Reaction unit and method for atom layer film deposition

A thin film deposition and reaction device technology, which is applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of uneven distribution, slow deposition rate, weak power, etc., to reduce the temperature gradient, Effect of shortening heating time and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

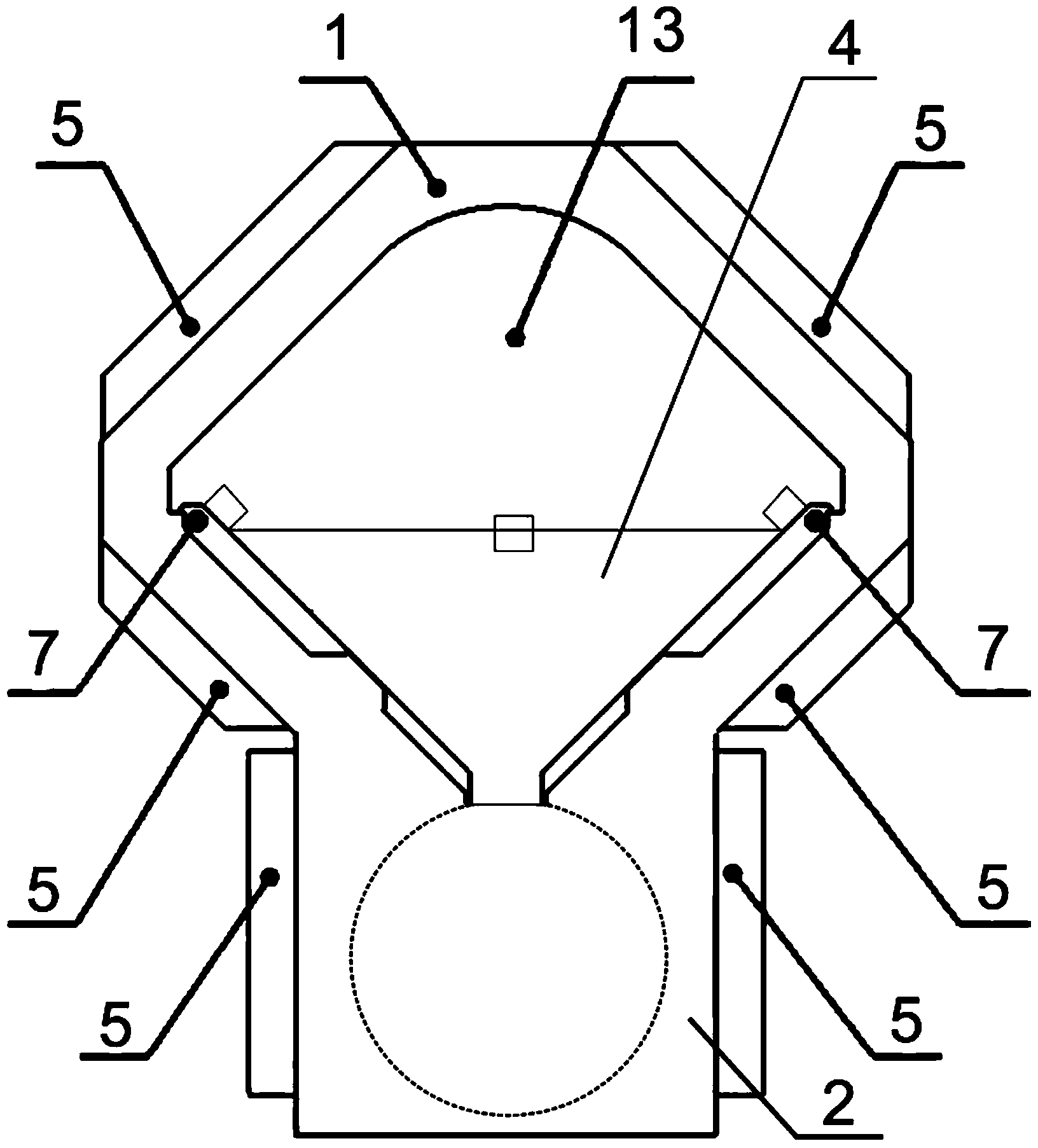

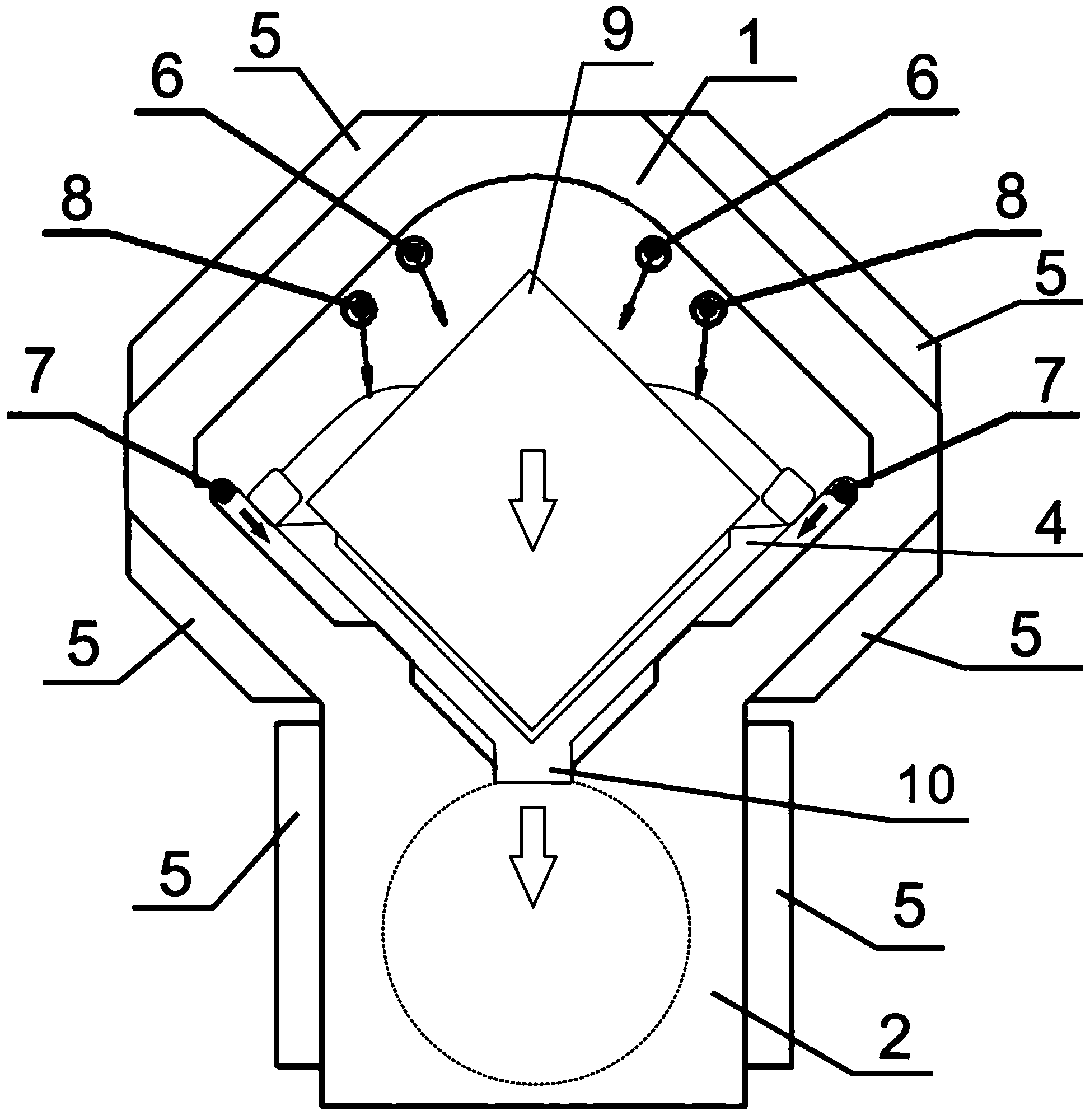

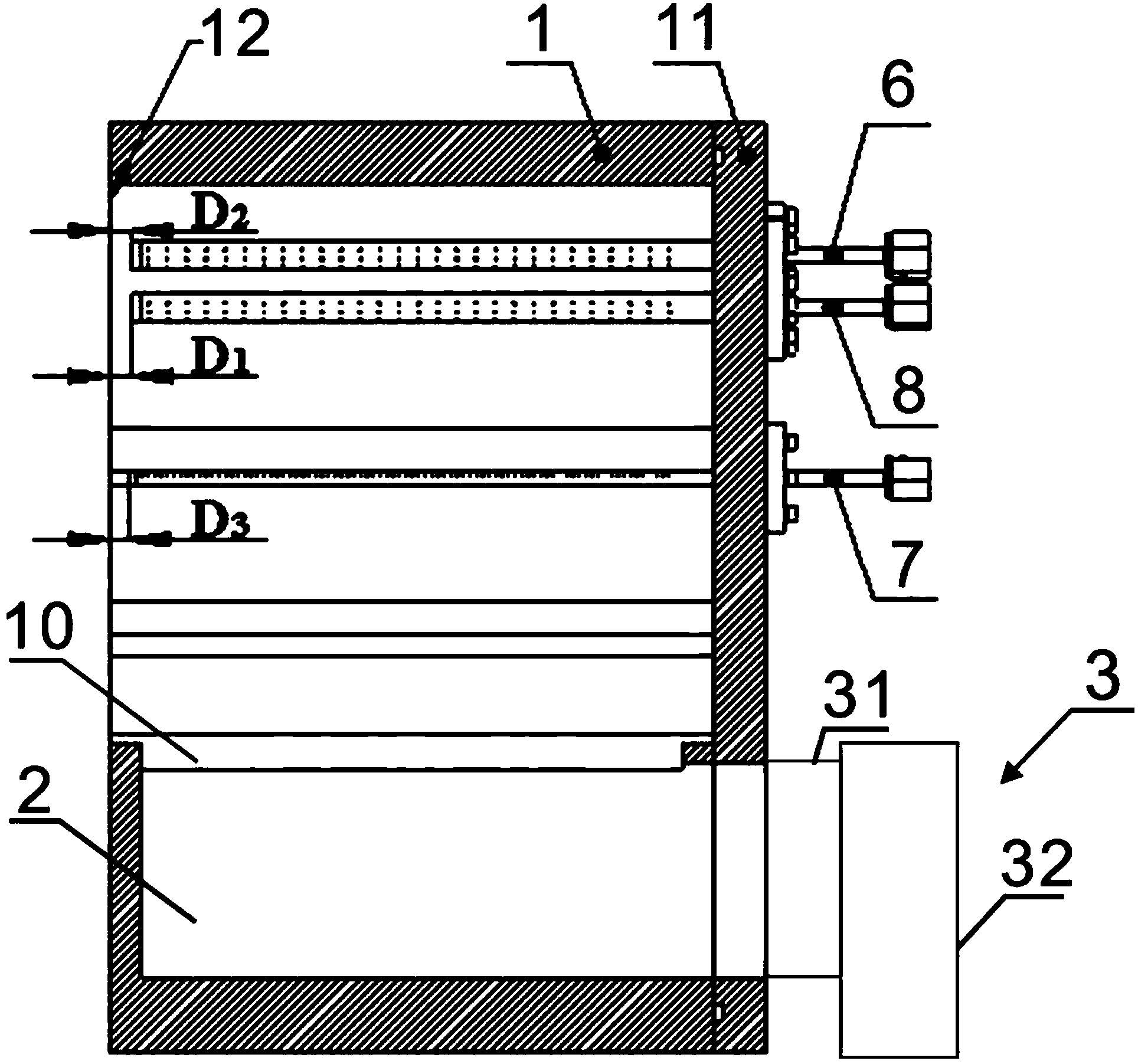

[0052] like Figure 1 to Figure 4 As shown, the present invention provides a reaction device for atomic layer thin film deposition, comprising: a reaction deposition chamber 1, a reaction evacuation chamber 2 and a vacuum system 3; The reaction evacuation chamber 2 is connected, and the reaction evacuation chamber 2 is connected to the vacuum system 3, and the vacuum system 3 is used to pump air to the reaction evacuation chamber, so that the reaction deposition chamber 1 is in the vacuum state; wherein, the reaction deposition chamber 1 includes a silicon wafer carrying unit 4, a heating unit 5, a precursor feeding unit 6, and a purge gas intake unit 7; the silicon wafer carrying unit 4 is provided with several silicon The wafer carrying position and the bottom of the silicon wafer carrying unit are provided with some ventilation holes, and the silicon wafer carrying unit 4 is provided with a shield cover 13 for sealing the reaction deposition chamber 1; the heating unit 5 is...

Embodiment 2

[0069] On the basis of implementing one, the difference from Example one is: the internal pressure of the reaction deposition chamber 1 is 3Torr, and the first gaseous reaction precursor is trimethylaluminum (TMA) and ozone (O 3 ), the second gaseous reaction precursor is ozone (O 3 ); the angle β1 between the direction of the air outlet of the precursor feeding unit 6 and the wall of the reaction deposition chamber 1 is 90°, and the distance D2 between the end of the heating gas inlet unit 8 and the front face 12 of the reaction chamber is 3mm. The reaction chamber in the present embodiment can complete the deposition of Al with a thickness of 20nm to 250 P-type silicon wafers 9 every 30 minutes. 2 o 3 Thin film, production capacity up to 500 pieces / hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com