Waste tire continuous cracking equipment and technology for preventing generation of dioxin and catching carbon black

A technology for waste tires and carbon black, which is applied in the field of continuous pyrolysis equipment and process of waste tires, can solve the problems of difficult capture of carbon black, air pollution, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

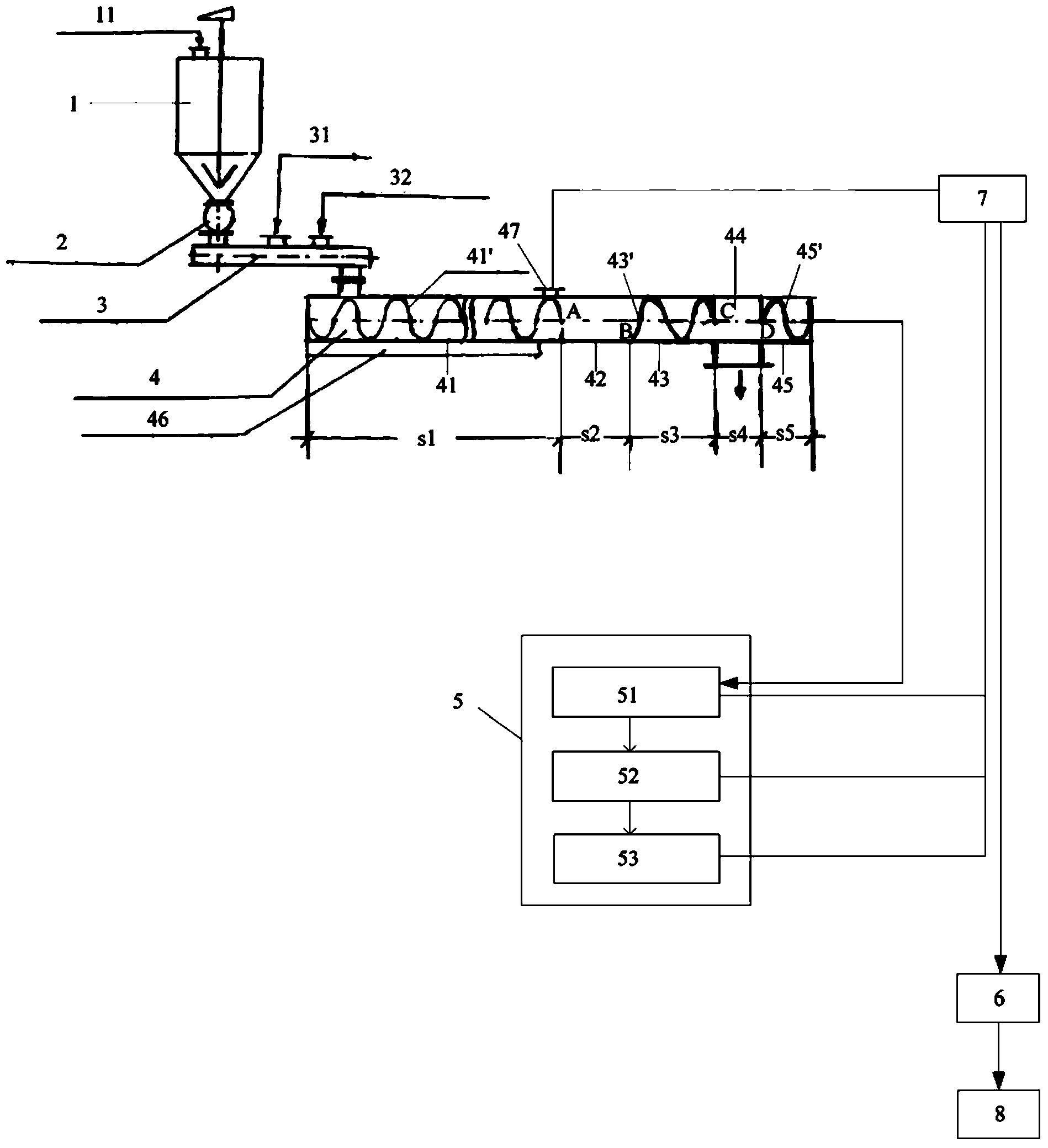

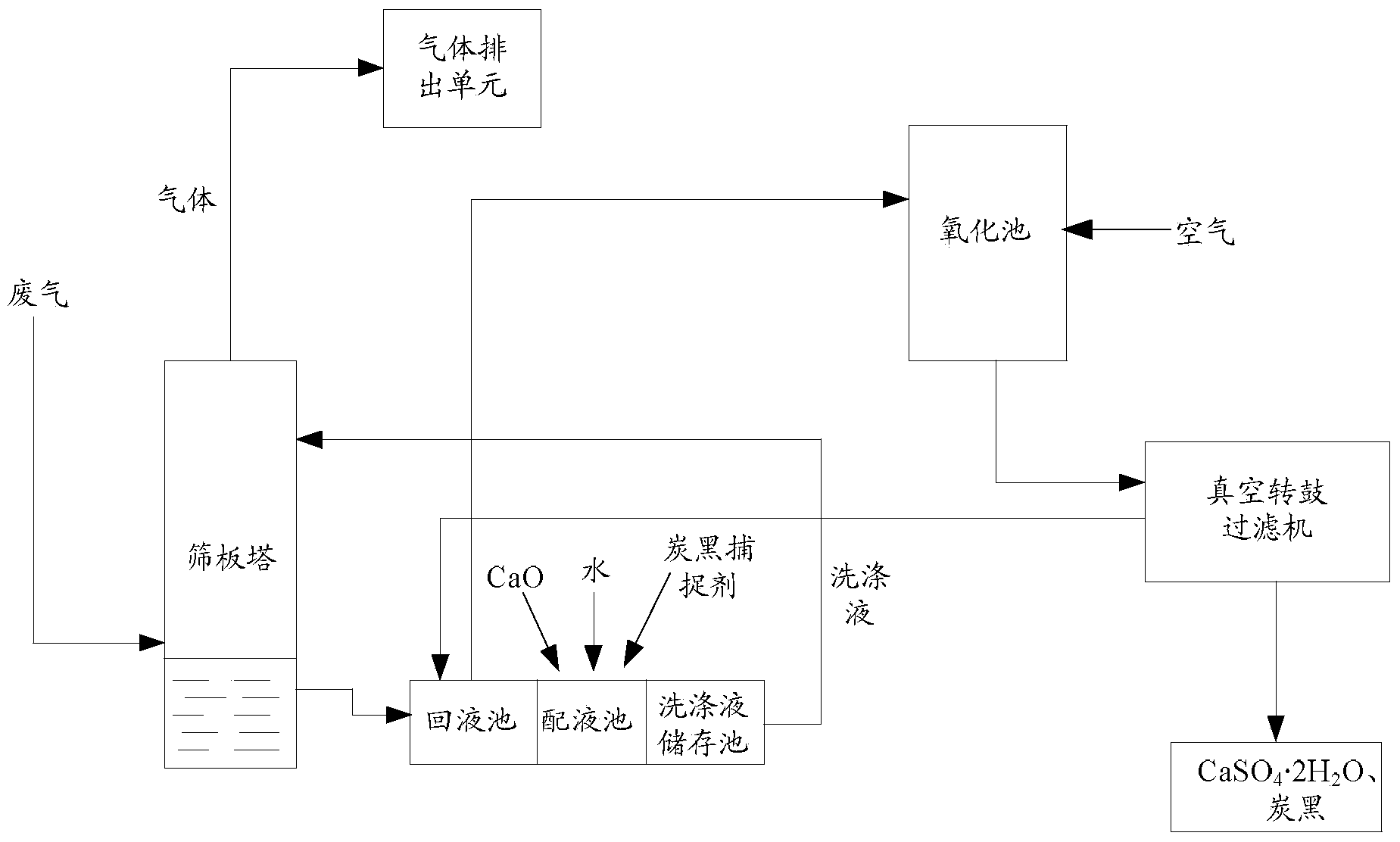

[0123] use figure 1 The waste tire continuous pyrolysis equipment (wherein the heating section 41 of the preheating furnace 4, the sealing section 42, the forward advancing section 43, the feeding section 44 and the reverse advancing section 45) of the waste tire continuous pyrolysis equipment for preventing dioxin generation and capturing carbon black The length ratio is 19:1:1.5:1.5:1) to process waste tire materials. First, waste tires are processed into small rubber blocks with steel wires of about 1 to 2 cm, and then enter the raw material bin 1 through the raw material inlet 11, and then the raw materials enter the mixing and feeding screw conveyor 3 through the sealed feeder 22, and are conveyed by the mixing and feeding screw Catalyst inlet 31 and reuse high-temperature carbon black inlet 32 of device 3, add respectively the high-temperature carbon black that the waste tire cracking catalyst and waste tire pyrolysis produce, then the material enters the preheating fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com