Glue spraying head used for accurately gluing iron cores of driving motors of new energy automobiles

A new energy vehicle and drive motor technology, applied in the field of glue spray head, can solve the problems of unstable glue spray amount, unfavorable glue liquid stability, and reduced automation effect, so as to reduce the frequency of human maintenance, improve automation effect, Precisely control the effect of spray glue dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

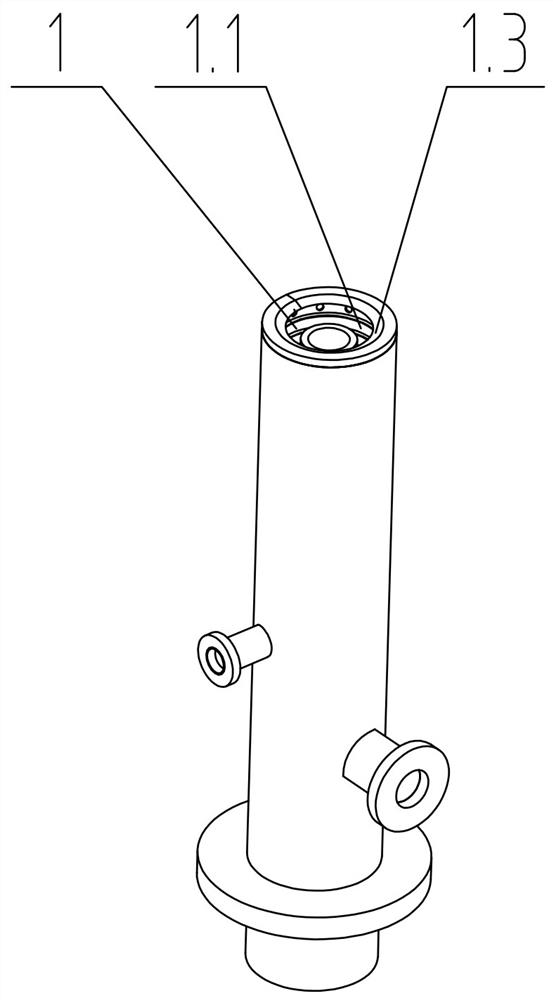

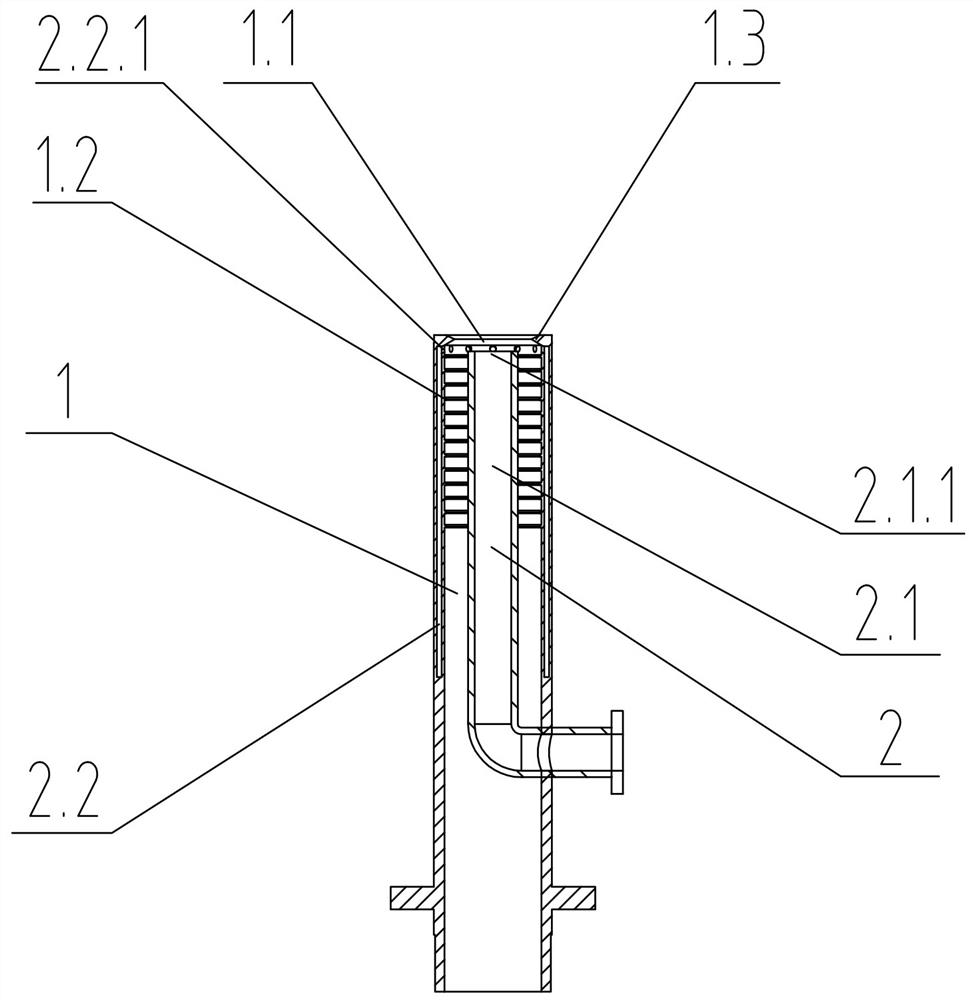

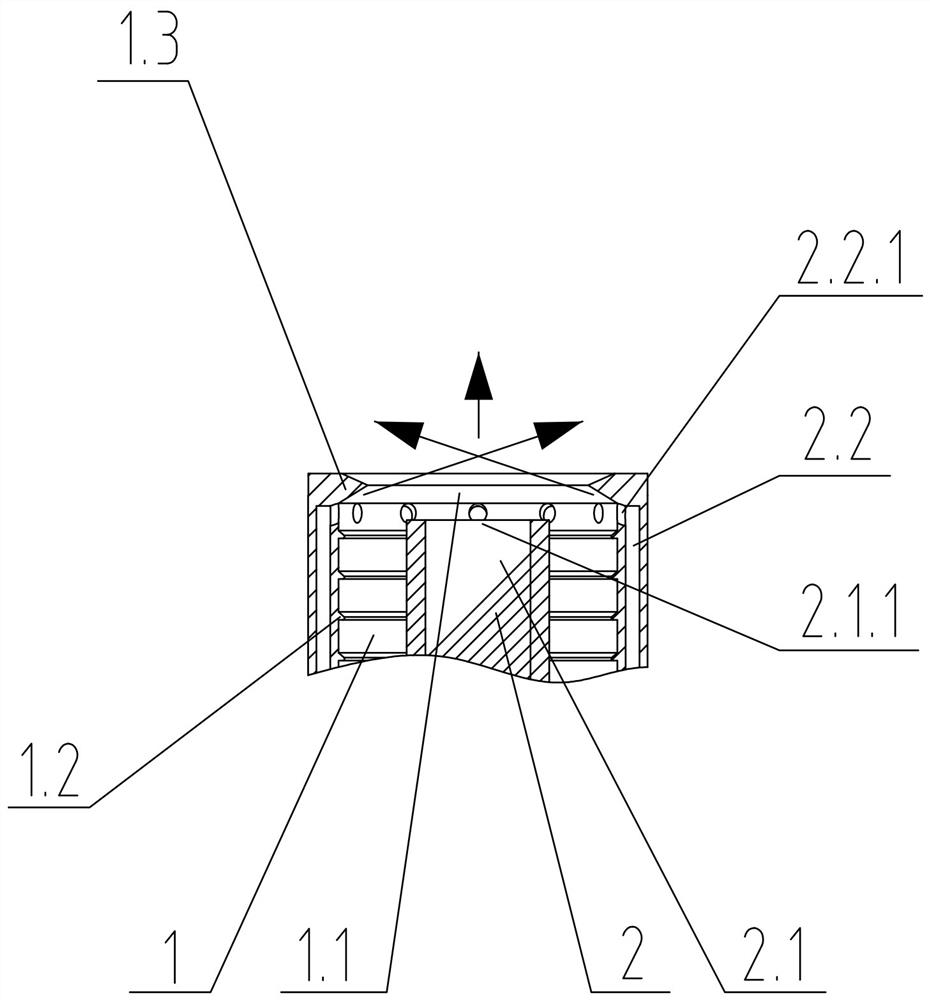

[0024] like Figure 1-3 As shown, a glue spraying head for precise gluing of new energy vehicle drive motor cores, including a glue supply channel 1 for glue supply and a cutting wind for separating glue droplets from the glue supply channel 1 Road 2, the glue supply channel 1 includes a glue outlet 1.1, the glue outlet 1.1 is set vertically upward, and the inside of the side wall of the glue supply channel 1 is provided with a damping pattern 1.2, and the damping pattern 1.2 is located on the glue outlet One end of the opening 1.1, the cutting air duct 2 includes a first air duct 2.1 and a second air duct 2.2, the first air duct 2.1 is set on the axis of the glue supply channel 1, and the first air duct 2.1 includes a second air duct 2.1 An air outlet 2.1.1, the first air outlet 2.1.1 is located directly below the glue droplet to be separated for sending the glue droplet away from the glue supply channel 1, and the second air duct 2.2 is located in the glue supply channel 1,...

Embodiment 2

[0026] like Figure 4-6 As shown, a glue spraying head for precise gluing of new energy vehicle drive motor cores, including a glue supply channel 1 for glue supply and a cutting wind for separating glue droplets from the glue supply channel 1 Road 2, the glue supply channel 1 includes a glue outlet 1.1, the glue outlet 1.1 is set vertically upward, and the inside of the side wall of the glue supply channel 1 is provided with a damping pattern 1.2, and the damping pattern 1.2 is located on the glue outlet One end of the mouth 1.1, the cutting air duct 2 is set on the axis of the glue supply channel 1, and the axial direction of the cutting air duct 2 is provided with a delivery outlet 2.3, and the delivery outlet 2.3 is used to send glue Drops are sent away from the glue supply channel 1, and a plurality of cutting air outlets 2.4 are evenly distributed on the circumference of the cutting air channel 2, and the plurality of cutting air outlets 2.4 are used to separate the glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com