Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Prevent re-aggregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous segmented cracking equipment and technology used for waste and old tyres and capable of preventing generation of dioxin

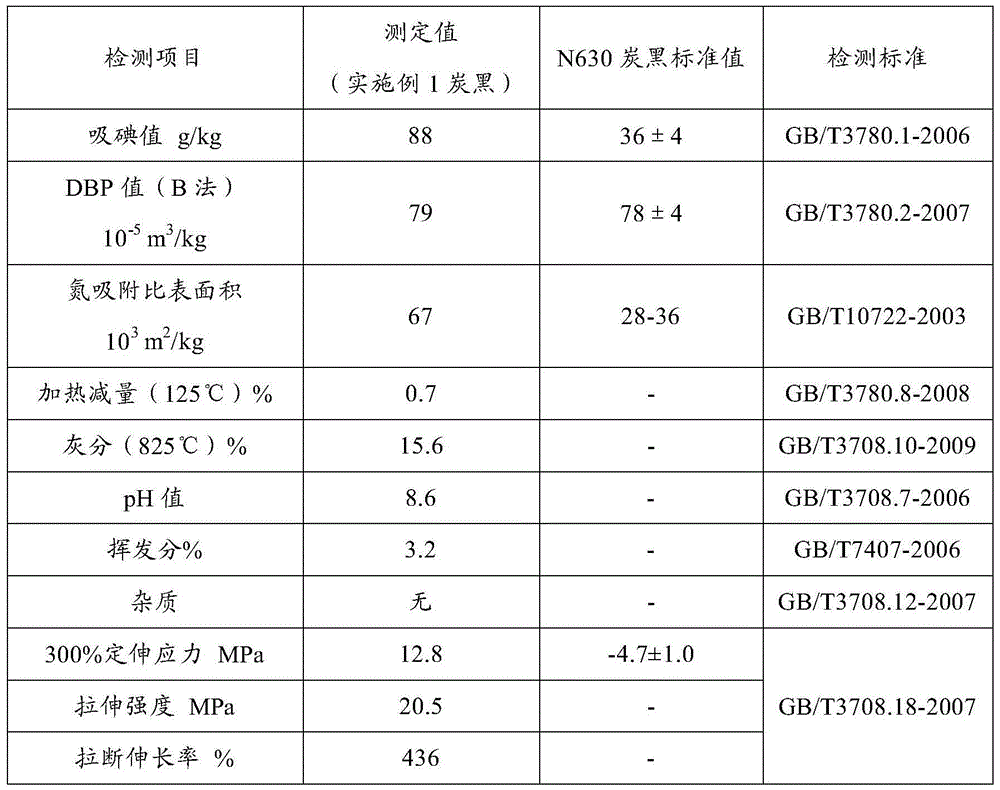

InactiveCN104479722AHigh activityQuality improvementPigmenting treatmentPlastic recyclingScrew conveyorCarbon black

The invention provides a continuous segmented cracking equipment and a technology used for waste and old tyres and capable of preventing generation of dioxin. The equipment comprises a raw material bin, a mixing feeding screw conveyor, a preheating furnace, a continuous thermal cracking device and an oil gas recovery device; the raw material bin is successively connected with the mixing feeding screw conveyor, the preheating furnace and the continuous cracking device; the preheating furnace successively comprises a heating segment, a sealing segment, a forward pushing segment and a discharging segment along the flowing direction of a raw material, the heating segment and the forward pushing segment are both provided with a screw pusher, and the screwing direction of the screw pushers in the heating segment and in the forward pushing segment are same, and the sealing segment is not provided with a screw pusher; and the continuous cracking device successively comprises a first cracking unit with the heating temperature of 340-360 DEG C, a second cracking unit with the heating temperature of 440-460 DEG C and a third cracking unit with the heating temperature of 540-560 DEG C. The equipment and the technology are capable of effectively preventing generation of dioxin in the process of processing waste and old tyres, improving the activity and the quality of carbon black, and realizing continuous cracking production of waste and old tyres.

Owner:中机国宏高分子技术研究(北京)中心

Soft-pellet creep feed and preparation method thereof

ActiveCN103416591AImprove palatabilityEliminate lossAnimal feeding stuffAdditive ingredientBlood plasma

The invention discloses a soft-pellet creep feed and a preparation method thereof, and belongs to the field of feed formulation design and feed processing techniques. The preparation method comprises the following steps: mixing and bacillus subtilis and pickled vegetables fermentation liquor, performing fermentation in sequence to form fermented soybean meal and rice which are taken as main raw materials; adding steam fish meal, blood plasma powder, soybean meal and the like in a matched manner; utilizing a soft pelletizer to prepare pellet materials through ultramicro smashing; utilizing a syrup spray device to uniformly spray syrup on the surfaces of the pellet materials. The creep feed provided by the invention is full and balanced in nutrition, is easy to digest and intake, has stable quality, and is subjected to multiple fermentation. Moreover, feed inducing performance, soft protection performance and nutrition full value performance are improved, as a process of combining a soft manufacturing system and the syrup spray system is adopted; the incidence of hardening of medium-sized pellet feed during the preservation process is reduced; compared with a dry pellet feed, the loss of nutritional ingredient during the granulating heating and drying process is avoided, and the palatability of soft pellet feed is kept well.

Owner:LIAONING WELLHOPE AGRI TECH

Anti-hardening white square rice cake and production method thereof

InactiveCN102771714AExtended soft periodSolve short-term hardening quality problemsFood preparationBiotechnologyMaize starch

The invention relates to the technical field of food processing methods, in particular to an anti-hardening white square rice cake and a production method for the anti-hardening white square rice cake. The anti-hardening white square rice cake is produced by taking glutinous rice flour, anti-hardening syrup, lard oil, modified maize starch and black sesame and the like as raw materials, and according to a certain formula, performing the following steps of: (1) checking materials; (2) making the glutinous rice flour; (3) frying the black sesame; (4) mixing; (5) beating; (6) stewing; (7) re-steaming; (8) cooling, re-moisturizing and slicing; and (9) packaging and the like. The anti-hardening white square rice cake not only keeps the characteristics that the conventional white square rice cake is moist, soft, frozen grease-like, sweet and delicious and the like; and compared with the conventional white square rice cake, the a quality problem of short-term hardening is avoided and a softness guarantee period is prolonged by 40-45 days.

Owner:东莞市圣心食品有限公司

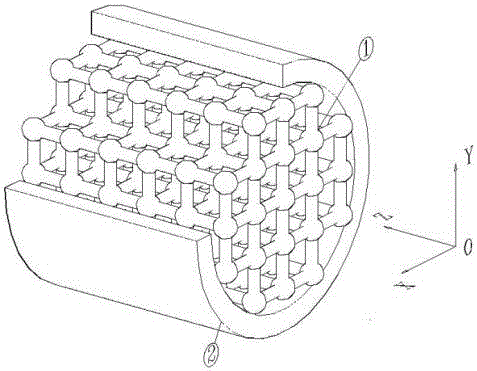

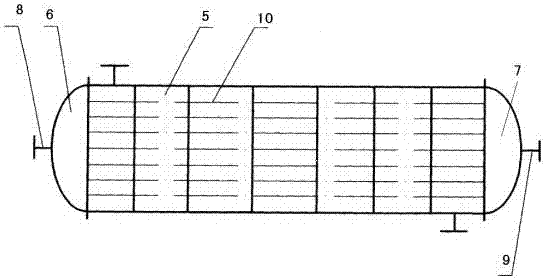

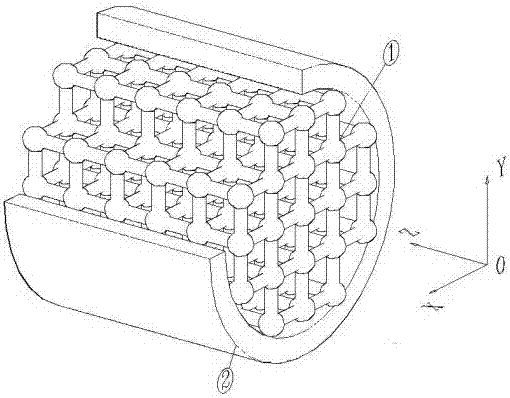

Porous medium two-phase flow shell-and-tube heat exchanger and stabilization device thereof

ActiveCN106679466ASpeed up the flowInhibit refluxStationary tubular conduit assembliesTubular elementsVibration attenuationPlate heat exchanger

The invention provides a two-phase flow shell-and-tube heat exchanger which comprises a shell. Sealing heads are arranged at the two ends of the shell, at least one sealing head is provided with a two-phase flow fluid inlet pipe, and a porous medium two-phase flow stabilization device is arranged in the fluid inlet pipe; the two-phase flow stabilization device comprises a porous medium core which is formed by connecting a plurality of stick-like objects; and the stick-like objects are crossed and welded in the X,Y and Z three-dimensional direction to form a porous medium structure with through holes. The passive two-phase flow stabilization device with the vibration attenuation and noise reduction function can separate two-phase flow into a liquid phase and a gas phase under the condition of being independent of external power or power sources, the liquid phase is divided into small liquid groups, the gas phase is divided into small bubbles, backflow of the liquid phase is restrained, smooth flowing of the gas phase is promoted, the effect of stabilizing flow is achieved, and the effects of vibration attenuation and noise reduction are achieved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Continuous thermal-cracking method and apparatus for waste and old tires

InactiveCN104031672AImprove activity and qualityAchieve recyclingPigmenting treatmentPlastic recyclingButadiene-styrene rubberProduct gas

The invention provides a continuous thermal-cracking method and an apparatus for waste and old tires. The method comprises the following steps: (1) preheating waste and old tire at 230-250 DEG C for 15-25 min, and under a vacuum condition, extracting and removing a gas generated in the preheating process; (2) heating the material obtained in the step (1) to 340-360 DEG C, and performing cracking at 340-360 DEG C for 8-12 min to enable natural rubber to be cracked, and under a vacuum condition, extracting and removing a gas generated in the cracking process; (3) heating the material obtained in the step (2) to 440-460 DEG C, and performing cracking at 440-460 DEG C for 8-12 min to enable cis-1,4-polybutadiene rubber and styrene-butadiene rubber to be cracked, and under a vacuum condition, extracting and removing a gas generated in the cracking process; and (4) heating the material obtained in the step (3) to 540-560 DEG C, and performing cracking at 540-560 DEG C for 8-12 min to enable carbonaceous sediment on the surface of carbon black to be cracked, and under a vacuum condition, extracting and removing a gas generated in the cracking process. The method and the apparatus are capable of effectively removing sediment on the surface of carbon black, improving the activity and the quality of carbon black, and realizing cracking continuous production of waste and old tires in a low energy consumption way.

Owner:中机国宏高分子技术研究(北京)中心

Soft particle milk replacer containing high fructose corn syrup and preparation thereof

The invention discloses a soft particle milk replacer containing a high fructose corn syrup, belonging to the technical field of a feed formula design and feed processing. The soft particle milk replacer is prepared by the following steps of: taking a compound fermented soybean meal which is prepared by sequentially mixing bacillus subtilis and a pickle fermentation solution to ferment, and rice as main materials; adding steam fish meal, flour, a peeled soybean meal and the like for match; carrying out ultrafine crushing on the materials and preparing particle materials by using a soft granulator; uniformly spraying a composite syrup prepared from dissolvable components including emulsified fat powder, whey powder, milk powder, white granulated sugar, mycose, soyabean lecithin powder, calcium formate and the like to the surface of the particle materials by using a syrup spraying and dripping device. The nutrition of a product is fully balanced and the nutrition is complete; the soft particle milk replacer is easy to digest and absorb after multiple times of fermentation; the quality is stable; a process of combining a soft granulation system with a syrup spraying and dripping system is adopted so that the occurrence that particles become hard in a storage process of the particle feed is reduced; compared with a dry particle feed, the soft particle milk replacer has the advantages that the loss of the nutrition in a granulation heating and drying process is avoided, and the good palatability of the soft particle feed can also be kept.

Owner:LIAONING WELLHOPE AGRI TECH

Two-phase flow shell and tube heat exchanger and stabilizing device thereof

ActiveCN107062952ASpeed up the flowInhibit refluxSafety devices for heat exchange apparatusHeat exchanger casingsShell and tube heat exchangerGas phase

The invention provides a two-phase flow shell and tube heat exchanger and a stabilizing device thereof. The two-phase flow shell and tube heat exchanger comprises the sleeve type two-phase flow stabilizing device arranged on a fluid inlet pipe and / or a fluid outlet pipe of the heat exchanger. The two-phase flow stabilizing device comprises a core body, the core body comprises a plurality of concentric pipes and a plurality of fins, and the fins are connected with the adjacent concentric pipes. According to the two-phase flow shell and tube heat exchanger and the stabilizing device thereof, the passive two-phase flow stabilizing device with vibration and noise reduction functions can divide two-phase fluid into a liquid phase and a gas phase under the condition of not relying on external power or power sources, the liquid phase is divided into small liquid balls, the gas phase is divided into small bubbles, liquid phase back flowing is prohibited, smooth flowing of the gas phase is facilitated, the function of stabilizing the flow rate is achieved, and the vibration and noise reduction effects are achieved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Edible anti-hardening syrup and preparation method thereof

The invention relates to the field of processing technologies of edible syrups, and particularly relates to an edible anti-hardening syrup and a preparation method thereof, wherein the edible anti-hardening syrup is formed from the following raw materials in parts by weight: 80-120 parts of white granulated sugar, 30-50 parts of trehalose, 40-60 parts of malt syrup and 0.10-0.40 part of sucrose fatty acid ester. The preparation method comprises the steps of: (1) examining raw materials; (2) screening; (3) weighing; (4) boiling; and (5) packing to the obtain the finished product. Compared with the prior art, the edible anti-hardening syrup has the advantages that through reasonably collocating the materials with better water holding capacity, softness holding property and emulsification property, the prepared edible anti-hardening syrup is capable of replacing the components such as water, sucrose and the like in the traditional processing; and by using the edible anti-hardening syrup, the quality problem of short-time hardening of the prepared dry rice cake type foods can be solved.

Owner:东莞市圣心食品有限公司

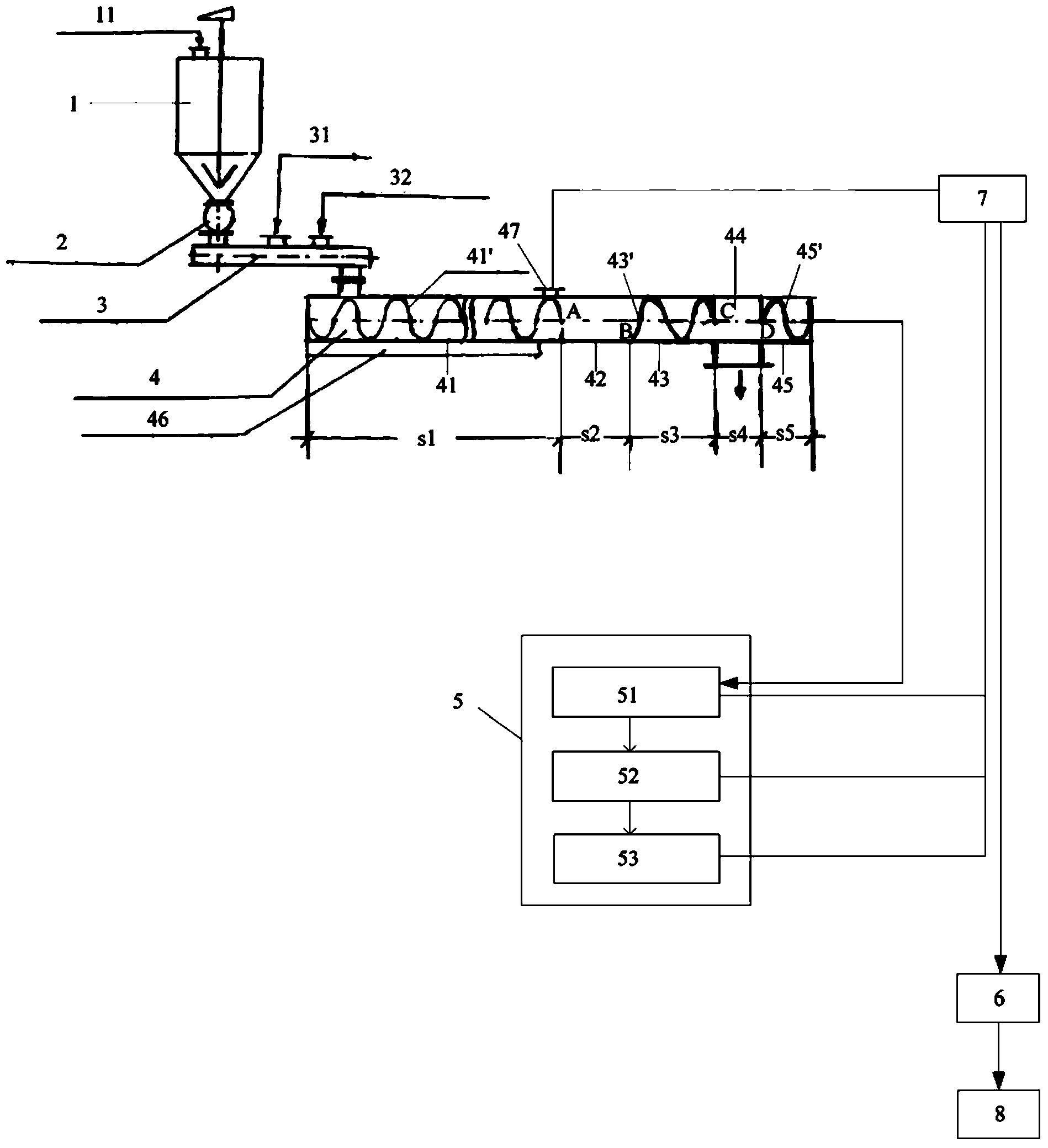

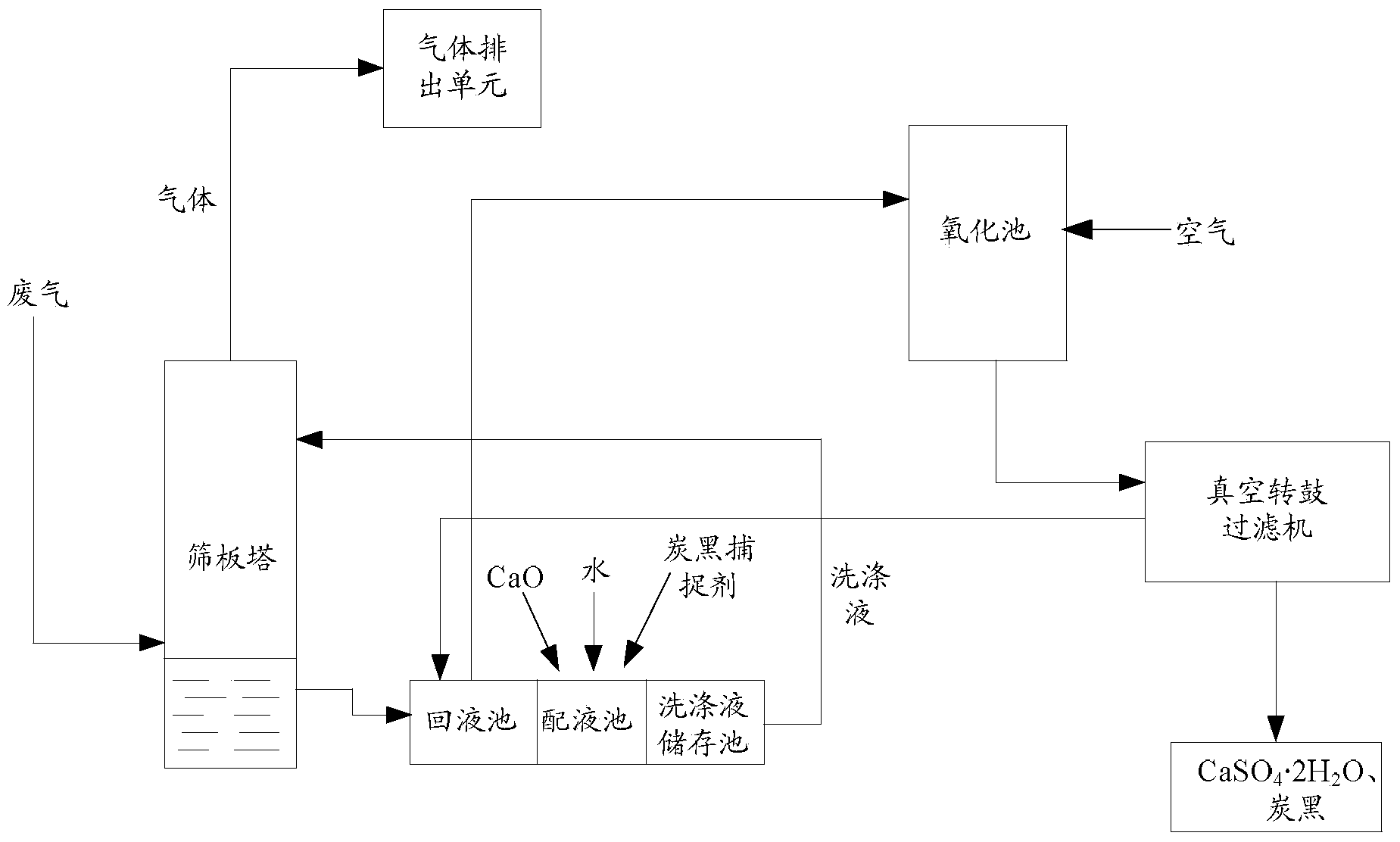

Waste tire continuous cracking equipment and technology for preventing generation of dioxin and catching carbon black

InactiveCN104073279AAvoid it happening againPrevent re-aggregationPigmenting treatmentProductsMixed feedingProcess engineering

The invention relates to a waste tire continuous cracking equipment and technology for preventing generation of dioxin and catching carbon black. The equipment comprises a stock bin, a mixed-feeding spiral conveyor, a preheating furnace, a continuous cracking device, a vacuumizing device, an oil-gas treatment device and a carbon black catching device, wherein the stock bin is connected with the mixed-feeding spiral conveyor, the preheating furnace and the continuous cracking device sequentially; the preheating furnace sequentially comprises a heating section, a sealing section, a forward thrust section and a discharging section from the flowing direction of a raw material, a spiral pusher is respectively arranged in the heating section and the forward thrust section, and a spiral pusher is not arranged in the sealing section; the continuous cracking device comprises a first cracking unit at the heating temperature of 340-360DEG C, a second cracking unit at the heating temperature of 440-460DEG C, and a third cracking unit at the heating temperature of 540-560DEG C, which are connected in sequence. According to the equipment and technology, the generation of dioxin in the treatment process of waste tires can be effectively prevented, the carbon black in a waste gas collection tube can be caught, the activity and quality of carbon black can be improved, and the continuous cracking production of waste tires can be realized.

Owner:中机国宏高分子技术研究(北京)中心

Single-layer graphene macromolecular composite epoxy resin adhesive and preparation method thereof

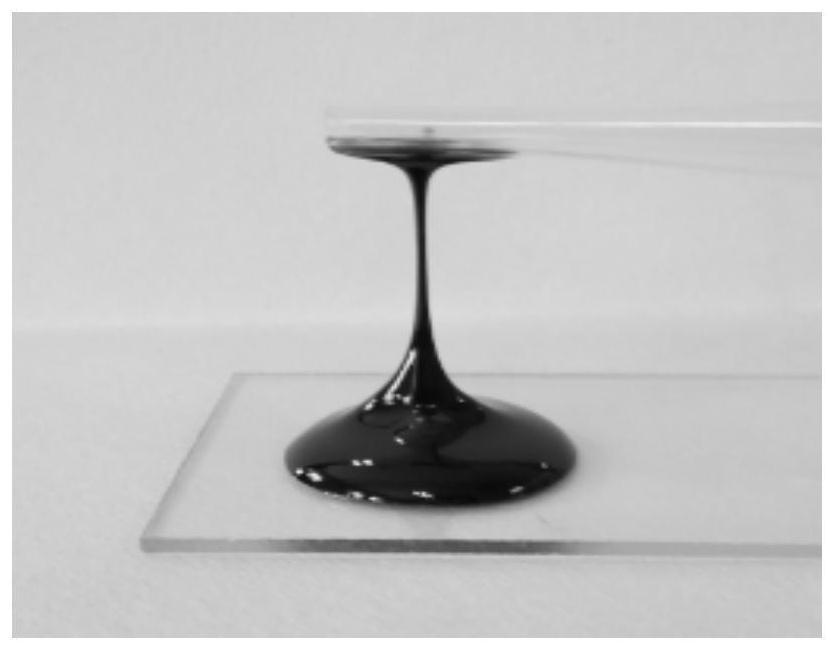

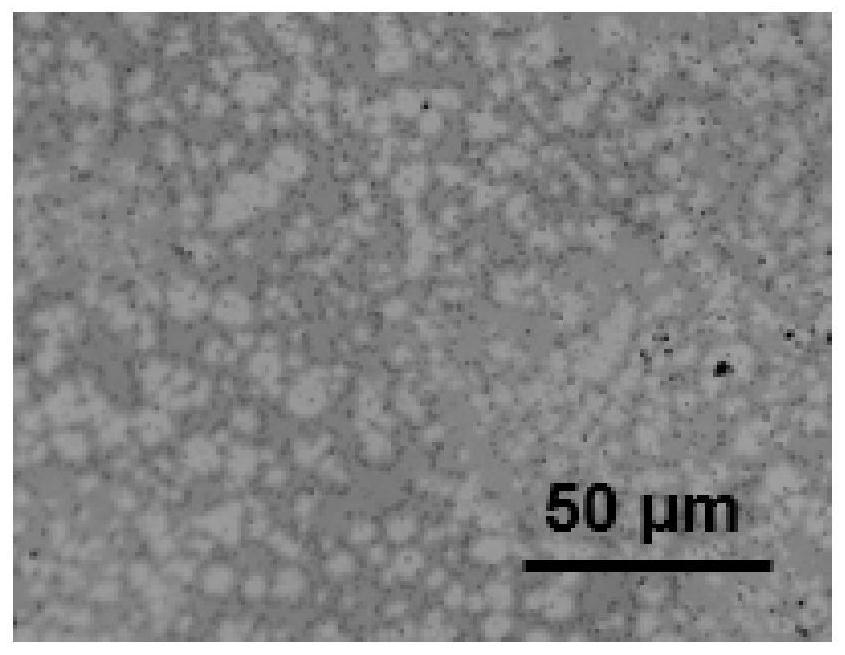

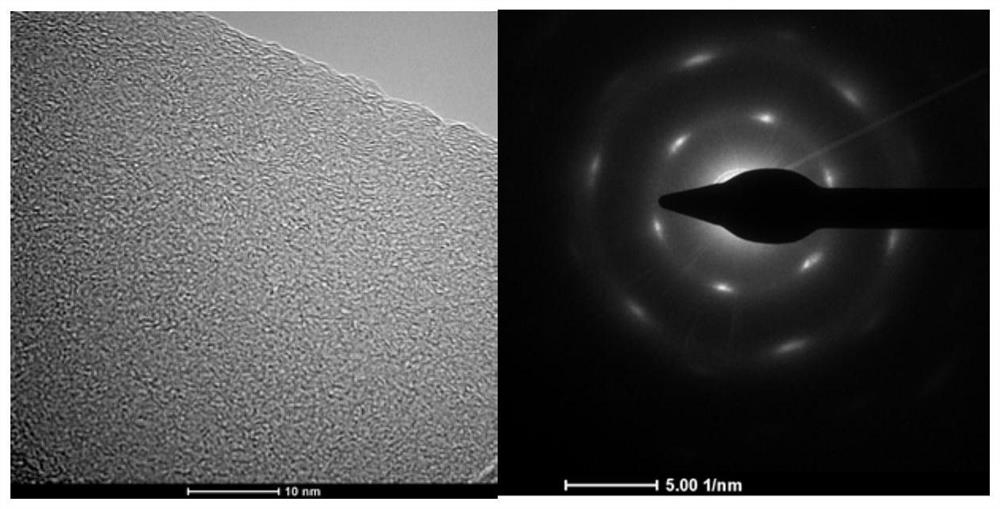

ActiveCN109161371APrevent re-aggregationAchieve highly uniform compoundingNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyOrganic solvent

The invention discloses a single-layer graphene macromolecular composite epoxy resin adhesive and a preparation method thereof. The method comprises the following steps: (1) preparing a solvated graphene film; (2) mixing the solvated graphene film with an epoxy resin solution, and then removing the solvent from the mixed solution to obtain the single-layer graphene macromolecular composite epoxy resin adhesive; wherein the graphene film is obtained by suction filtration of a single-layer graphene dispersion, and the single-layer graphene dispersion is obtained by direct thermal reduction or chemical reduction of single-layer graphene oxide. The solvent for the solvation is an organic solvent capable of simultaneously dispersing graphene and epoxy resin, such as dimethyl sulfoxide. The solvation completely avoids re-aggregation of the single-layer graphene, and ensures a single-layer structure. The single-layer graphene molecular composite epoxy resin adhesive can be obtained without using complicated technology. The graphene exists in a single layer rather than agglomerate in the adhesive, so a very small amount (0.01 wt%) of graphene can significantly improve the performance of the epoxy resin adhesive, such as adhesive property.

Owner:TSINGHUA UNIV

Preparation method of monodispersed nano-calcium carbonate with low surface energy

ActiveCN109850931ATo achieve the purpose of disaggregating secondary aggregatesLower surface energyCalcium/strontium/barium carbonatesMaterial nanotechnologyDepolymerizationFiltration

The invention provides a preparation method of monodispersed nano-calcium carbonate with low surface energy and relates to the technical fields of preparation and processing of nano-calcium carbonatepowder. The preparation method comprises the following steps: S1, preparing boiled nano-calcium carbonate pulp; S2, adding an aging agent into the boiled nano-calcium carbonate pulp prepared in S1, and carrying out aging treatment to obtain a nano-calcium carbonate aging suspension; and S3, adding a surface treating agent into the nano-calcium carbonate aging suspension prepared in S2 to carry outsurface treatment, and then, carrying out filtration pressing dehydrating, drying and smashing to obtain the monodispersed nano-calcium carbonate with low surface energy. According to the preparationmethod, due to the addition of the aging agent, secondary aggregate depolymerization is realized, meanwhile, the specific surface energy of a powder is greatly reduced, and a monodispersed nano-calcium carbonate product is achieved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY +1

Heat supply system pipeline scale removing agent and preparation method thereof

InactiveCN107164106AProtection hasEfficient removalInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSodium stearateSulfate

The present invention discloses a heat supply system pipeline scale removing agent, which comprises the following raw materials by weight: 3-7 parts of manganese sulfate, 4-8 parts of an acrylic acid copolymer, 0.5-1.5 parts of sodium stearate, 3-7 parts of a bactericide, 7-9 parts of a rust removing agent, 5-9 parts of a penetrating agent, 5-8 parts of a protein decomposing agent, and 3-6 parts of a scale inhibitor. According to the present invention, the heat supply system pipeline scale removing agent can effectively remove water scale existing in the pipeline for a long time, has advantages of strong scale removing and no secondary damage on the pipeline, can make the pipeline form the scale inhibition function, can delay the secondary formation of scale, can increase the service life of the pipeline, can ensure the smoothness of the pipeline, can effectively remove a variety of bacteria produced during the use process of the heat supply pipeline, and further has excellent comprehensive performance; the preparation method has characteristics of low material cost, easily available raw materials, and simple process; and the obtained product as the heat supply system pipeline scale removing agent has high practical value and good application prospects.

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

Preparation process of an aluminum-based graphene composite wear-resistant self-lubricating material

The invention discloses a preparation process of an aluminum-based graphene composite wear-resistant self-lubricating material. The preparation process steps are: S1: using a chemical expansion method to prepare flake graphite into a graphene oxide suspension; S2: adding the graphene oxide suspension to a suspension containing Soluble salt of copper to form a layered composite structure of graphene oxide and Cu2+, adding a strong reducing agent to the aqueous solution to reduce the middle functional groups and Cu2+ of graphene oxide into a mixture of graphene and simple copper; S3: the mixture of step S2 The mixture is static and filtered; dried in a vacuum heating furnace drying chamber, weighed and sealed for packaging; S4: after the aluminum alloy is melted, the composite of graphene and metal copper is forced to be placed in the aluminum alloy melt to heat up to a temperature higher than Melting point 120-150°C, keep warm for 20-50 minutes; S5: Cast the uniformly mixed aluminum and graphene liquid melt into various parts; copper plating on the surface of graphene not only prevents the aggregation of graphene layered structure, but also increases the concentration of graphene and graphene Wettability of aluminum alloys. Copper and aluminum alloys can be melted in any proportion.

Owner:深圳市中科创想科技有限责任公司 +1

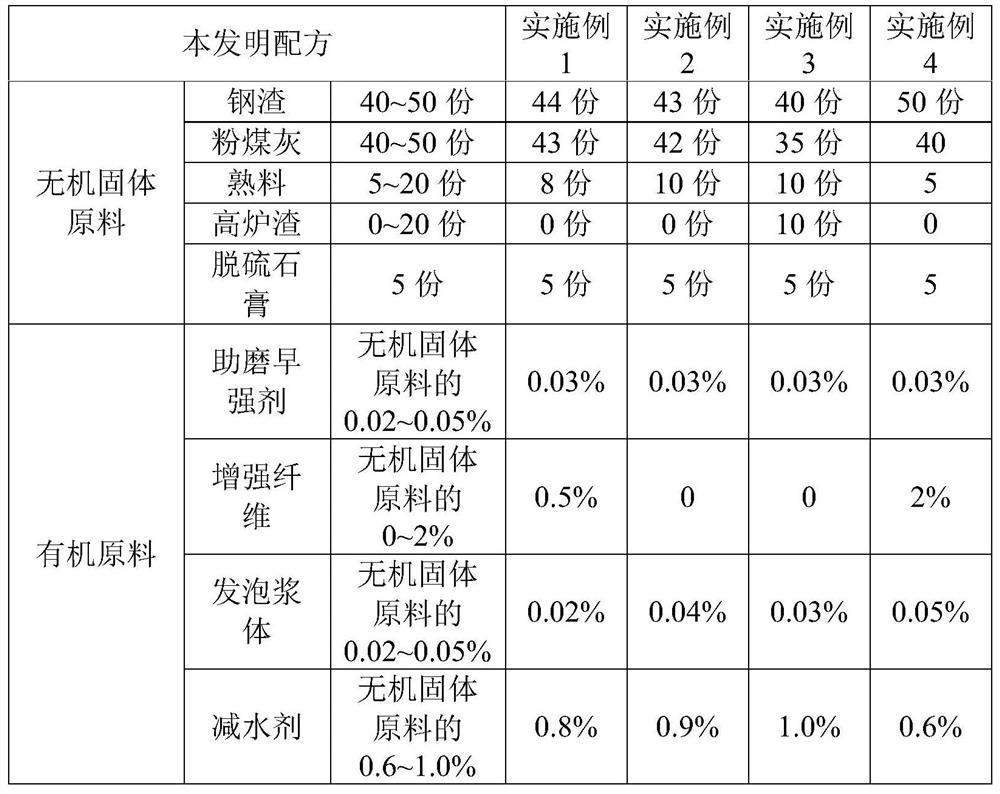

Method for preparing lightweight energy-saving building wall material from high-content steel slag

InactiveCN112919877AEliminate negative effectsImprove mechanical excitation effectSolid waste managementCeramicwareFiberSlag

The invention discloses a method for preparing a lightweight energy-saving building wall material by using high-content steel slag, and solves the problems of low utilization rate, low additional value and low consumption of the existing steel slag. The preparation method comprises the following steps: mixing 40-50 parts of steel slag, 10-20 parts of clinker, 0-20 parts of blast furnace slag, 40-50 parts of fly ash and 5 parts of desulfurized gypsum powder; performing mixing, adding 0.02-0.05% of a grinding-aid early strength agent, and performing fine grinding; adding 0-2% of reinforcing fibers into the mixture after fine grinding; mixing with foaming slurry, and adding a water reducing agent; after uniform stirring, pouring the mixture into a mold; curing the test piece for 1 day under the condition of constant humidity of 30 DEG C, performing demolding, performing curing for 3-6 days under the condition of constant humidity of 35-65 DEG C, and performing natural curing for 28 days to prepare the qualified light energy-saving wall material. The solid waste utilization rate can reach 90%, and the steel slag utilization rate can reach 42.5% or above.

Owner:安徽马钢嘉华新型建材有限公司 +1

Preparation method of viscous oil hydrothermal cracking catalysis viscosity reducer having double structures of hydrogen supply and metal catalysis center

The present invention discloses a preparation method of a viscous oil hydrothermal cracking catalysis viscosity reducer having double structures of hydrogen supply and metal catalysis center. The preparation method comprises: heating tetrahydronaphthalene to a temperature of 145-155 DEG C, adding concentrated sulfuric acid in a dropwise manner within 1 h, carrying out sulfonation, heating to a temperature of 155-165 DEG C, reacting for 2-3 h to obtain a tetrahydronaphthalene sulfonation product, adding water to the obtained tetrahydronaphthalene sulfonation product, adding a metal oxide, reacting for 1-1.5 h at a temperature of 105-115 DEG C, filtering, and evaporating to obtain the viscous oil hydrothermal cracking catalysis viscosity reducer having the double structures of hydrogen supply and metal catalysis center, wherein the metal oxide is any one selected from chromium oxide, ferric oxide, and nickel oxide. According to the present invention, the catalysis viscosity reducer has the hydrogen supply function, such that the hydrogen protons can be provided while the catalytic viscosity reducer catalyzes the cracking of the viscous oil macromolecule; and the chromium, iron or nickel metal center provides the catalytic cracking effect so as to effectively reduce the viscosity of the viscous oil and improve the quality of the viscous oil.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

A kind of soft particle creeper containing fructose syrup and its preparation

ActiveCN103385350BGreat tasteImprove palatabilityAnimal feeding stuffAdditive ingredientCalcium formate

The invention discloses a soft particle milk replacer containing a high fructose corn syrup, belonging to the technical field of a feed formula design and feed processing. The soft particle milk replacer is prepared by the following steps of: taking a compound fermented soybean meal which is prepared by sequentially mixing bacillus subtilis and a pickle fermentation solution to ferment, and rice as main materials; adding steam fish meal, flour, a peeled soybean meal and the like for match; carrying out ultrafine crushing on the materials and preparing particle materials by using a soft granulator; uniformly spraying a composite syrup prepared from dissolvable components including emulsified fat powder, whey powder, milk powder, white granulated sugar, mycose, soyabean lecithin powder, calcium formate and the like to the surface of the particle materials by using a syrup spraying and dripping device. The nutrition of a product is fully balanced and the nutrition is complete; the soft particle milk replacer is easy to digest and absorb after multiple times of fermentation; the quality is stable; a process of combining a soft granulation system with a syrup spraying and dripping system is adopted so that the occurrence that particles become hard in a storage process of the particle feed is reduced; compared with a dry particle feed, the soft particle milk replacer has the advantages that the loss of the nutrition in a granulation heating and drying process is avoided, and the good palatability of the soft particle feed can also be kept.

Owner:LIAONING WELLHOPE AGRI TECH

Printing dye formula and production process thereof

The invention discloses a printing dye formula and a production process thereof. The printing dye formula is mainly composed of, by weight part, 35-45 parts of acrylic resin, 15-25 parts of amino resin dyes, 10-15 parts of oil diluting solvent, 3-5 parts of slipping agent, 5-9 parts of coloring agent, 0.2-0.6 part of surfactant, 1-3 parts of ethyl alcohol, 5-7 parts of deionized water, 0.5-0.8 part of filler and 0.3-0.8 part of defoamer. The printing dye formula can improve the rubbing resistance and the fluidity, enhance glossiness of films and reduce paper picking; by adding the filler, thethickness as well as the rubbing resistance of films of the printing dye can be increased; the surfactant can improve the moisturizing performance of pigments and binders to avoid re-agglomeration ofprinting dye particles, ensure the uniformity of the printing dye and further improve the resistance of the printing dye; during application, the printing dye can effectively maintain functionality and greatly prolong the service life of printed articles.

Owner:平湖市飞豹印刷有限公司

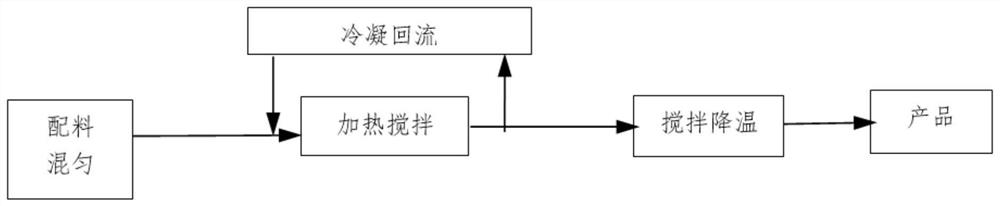

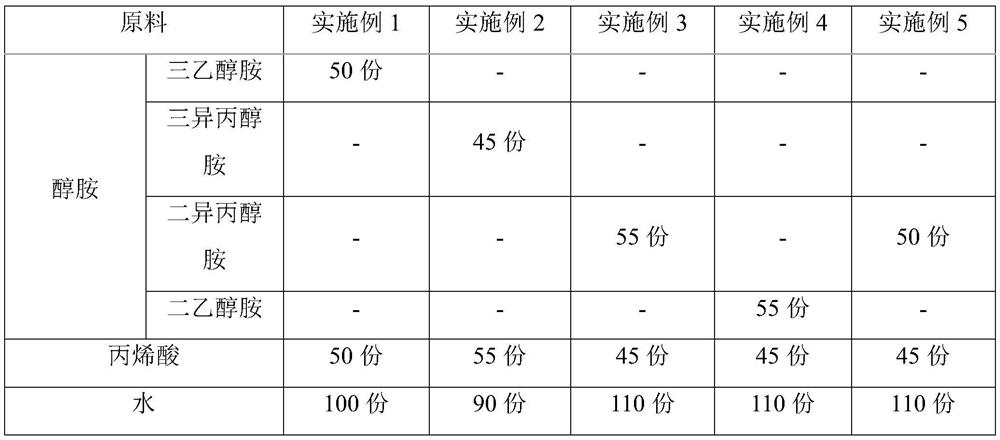

Modified grinding-aiding early strength agent for steel slag as well as preparation method and application method of modified grinding-aiding early strength agent

The invention discloses a modified grinding-aiding early strength agent for steel slag as well as a preparation method and an application method of the modified grinding-aiding early strength agent, and relates to the field of steel slag grinding aiding. The modified grinding-aid early strength agent comprises (a) 60%-75% of ester compounds based on the total weight of the modified grinding-aid early strength agent; (b) 5%-15% of polyacrylic acid based on the total weight of the modified grinding-aid early strength agent; (c) 10%-35% of alcohol amine and acrylic acid monomers based on the total weight of the modified grinding-aid early strength agent, the preparation method comprises the following steps: adding water into alcohol amine and acrylic acid, uniformly mixing, heating while stirring, reacting at 60-80 DEG C for 3-4 hours, and cooling the solution to room temperature to obtain the modified grinding-aiding early strength agent which is applied to grinding of a gel material with high doping amount of steel slag, so the problems of low grinding efficiency of an existing grinding aid, low activity of the steel slag in the early stage, complex synthesis process, high cost and the like are solved. The preparation process is simple, the raw material cost is low, the finished product quality and performance are stable, the use effect is good, and the 7d strength increase is greater than or equal to 30%.

Owner:安徽马钢嘉华新型建材有限公司 +1

Long-acting boiler scale remover and preparation method for same

InactiveCN106554854ALong-term protection functionPrevent re-aggregationOrganic detergent compounding agentsAnionic surface-active compoundsChemistryEnvironmental resistance

The invention discloses a long-acting boiler scale remover and a preparation method for same. The scale remover is composed of, by weight, 15-18 parts of lauryl sodium sulfate, 5-10 parts of sulfamic acid, 6-12 parts of dodecenyl succinic acid, 6-9 parts of lignin, 8-10 parts of sodium gluconate, 4-9 parts of vinyl bis-stearamide, 3-6 parts of aniline, 5-8 parts of polyacrylamide, 10-20 parts of ethylene glycol, 8-12 parts of sodium carbonate, and 200-300 parts of water. The boiler scale remover has the following advantages: 1) the scale remover is green, environment-friendly and pollution free and has no damages on environment and human body during production and usage; 2) the scale remover has excellent scale removal performance, can quickly remove the water scale in the interior of the boiler, and can form a protective layer on an inner wall of the boiler after use, so that accumulation rate of the water scale is reduced and maintenance cost is effectively reduced; and 3) the scale remover has low cost and simple components, is simplified and reasonable in selection on raw materials, has simple and convenient production process, and is suitable for large-scale application.

Owner:牛誉博

Ultrathin nata de coco slurry and preparation method thereof

The invention relates to ultrathin nata de coco slurry and a preparation method thereof. The ultrathin nata de coco slurry is prepared by talking nata de coco gel as a raw material, wherein a mean particle size of a solid matter is less than 100 microns. The preparation method of the ultrathin nata de coco slurry comprises the following steps: at first, quickly freezing the nata de coco gel; secondly, breaking the frozen nata de coco gel; thirdly, adding small particles of the broken nata de coco gel to a mixture of ice and water; fourthly, adding glycerol; and finally, preparing the ultrathin nata de coco slurry through high-pressure homogenization. Before the high-pressure homogenization, a thickening agent can be further added into the mixture of the ice and the water. The preparation method of the ultrathin nata de coco slurry provided by the invention can crush nata de coco into ultrathin particles, and can effectively prevent the ultrathin nata de coco particles from being repeatedly polymerized, so that the ultrathin nata de coco slurry with white color, stable quality and good taste and processing property can be produced. The preparation method of the ultrathin nata de coco slurry provided by the invention can be conveniently and widely applied to producing various food products.

Owner:HAINAN YEGUO FOODS

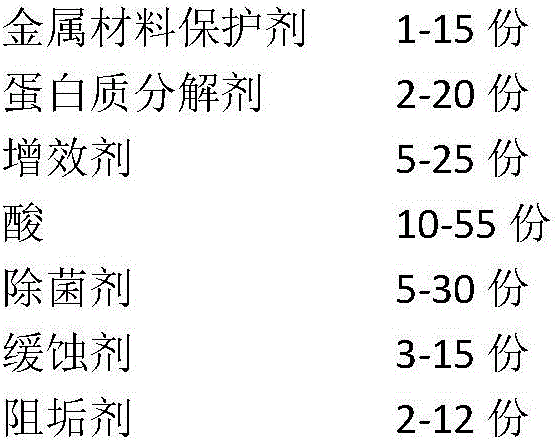

A geothermal system pipeline descaling agent and preparation method thereof

InactiveCN104909472BHigh activityEfficient removalTreatment using complexing/solubilising chemicalsEscherichia coliDecomposition

The invention discloses a scale remover for pipelines of a geothermal system and a preparation method thereof. The scale remover comprises the following components by mass: 1 to 15 parts of a metal material protective agent, 2 to 20 parts of a protein decomposition agent, 5 to 25 parts of a synergist, 10 to 55 parts of acid, 5 to 30 parts of a degerming agent, 3 to 15 parts of a corrosion inhibitor and 2 to 12 parts of a scale inhibitor. According to the scale remover for pipelines of the geothermal system and the preparation method thereof in the invention, through improvement of the composition of the scale remover and increase of protein clastic enzyme in the composition, a variety of bacteria such as a plurality of pathogenic bacteria like Escherichia coli, Clostridium botulinum, Salmonella and Shigella produced during usage of the geothermal pipelines can be effectively removed; and in consideration of the fact that a plurality of protein clastic enzymes are suitable for living in a neutral environment, the protein clastic enzyme is ultimately added in the preparation process, so high activity of the protein clastic enzyme is guaranteed, and good descaling effect is obtained.

Owner:北京市地热研究院

Heat exchanger system provided with multiple two-phase flow stabilizing devices and pipeline of heat exchanger system

The invention provides a heat exchanger system provided with a plurality of two-phase flow stabilizing devices and a pipeline of the heat exchanger system. The two-phase flow stabilizing devices are arranged in the pipeline; each of the two-phase flow stabilizing devices comprises a core body; the core body can divide two phase flow runners in the pipeline into a plurality of small runners; and the two-phase flow stabilizing devices are continuously arranged or arranged at intervals. According to the invention, the two-phase flow stabilizing devices are continuously arranged or arranged at intervals, so that the liquid phase and the gaseous phase can be separated through a plurality of stages and steps, heat transfer can be further enhanced, and the effects of vibration and noise reduction are realized.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

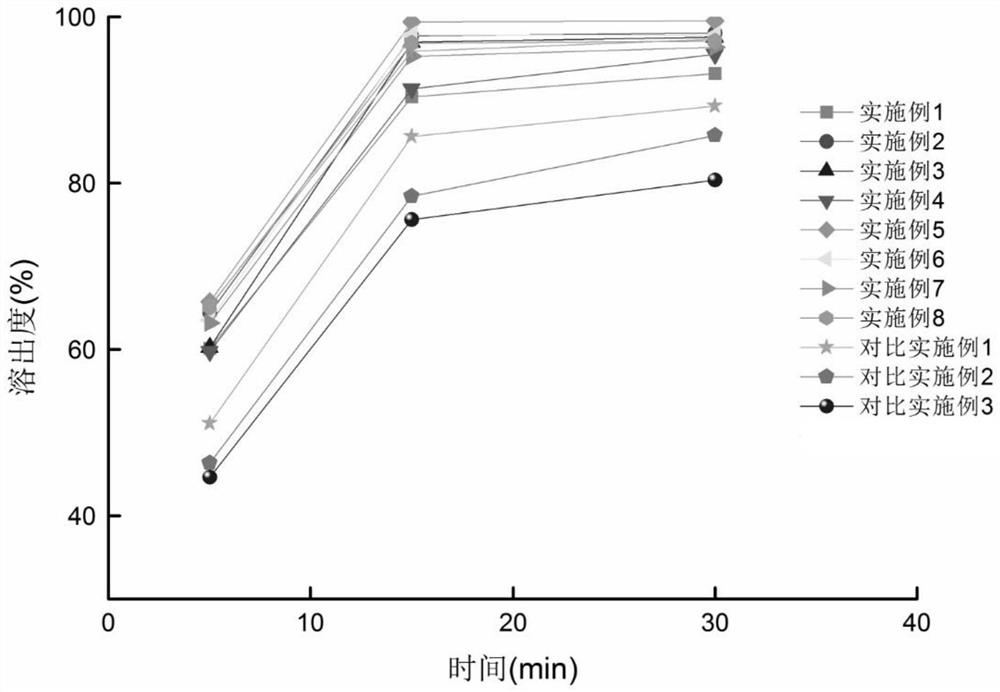

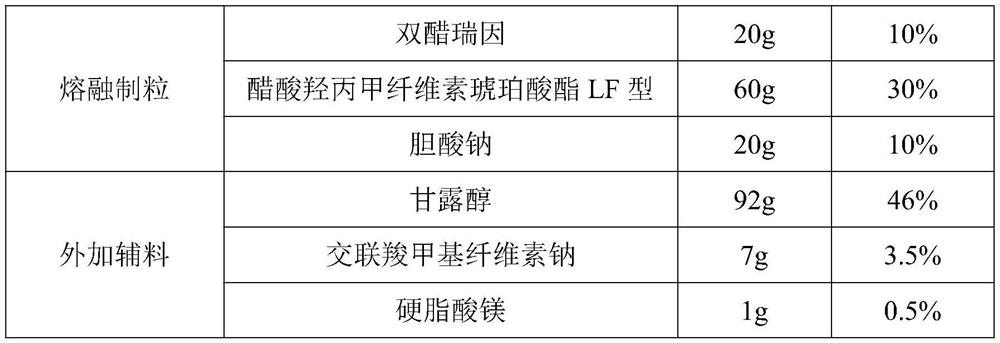

Diacerein capsule with high bioavailability and preparation method thereof

PendingCN114796149AProcess stabilityThe process is simple and easy to controlOrganic active ingredientsAntipyreticCaplet Dosage FormActive agent

The invention discloses a diacerein capsule and a preparation method thereof, and belongs to the technical field of pharmaceutical preparations. The capsule is composed of a content and a capsule shell, the content comprises enteric drug particles, a filler, a disintegrating agent and a lubricant, and the enteric drug particles are prepared by uniformly mixing, hot-melting, extruding and crushing the following components in percentage by mass: 10-40% of diacerein, 50-80% of an enteric polymer carrier material and 5-20% of a surfactant. The enteric polymer carrier contained in the capsule can inhibit recrystallization of diacerein in gastrointestinal tracts, so that the bioavailability is improved, and adverse reactions are reduced. Dissolution tests and beagle in-vivo pharmacokinetic tests show that the diacerein capsule prepared by the invention is good in dissolution effect and high in bioavailability.

Owner:SUZHOU CHUNGHWA CHEM & PHARMA IND

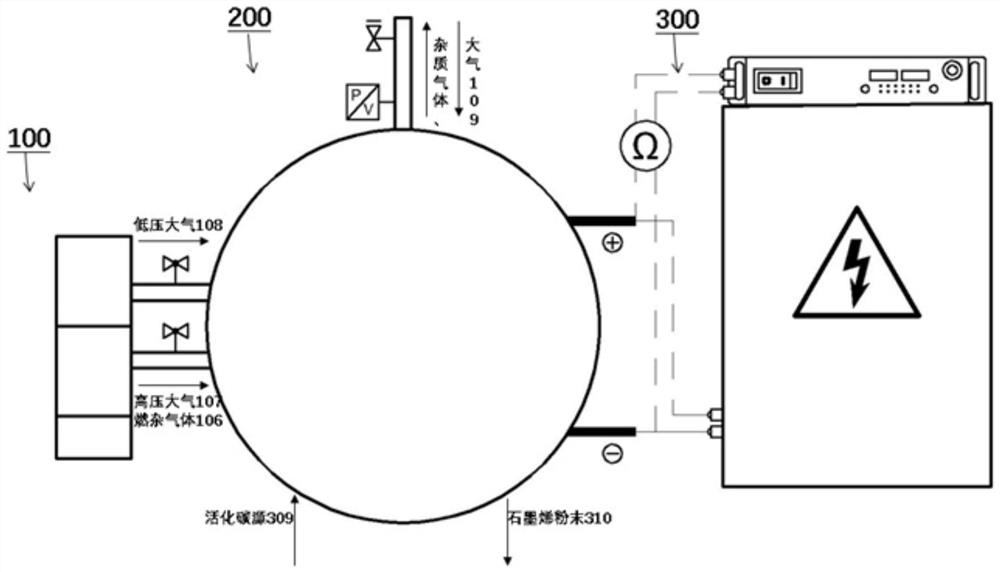

A kind of device and method for preparing graphene powder

ActiveCN112607731BImprove responseFully strong current pulse discharge responseGrapheneActivated carbonGraphite

A device for preparing graphene powder, the reaction chamber is connected to the atmosphere generating component; the high-energy discharge component includes a graphene synthesis tube, a first electrode and a second electrode installed at both ends of the graphene synthesis tube, a main controller, an adjustable output power supply and Feed assembly; the graphene synthesis tube, the first electrode and the second electrode are all arranged in a sealed dish, and the first electrode and the second electrode form a ventilation structure with the graphene synthesis tube; the graphene synthesis tube is provided with a carbon source chamber and In the graphene powder chamber, the carbon source chamber is provided with a carbon source addition port; the feeding component is connected to the first control conductive copper column and the second control conductive copper column, and the feeding component is also connected to the adjustable output power supply and the second electrode; the first The electrodes are electrically connected to the main controller, and the main controller is connected to the adjustable output power supply; the second electrode is electrically connected to the adjustable output power supply. The present invention uses lignin as a carbon source, adds a carbon source additive and mixes an activated carbon source, and generates graphene powder under the action of a strong current pulse discharge.

Owner:GUANGDONG UNIV OF TECH

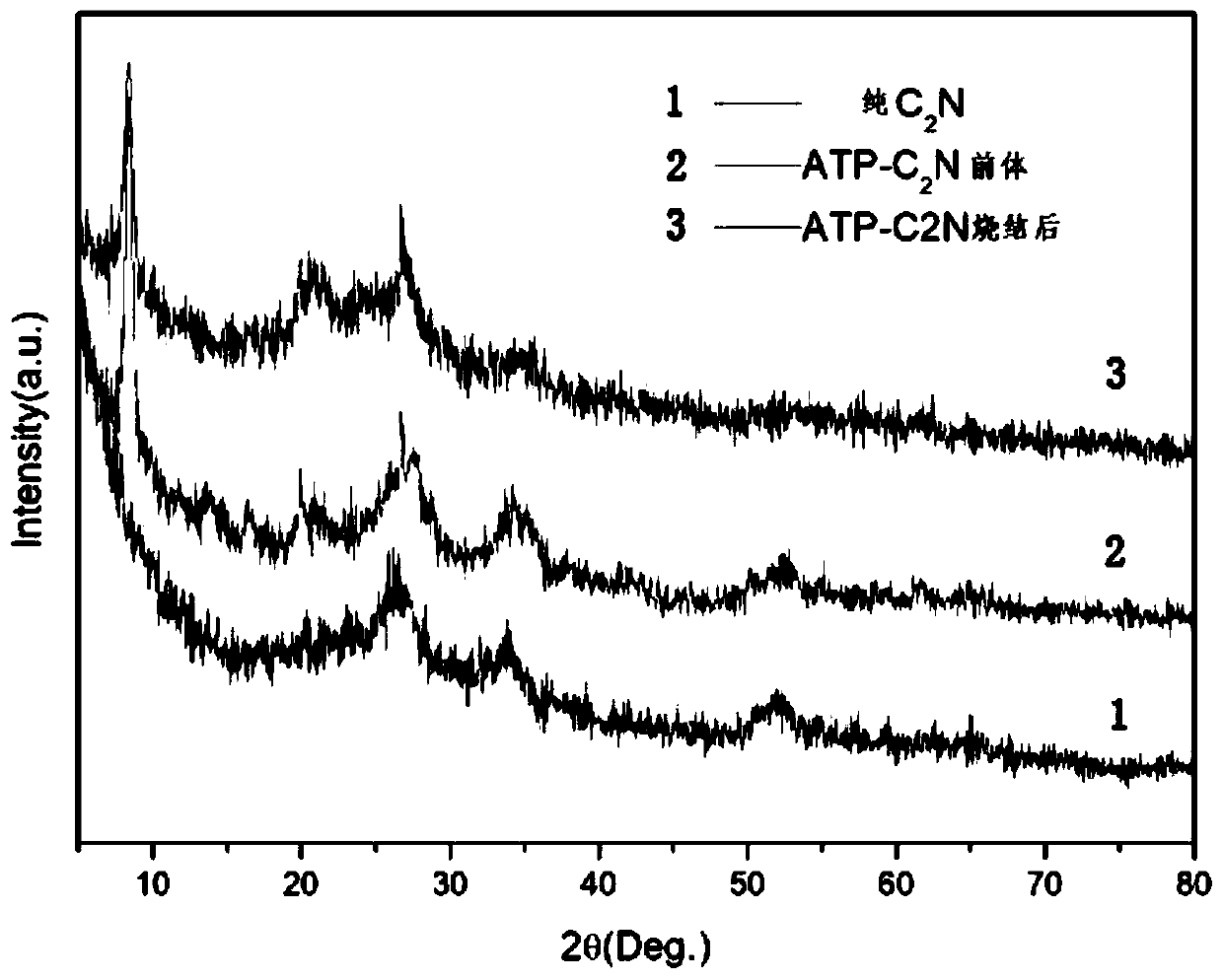

Attapulgite/C2N one-dimensional/two-dimensional composite, preparation method and application

ActiveCN110404570AEffective exposurePrevent re-aggregationPhysical/chemical process catalystsWater/sewage treatment by irradiationChemical reactionThin layer

The invention provides a preparation method of an attapulgite / C2N one-dimensional / two-dimensional composite. A two-dimensional C2N thin layer is supported on the surface of one-dimensional attapulgitethrough an in-situ chemical reaction, secondary aggregation of the C2N thin layer is effectively inhibited, the specific surface area of the thin layer is increased while active sites are effectivelyexposed, and the novel attapulgite / C2N one-dimensional / two-dimensional composite with excellent optical and electrical performance is obtained.

Owner:HUAIYIN TEACHERS COLLEGE

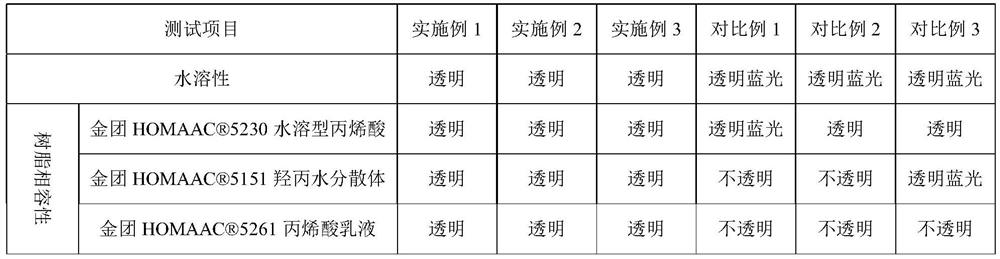

A kind of water-based polymer nano-iron oxide dispersant and preparation method thereof

ActiveCN112266465BExcellent wetting and anchoring effectIncrease stickinessCoatingsPigment pastesPolymer sciencePtru catalyst

Owner:KITO CHEM CO LTD

A sludge drying and feeding device and feeding method

ActiveCN112094027BIncrease moisture contentHigh viscositySludge treatment by de-watering/drying/thickeningSludgeProcess engineering

Owner:山东达源环保工程有限公司

A heat exchanger system with multiple two-phase flow stabilization devices and its pipelines

ActiveCN106767088BImprove heat transfer performanceHas the effect of reducing vibration and noiseTubular elementsEngineeringNoise reduction

The invention provides a heat exchanger system provided with a plurality of two-phase flow stabilizing devices and a pipeline of the heat exchanger system. The two-phase flow stabilizing devices are arranged in the pipeline; each of the two-phase flow stabilizing devices comprises a core body; the core body can divide two phase flow runners in the pipeline into a plurality of small runners; and the two-phase flow stabilizing devices are continuously arranged or arranged at intervals. According to the invention, the two-phase flow stabilizing devices are continuously arranged or arranged at intervals, so that the liquid phase and the gaseous phase can be separated through a plurality of stages and steps, heat transfer can be further enhanced, and the effects of vibration and noise reduction are realized.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

A kind of preparation method of ionic liquid type heavy oil catalytic viscosity reducer

The invention relates to a preparation method of a thickened oil catalyzing viscosity reducer, in particular to a preparation method of an ionic liquid type thickened oil catalyzing viscosity reducer with a hydrogen supply and aromatic ring binuclear catalyzing center. The preparation method is characterized by comprising the following steps: (1) taking N, N-dimethylformamide as a reaction solvent, adding 1,4-dibromo butane in 4-picoline, reacting for 24-30 hours while stirring at the temperature of 80-90 DEG C, separating liquid, and taking lower-layer liquid; and (2) adding SbBr3 into the lower-layer liquid, reacting for 10-30 minutes at the temperature of 70-90 DEG C, and drying the product under vacuum to obtain the ionic liquid type thickened oil catalyzing viscosity reducer with the hydrogen supply and aromatic ring binuclear catalyzing center, wherein the molar ratio of the 1,4-dibromo butane, the 4-picoline, SbBr3 and the N, N-dimethylformamide is 1:2.0-2.2:0.9-1.1:10-12. The viscosity reducer prepared by the method has good viscosity reducing effect on thickened oil.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

A kind of single-layer graphene macromolecule composite epoxy resin adhesive and preparation method thereof

ActiveCN109161371BPrevent re-aggregationAchieve highly uniform compoundingNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyPolymer science

The invention discloses a single-layer graphene macromolecular composite epoxy resin adhesive and a preparation method thereof. The method comprises the following steps: (1) preparing a solvated graphene film; (2) mixing the solvated graphene film with an epoxy resin solution, and then removing the solvent from the mixed solution to obtain the single-layer graphene macromolecular composite epoxy resin adhesive; wherein the graphene film is obtained by suction filtration of a single-layer graphene dispersion, and the single-layer graphene dispersion is obtained by direct thermal reduction or chemical reduction of single-layer graphene oxide. The solvent for the solvation is an organic solvent capable of simultaneously dispersing graphene and epoxy resin, such as dimethyl sulfoxide. The solvation completely avoids re-aggregation of the single-layer graphene, and ensures a single-layer structure. The single-layer graphene molecular composite epoxy resin adhesive can be obtained without using complicated technology. The graphene exists in a single layer rather than agglomerate in the adhesive, so a very small amount (0.01 wt%) of graphene can significantly improve the performance of the epoxy resin adhesive, such as adhesive property.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com