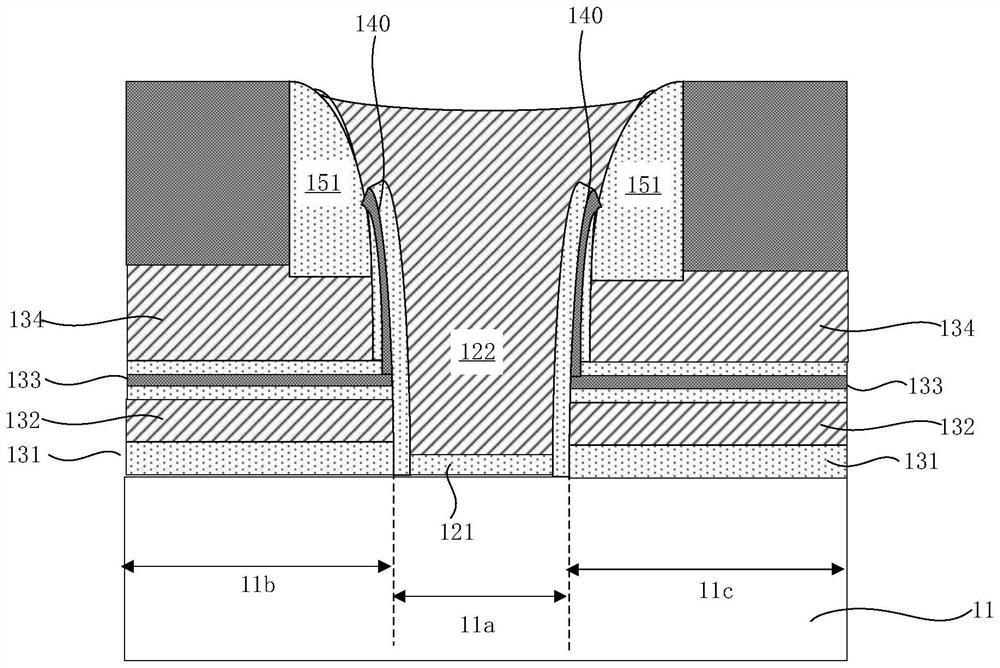

NORD flash memory and manufacturing method thereof

ActiveCN111696991AImprove surface structureAvoid squeezingSolid-state devicesSemiconductor devicesIntegrated circuit manufacturingEtching

The invention relates to the field of semiconductor integrated circuit manufacturing, in particular to an NORD flash memory and a manufacturing method thereof. The manufacturing method of the NORD flash memory at least comprises the following steps that a semiconductor device provided with a word line structure and a control gate structure is provided, the word line structure comprises word line polycrystalline silicon, and the control gate structure is located atthe two sides of the word line polycrystalline silicon; maskless etching is carried out on the upper surface of the semiconductor device, and etching is carried out to remove the upper layer of the word line polycrystalline silicon; the upper surface of the word line polycrystalline silicon is oxidized to form a protective oxide layer; a silicon nitride layer isdeposited and formed on the protective oxide layer; under the protection of the silicon nitride layer and the protective oxide layer, the control gate structure is etched to form NORD flash memory cells; and an isolation trench structure is manufactured and formedbetween the adjacent NORD flash memory cells. According to the NORD flash memory and the manufacturing method thereof, the problem that the uniformity of theprotective oxide layer is difficult to guarantee in related technologies can be solved.

Owner:HUA HONG SEMICON WUXI LTD

Manufacturing method of shield gate MOSFET device with up-down structure

PendingCN114038751AReduce capacitanceReduce manufacturing costSemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETPhysical chemistry

The invention discloses a manufacturing method of a shield gate MOSFET with an up-down structure. The manufacturing method comprises the following steps of: performing groove etching on a selected epitaxial silicon substrate; preparing a field oxide layer in a thermal oxidation or thermal oxidation and oxide layer deposition mode; after the shield gate polycrystalline silicon is filled, carrying out first back etching to the silicon surface; depositing a silicon nitride hard mask layer, then photoetching and etching an active region, and leaving an active region window in the silicon nitride layer; performing field oxide layer wet etching in the active region window, and carrying out second shield gate polycrystalline silicon back etching, wherein the surface of the shield gate polycrystalline silicon is 0.1 micrometer lower than the surface of the field oxide layer in the groove after the second shield gate polycrystalline silicon back etching is carried out; removing the oxide layer on the silicon surface and a part of field oxide layer in the groove by wet etching, so that the height difference between the shield gate and the field oxide layer in the groove is within 0.2 micron; simultaneously oxidizing the side walls of the groove and the shield gate to form a gate oxide layer and an inter-gate oxide layer; and filling and back-etching the gate polycrystalline silicon to form a control gate.

Owner:SHANGHAI DAOZHI TECH CO LTD

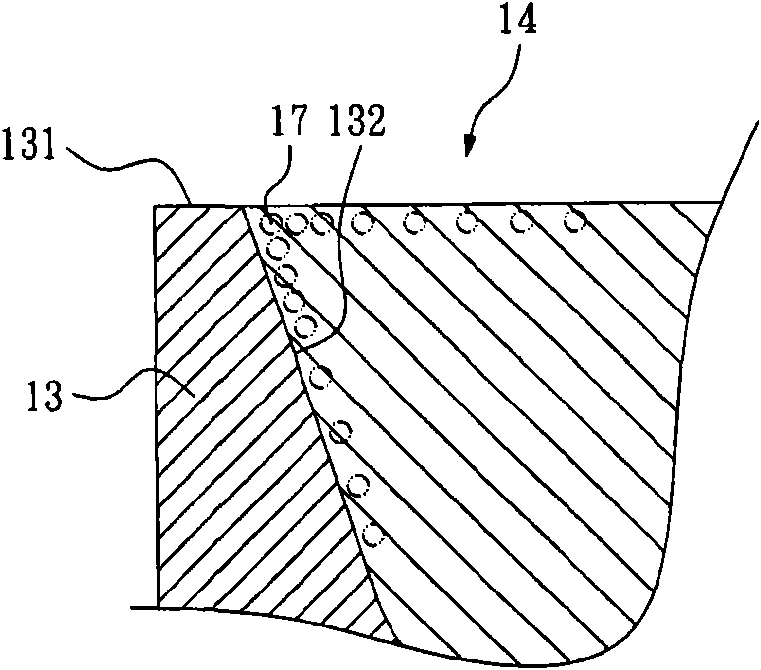

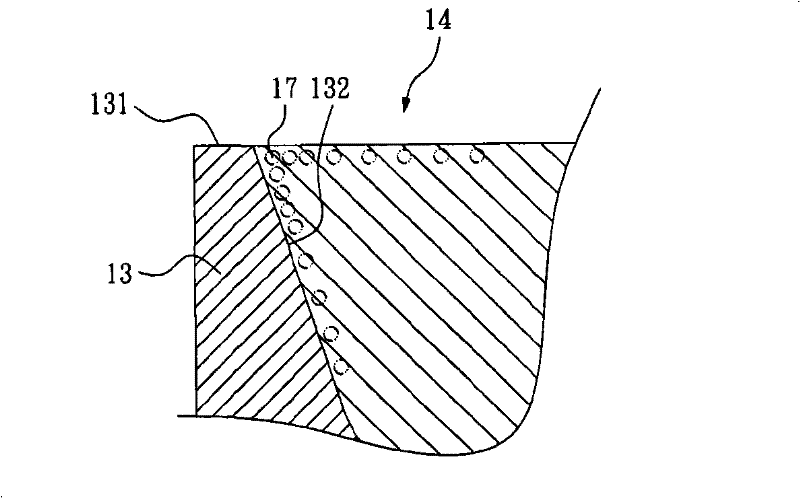

Embedded substrate provided with side-inclined plane line layer assembly and manufacturing method thereof

ActiveCN101888738AAvoid sharp cornersLoss of strengthElectrical connection printed elementsPrinted element electric connection formationEngineeringCopper

The invention relates to an embedded substrate provided with side-inclined plane line layer assembly and a manufacturing method thereof. The embedded substrate comprises a dielectric layer and a line layer assembly. The dielectric layer is provided with an upper surface and a containing slot. The line layer assembly is arranged in the containing slot. The line layer assembly is provided with an upper surface, a chemical copper layer, an electroplated copper layer and a side-inclined plane. The upper surface is higher or lower the upper surface of the dielectric layer. The chemical copper layer is provided with palladium (Pd). The electroplated copper layer is arranged on the chemical copper layer. The side-inclined layer is arranged closed to the hole wall of the containing slot on the upper surface of the line layer assembly and is extended downward to the hole wall of the containing slot from the upper surface of the line layer assembly. Thus, the side-inclined plane of the line layer assembly can avoid that electrons are aggregated on the point angle of the line layer assembly in the prior art.

Owner:ADVANCED SEMICON ENG INC

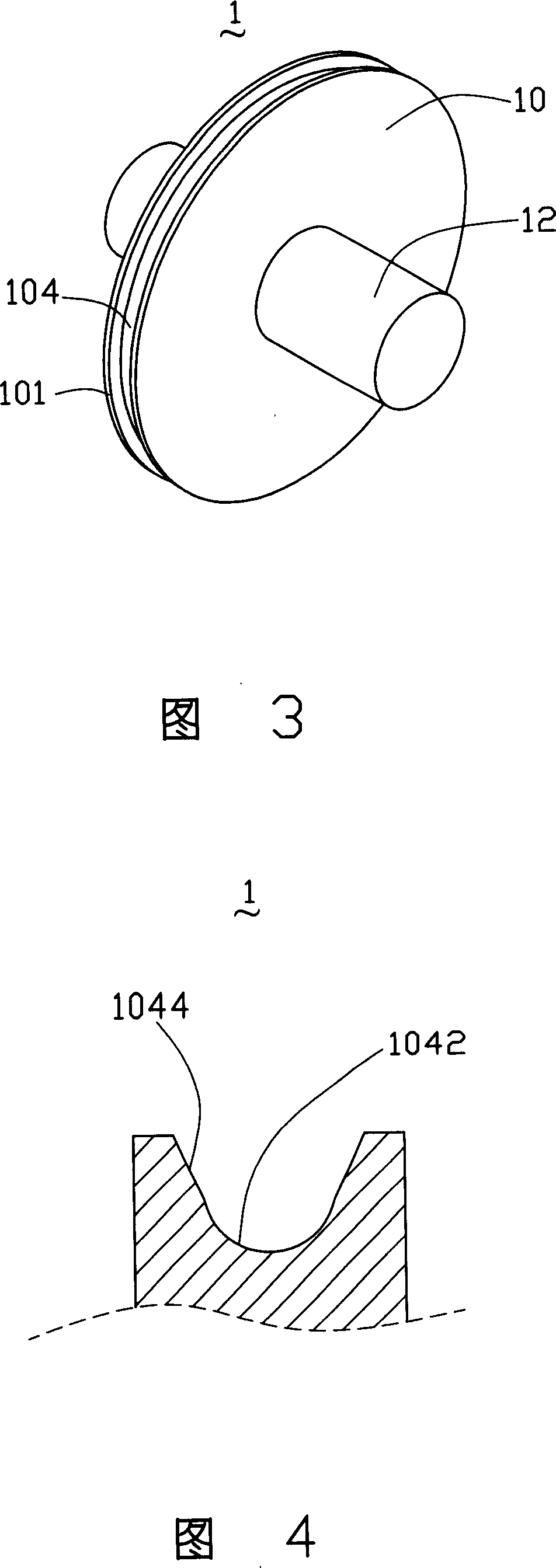

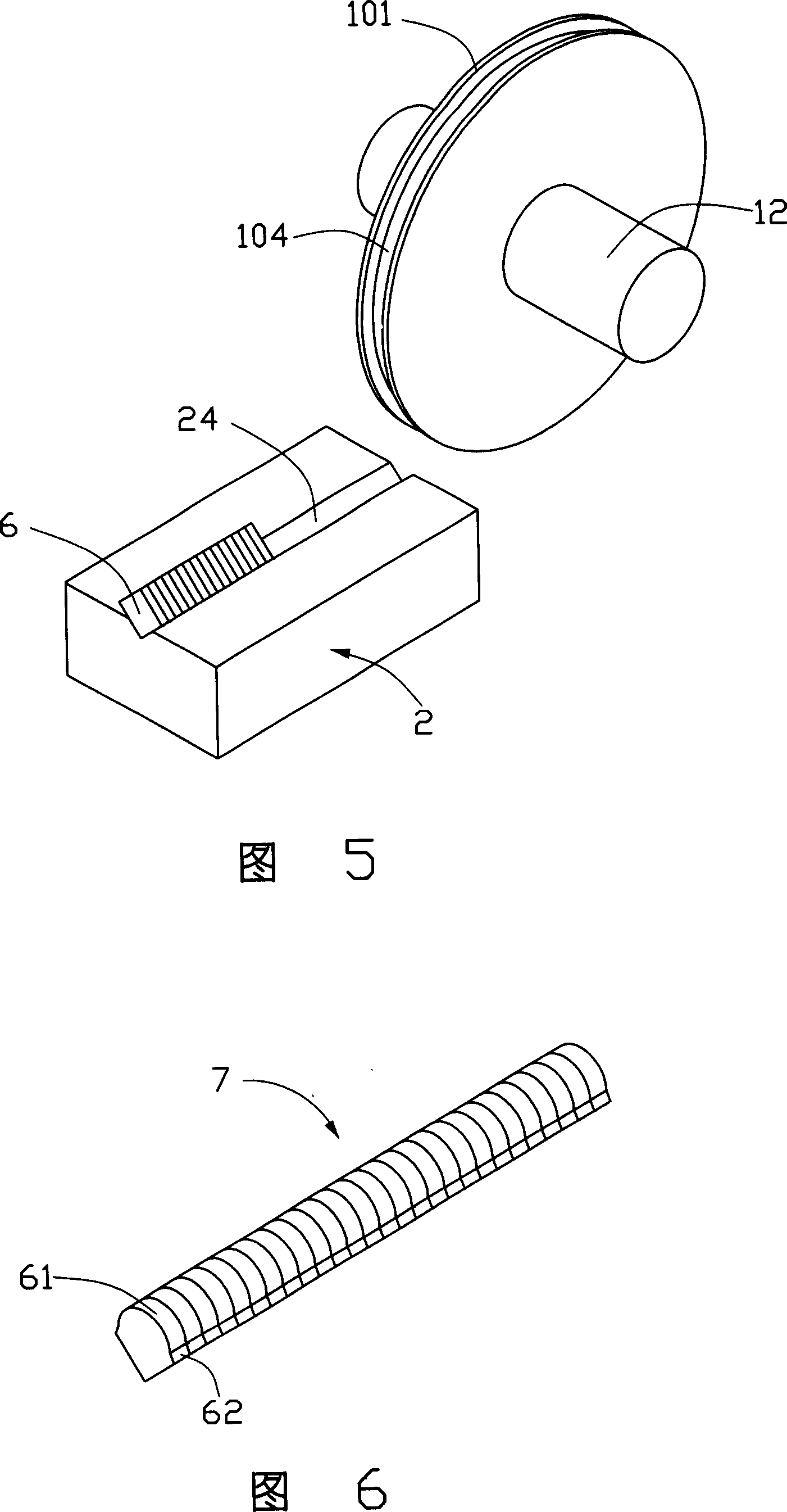

Grinding wheel, rounding device of using the grinding wheel, and rounding method

InactiveCN101003123AAvoid sharp cornersAvoid crackingOptical surface grinding machinesLensEngineeringGrinding wheel

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Preparation method of Zisha mineral yellow gold clay

The invention relates to a preparation method of Zisha mineral yellow gold clay. Mineral yellow raw ore scattered on a tender clay ore seam is selected manually, and stacked in the open air for natural weathering in winter and summer; the weathered raw ore is dried in the air and milled by a hard stone mill into 60-mesh and 80-mesh powder and 120-mesh fine powder, water is added, and sealing and aging are performed after uniform mixing and stirring; vacuum clay refining, clay strip pressing, sealing and aging are performed repeatedly 3-6 times, and the Zisha mineral yellow gold clay is prepared. The clay prepared with the method is original and pure without any chemical raw materials or artificial pigments, and is not easy to crack when a Zisha earthenware product is fired; the prepared Zisha earthenware product not only is natural and environmentally friendly, but also has excellent quality, natural texture, delicate handfeel and good light transmittance, water color and color appearance; the purpose of changing waste materials of Zisha ore into valuable materials is also achieved.

Owner:宜兴市天恩陶舍紫砂文化有限公司

Fluororubber and preparation method thereof

The invention relates to the field of rubber, in particular to fluororubber which comprises the following components by mass: 100 parts of fluororubber 2602, 3 parts of an acid-acceptor, 10 parts of spraying carbon black, 2 parts of a vulcanizing machine, 1 part of a vulcanizing agent, 2.5 parts of a release agent and 2 parts of STR anti-tear resin. According to the fluororubber and a preparation method thereof, the acid-acceptor is added in the formula to remove acidic materials inside all raw materials, and besides, the STR anti-tear resin is added to improve the anti-tear capability of the fluororubber; in the preparation process of the fluororubber, secondary vulcanizing is adopted to improve the mechanical property and the compression set of the fluororubber.

Owner:TONGXIANG SPRING RUBBER & PLASTICS TECH

Embedded substrate provided with side-inclined plane line layer assembly and manufacturing method thereof

ActiveCN101888738BAvoid sharp cornersLoss of strengthElectrical connection printed elementsPrinted element electric connection formationEngineeringCopper

The invention relates to an embedded substrate provided with side-inclined plane line layer assembly and a manufacturing method thereof. The embedded substrate comprises a dielectric layer and a line layer assembly. The dielectric layer is provided with an upper surface and a containing slot. The line layer assembly is arranged in the containing slot. The line layer assembly is provided with an upper surface, a chemical copper layer, an electroplated copper layer and a side-inclined plane. The upper surface is higher or lower the upper surface of the dielectric layer. The chemical copper layer is provided with palladium (Pd). The electroplated copper layer is arranged on the chemical copper layer. The side-inclined layer is arranged closed to the hole wall of the containing slot on the upper surface of the line layer assembly and is extended downward to the hole wall of the containing slot from the upper surface of the line layer assembly. Thus, the side-inclined plane of the line layer assembly can avoid that electrons are aggregated on the point angle of the line layer assembly in the prior art.

Owner:ADVANCED SEMICON ENG INC

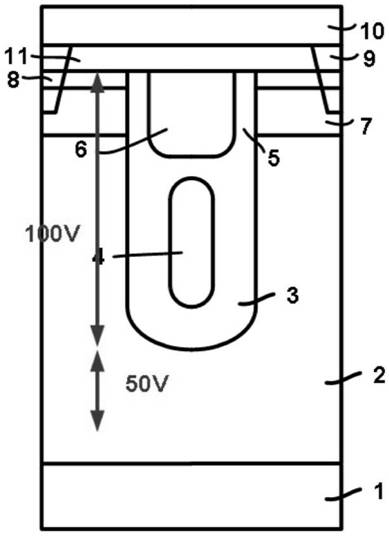

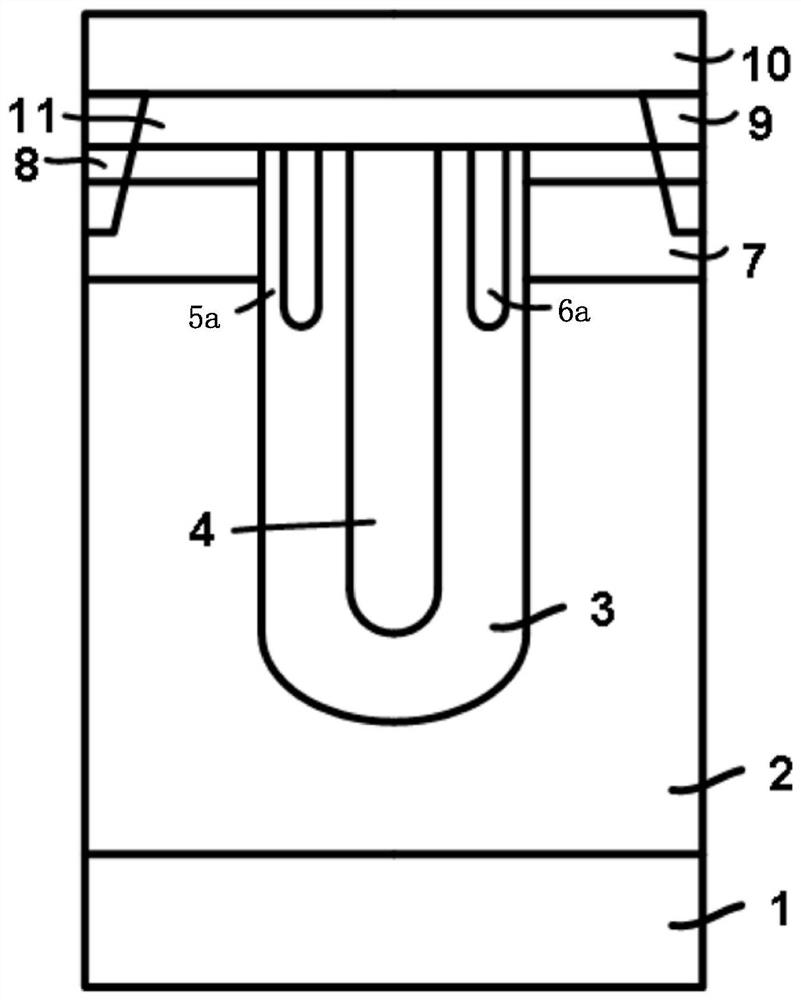

SGTMOSFET device and manufacturing method

PendingCN112864248AMeet pressure requirementsReduce widthSemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceEngineering physics

Dsiclosed is an SGTMOSFET device and a manufacturing method. A bottom oxide layer and source polycrystalline silicon of a grid structure are located at the bottom of a grid groove, the thickness of the bottom oxide layer meets the requirement for voltage resistance of 150V or above, the top of the grid groove is filled with a top oxide layer completely formed through CVD deposition, a polycrystalline silicon grid is formed in a top sub-groove formed by etching the top oxide layer, the width of the top sub-groove meets the requirement for filling the polycrystalline silicon grid, and when the depths of the two side faces of the top sub-groove are the same, the depths of the two side faces of the polycrystalline silicon grid are the same. The invention further provides a manufacturing method of an SGTMOSFET device. According to the invention, under the condition of ensuring that the bottom oxide layer realizes the withstand voltage of more than 150V, the polycrystalline silicon grid with a left-right structure is adopted, so that the width of the polycrystalline silicon grid can realize good and low-difficulty filling of the polycrystalline silicon grid, and the depths of the two side surfaces of the polycrystalline silicon grid can be ensured to be consistent; therefore, the increase of input capacitance can be avoided and the reliability of the device can be improved under the condition of meeting the coverage length of a channel region.

Owner:NANTONG SANRISE INTEGRATED CIRCUIT CO LTD

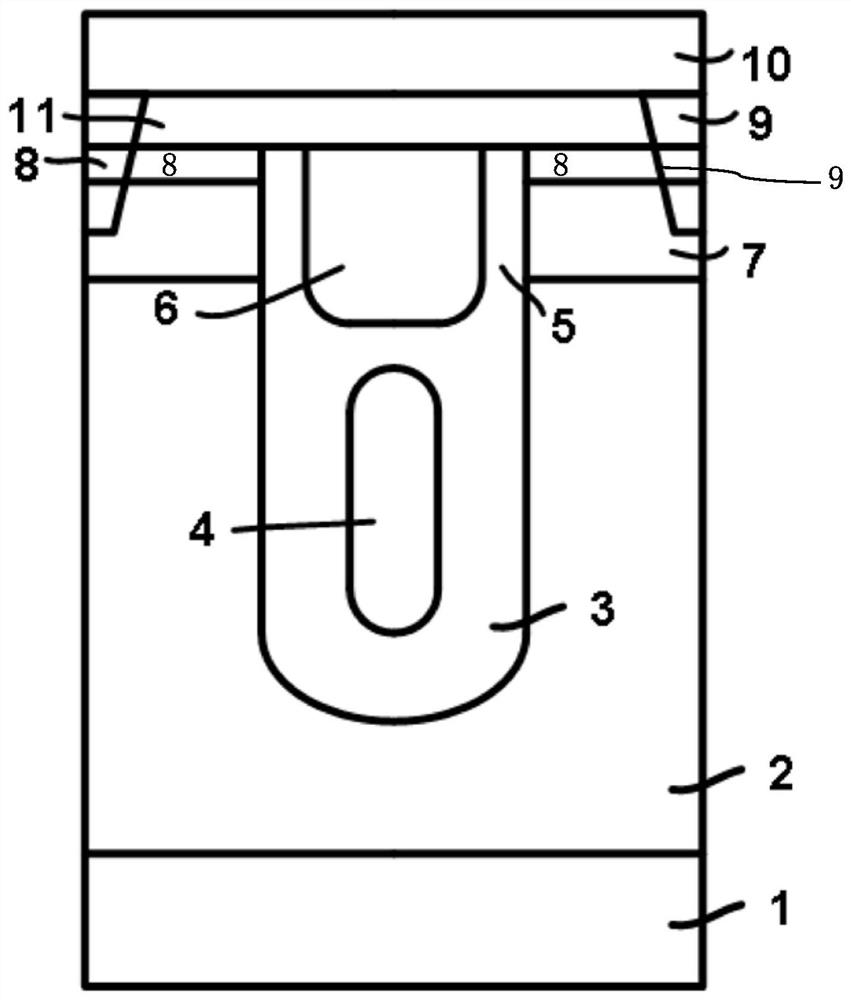

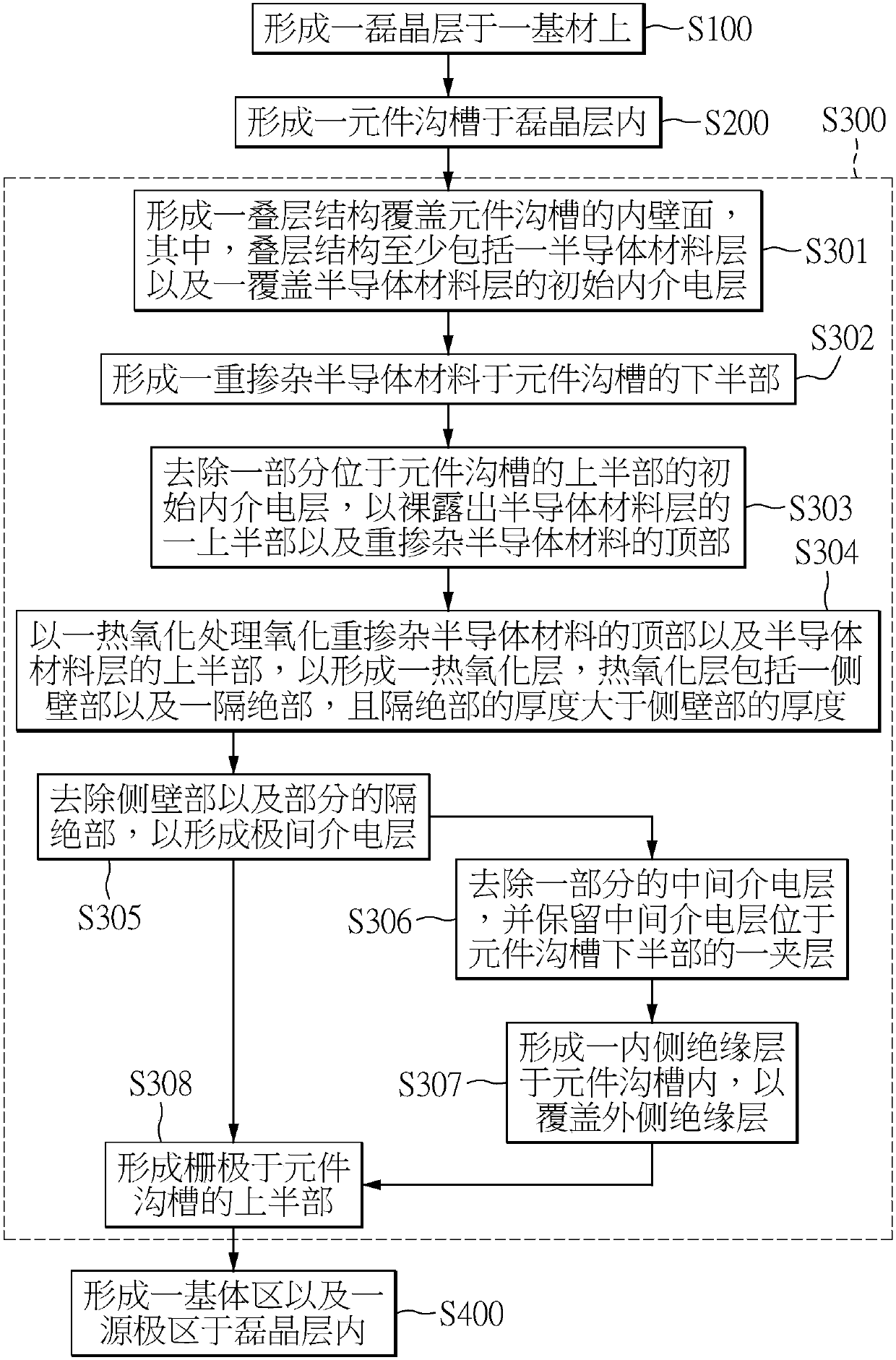

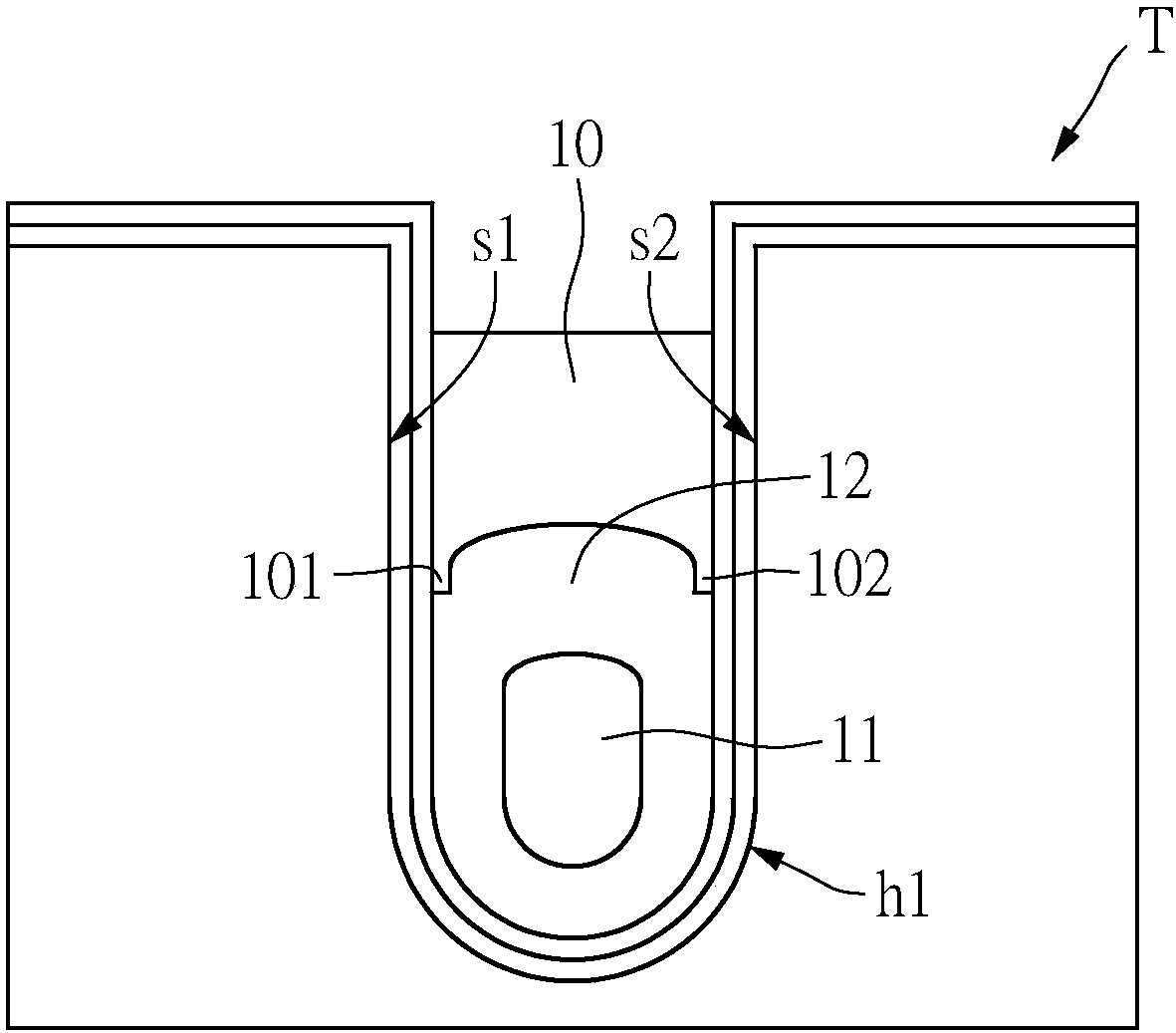

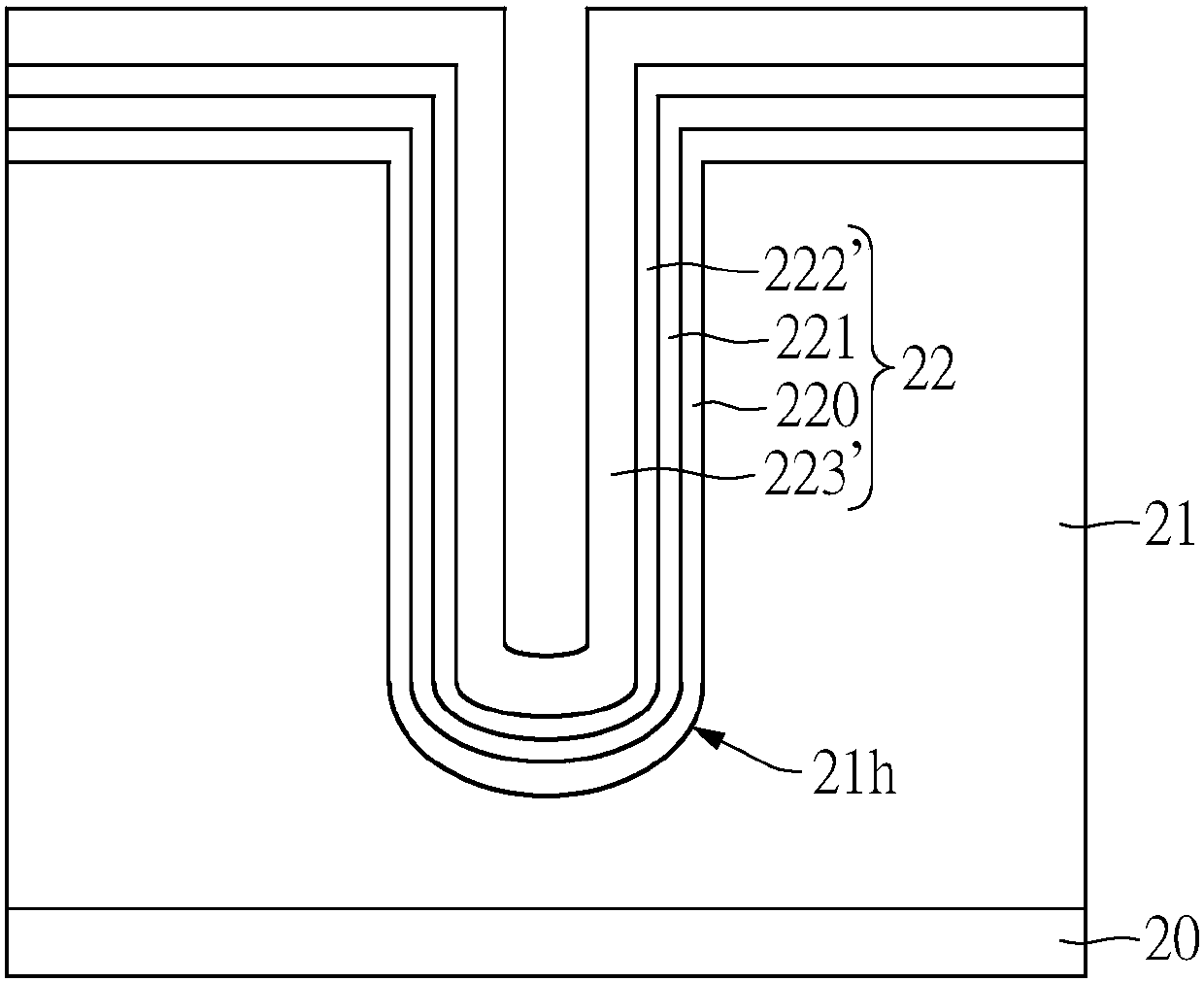

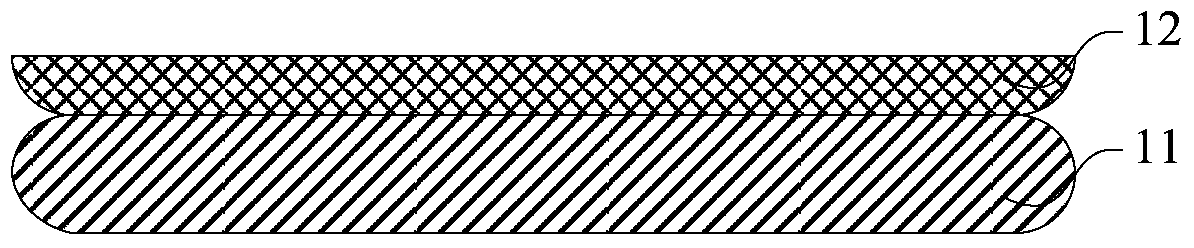

Trench type power semiconductor element and manufacturing method thereof

ActiveCN109585547AHigh gate withstand voltageImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorSemiconductor materials

The invention discloses a trench type power semiconductor element and a manufacturing method thereof. The trench gate structure of the trench type power semiconductor element comprises a shielding electrode, a grid electrode located above the shielding electrode, and an inter-electrode dielectric layer located between the shielding electrode and the grid electrode. Before forming the inter-electrode dielectric layer, the step of forming the trench gate structure at least comprises the step that a laminated structure is formed to cover the inner wall surface of the element trench, wherein the laminated structure at least comprises a semiconductor material layer and an initial inner dielectric layer for covering the semiconductor material layer; a heavily-doped semiconductor material is formed at the lower half part of the element trench; and a part of the initial inner dielectric layer on the upper half part of the element trench is removed, so as to expose the upper half part of the semiconductor material layer and the top of the heavily-doped semiconductor material. Therefore, the bottom of the grid electrode formed in the subsequent manufacturing process can be prevented from having a sharp angle.

Owner:SUPER GROUP SEMICON

A method for thinning bonded wafers

ActiveCN104733300BAvoid sharp cornersPrevent ruptureSemiconductor/solid-state device manufacturingWafer thinningGrinding wheel

The invention provides a bonded wafer thinning method. Before a device wafer is thinned, the edge of the wafer is ground first through a grinding wheel to remove the arc-shaped edge. According to the method, the bonded wafer is treated through the grinding wheel before the thinning process starts, and the arc-shaped edge of the device wafer is ground off, so the situation that sharp corners are formed on the bonded wafer in the thinning process is effectively avoided, the phenomenon of edge fractures of the device wafer is eradicated, the wafer can be thinned to less than 50 microns on the premise of guaranteeing that the edge of the device wafer does not fracture so as to meet the requirements of the follow-up preparation technology, and the performance of a semiconductor device manufactured later can be guaranteed. Compared with an existing thinning technology, the method has the advantages that no pollution will happen to a thinning machine platform and the follow-up technology, equipment adopted in the method is simple and easy to operate and concise in process, the production efficiency is greatly improved, and the production cost and equipment cost are lowered.

Owner:SEMICON MFG INT (SHANGHAI) CORP

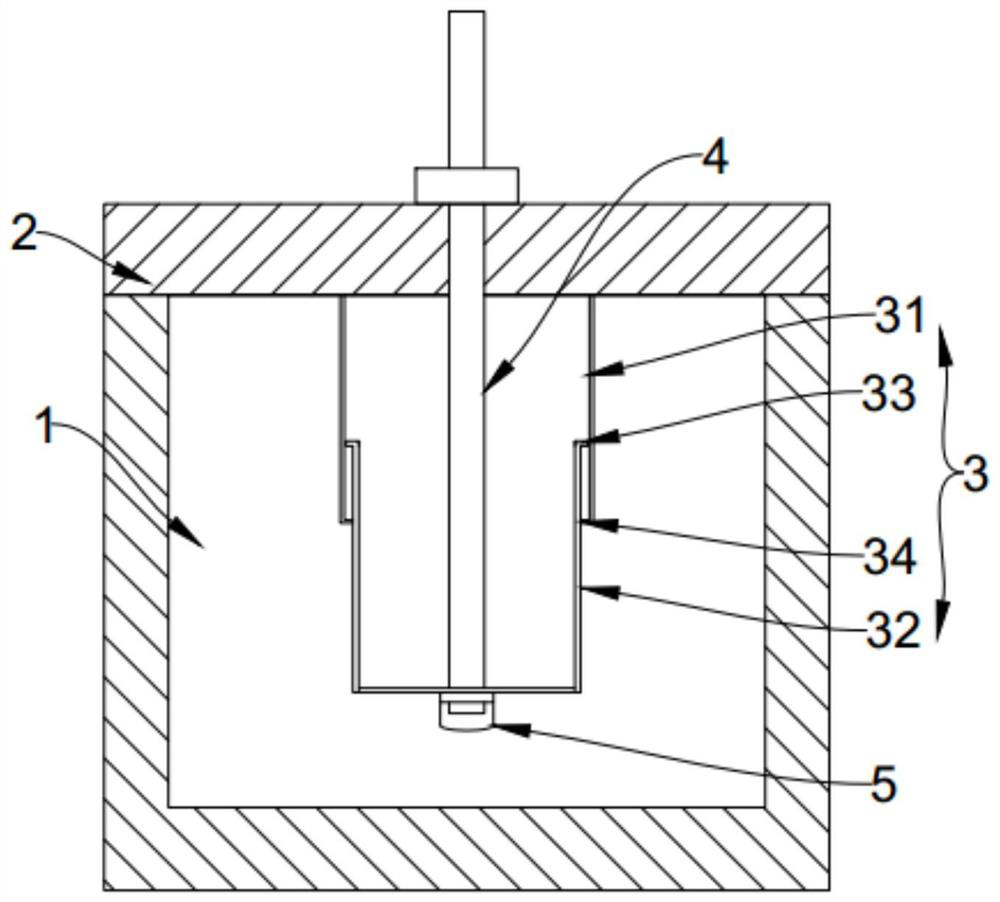

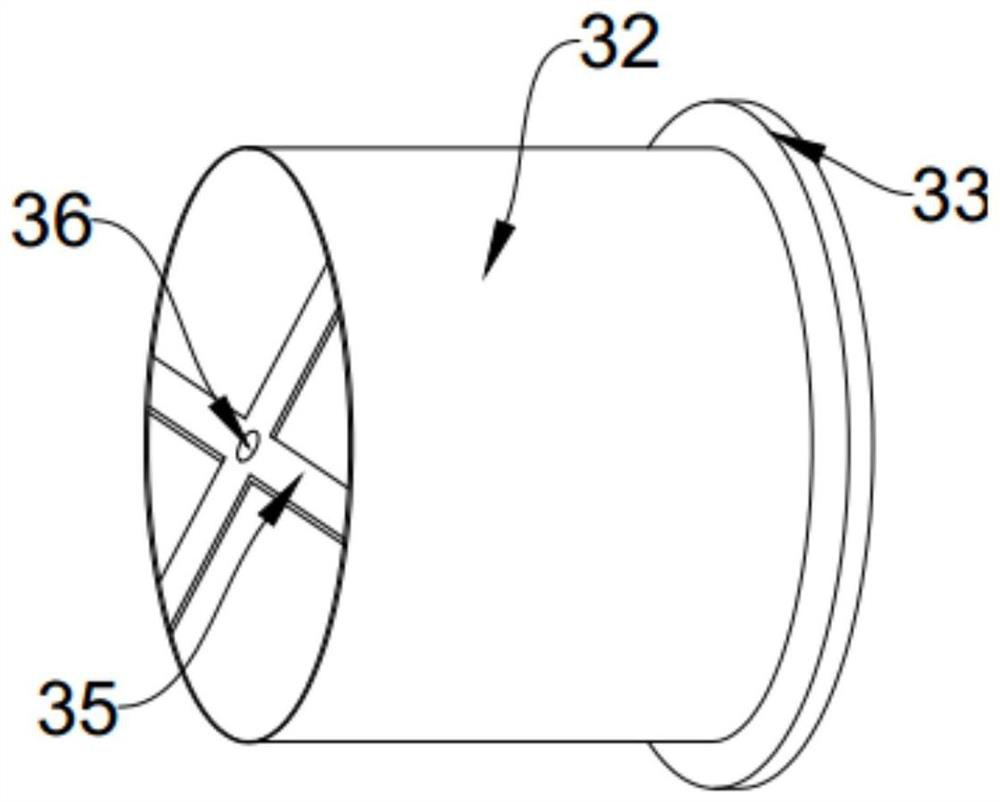

High-pass radio frequency filter

InactiveCN112072233AAvoid installationSimple structureWaveguide type devicesResonant cavityEngineering

The invention relates to a high-pass radio frequency filter, which comprises a resonant cavity, a cover plate and a resonant column arranged in the resonant cavity, the length of the resonant column is adjustable, a tuning screw rod is connected to the resonant column, the tuning screw rod penetrates out of the cover plate, and the resonant column participates in working length adjustment in the resonant cavity. The resonance column comprises a fixed part fixedly connected with the inner surface of the cover plate and a movable part sleeved with the fixed part, and the movable part is fixedlyconnected with the tuning screw rod; according to the high-pass radio frequency filter, the arrangement of various structures and components in the resonant cavity of the filter in the prior art is solved, the existence of sharp corners in one or the cavity is avoided, and meanwhile, the length of the resonant column is adjustable, and the output frequency is high.

Owner:安徽蓝讯电子科技有限公司

Battery protection piece and protection method and battery module

Owner:江西美晨通讯有限公司 +2

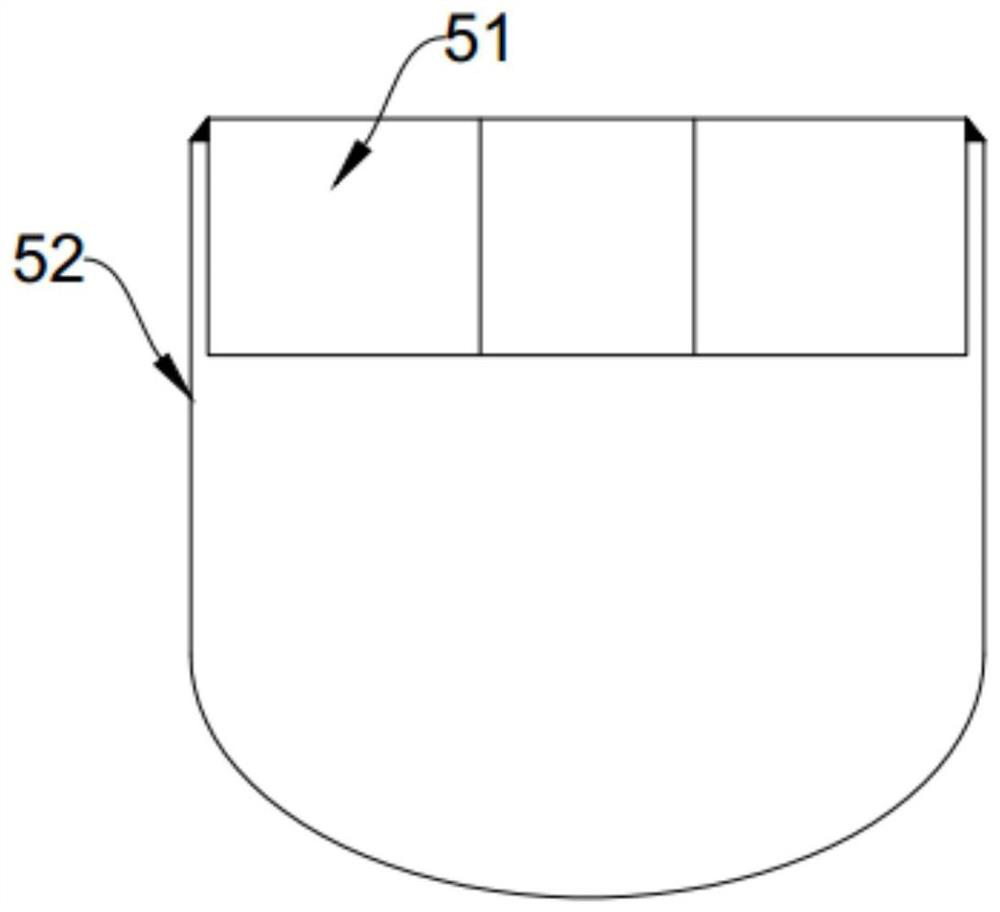

Oil chamber for oil cooler

InactiveCN104457383AAvoid sharp cornersFix the tearHeat exchanger casingsHigh intensityMaximum pressure

The invention provides an oil chamber for an oil cooler. The oil chamber comprises an oil chamber body which comprises an oil chamber upper portion and an oil chamber lower portion, the oil chamber lower portion is circular-arc-shaped and is parallelly provided with assembly grooves axially, the assembly grooves are matched with one ends of heat radiating pipes of the oil cooler, and interval and size of the assembly grooves are set according to those of the heat radiating pipes. The lower portion, needing to bearing maximum pressure, of the oil chamber body is arranged to be circular-arc-shaped and integrally formed with the oil chamber body, so that welding of the heat radiating pipes is enabled to be easier. The oil chamber is simple in structure and convenient to assemble and replace, a joint and the oil chamber body are avoided forming sharp corners, the problem of tearing of positions where the oil chamber is welded with the heat radiating pipes due to the fact that the oil chamber deforms during high-intensity running of the oil cooler is solved, and durability of the oil cooler is improved.

Owner:CHONGQING TOKYO RADIATOR

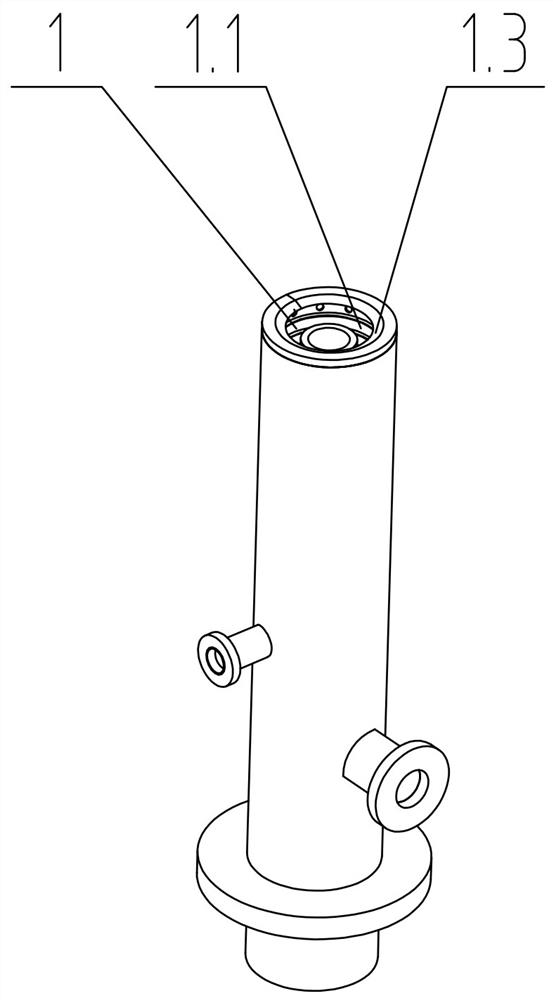

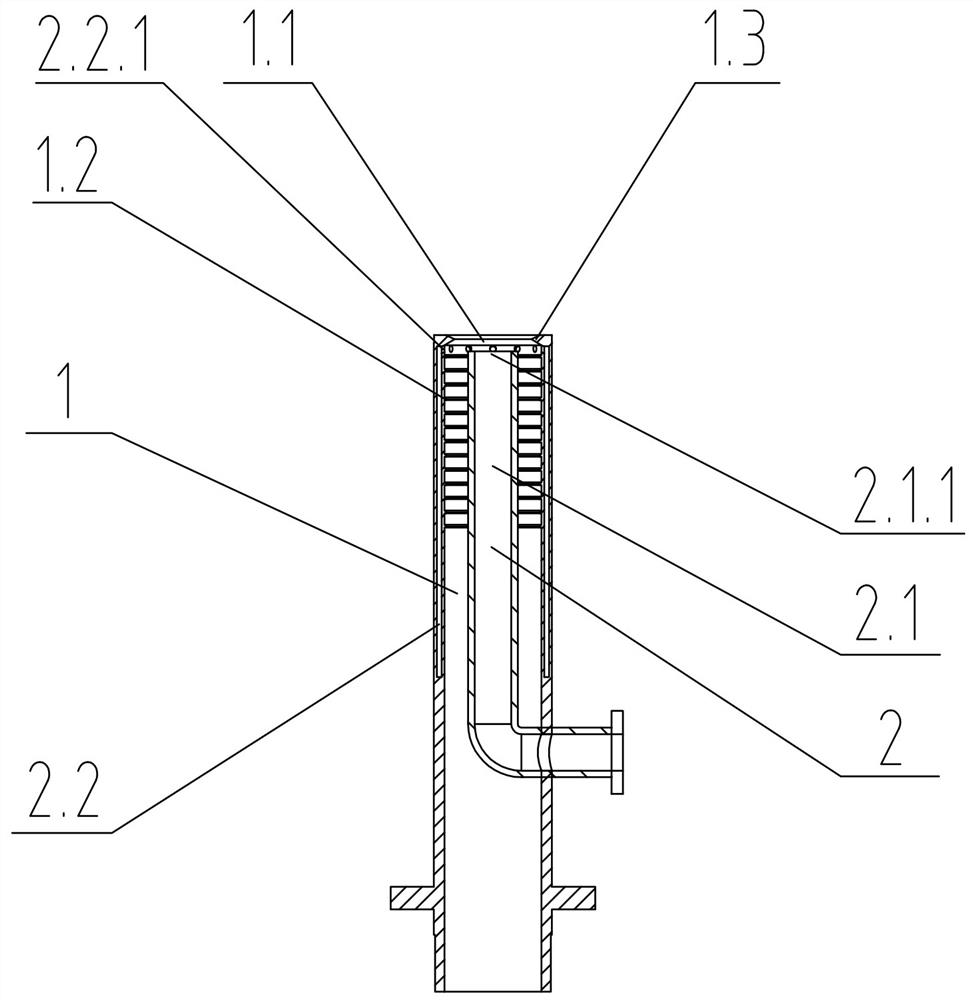

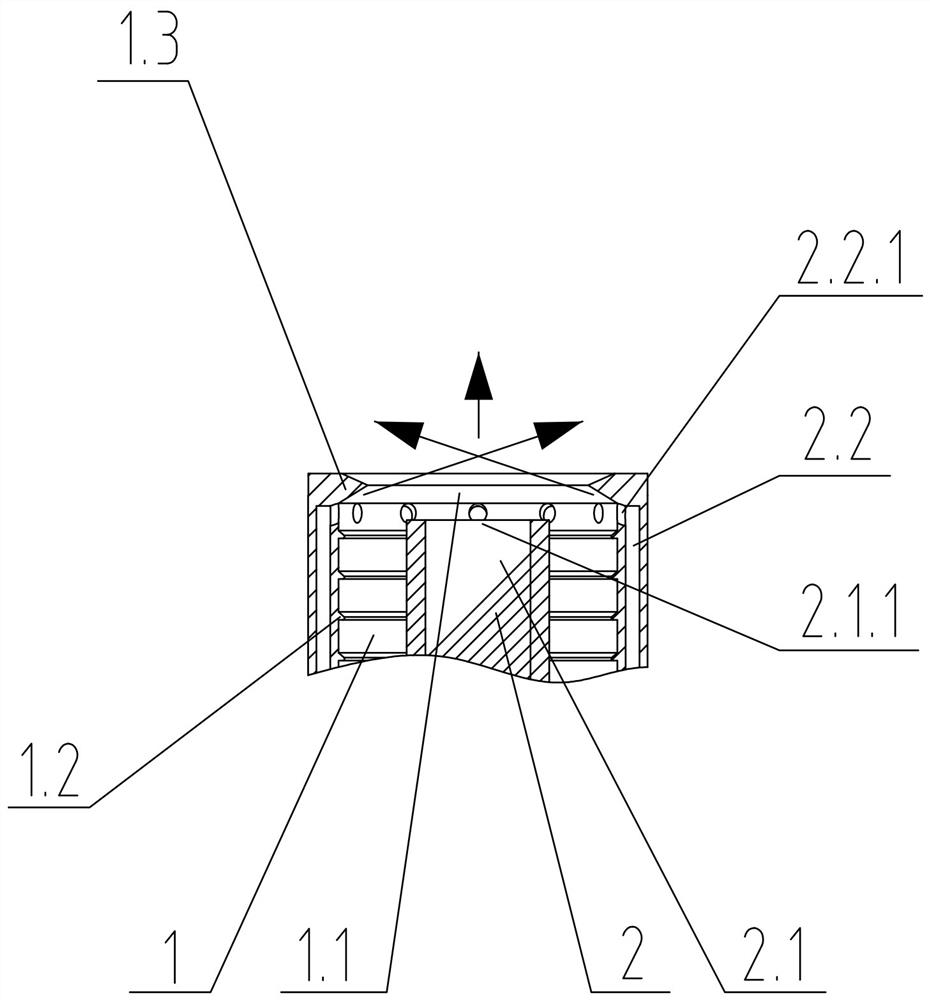

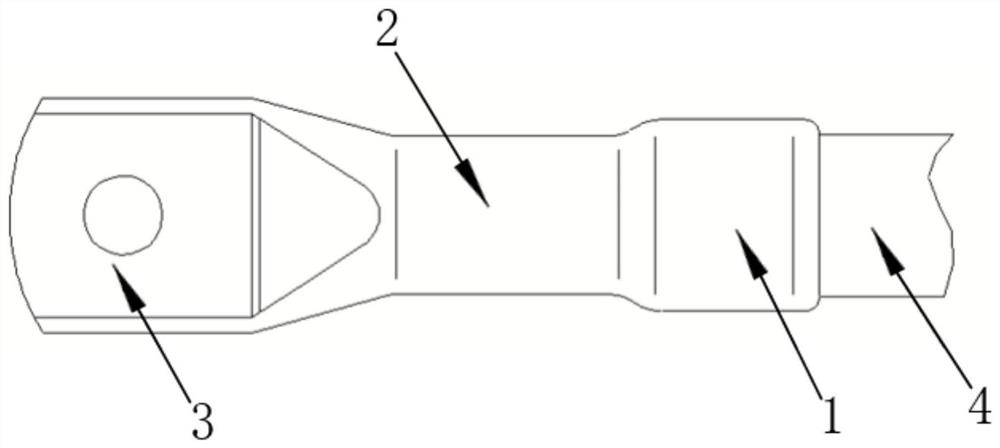

Glue spraying head used for accurately gluing iron cores of driving motors of new energy automobiles

ActiveCN113522640AAvoid distractionFast liquid supplyLiquid surface applicatorsManufacturing stator/rotor bodiesNew energyElectric machinery

The invention discloses a glue spraying head used for accurately gluing iron cores of driving motors of new energy automobiles. The glue spraying head is characterized by comprising a glue supply channel (1) which is used for supplying glue and a cutting air channel (2) which is used for separating glue drops from the glue supply channel (1), the glue supply channel (1) comprises a glue outlet (1.1), the glue outlet (1.1) is vertically arranged upwards, and damping lines (1.2) are arranged on the inner side of the side wall of the glue supply channel (1). The invention provides the glue spraying head used for accurately gluing the iron cores of the driving motors of the new energy automobiles, and through the glue spraying head, glue solution can be prevented from being solidified and adhered at the glue outlet of the glue spraying head, and the glue spraying amount can be accurately controlled.

Owner:浙大宁波理工学院

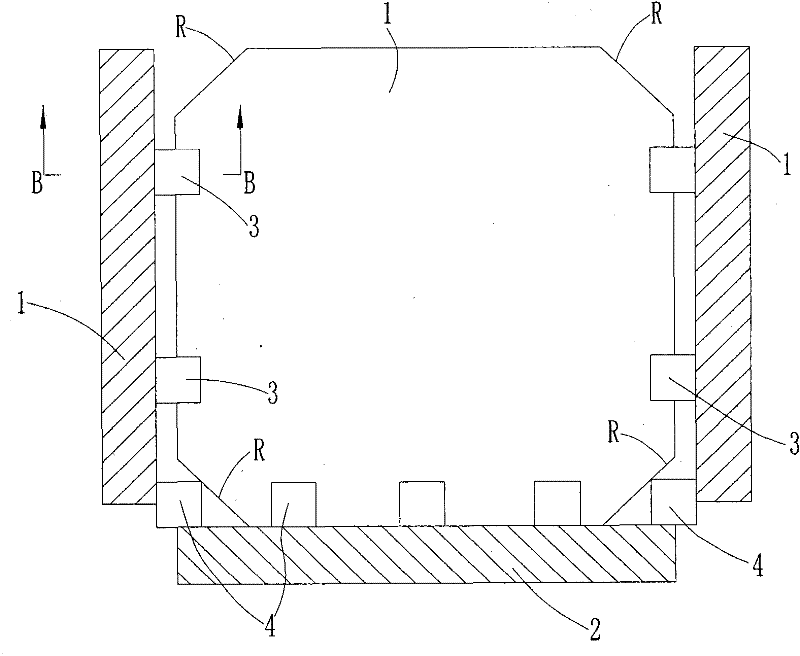

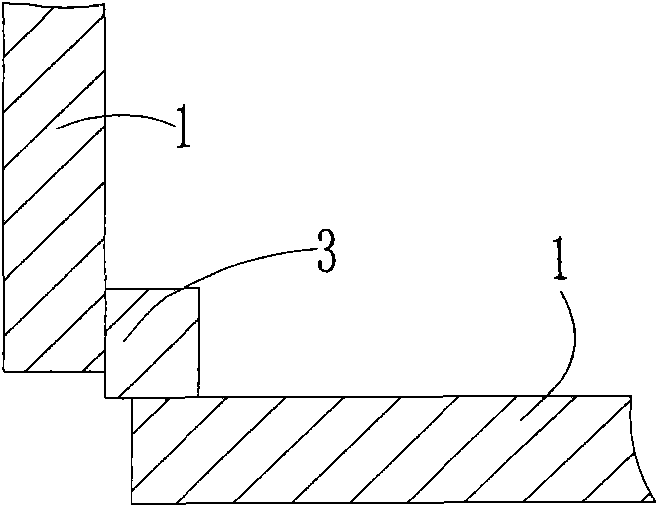

Electrode device of electrochemical cleaning salt-bath furnace

InactiveCN102127799AReduce tip dense phenomenonEvenly distributedElectrolysis componentsEngineeringElectrochemistry

The invention relates to an electrode device of an electrochemical cleaning salt-bath furnace. The device comprises a square cylinder enclosed by four electrically-conducting square side plates and a square bottom plate, wherein every two adjacent side plates are connected through a plurality of first electrically-conducting blocks that are vertically arranged and spaced with each other, so as to form a gap between every two adjacent side plates, and each side plate is connected with the bottom plate through a plurality of second electrically-conducting blocks that are vertically arranged and spaced with each other, so as to form a gap between each side plate and the bottom plate. A 45-degree chamfer is formed at each corner of the bottom plate and each of the side plates, and the bottom plate and each of the side plates are all steel plates of thickness 12-20 mm. The distance between the two adjacent first electrically-conducting blocks is 200-300 mm, the distance between the two adjacent second electrically-conducting blocks is 200-300 mm, and the first electrically-conducting blocks and the second electrically-conducting blocks are all made of 18*18 mm square steel. The electrode device provided by the invention has the advantages of uniform charge distribution, slow corrosion and long service life, so that the electrochemical cleaning salt-bath furnace has good cleaning effect and high cleaning efficiency.

Owner:FIRST DESIGN & RES INST MI CHINA

Waterproof terminal wiring terminal and application method thereof

PendingCN112164908AConforms to electrical conductivityAvoid sharp cornersLine/current collector detailsConnections effected by permanent deformationElectrical conductorStructural engineering

The invention discloses a waterproof terminal wiring terminal and an application method thereof, and belongs to the technical field of cable wiring structures. The cable structure comprises a cable conductor wire core and a cable insulation skin wrapping the outer side of the cable conductor wire core. The waterproof terminal wiring terminal comprises a conductor crimping part and an insulating skin crimping part which are fixedly connected with each other; each of the conductor crimping part and the insulating skin crimping part is provided with a channel, and the channel of the insulating skin crimping part is connected with the channel of the conductor crimping part; the insulating skin crimping part is a crimping part with a circular channel section, and the insulating skin crimping part is crimped on the cable insulating skin and forms a circular indentation on the cable insulating skin. The waterproof terminal wiring terminal not only accords with the conductivity of a common wiring terminal, but also is suitable for the railway and rail transit industry and the wind power industry, has reliability and maintenance-free performance, and improves the electrical performance of the crimping waterproof terminal wiring terminal.

Owner:TIANZE ELECTRIC POWER (JIANGSU) CO LTD

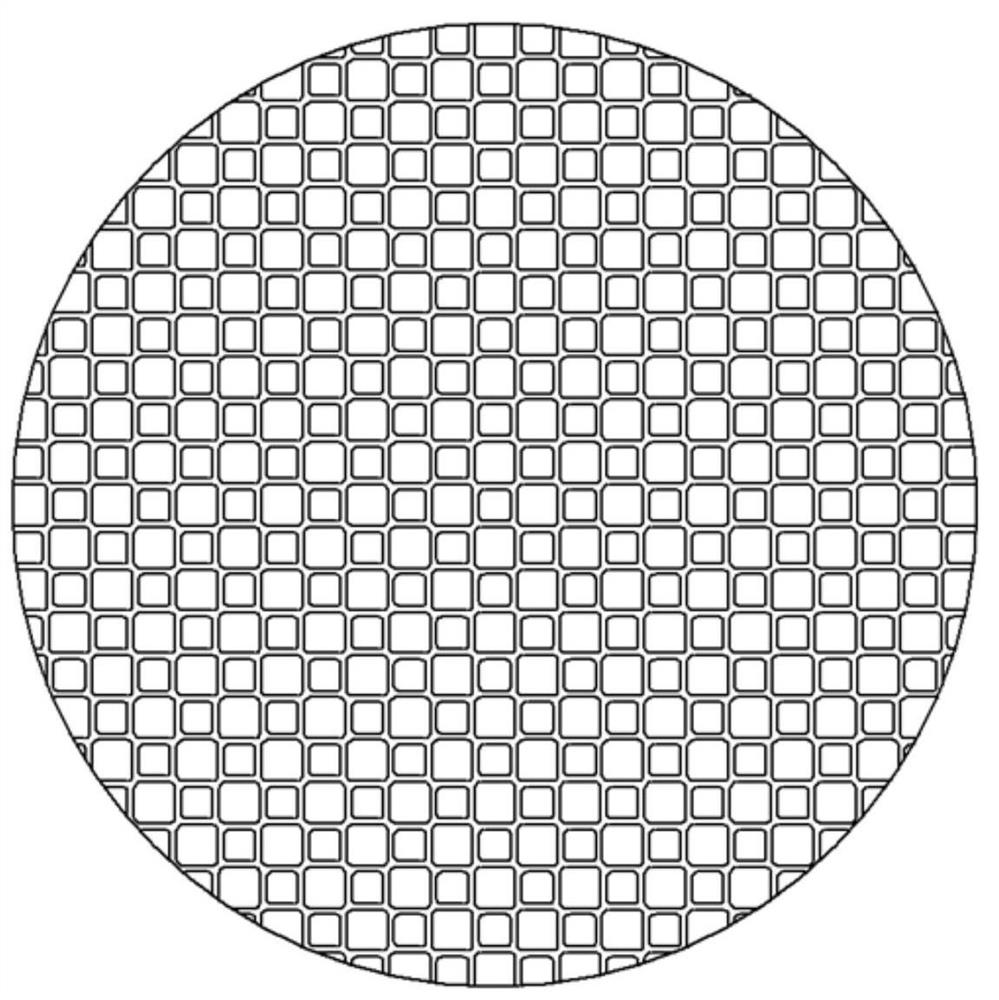

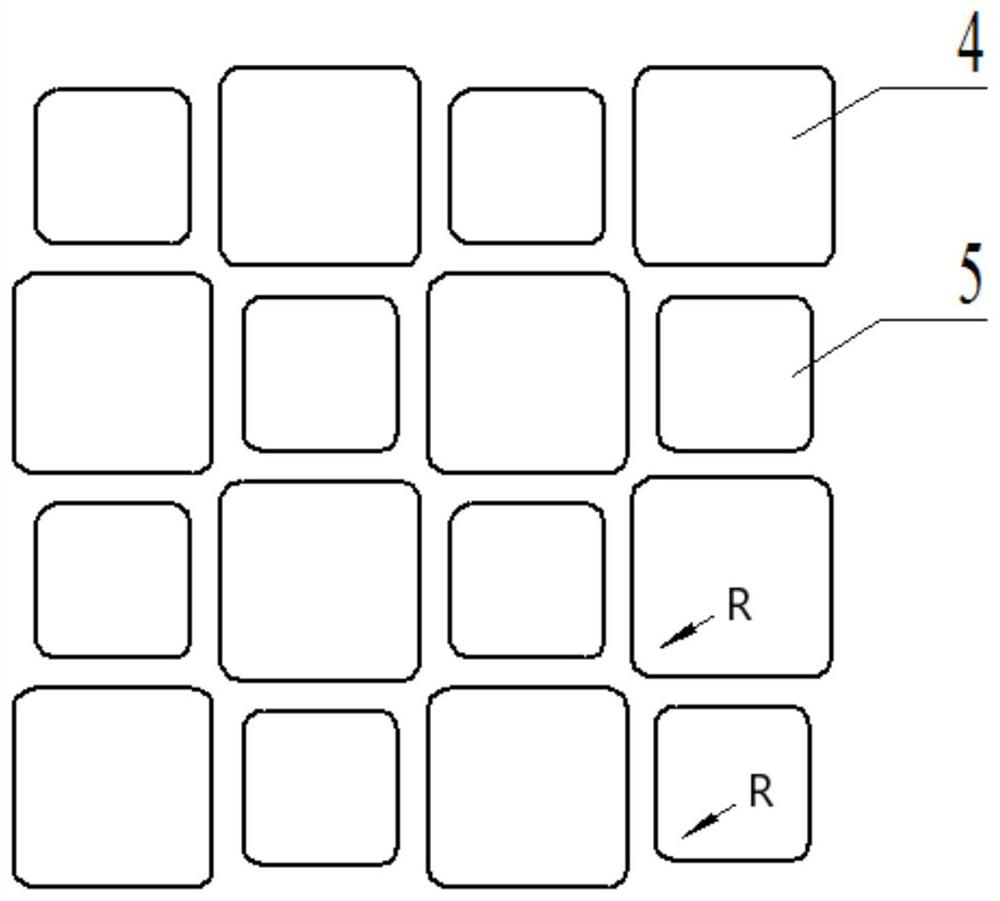

Asymmetric DPF die and manufacturing method thereof

PendingCN113414456AAvoid sharp cornersImprove end face cracking defectsElectrical-based machining electrodesStructural engineeringManufacturing engineering

The invention discloses an asymmetric DPF die and a manufacturing method thereof. The asymmetric DPF die comprises an overall die plate, two or more evenly-distributed feeding holes are formed in the back face of the overall die plate, two or more evenly-distributed discharging grooves are formed in the front face of the overall die plate, and the discharging grooves communicate with the corresponding feeding holes, wherein the two or more discharging grooves are composed of two types of tooth columns with different sizes. According to the asymmetric DPF die, groove face tooth columns are designed through the round corners, sharp corner interference is avoided, and the end face cracking defect during product firing can be effectively overcome; according to the asymmetric DPF die, split type XY electrodes are adopted for machining the groove face, the number of electrode machining devices is large, the selection range of electrode materials is wide, cost is low, machining is more convenient, efficiency is higher, the machining period is short, and machining cost is lower; and the advantages that a narrow slit is not prone to deforming during machining is achieved, the roughness of the inner wall of the groove can reach Ra1.0, so that the forming extrusion requirement is met, and good practicability is achieved.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

Air tightness detection device for shell die casting

ActiveCN114346939ALarge amount of bindingAvoid sharp cornersWork holdersFluid-tightness measurement using fluid/vacuumStructural engineeringManufacturing engineering

The invention discloses an air tightness detection device for a shell die casting, and the device comprises a bottom plate which is provided with at least one die casting positioning region. The lifting pressing plate is arranged above the bottom plate to ascend and descend, and a plurality of die casting pressing assemblies are vertically installed at the lower end of the lifting pressing plate; the sealing groove encloses the die casting positioning area, and a sealing strip is arranged in the sealing groove in an embedded mode; the arc-shaped grooves are formed in the two ends of the die casting positioning area, and the ends of the sealing grooves extend to be communicated with the arc-shaped grooves; the end sealing columns are installed at the two ends of the die casting positioning area and embedded into the arc-shaped grooves, and the outer sides of the end sealing columns are connected with sealing rings in a sleeved mode, and the sealing rings make contact with the ends of the sealing strips. And the extrusion sleeve is axially arranged on one side of the end sealing column and is driven by an execution component on the bottom plate to axially move to extrude the sealing ring. According to the invention, the material cost of the sealing strip is not increased under the condition that the product structure is not allowed to be changed.

Owner:NINGBO HUIWANG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com