Embedded substrate provided with side-inclined plane line layer assembly and manufacturing method thereof

A circuit layer, embedded technology, applied in the direction of printed circuit components, electrical connection printed components, printed components electrical connection formation, etc., can solve problems such as inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

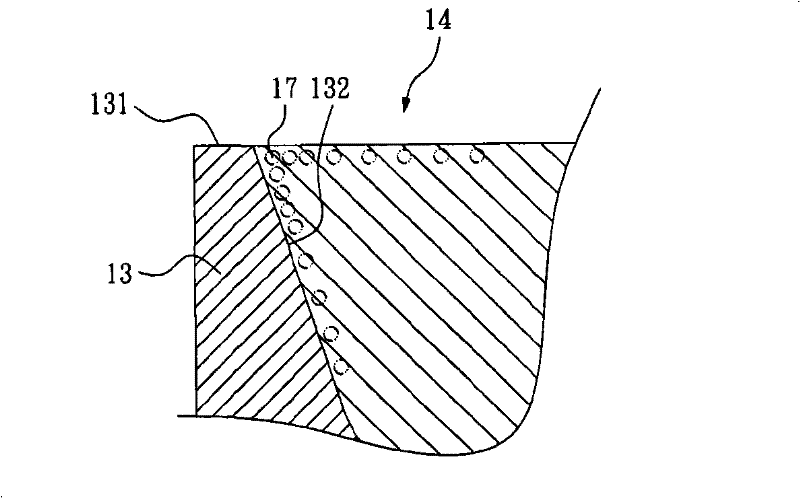

[0049] refer to Figure 3 to Figure 8 , is a schematic diagram showing a method for manufacturing an embedded substrate of a circuit layer assembly with side bevels according to the present invention. refer to image 3 , providing a substrate 2 including a dielectric layer 23 having an upper surface 231 . In this embodiment, the substrate 2 further includes a core layer 21 and a first copper layer 22 , the first copper layer 22 is located on the core layer 21 , and the dielectric layer 23 is located on the first copper layer 22 .

[0050] refer to Figure 4 , removing part of the dielectric layer 23 from the upper surface 231 of the dielectric layer 23 to form at least one accommodating groove 232, 233, 234, and these accommodating grooves 232, 233, 234 are opened on the upper surface 231, And viewed from a top view, it has a pattern. In this embodiment, laser or plasma is used to remove part of the dielectric layer 23 from the upper surface 231 of the dielectric layer 23, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com