Grinding wheel, rounding device of using the grinding wheel, and rounding method

A grinding wheel and spheronizing technology, applied in the field of grinding wheels, can solve the problems of easy force fracture, low yield of workpiece finished products, and finished workpiece products that do not meet specifications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

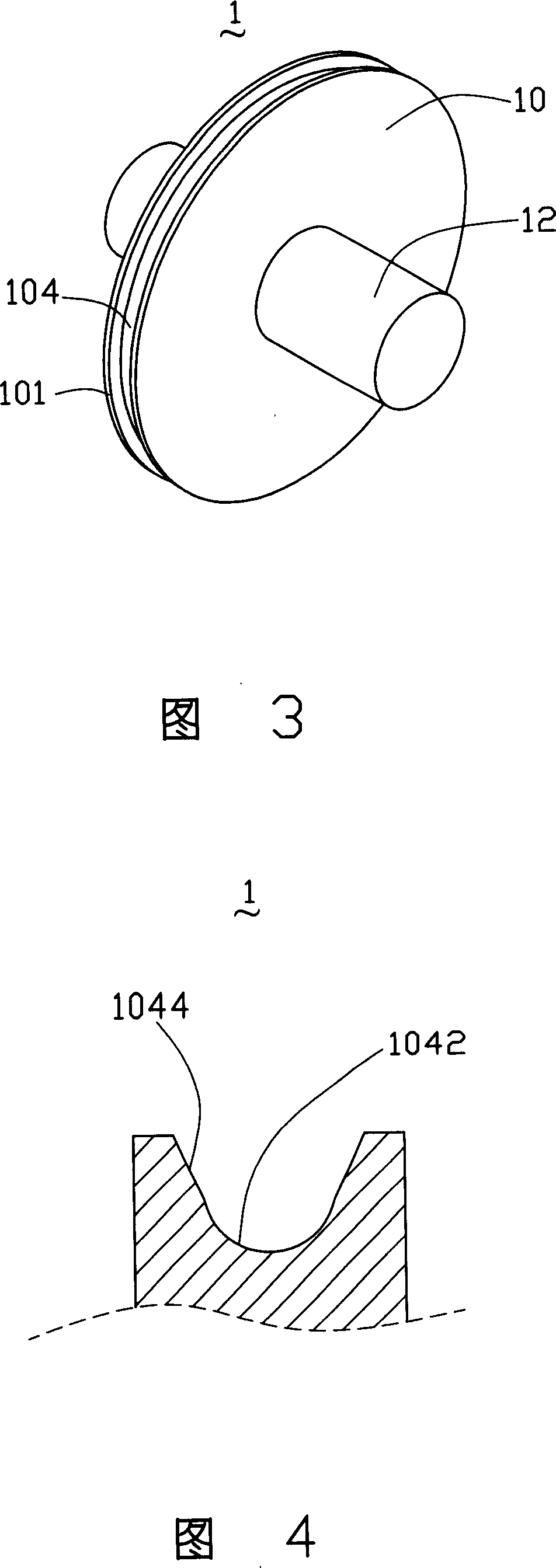

[0026] Please refer to FIG. 3 and FIG. 4 , the grinding wheel 1 according to the preferred embodiment of the present invention includes a wheel body 10 and a shaft body 12 , and the wheel body 10 is fixed on the shaft body 12 .

[0027] The wheel body 10 has a rim 101, and an annular groove 104 is provided along its circumferential direction on the rim 101, which has a semicircular groove wall 1042, and the two sides of the semicircular groove wall 1042 of the groove 104 respectively face There is an inclined wall 1044 extending outward, and the distance between the openings of the two inclined walls 1044 gradually increases outward from the joint between the two inclined walls 1044 and the semicircular groove wall 1042 . Wherein, a cross section of the groove 104 along the radial direction of the wheel body 10 is shown in FIG. 4 .

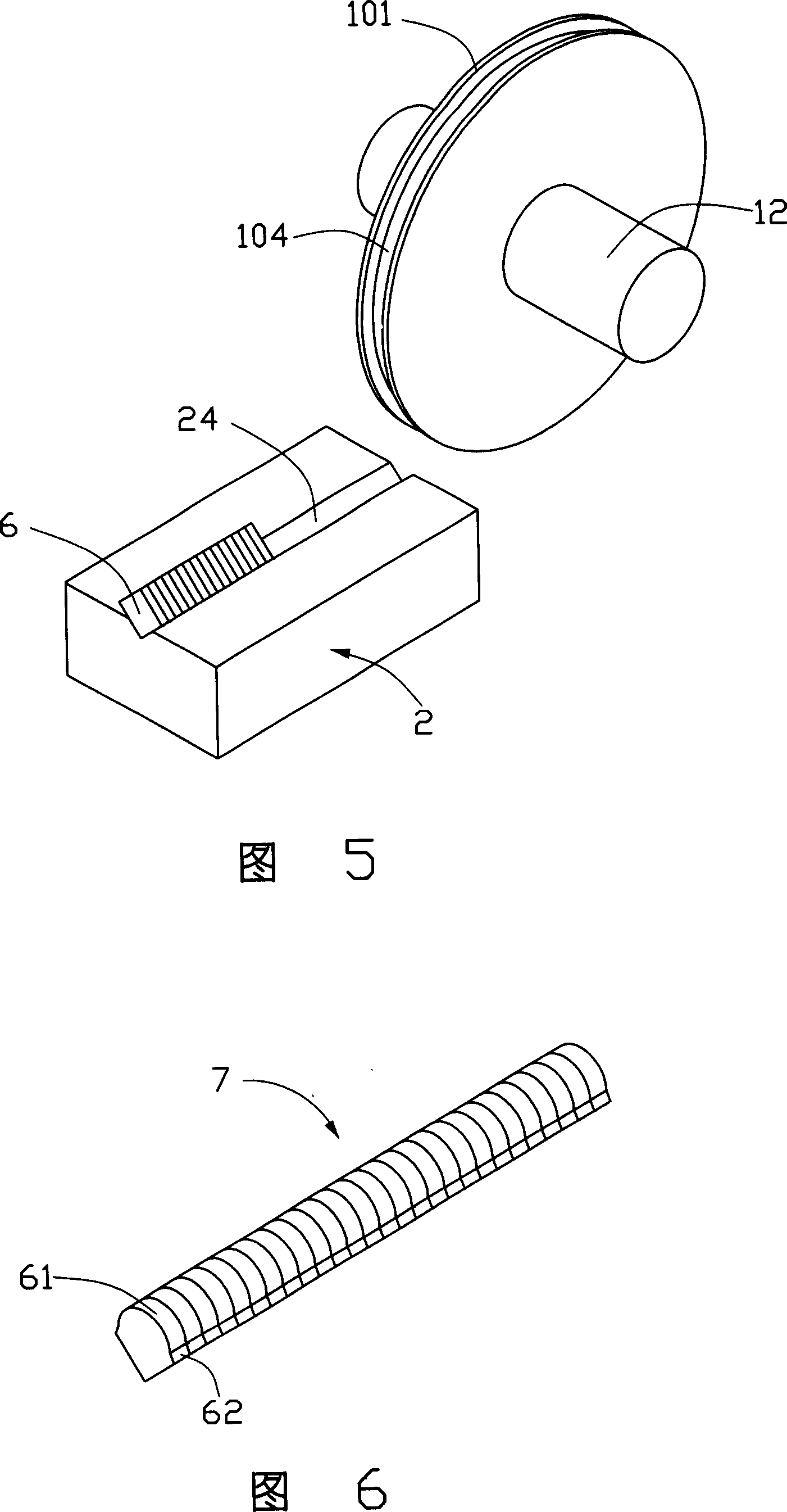

[0028] Please refer to FIG. 5 and FIG. 7 at the same time. The rounding equipment described in the preferred embodiment of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com