Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

252results about How to "Concentrated particle size distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

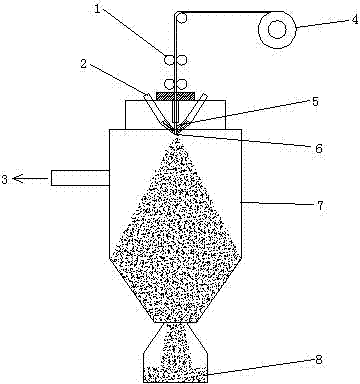

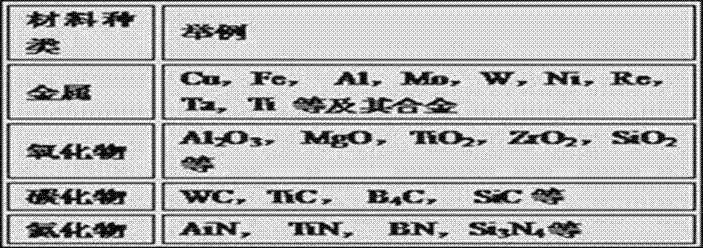

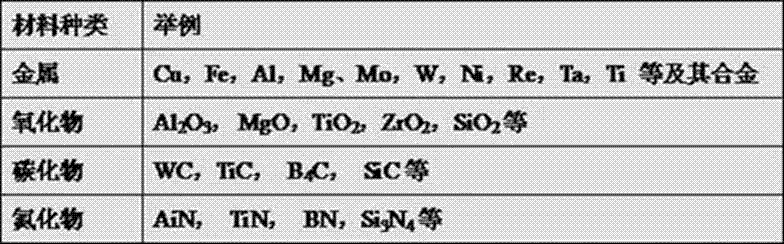

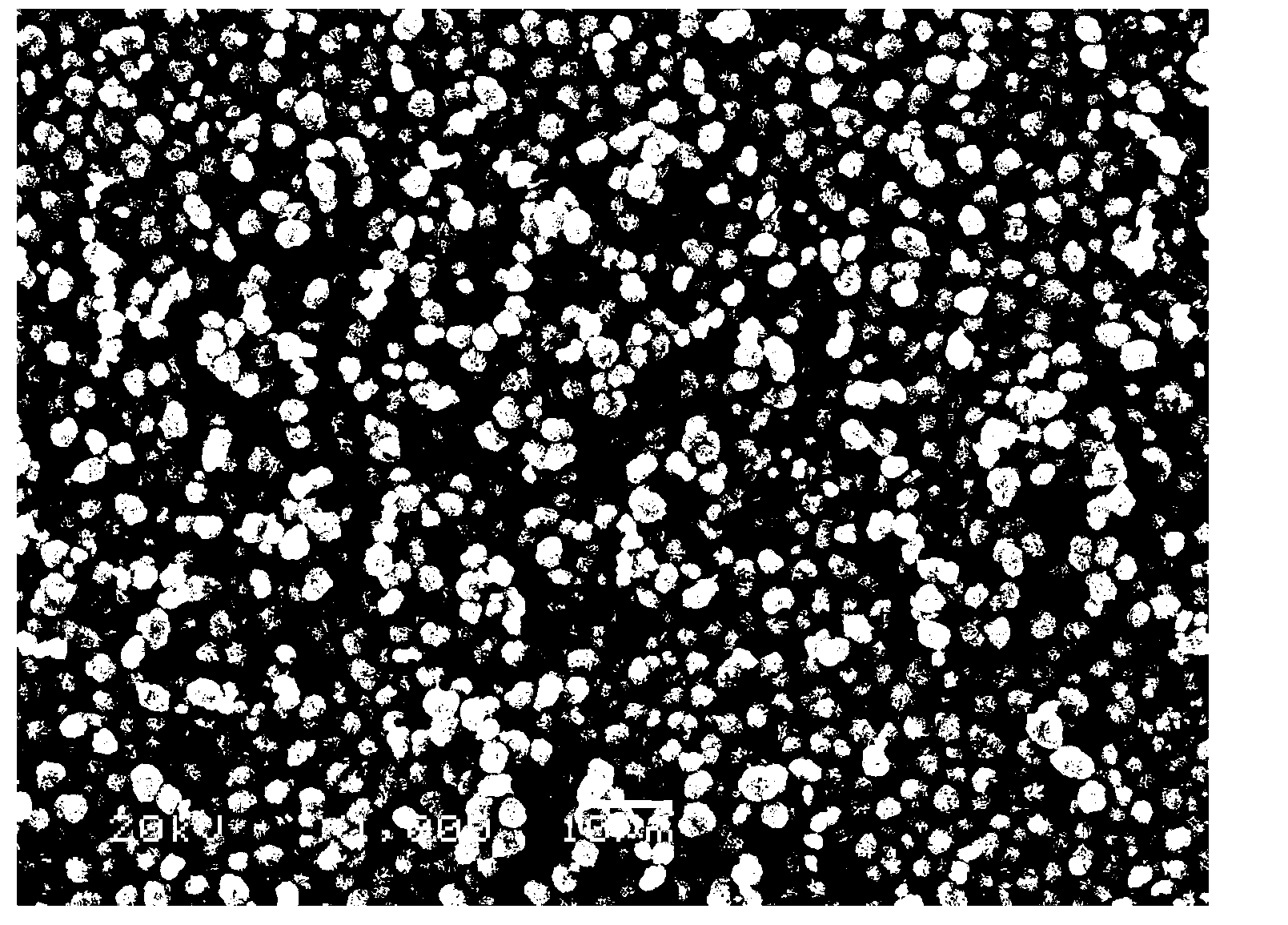

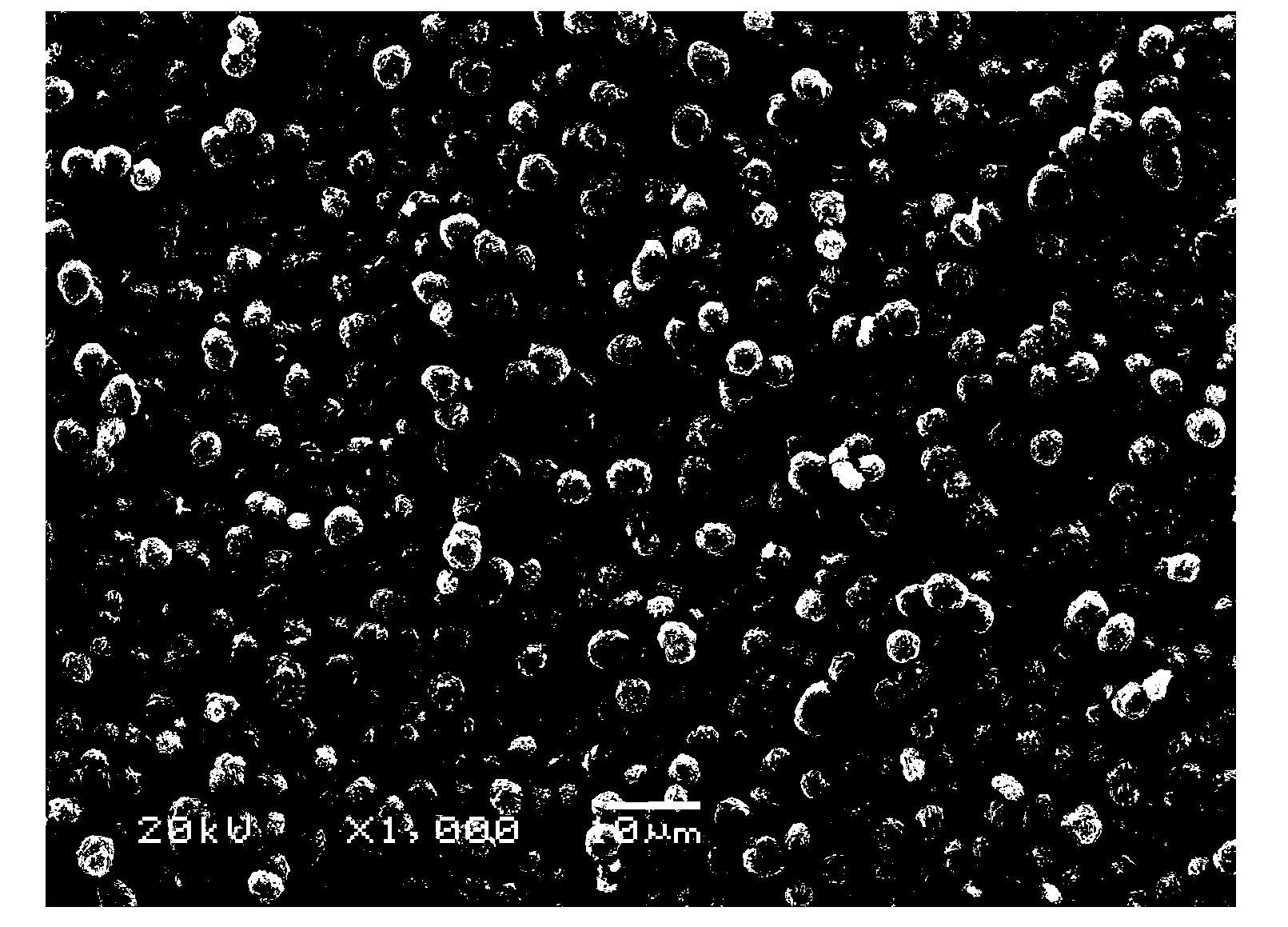

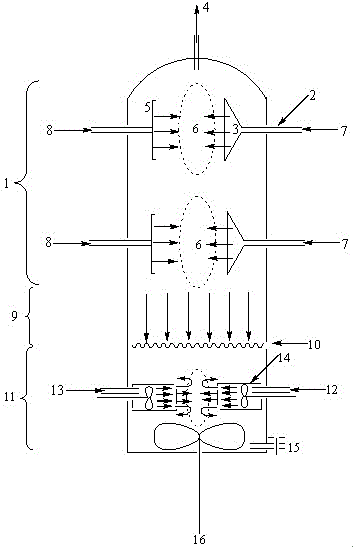

Technological method and device for preparing high-purity spherical superfine/nanoscale powdered materials in plasma atomization mode

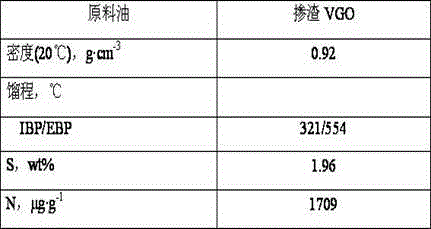

InactiveCN103769594AHigh purityConcentrated particle size distributionNanotechnologyChemical purityPlasma torch

The invention discloses a technological method and device for preparing high-purity spherical superfine / nanoscale powdered materials in a plasma atomization mode. The device comprises a feeding system, symmetric plasma torches, a vacuum system, a metal wire reel, metal wires, a plasma focus, an atomization tower, a powder collection device, a gas-powder separation system, a powder collection system and a gas purification cyclic utilization system, wherein the gas-powder separation system, the powder collection system and the gas purification cyclic utilization system are connected with the powder collection device. The technological method is characterized by comprising the steps that solid raw materials such as bars, wires and powder particle raw materials, or liquid raw materials or gas raw materials are utilized for being directly fed into a plasma focus area through a special feeding device, the plasma focus area is formed by the plasma torches, the temperature can reach up to 10000 K, the raw materials are instantly liquefied or vaporized or achieve thermal reaction decomposition / synthesis at the high temperature, and are dispersed and atomized by high-speed impact of plasma to form superfine liquid drops or aerial fog, in the flight sedimentation process in the atomization tower, heat exchange is conducted between the superfine liquid drops or aerial fog and cooling argon continuously fed into the atomization tower, and the superfine liquid drops or aerial fog is cooled and solidified into the various high-chemical-purity spherical superfine / nanoscale powdered materials.

Owner:王利民

Method for preparing small-size nickel-cobalt lithium manganate precursor

ActiveCN103253717ARealize industrial productionConcentrated particle size distributionManganese oxides/hydroxidesNickel oxides/hydroxidesManganateManganese

The invention relates to a method for preparing a small-size nickel-cobalt lithium manganate precursor. The method is characterized by comprising the following steps of: (1) preparing a solution from soluble salts of nickel, cobalt and manganese as materials, adopting a sodium hydroxide water solution as a precipitator, and adopting ammonia water or ammonium salt as a complexing agent; (2) merging and adding the obtained three solutions into a reaction kettle which contains bottom water and includes stirring and temperature control devices; leading in nitrogen to protect in a reaction process, and continuously carrying out reaction; and (3) stirring and aging for 4-6 hours after a temporary kettle is full, putting the aged material into washing and press filtering equipment to wash; removing moisture in a filter pressing manner; and then mixing and sieving by a 200mesh screen after baking and crushing. By adopting the method disclosed by the invention, industrialized production of the small-size nickel-cobalt lithium manganate precursor can be conveniently achieved; and the method is stable to control the particle size, and convenient to achieve requirements of the materials and equipment.

Owner:宁夏中色金辉新能源有限公司

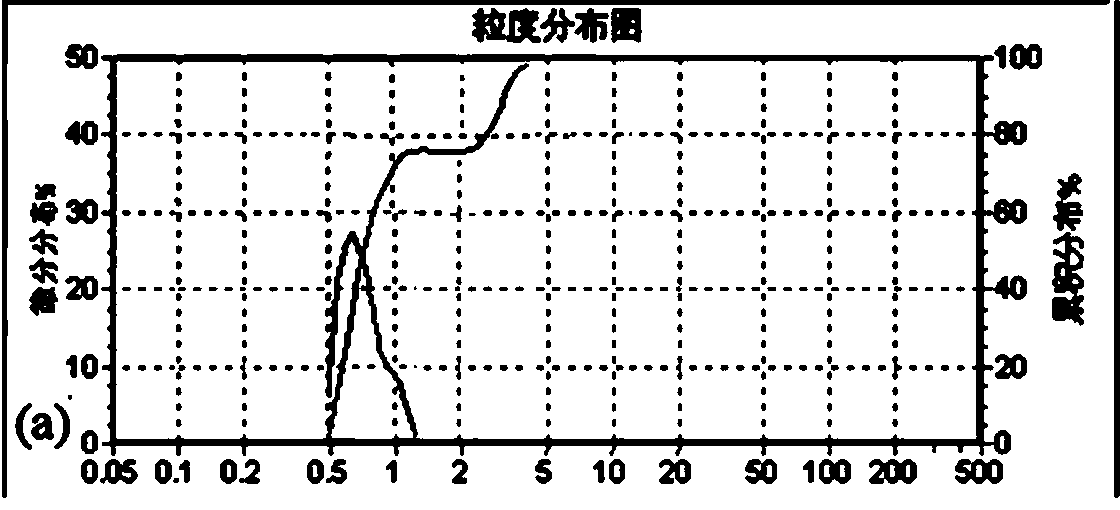

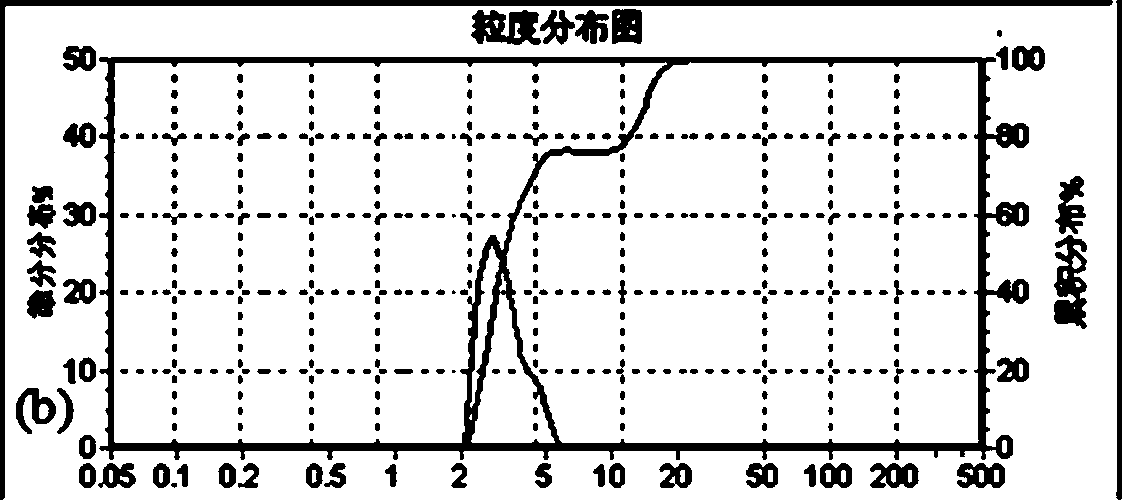

Yttria-stabilized zirconia powder and preparation method thereof

The invention relates to yttria-stabilized zirconia powder and a preparation method thereof. The yttria-stabilized zirconia powder has the composition characteristics that yttria is taken as a stabilizer of a zirconia material; the powder comprises a doping system formed by one or more following third components: alumina, ceria, lanthana, copper oxide, magnesium oxide and calcium oxide, wherein the weight of the yttria is 2-8mol%, and the total doping weight of the alumina, the ceria, the lanthana, the copper oxide, the magnesium oxide and the calcium oxide is 0-5wt%. According to the yttria-stabilized zirconia powder and the preparation method, the deficiencies of an existing liquid phase preparation process of nanometer zirconia powder are overcome, and the prepared nanometer ZrO2 composite powder has the performance of uniformity in dispersion of components, uniform grain size, super-fineness, high sintering activity, good liquidity and the like. Furthermore, the preparation method is simple in process and low in cost and is easy to industrialize.

Owner:YAAN YUANCHUANG CERAMIC

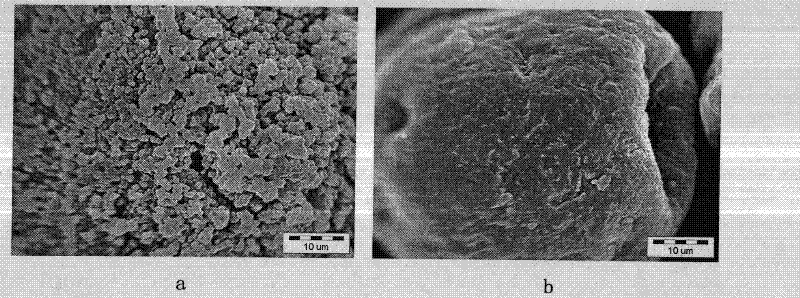

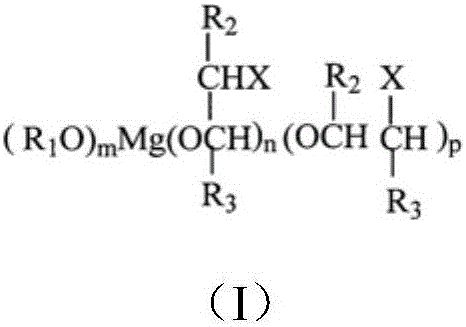

Method for preparing solid catalyst in olefin polymerization catalyst

ActiveCN101054424AProduct quality is easy to controlHigh particle sphericityContinuous/uninterruptedPolymer science

The invention provides a preparation method of solid catalyst used in olefinic polymerization catalyst, the method synthetizes the solid catalyst of olefinic polymerization continuously by magnesium powder, simplifies the technology of preparing magnesium compounds solid firstly then preparing the solid catalyst of olefinic polymerization, reduces quantity of equipment needed in industrialization, has advantages of simple technics, easy operation, low industrializing installation cost, low production cost, easy controlled product quality. The ball solid catalyst of olefinic polymerization which D(50) is in range of 10-80 mum is produced through the method of the invention, the catalyst has particle sphericity height L / W<1.4 (L expresses the longest axle of the particle, W is the minimum axle of the particle), has advantages of high polymerization activity, hydrogen regulating sensibility, high isotacticity of the polymer, centralized particle-size distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

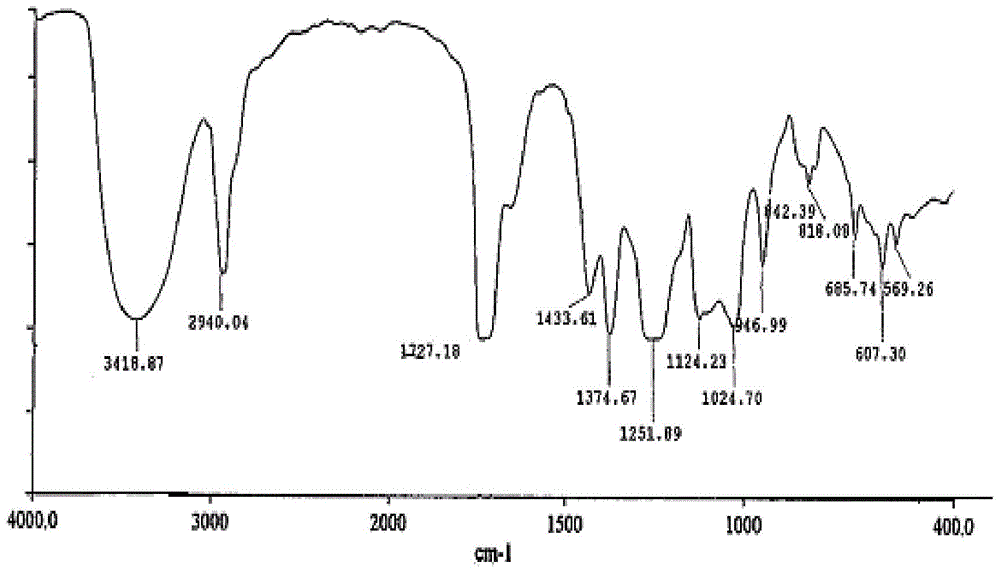

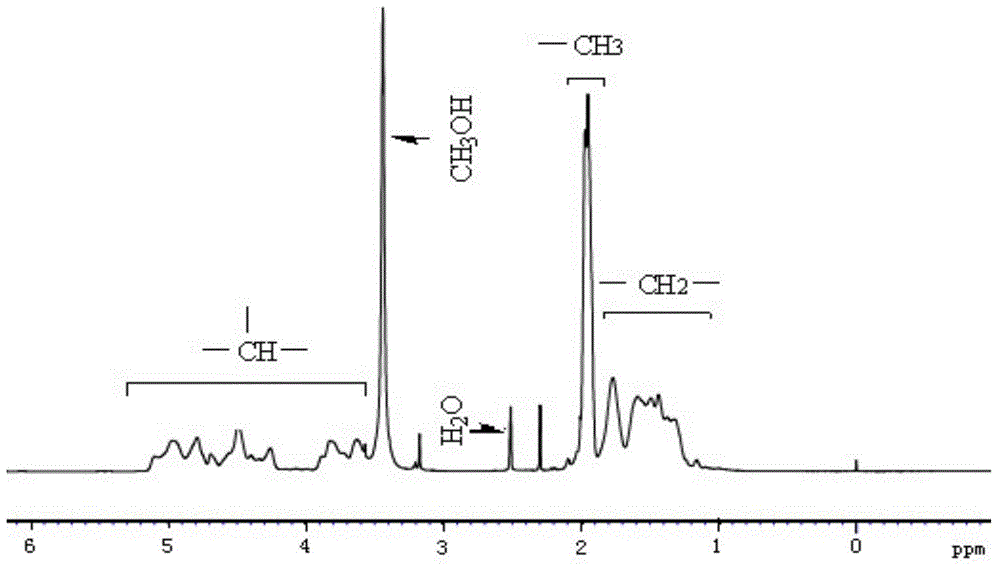

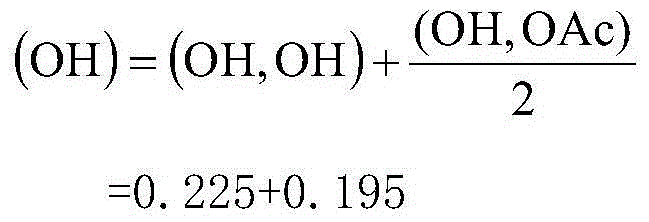

Polyvinyl alcohol, preparation method and applications

The invention provides polyvinyl alcohol. The polyvinyl alcohol is characterized in that the average polymerization degree is no higher than 500, the blocking degree is 0.50-0.85, and the alcoholysis degree is 35mol%-65mol%. The provided polyvinyl alcohol with a low polymerization degree, a low alcoholysis degree and a low viscosity has especially excellent viscosity stability. When the provided polyvinyl alcohol is used for a vinyl polymer suspension polymerization reaction, the monomer droplet disperse dispersion capability is strong, the dispersion stability is good, and the provided polyvinyl alcohol is free from vinyl polymer polymerization conditions. The pores of the prepared vinyl polymers are distributed uniformly and the porosity is high. The removal performance of reaction residual monomers is good, the absorption capability of added plasticizers is excellent during the subsequent processing process, the processing properties are excellent, plasticizing time can be shortened, and the fisheye number is decreased.

Owner:CHINA PETROCHEMICAL CORP +1

High-capacity nickel-cobalt-lithium manganate precursor and preparation method thereof

InactiveCN105118981AHigh tap densityConcentrated particle size distributionCell electrodesSecondary cellsManganateCharge discharge

The invention relates to a positive electrode material of a lithium ion battery, especially to a high-capacity nickel-cobalt-lithium manganate precursor and a preparation method thereof. The high-capacity nickel-cobalt-lithium manganate precursor is characterized by having a chemical formula of NixCoyMnz(OH)2, wherein x is no less than 0.5 and no more than 0.9, y is no less than 0.05 and no more than 0.2, z is no less than 0.05 and no more than 0.3, and x+y+z is equal to 1. The invention provides the high-capacity nickel-cobalt-lithium manganate precursor prepared through coprecipitation and the preparation method thereof; and the prepared precursor has concentratedly distributed particle size, high tap density, good sphericility, high specific capacity, low cost, long service life, higher discharge plateau and energy density, primary 1C charge-discharge specific capacity of 195 mA.h / g and 186.5 mA.h / g, and capacity retention ratio of 95.6% after 50 cycles.

Owner:NINGXIA ORIENT TANTALUM IND

Preparation process of catalyst for ethylene polymerization

InactiveCN1861650AHigh titanium contentImprove particle size distributionPolymer scienceZiegler–Natta catalyst

A process for preparing a Ziegler-Natta catalyst used for the sludge polymerization of ethene features that in its preparing procedure the ultrasonic wave technique is used for increasing the content of Ti and improving the granularity distribution of polymer.

Owner:北京燕化高新催化剂有限公司

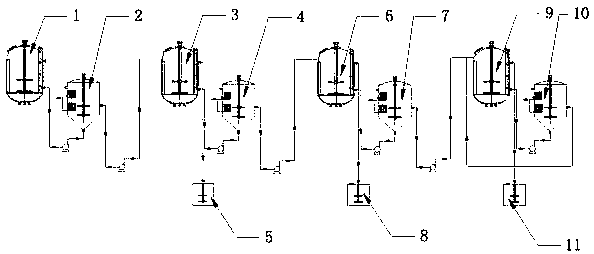

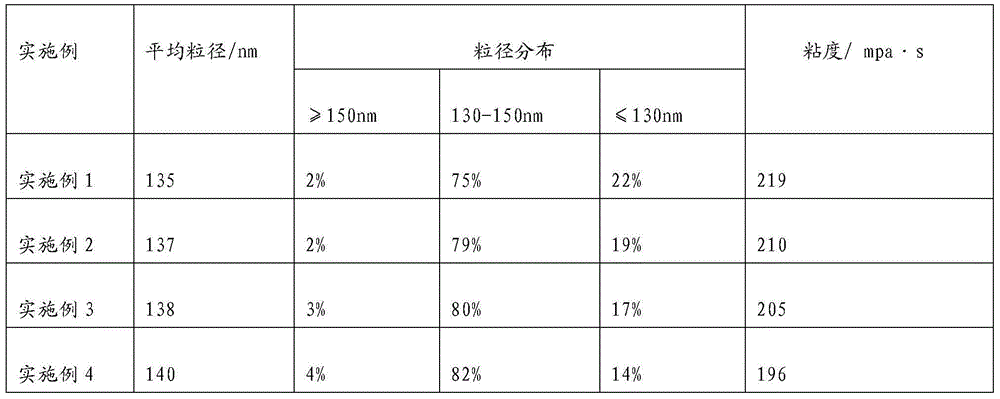

Preparation method for multiple precursors with concentrated particle size distribution by multistage continuous synthesis

InactiveCN108172892AImprove processing efficiencyRelieve pressureFinal product manufactureCell electrodesAmmonium hydroxideSlurry

Disclosed is a preparation method for multiple precursors with concentrated particle size distribution by multistage continuous synthesis. The preparation method comprises the following steps of: 1) preparing a metal salt solution, an alkali solution and an ammonium hydroxide solution; 2) enabling a reaction kettle and a solid concentration thickener to be connected in series; 3) injecting the metal salt solution, the alkali solution and the ammonium hydroxide solution into the reaction kettle 1, wherein the slurry in the reaction kettle 1 is pumped into the thickener 1 for solid-liquid separation to increase solid content when the liquid level in the reaction kettle 1 reaches the full kettle state, and the thick slurry in the thickener 1 is pumped into a reaction kettle 2; 4) performing stirring when the reaction kettle 2 is full of the slurry, and adding the metal salt solution, the alkali solution and the ammonium hydroxide solution to continue a continuous precipitation reaction, and then overflowing the product in the reaction kettle 2 into an aging tank 1; and 5) enabling the product in the aging tank 1 to be centrifuged, washed and dried. The preparation method has the advantages that the technology is simple, easily operated, energy-saving and environment-friendly. The product features good appearance, concentrated particle size distribution, high vibration density andhigh efficiency.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD +1

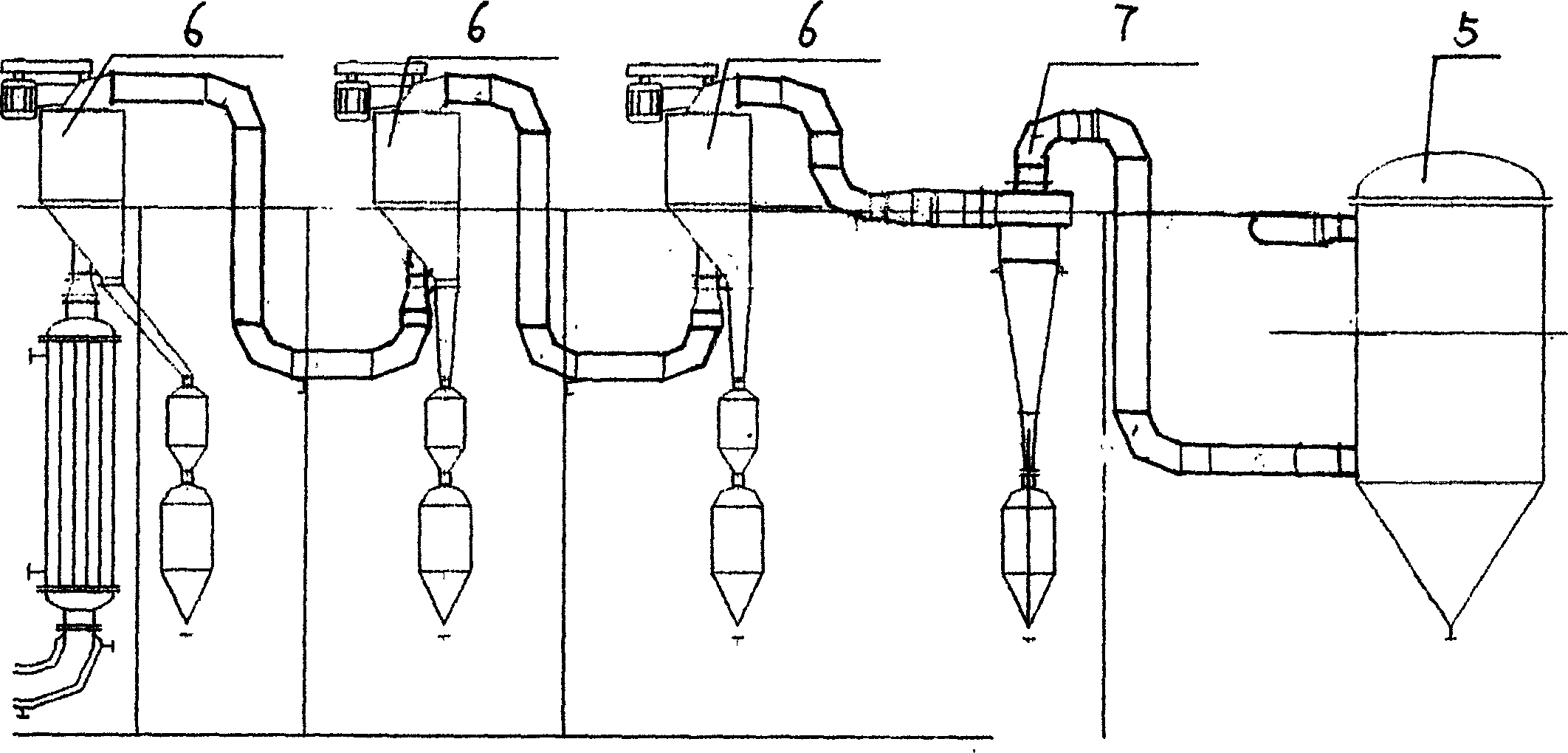

Production technology of two-nozzle atomization aluminium powder

The double nozzle atomizing aluminum powder production process includes the following steps: smelting aluminum ingot in aluminum smelting furnace with two heating silicon carbon rods, atomizing the liquid aluminum in double nozzle atomizing chamber, blowing high temperature and high pressure nitrogen with air compressor into the atomizing chamber to cooling liquid aluminum into aluminum grains, grading in a grading system comprising three stages centrifugal grading machine and one cyclonic collector, and circulating through a circulating system comprising double balance tank and double blower. The present invention has greatly raised production capacity, saving in investment and low production cost.

Owner:鞍钢实业微细铝粉有限公司

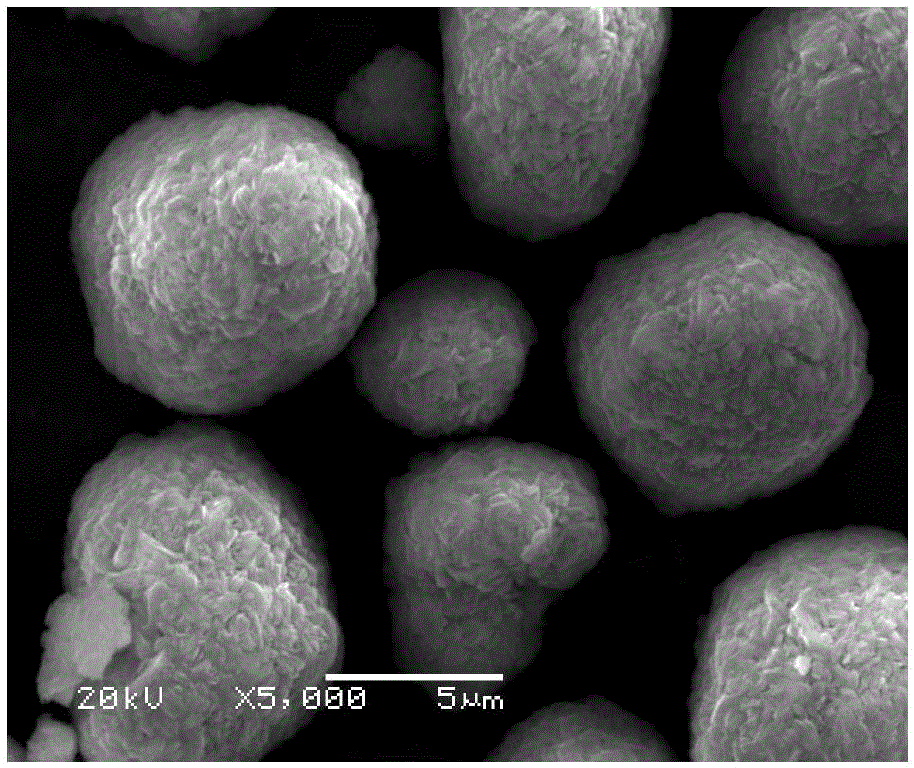

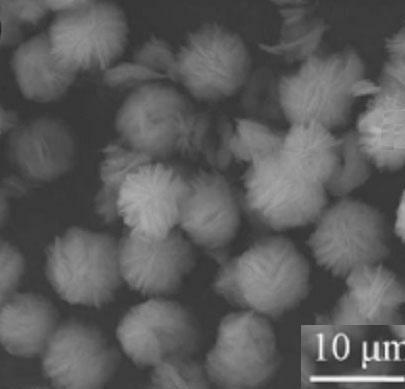

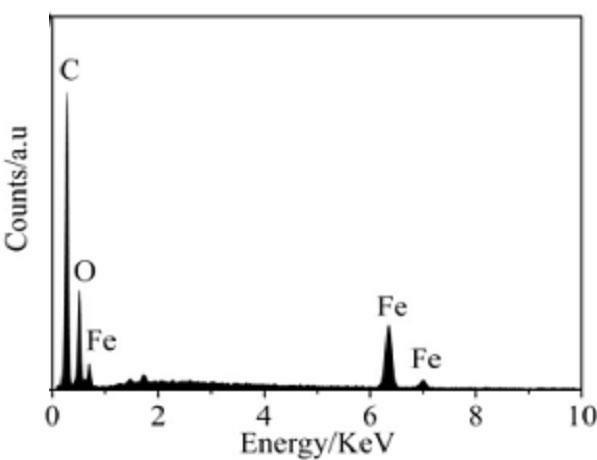

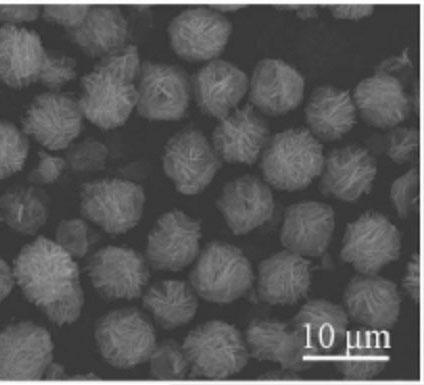

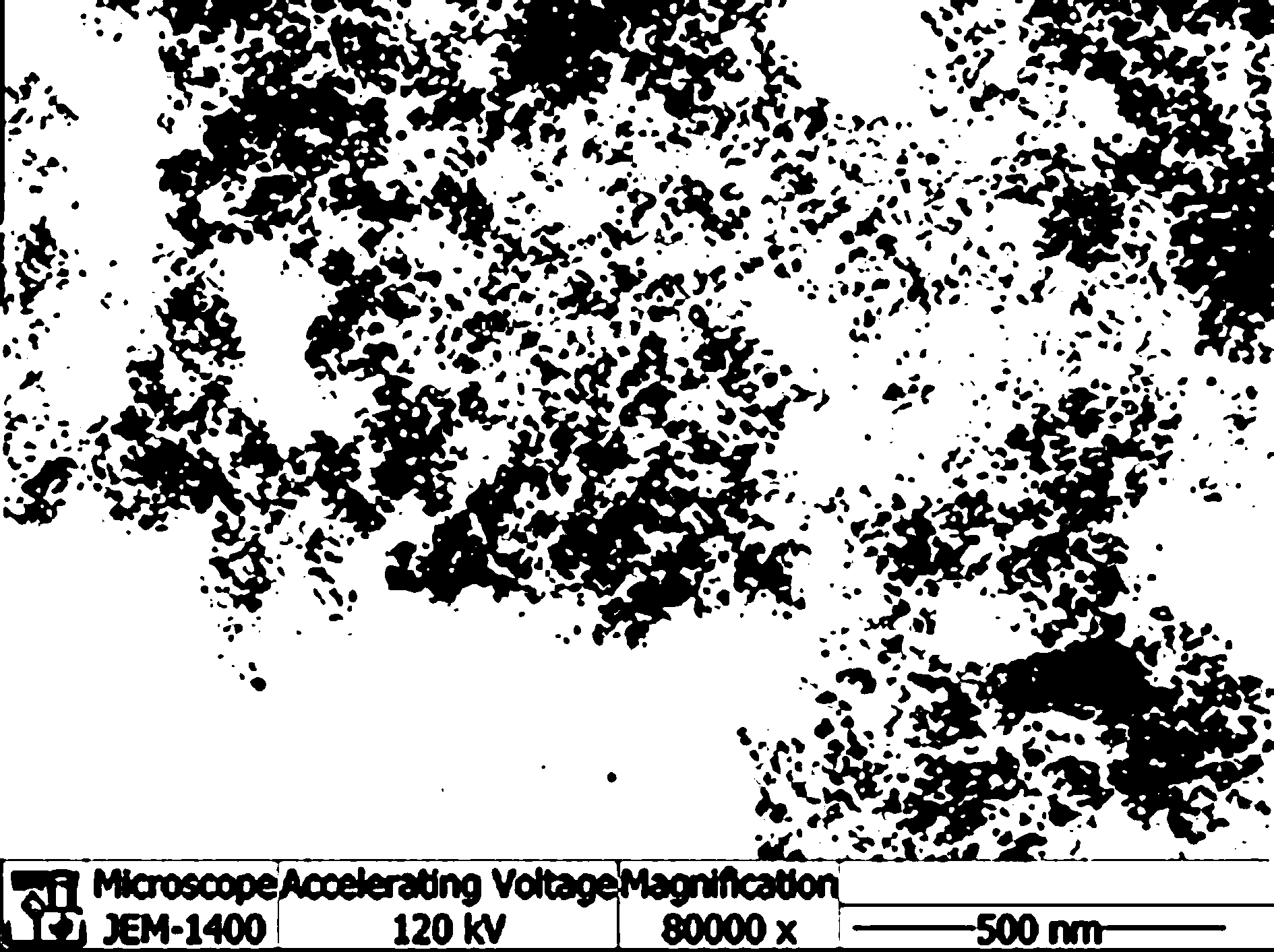

Magnetic ferric oxide micrometer flower material with multi-stage structure and preparation method thereof

InactiveCN102659188ASimple preparation processReduce manufacturing costFerric oxidesMicrometerNanoparticle

The invention discloses a magnetic ferric oxide micrometer flower material with a multi-stage structure and a preparation method of the magnetic ferric oxide micrometer flower material. The magnetic ferric oxide micrometer flower material with the multi-stage structure has the shape of a flower which is arranged by nano-pieces with the thickness of 85-95nm in an interlaced way assembled by spherical particles with the particle sizes from 20nm to 30nm and has the multi-stage structure, and integrates the nano-grains, the nano-pieces and the micro flower. The preparation method comprises the following steps of: preparing a solution with the concentration of 0.05-0.6mol / L based on hexahydrated ferric trichloride as an iron source and ethylene glycol as solvent, adding a surface active agent, stirring to obtain clear solution, adding urea, reacting for 30-90min by an ethylene glycol auxiliary method at the temperature of 190-197 DEG C, centrifugally separating, cleaning and drying, and calcining for 1-5h at high temperature of 300-500 DEG C, so that the magnetic ferric oxide micrometer flower material can be obtained. The preparation method is simple in technology, low in cost, easy to produce on a large scale, and safe and reliable in production process; and the product is good in repeatability, regular in shape, concentrated in particle size distribution, and free from agglomeration.

Owner:ZHONGBEI UNIV

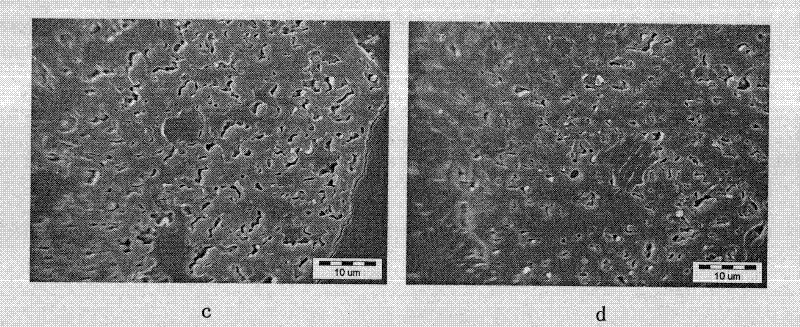

Preparation method of PVC (polrvinyl chloride) resin with high porosity and low film coverage rate

The invention discloses a preparation method of a PVC resin with high porosity and low film coverage rate, which adopts suspension polymerization. The preparation method is characterized in that the preparation method comprises the following steps: 1, adding water, a vinyl chloride monomer, a composite dispersion system, a porosity conditioning agent, a chain transferring agent, a pH buffer and an initiator to a polymerization reactor; 2, carrying out a polymerization reaction on above materials in the polymerization reactor under conditions that the pressure is 0.90-1.20MPa and the temperature is 50-75DEG C; 3, adding a reaction terminator when the polymerization temperature is maintained and the polymerization pressure is decreased to 0.1-0.30MPa; 4, discharging the residual vinyl chloride monomer; and 5, collecting the target product from reaction products, wherein the composite dispersion system is a mixture of partially-alcoholized polyvinyl alcohol and partially-alcoholized hydroxypropyl methyl cellulose. The PVC resin prepared with the method disclosed in the invention has the advantages of high porosity, less fisheye, low film coverage rate, structured particle form, concentrated resin particle size distribution, and easy residual monomer removal.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method for fluidized bed catalyst

ActiveCN104549528AAdvantages of preparation methodAdequate responseCatalyst carriersCatalyst activation/preparationAluminateGas phase

The invention discloses a preparation method for a fluidized bed catalyst. The preparation method comprises the following steps: (1) adding reaction liquid into an impinging stream reactor, enabling the reaction liquid to reach the bottom of the impinging stream reactor, heating and starting a stirring paddle at the bottom; (2) respectively injecting an alkali metal aluminate aqueous solution and CO2 gas flow through an acceleration pipe at the upper part of the impinging stream reactor, performing gas-liquid impinging stream reaction on the alkali metal aluminate aqueous solution subjected to atomization and the CO2 gas flow to generate an aluminum hydroxide crystal nucleus entering a settling region; (3) at the end of the gas-liquid impinging stream reaction, simultaneously and continuously adding an acidic aluminum salt aqueous solution and the alkali metal aluminate aqueous solution or an alkaline settling agent from feed inlets II and III, adjusting the pH value, and performing neutral reaction; (4) performing aging, filtering, washing and drying to obtain aluminium oxide dry glue; (5) uniformly mixing the aluminium oxide dry glue, small-hole SB powder and sesbania powder, adding an adhesive to form a plasticizer, performing extrusion and forming, drying and roasting to obtain an aluminum oxide carrier, immersing active metal, drying and roasting to obtain the fluidized bed catalyst. The impinging stream reactor is adopted in the method, so that the transfer characteristic between the gas phase and the liquid phase as well as between one liquid phase and another liquid phase is enhanced, so that the prepared fluidized bed catalyst is high in intensity and low in abrasion; furthermore, the pore volume and the aperture of the catalyst are larger.

Owner:CHINA PETROLEUM & CHEM CORP +1

Xylitol refining crystallization process

InactiveCN1736970AQuality improvementHigh yieldHydroxy compound separation/purificationCrystallization temperatureNucleation

The invention relates to refine crystallization method for xylitol. Wherein, conveying the xylitol solution with mass concentration of 85-92% into crystallizer with original temperature of 65-85Deg; cooling and crystallizing; adding crystal seed to control refine crystallizing nucleation at temperature of 55-70Deg, holding for 15-60min; controlling cooling rate between 1Deg / hr-10Deg / hr during the process; the crystallization temperature is 30-45Deg, and the operation time is less than ten hours; centrifugal separating, cleaning, drying for 1-8h at temperature of 40-80Deg, finally, one obtains the product.

Owner:TIANJIN UNIV +1

Polyamide powder and preparation method thereof

The invention relates to the technical field of polyamide preparation, in particular to polyamide powder and a preparation method thereof. The preparation method comprises the following steps: dissolution and heat preservation, wherein polyamide is dissolved and added into a reaction kettle, heating is conducted, and the temperature is raised to be 25-80 DEG C higher than the polyamide precipitation temperature; cooling and powder making, wherein the temperature is lowered to be 14-16 DEG C higher than the polyamide powder precipitation temperature at the speed of 0.5-2.0 DEG C / min, then the temperature is lowered to the polyamide powder precipitation temperature at the speed of 0.1-0.4 DEG C / min, finally the temperature is lowered to the room temperature at the speed of 1-5 DEG C / min, precipitation is conducted, and polyamide precipitate is obtained; drying, wherein the polyamide precipitate is dried, and polyamide powder particles are obtained. The polyamide powder particles prepared through the preparation method are good in size concentration degree, simple and convenient in process and particularly applicable to SLS process requirements, and performance of products is excellent.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

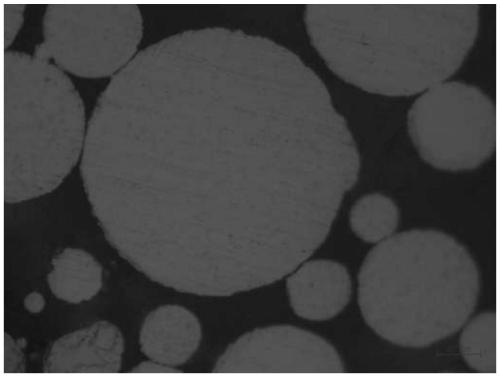

Microspheres prepared from composition containing zirconium oxide and preparation method of microspheres

The invention relates to composite zirconium oxide microspheres and a preparation method thereof. The microspheres are prepared from yttrium oxide as a stabilizer of a zirconium oxide material. The microspheres comprises a doped system of third components including one or more of alumina, cerium oxide, copper oxide, magnesia, calcium oxide and silica, wherein the content of the yttrium oxide in the zirconium oxide is 0.1-8mol% while the total doping amount of the alumina, the cerium oxide, the copper oxide, the magnesia, the calcium oxide and the silica is 0-30wt%. According to the method, sediment dry gel is molded and further sintered to finish preparation of the composite zirconium oxide ceramic microspheres. The preparation method is simple in production technology, relatively low in cost, and applicable to industrialization. A lot of energy sources are saved for industrialization of the zirconium oxide ceramic microspheres. Meanwhile, the prepared ceramic microspheres disclosed by the invention have the characteristics of large density, durability, stability and the like.

Owner:YAAN YUANCHUANG CERAMIC

Solvent-out crystallization method of erythritol

InactiveCN102992957AShorten the production cycleReduce manufacturing costHydroxy compound separation/purificationPhysical chemistrySlurry

The invention relates to a solvent-out crystallization method of erythritol. The technical solution is as follows: firstly, a clear supersaturated crystallization solution is prepared by feeding a solvent-out agent in an erythritol crystallization mother solurion; then, a suspension crystal fluid is prepared by adding seed crystals to the supersaturated crystallization solution for controlling nucleation; a suspension slurry is prepared by adding the solvent-out agent at different speed continuously in three stages; and finally, an erythritol crystal product is obtained by growing the crystal with the suspension slurry via a programmed temperature control method, filtering, washing and drying. Crystals with the diameter of 30-60 meshes or 40-80 meshes in the erythritol crystal product accounts for more than 90%; the erythritol crystal product has smooth and clean crystal surface, high purity and good flowability; and single-process crystallization yield is higher than 80%. Average particle size and particle size distribution of the erythritol crystal product can be regulated in the crystallization process by changing the particle size of the seed crystals and the addition amount. The solvent-out crystallization method has the advantages of low production cost, short production period, controllable average particle size, concentrated particle size distribution, high single-process crystallization yield and high product quality.

Owner:WUHAN UNIV OF SCI & TECH

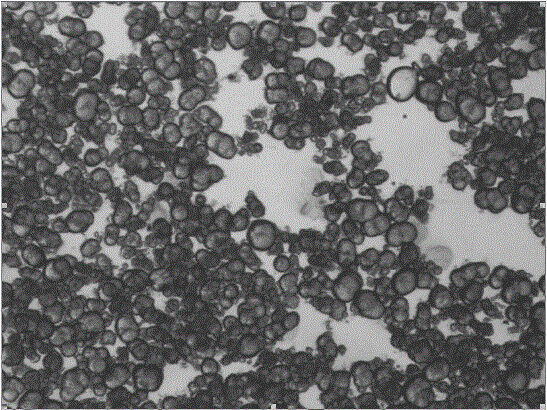

Kit and method for preparing exosomes in serum or plasma

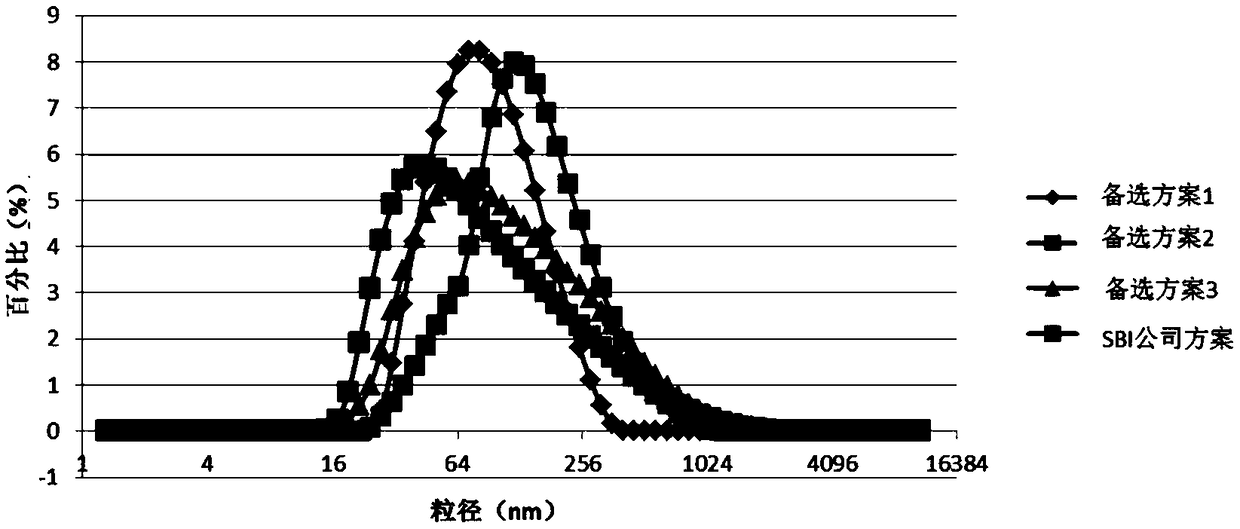

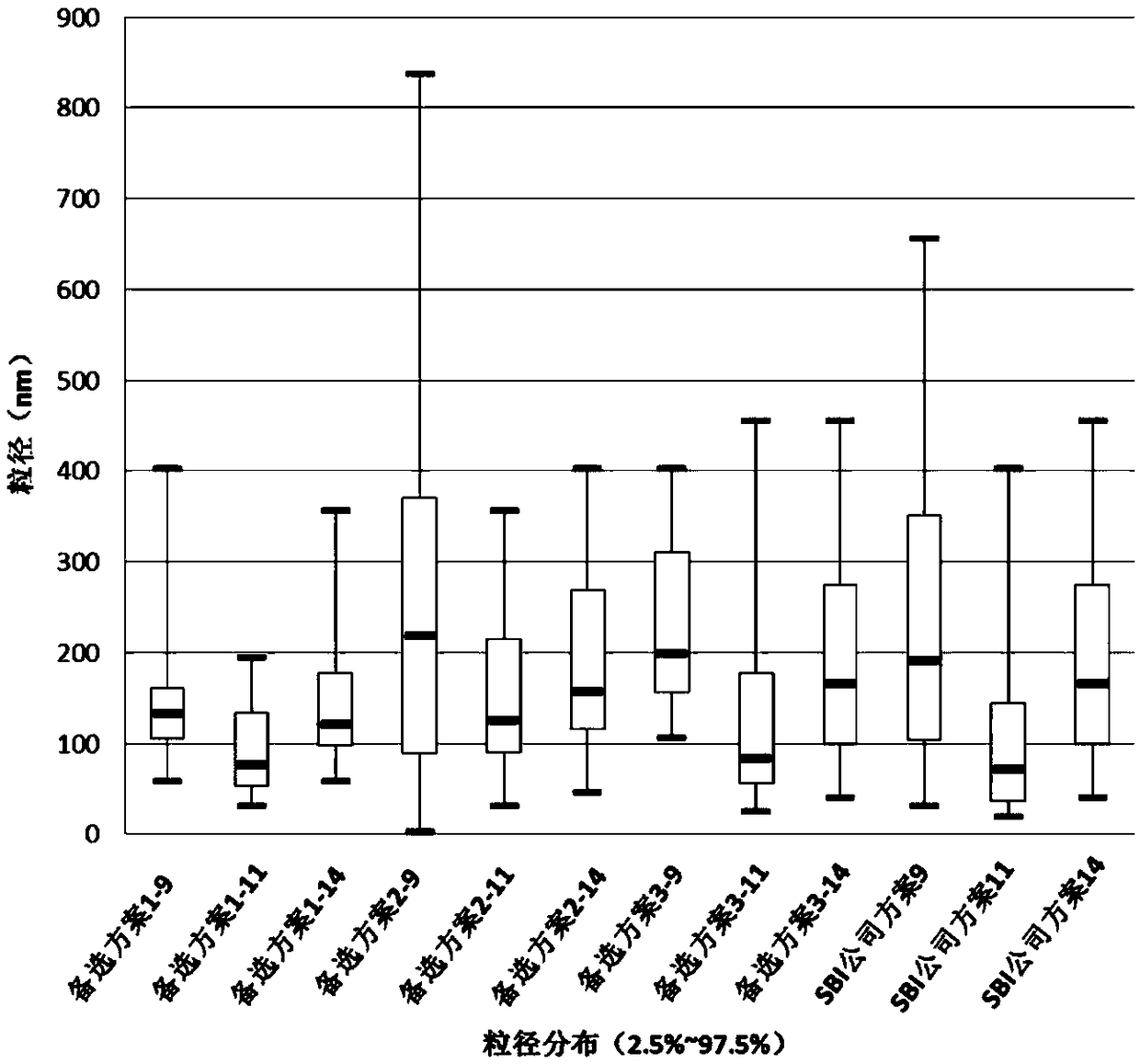

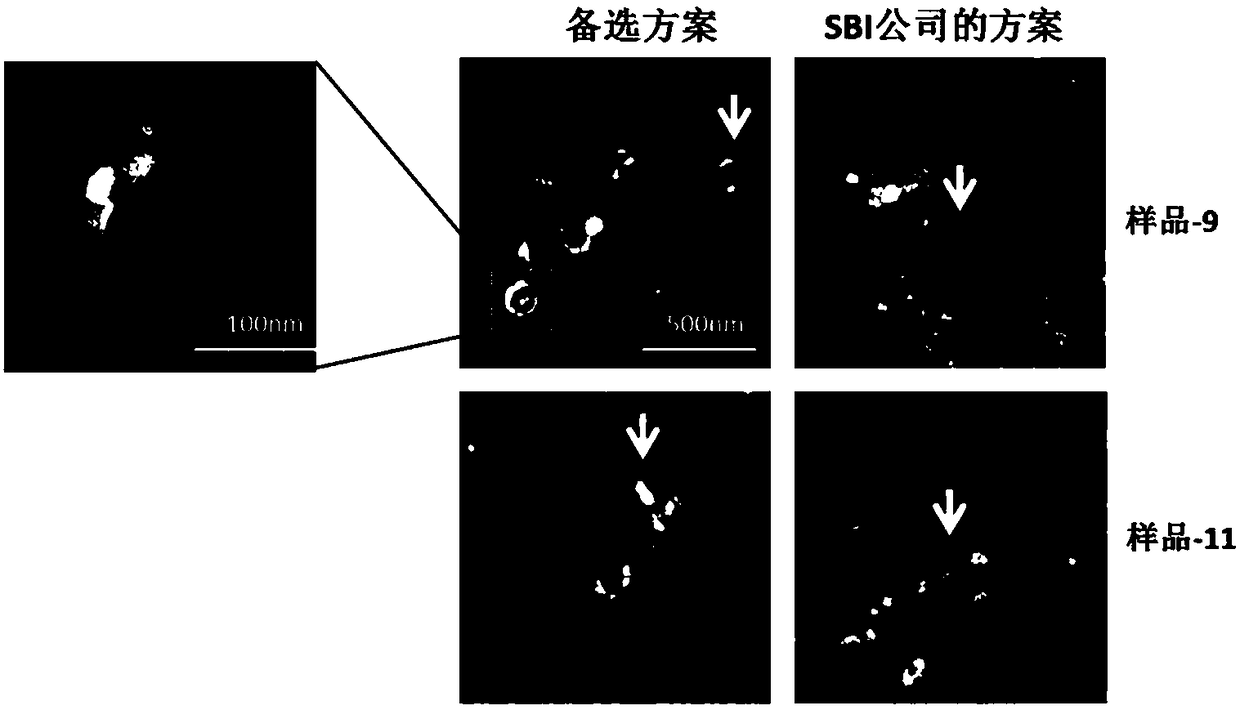

ActiveCN108918228AConcentrated particle size distributionSimple purification processPreparing sample for investigationHydrophilic polymersPolyethylene glycol

The invention discloses a kit and method for preparing exosomes in serum or plasma. The kit comprises an exosome extracting reagent, wherein the exosome extracting reagent is a hydrophilic polymer ora solution of the hydrophilic polymer; the hydrophilic polymer comprises one or a combination of PEG (Poly Ethylene Glycol), dextran sulfate and PVP (Poly Vinyl Pyrrolidone); the molecular weight of the PEG is 20000-1200000 Daltons; the molecular weight of the dextran sulfate is 5000 to 20000 Daltons; and the molecular weight of the PVP is 10000 or 40000-700000 Daltons. The particle size distribution of the exosomes obtained by utilizing the kit is more concentrated; and according to the method for preparing the exosomes, which is provided by the invention, the step of purifying the exosomes is also optimized, so that the exosomes have less impurities and higher purity.

Owner:BEIJING TRANSGEN BIOTECH CO LTD

Method for preparing GRCop-84 spherical powder based on plasma rotary atomization method

ActiveCN110405220AHigh sphericityReduce oxygen contentIncreasing energy efficiencyPumping vacuumImpurity

The invention discloses a method for preparing GRCop-84 spherical powder based on a plasma rotary atomization method. The method comprises the following steps of S1, smelting according to the proportion of elements and a specific adding mode, and forging after casting to obtain a bar blank; S2, machining the GRCop-84 bar meeting the requirement of the plasma rotary atomization method by using a lathe; S3, placing the GRCop-84 bar as a positive electrode in atomizing equipment, carrying out pre-pumping vacuum treatment on an atomizing chamber of whole powder making equipment, and then injectinginert protective gas; S4, starting the equipment, heating and melting the end surface of the GRCop-84 bar rotating at a high speed by using a plasma torch, and centrifugally condensing molten liquiddrops in the atomizing chamber; and S5, obtaining the GRCop-84 spherical powder through a powder collecting device, and screening and vacuum packaging according to requirements after the powder is completely cooled. According to the method, the GRCop-84 spherical powder which is uniform in particle size, high in sphericity and low in impurity content can be prepared in batches and stably.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

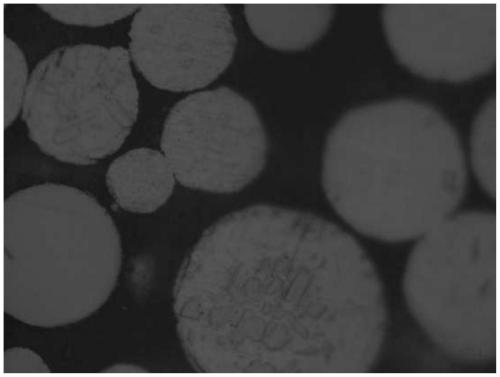

Low-density composite proppant, preparation method and applications thereof

The present invention provides a low-density composite proppant, which is prepared by carrying out a polymerization reaction on an oil phase and an aqueous phase, wherein the oil phase comprises, by weight, 60-90 parts of a monomer, 5-25 parts of a cross-linking agent, 0.01-10 parts of a filler, 0.1-5 parts of an initiator and 0-2 parts of a filler dispersant, and the aqueous phase comprises, by weight, 90-100 parts of water, 0.1-5 parts of a dispersant and 0.1-5 parts of an inorganic salt. The present invention further provides a preparation method of the proppant, wherein the preparation method comprises: uniformly mixing the dispersant, the inorganic salt and the water to obtain the aqueous phase, uniformly mixing the monomer, the cross-linking agent, the initiator, the filler and the optional filler dispersant to obtain the oil phase, mixing the oil phase and the aqueous phase, carrying out a polymerization reaction at a certain temperature to obtain a polymerization product system, and post-treating the obtained polymerization product system. The present invention further discloses applications of the proppant or the proppant prepared according to the method in reservoir fracturing reforming.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing high-degree of polymerization polyvinyl chloride resin by using suspension method

The invention discloses a method for producing high-degree of polymerization polyvinyl chloride resin by using a suspension method, which comprises the following steps of: step 1, charging by adopting a constant-temperate water feeding technology, a whole-process airtight feeding technology and a DCS (Distributed Control System) automatic control technology; step 2, producing the high-degree of polymerization polyvinyl chloride resin by adopting a low-temperature method; and step 3, obtaining the high-degree of polymerization polyvinyl chloride resin with a degree of polymerization of 1700-3000. With the adoption of the method for producing the high-degree of polymerization polyvinyl chloride resin by using the suspension method, the high-degree of polymerization polyvinyl chloride resin with a degree of polymerization of 1700-3000 can be produced in a 70 m<3> polymerization kettle system, has the advantages of low energy consumption, large batch production and stable quality and can be produced in the whole year.

Owner:HANGZHOU ELECTROCHEM GROUP

Method for preparing high-purity high-compactness battery-grade ferric phosphate

ActiveCN108840317AAvoid introducingEmission reductionNanotechnologyPhosphorus compoundsPhosphatePhosphoric acid

The invention provides a method for preparing high-purity high-compactness battery-grade ferric phosphate. The method comprises the following steps: firstly, enabling a certain amount of iron and 15-35% phosphoric acid to react at 40-100 DEG C so as to generate a phosphoric acid solution with ferrous ions, further heating the material liquid to 60-100 DEG C, adding a complexing agent, introducingozone to carry out oxidation for 3.5-7.5 hours so as to obtain ferric phosphate slurry, filtering the ferric phosphate slurry, repeatedly washing filter cakes, filtering till the filtrate is neutral,drying the collected solid for 2-4 hours, and calcining for 2-4 hours at 400-600 DEG C, thereby obtaining expected ferric phosphate, wherein the complexing agent is one or more of ethidene diamine, triethanolamine, 2-hydroxyl ethylamine, 1,2-propane diamine, 1,3-propane diamine, succinamide and malonamide. The method provided by the invention is simple in process, safe and environmental-friendly,high in atom utilization rate, low in cost and possible in continuous production, and the ferric phosphate prepared by using the method has an iron-phosphorus ratio of 0.96-0.99, a D95 granularity of78-150 nanometers and a compact density of 2.40-2.50g / cm<3>, and is particularly applicable to application as a raw material of lithium battery anode material lithium iron phosphate.

Owner:GUANGDONG GUANGHUA SCI TECH

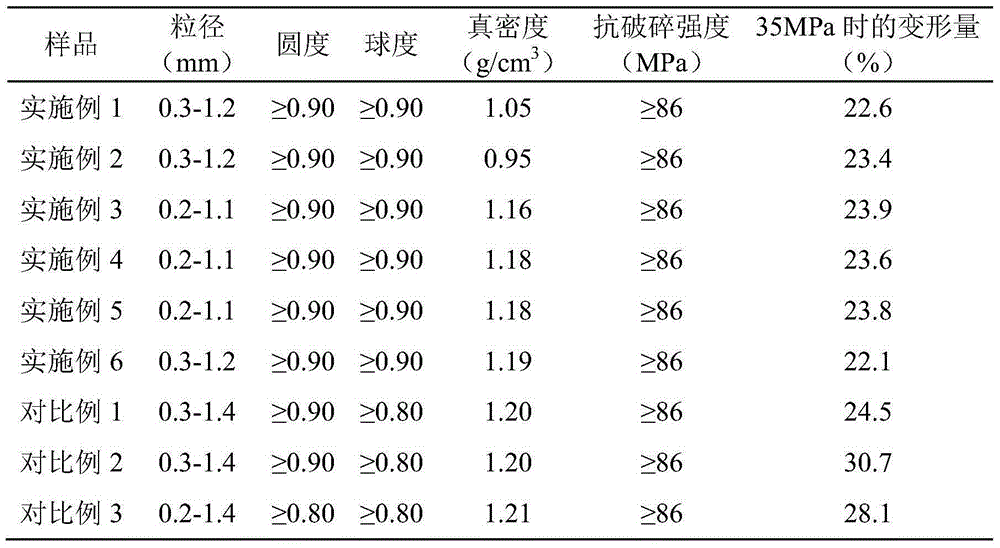

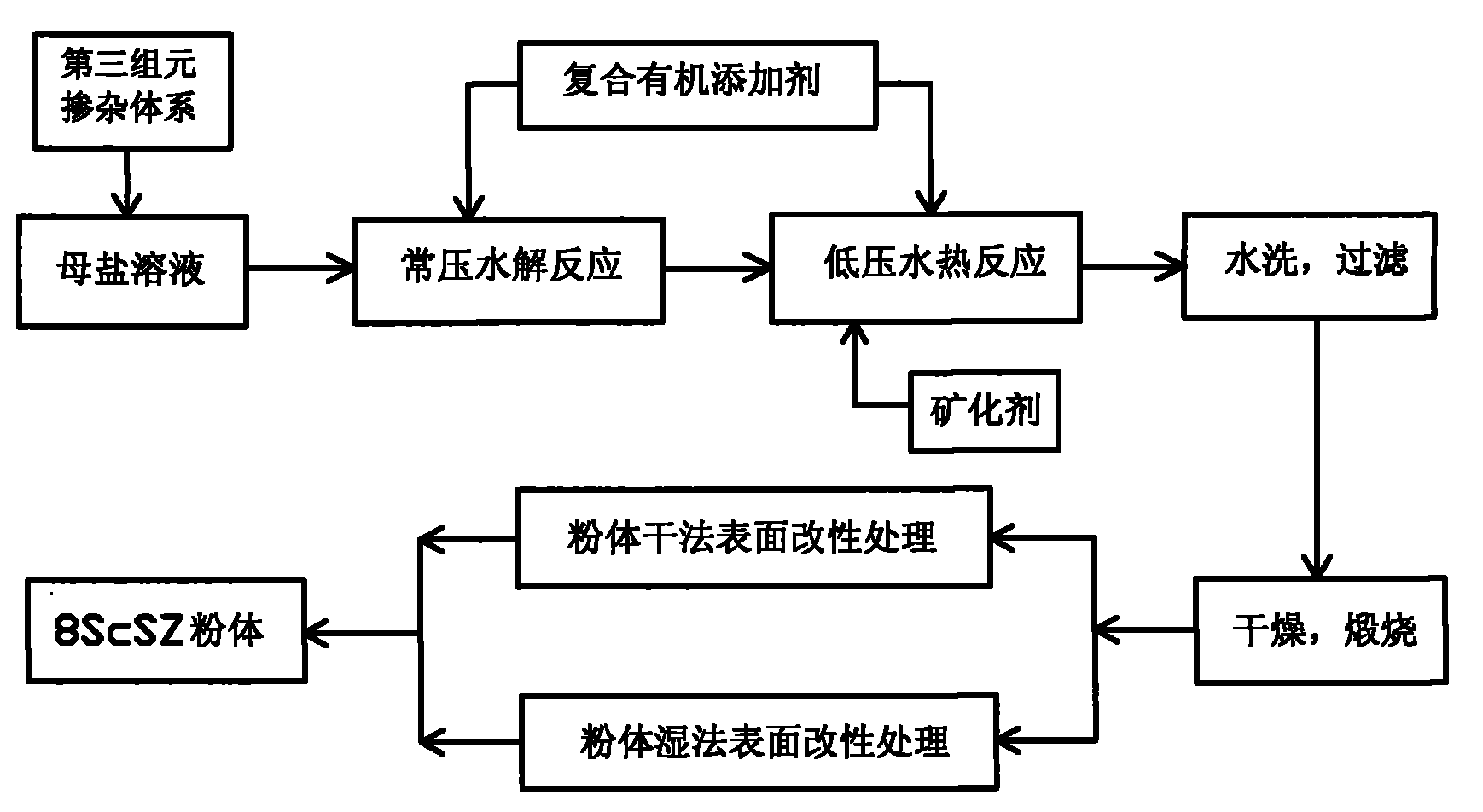

Scandium oxide-stabilizing zirconia powder and preparation method thereof

InactiveCN101830505AAvoid harsh production conditionsLow costZirconium oxidesFiltrationZirconium oxychloride

The invention relates to a scandium oxide-stabilizing zirconia powder and a preparation method thereof. The scandium oxide-stabilizing zirconia powder comprises zirconium oxychloride as precursor mother salt, one or more third elements of aluminum oxide, cerium oxide and bismuth oxide and a doping system, wherein the doping quantity of the scandium oxide is 8 mol%, and the total doping quantity of the aluminum oxide, the cerium oxide and the bismuth oxide is 0-7 wt%. The preparation method comprises the steps of water washing, filtration, drying, calcinations and powder surface dry and wet modification as well as constant-pressure hydrolysis reaction and low-pressure hydro-thermal reaction, wherein the constant-pressure hydrolysis reaction and low-pressure hydro-thermal reaction are carried out by the steps of: firstly carrying out constant-pressure hydrolysis on a water solution of the precursor mother salt ZrOCl2 (ScCl3) in a reactor, and then carrying out hydro-thermal treatment on hydrolysis liquid at the temperature less than 150 DEG C and the pressure of 0.3-0.5 MPa. The scandium oxide-stabilizing zirconia powder has the characteristics of small grain size, centralized size distribution, high sintering activity, lower specific surface area, suitability for the traditional casting process of a SOFC (Solid Oxide Fuel Cell) and high conductivity and strength index, and the preparation method has the advantages of simple and safe production process, lower cost, low requirement for equipment and easy realization of industrial big production.

Owner:江西泛美亚材料有限公司

Preparation method of extinction powder special for elastic paint

InactiveCN108557828AHigh oil absorption valueGood matting effectSilicaPigment treatment with macromolecular organic compoundsChemistryAmmonium hydroxide

The invention relates to a preparation method of extinction powder special for elastic paint. In a reaction kettle, sodium silicate and water are added, the temperature is increased to 45 DEG C, in the stirring state, sulfuric acid with the concentration being 30% is added, the PH value is regulated to 6-6.5, ammonium hydroxide is added to regulate the PH value to 8.5-9.0, aging is performed for 50 min, then, the temperature is increased to 90 DEG C, meanwhile, sodium silicate and sulfuric acid of the certain concentration are added, aging is performed for 50 min, acid is added till the PH value is 4-5, and filtering, washing, drying and smashing and classification are performed to obtain finished extinction powder. The extinction powder has the advantages of being high in oil absorption value, good in dispersibility, fine in touch, high in transparency and the like, and is reasonable in technology and high in production efficiency.

Owner:山西天一纳米科技股份有限公司

Preparation method of zirconium dioxide powder

The invention relates to a preparation method of zirconium dioxide powder, comprising the following steps: A. dissolving zirconium oxychloride into deionized water, and controlling mass ratio of the zirconium oxychloride and the deionized water to be 4:(21-35); B. dropwise adding ammonia water into mixed solution in the step A, and controlling mole ratio of the ammonia water and the zirconium oxychloride to be (1.8-3.7):1; C. carrying out washing, pressing and filtering or centrifugal separation on zirconium hydroxide hydrogel in the step B to obtain zirconium hydroxide gel; D. drying the zirconium hydroxide gel of the step C to obtain zirconium hydroxide, and calcining the zirconium hydroxide to obtain zirconium dioxide; E. mixing the zirconium dioxide in the step D with grinding medium and water and carrying out wet grinding on the mixture; and F. drying the zirconium dioxide slurry in the step E to prepare the zirconium dioxide powder. The zirconium dioxide powder product produced by the method has good particle monodispersity, complete particle form, concentrating distribution of particle size, high purity and controllable particle size and can realize low cost when in large-scale production of the zirconium dioxide.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

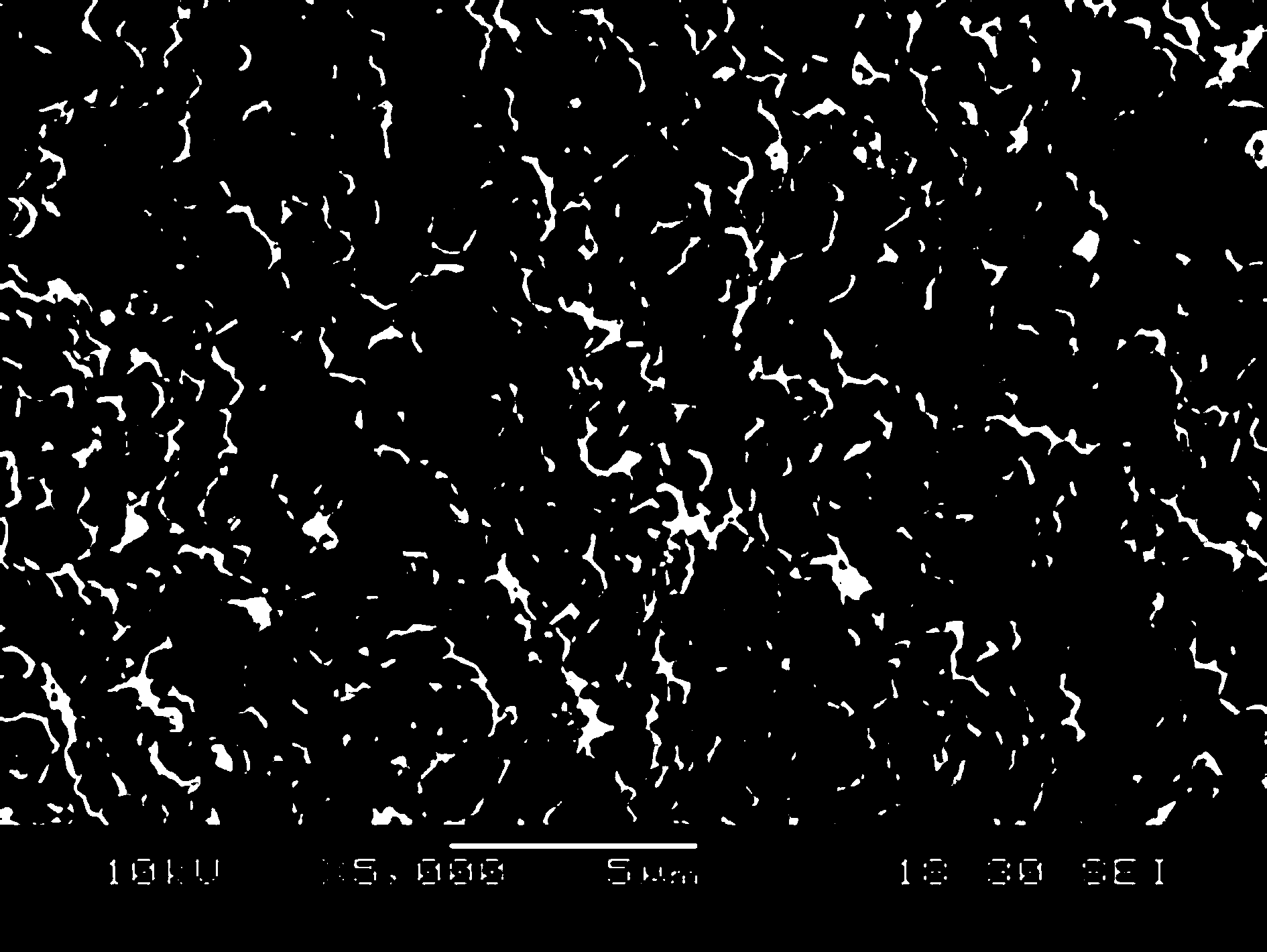

Refractory metal powder, preparing method thereof and metal product

ActiveCN108788129AConcentrated particle size distributionAdditive manufacturing apparatusIncreasing energy efficiencyDehydrogenationOxygen

The invention provides refractory metal powder which is in a sphere and / or similar sphere shape. The grain size distribution concentration ratio coefficient M of the refractory metal powder is 1.0-2.0. The refractory metal powder is pure-niobium powder or pure-tantalum powder or niobium alloy powder or tantalum alloy powder. The invention further provides a preparing method of the refractory metalpowder. In the preparing method, a series of steps including hydrogenation, ball milling crushing, dehydrogenation, airflow reshaping, acid pickling, vacuum heat treatment, oxygen reducing and acid pickling are sequentially conducted, and finally the sphere / sphere-like refractory metal powder is obtained. The invention further provides a metal product, and the metal product is obtained through the refractory metal powder via 3D printing.

Owner:NINGXIA ORIENT TANTALUM IND

FT synthesis sintered iron catalyst and preparation method and use thereof

ActiveCN101391219ALow priceSimple processHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSilicon oxideHigh intensity

The invention relates to a Fischer-Tropsch synthesis fused iron catalyst as well as a preparation method and an application thereof, the catalyst is an iron-based catalyst, the weight percentage of iron (Fe) is between 50 and 85 percent, and the weight ratio Fe<3+> / 2Fe<2+> of substance of ferric iron to that of bivalent iron which is two times the weight of ferric iron is 0.5 to 1.5, and the invention also includes a co-catalyst having the compositions: aluminum oxide (Al2O3) 0.1 to 1.5g / 100gFe, magnesium oxide (MgO) 0.1 to 1.5g / 100gFe, potassium oxide (K2O) 0.2 to 1.2g / 100gFe, sodium oxide (Na2O) 0.1 to 2g / 100gFe, calcium oxide (CaO) 0.1 to 1.5g / 100gFe, and silicon oxide (SiO2) 0.5 to 2g / 100gFe. Compared with the prior art, the catalyst has the advantages of high strength, low methane selectivity, high olefin selectivity, simple production process, low production cost and applicable mass production.

Owner:YANKUANG ENERGY R&D CO LTD

Carboxylated styrene-butadiene latex

ActiveCN104628953AStable molecular structureMolecular weight controllableButadiene-styrene rubberMechanical property

The invention relates to a carboxylated styrene-butadiene latex. High-speed steam is utilized to provide reaction heat energy for the reaction of the carboxylated styrene-butadiene latex, and the cooled steam is converted into high-temperature deionized water; the high-speed steam also drives the liquid in the reaction vessel to rotate, and the liquid in the reaction vessel is dispersed by the steam flow to form abundant micro steam-water combinations so as to push the material in the reaction vessel to quickly flow; and the substances and temperature in the reaction vessel are uniformly distributed, the polymerization reaction is uniform, and thus, the carboxylated styrene-butadiene latex has the advantages of stable molecular structure, controllable molecular weight and more centralized size distribution, has balanced and excellent mechanical properties, and enhances the qualification rate and quality of the product.

Owner:宁波卫山多宝建材有限公司

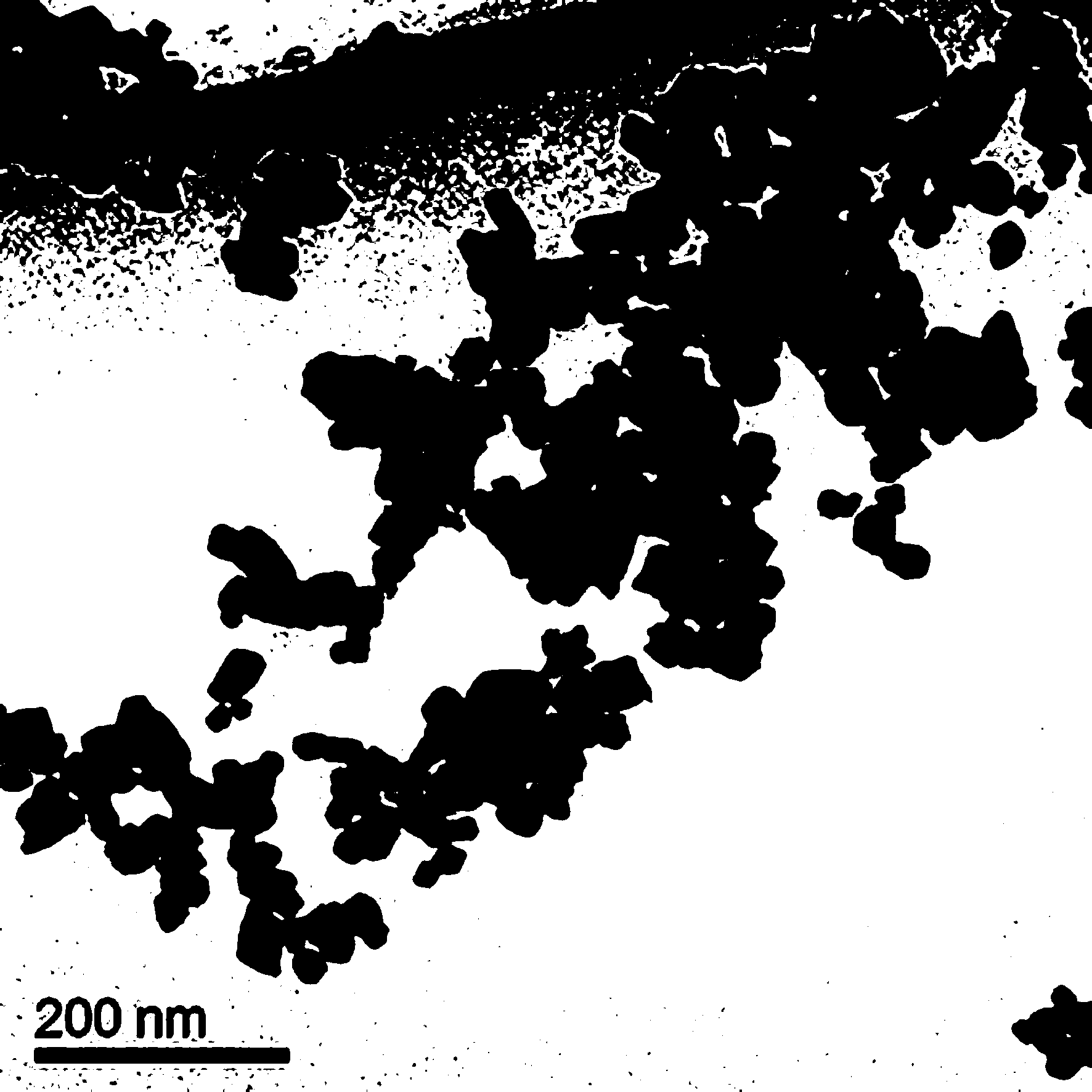

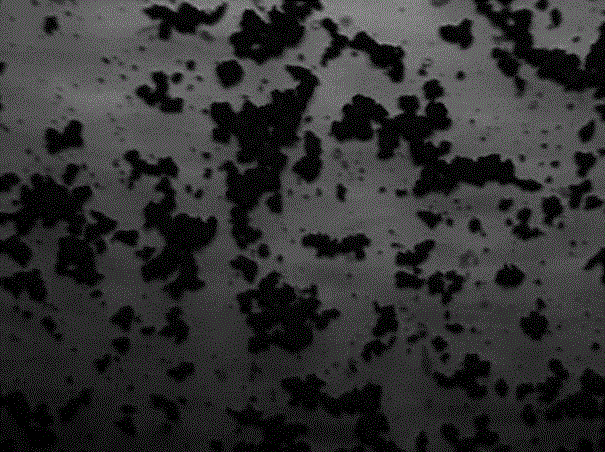

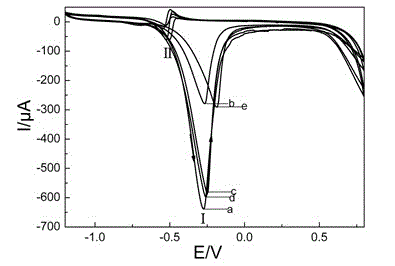

Method for preparing nano-palladium electro-catalyst by ethanol reduction

InactiveCN102872861AGuaranteed SolubilityHigh yieldCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystAqueous ethanol

The invention relates to a method for preparing a nano-palladium electro-catalyst by ethanol reduction. The method reduces PdCl2 (palladium chloride) to metal Pd (palladium) nano-particles by the aid of ethanol reduction and action of cosolvent, and includes the steps: firstly, preparing ethanol water; secondly, adding PdCl2 powder and protective agents into the ethanol water, feeding shielding gas, heating and stirring to enable palladium positive ions to generate reduction reaction so that the Pd nano-particles are obtained; and thirdly, performing centrifugal separation after reaction is finished to obtain black precipitates, and washing by ethanol and acetone prior to drying so that the nano-palladium electro-catalyst is obtained. The nano-palladium electro-catalyst is synthesized in one step in a normal-temperature environment by using the ethanol water as a solvent and utilizing the reduction action and the solvent effect of the ethanol without additionally adding chemical reduction agents such as ascorbic acid and by means of magnetic stirring and water-bath heating to guarantee solubility of the PdCl2. The method is low in cost, environment-friendly and simple and feasible in operation process, and the prepared nano-palladium electro-catalyst is high in yield and centralized in particle size distribution and has good application prospect.

Owner:ANHUI UNIV OF SCI & TECH

Catalyst used for olefin polymerization and preparation method thereof

The invention relates to a catalyst used for olefin polymerization and a preparation method thereof. The preparation method is as follows: in a reactor, under the protection of nitrogen, adding an organic solvent and a titanium compound, cooling to-30 to-10 DEG C, adding a carrier, maintaining at-30 to-10 DEG C, and stirring for 30-40min; slowly heating to 100 to 120 DEG C, in the heating process, adding an electron donor compound, reacting at 100-120 DEG C for 30-40min, filtering a liquid, again adding the titanium compound, heating to 110 to 130 DEG C, maintaining at 110 to 130 DEG C for 30-40min, filtering the liquid, washing an obtained solid, and drying under vacuum to obtain a target product. In a magnesium halide alcohol adduct formation process, a forming agent and a particle form control agent are added, the particle size distribution of the obtained carrier is more concentrated, the carrier is used for preparing the catalyst, activity and hydrogen sensitivity of the catalyst can be improved when the carrier is used for olefin polymerization especially for propylene polymerization, the bulk density of an obtained polymerization product is moderate, and the polymerization product is basically free of abnormity materials.

Owner:营口风光新材料股份有限公司

Preparation methods of spherical lithium manganate for lithium-ion power battery and precursor of spherical lithium manganate

ActiveCN103326012ALow impurity contentHigh discharge platformCell electrodesManganates/permanganatesWater bathsPower battery

The invention discloses preparation methods of a spherical lithium manganate for a lithium-ion power battery and a precursor of the spherical lithium manganate. The preparation method for the precursor is carried out as the following steps: (1) preparing a manganese salt water solution; (2) preparing a precipitant water solution; (3) injecting the prepared solutions in the step (1) and the step (2) to a reaction kettle with a stirrer and a constant-temperature water bath; (4) mixing the obtained MnCO3 and a compound containing an element M based on a mol ratio of M to Mn described in the invention, sintering and obtaining the precursor. The preparation method of the spherical lithium manganate is carried out as the following steps: mixing the precursor and Li2CO3, sintering and obtaining an M-doped spherical spinel lithium manganate. Compared with the prior art, the method of the invention has the advantages that: (1) impurity content is low, discharge plateau is high, specific capacity is high, cycle performance is good, high-temperature performance is good and tap density is high; and (2) raw material price and production cost are low, powder particle size can be controlled, microscale additive disperses uniformly, particle size distribution is concentrate, and microscopic morphology is spherical or spheroidic.

Owner:QINGDAO HUAGUAN HENGYUAN LI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com