Modified grinding-aiding early strength agent for steel slag as well as preparation method and application method of modified grinding-aiding early strength agent

An application method and early strength agent technology, applied in the field of steel slag modified grinding early strength agent and its preparation, can solve the problems of low molecular weight of early strength agent, poor grinding aid function, difficult steel slag utilization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

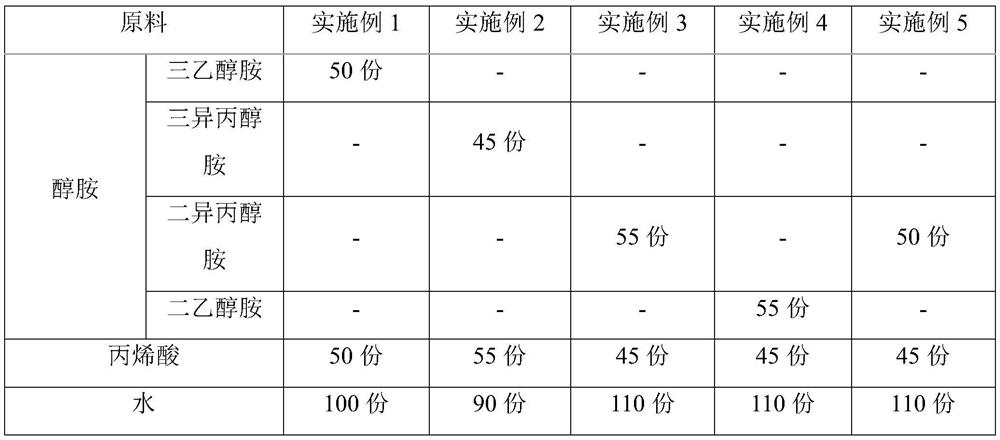

[0051] A modified grinding aid early-strength agent with steel slag, the weight parts of raw materials included in it are:

[0052] 50 parts of triethanolamine;

[0053] 50 parts of acrylic acid;

[0054] 100 parts of water;

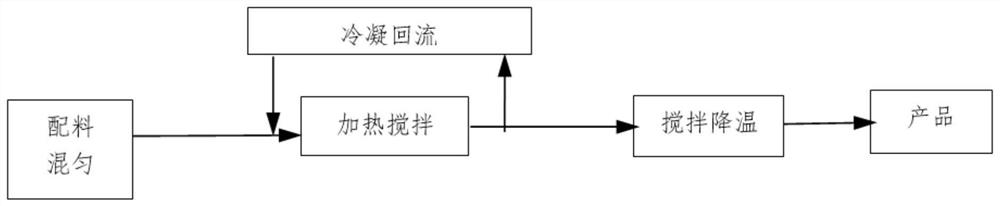

[0055] Preparation methods such as figure 1 The flow chart includes the following steps:

[0056] (1) Take the raw materials according to the proportion, put into the round bottom flask and mix evenly;

[0057] (2) Put the round bottom flask into a magnetic stirrer with a rotating speed of 500r / min and a temperature of 70°C, add a condensing reflux device, and react for 3.5h;

[0058] (3) Stop heating, continue stirring, and wait for the solution to cool down to room temperature to obtain a modified grinding aid early strength agent.

[0059] The modified grinding aid early-strength agent of the present embodiment is detected as figure 2 Shown, of which, 3628cm -1 O-H absorption peak at 3363cm -1 N-H absorption peak at 1734cm -1 The place is C=...

Embodiment 2

[0061] A modified grinding aid early strength agent with steel slag is characterized in that the parts by weight of the raw materials it includes are:

[0062] 45 parts of triisopropanolamine;

[0063] 55 parts of acrylic acid;

[0064] 90 parts of water;

[0065] Preparation methods such as figure 1 The flow chart includes the following steps:

[0066] (1) Take the raw materials according to the proportion, put into the round bottom flask and mix evenly;

[0067] (2) Put the round bottom flask into a magnetic stirrer with a rotating speed of 400r / min and a temperature of 60°C, add a condensing reflux device, and react for 3h;

[0068] (3) Stop heating, continue stirring, and wait for the solution to cool down to room temperature to obtain a modified grinding aid early strength agent.

[0069] In the modified grinding aid and early strength agent product obtained in this embodiment, liquid chromatography measures, among the organic matter, the ester compound accounts for ...

Embodiment 3

[0071] A modified grinding aid early strength agent with steel slag is characterized in that the weight parts of the raw materials it includes are:

[0072] 55 parts of diisopropanolamine;

[0073] 45 parts of acrylic acid;

[0074] 110 parts of water;

[0075] Preparation methods such as figure 1 The flow chart includes the following steps:

[0076] (1) Take the raw materials according to the proportion, put into the round bottom flask and mix evenly;

[0077] (2) Put the round bottom flask into a magnetic stirrer with a rotating speed of 600r / min and a temperature of 80°C, add a condensing reflux device, and react for 4h;

[0078] (3) Stop heating, continue stirring, and wait for the solution to cool down to room temperature to obtain a modified grinding aid early strength agent.

[0079] In the modified grinding aid early-strength agent product obtained in this embodiment, liquid chromatography measures, among organic matters, ester compound accounts for 74.6% by mass,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com