Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Embody novelty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

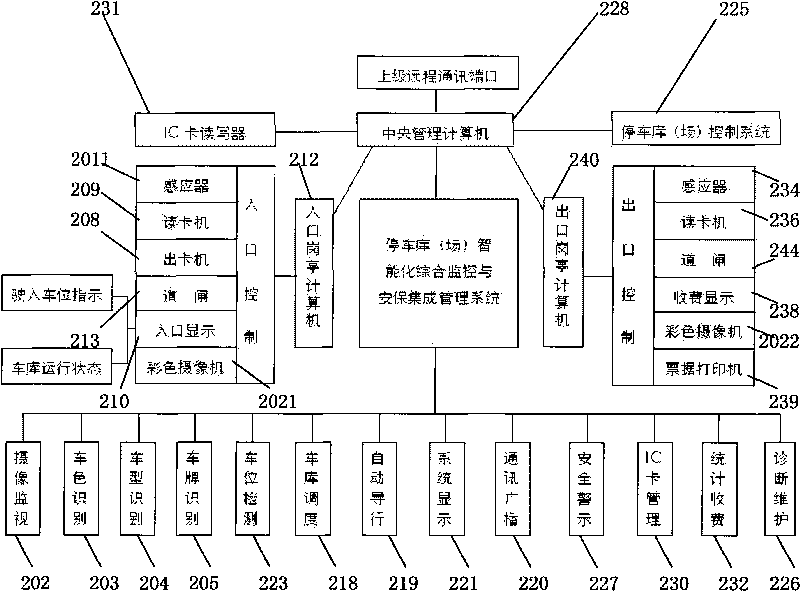

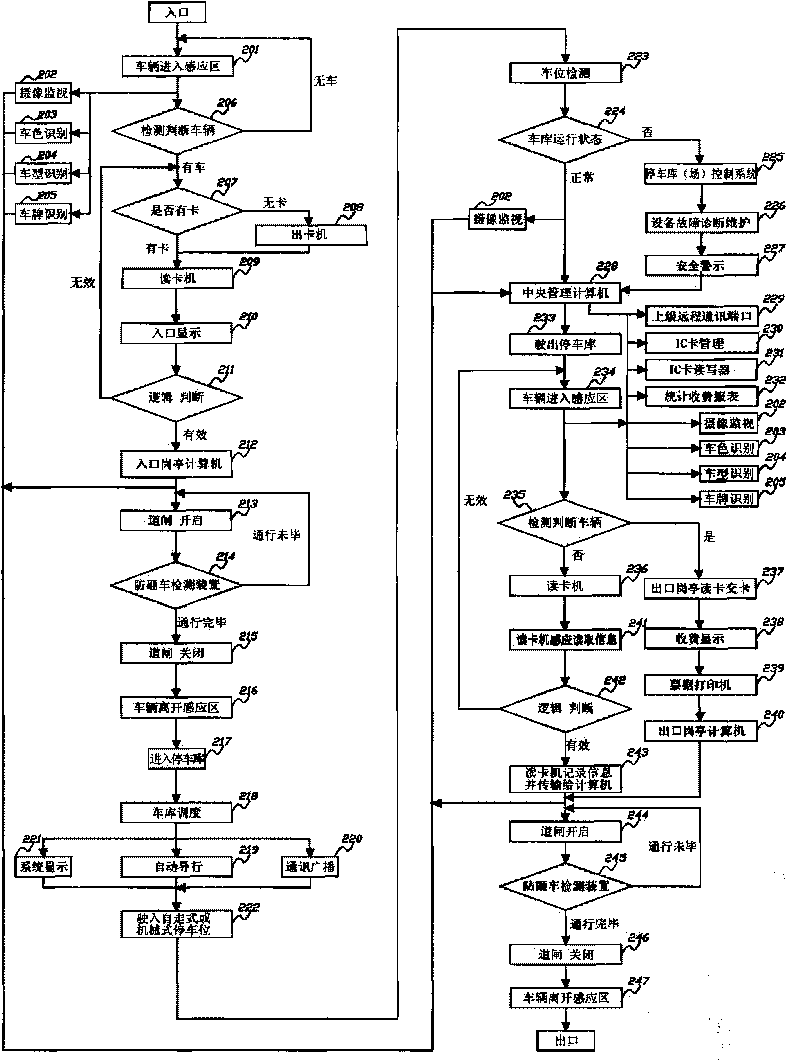

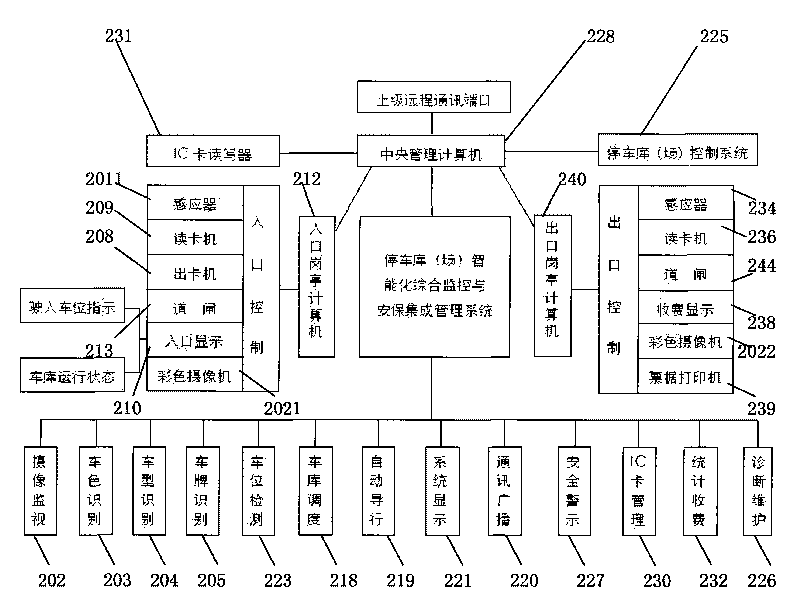

Intelligent comprehensive monitoring and security integrated management system for parking garage

ActiveCN101739841AComplete monitoringPracticalTicket-issuing apparatusIndication of parksing free spacesIntegrated monitoringEconomic benefits

The invention provides an intelligent comprehensive monitoring and security integrated management system for a parking garage. The system solves the comprehensive intelligent management problems of related automatic monitoring, automatic detection, display, different languages and voices, communication, dispatching, guide, digital quantity identification, security, forbidding and passing, charging, statistics, self diagnosis and maintenance and the like of various self-propelled and automatic three-dimensional mechanical parking garages. The system has significant meanings for improving the monitoring, security and management levels of various parking garages, promoting static traffic modernization construction and increasing the social and economic benefits of the parking garages.

Owner:上海久银车库工程有限公司

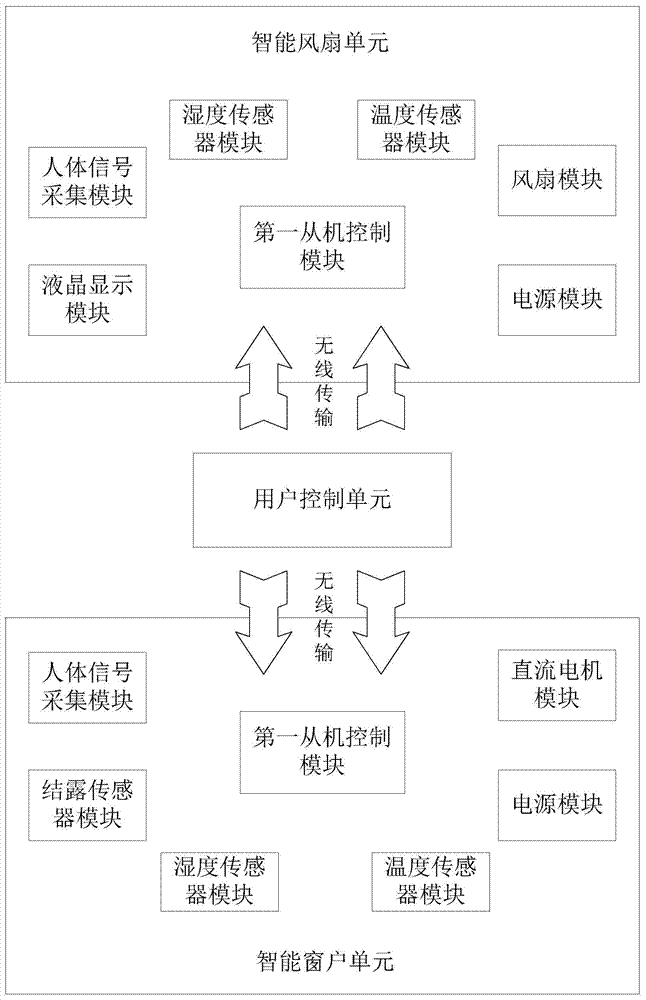

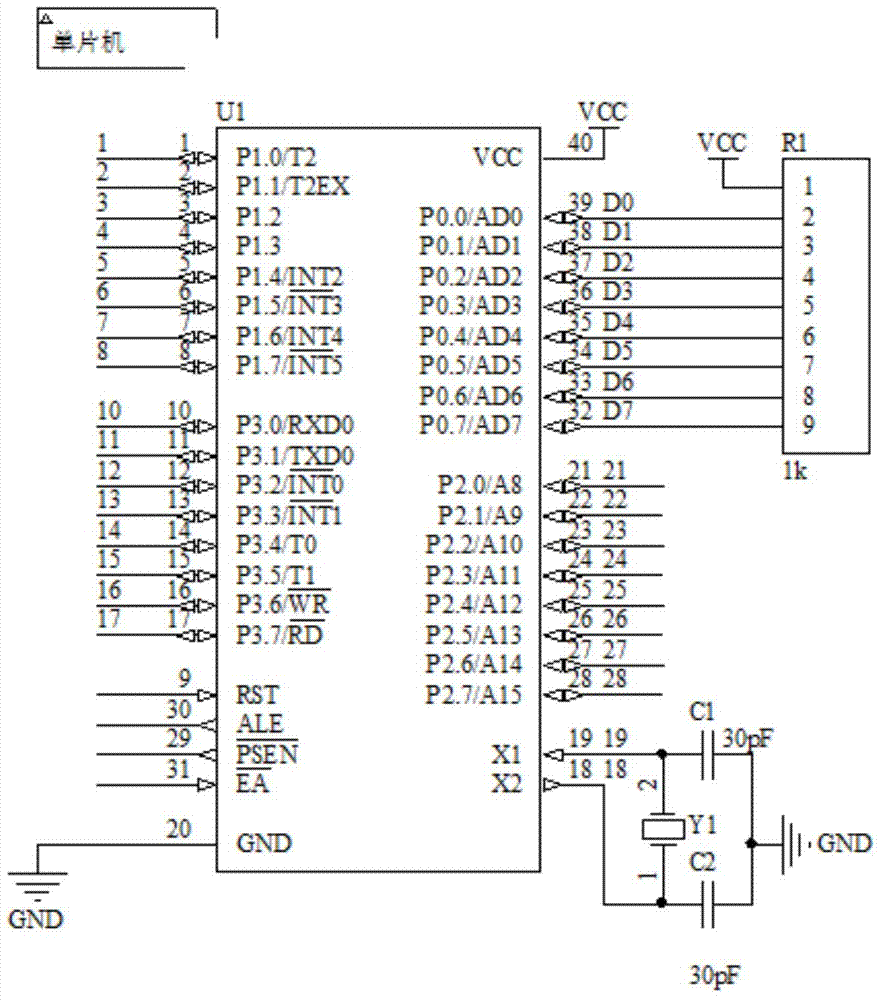

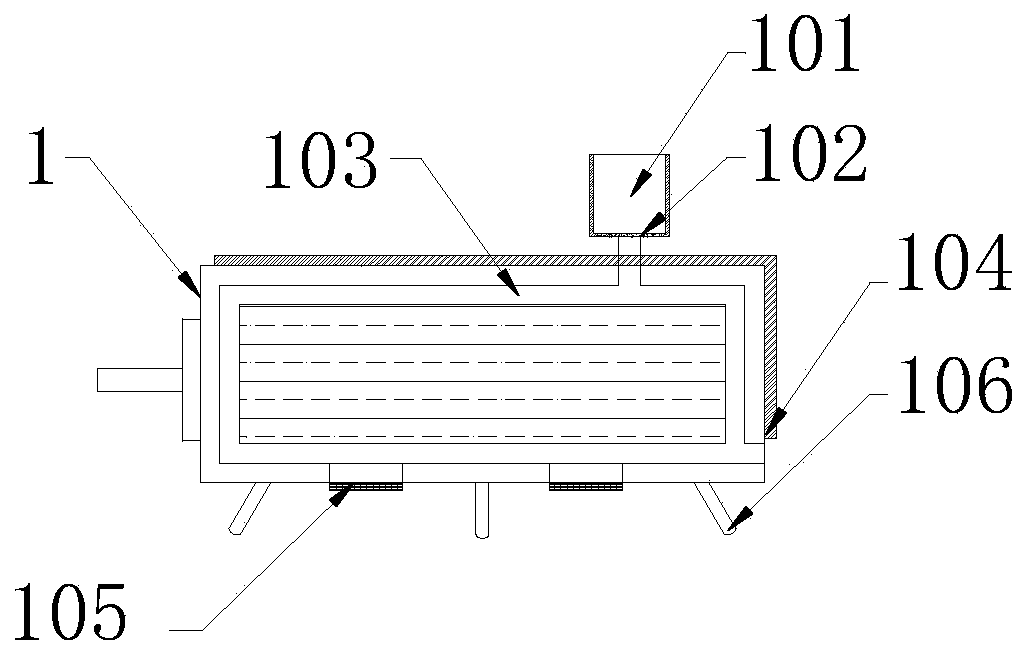

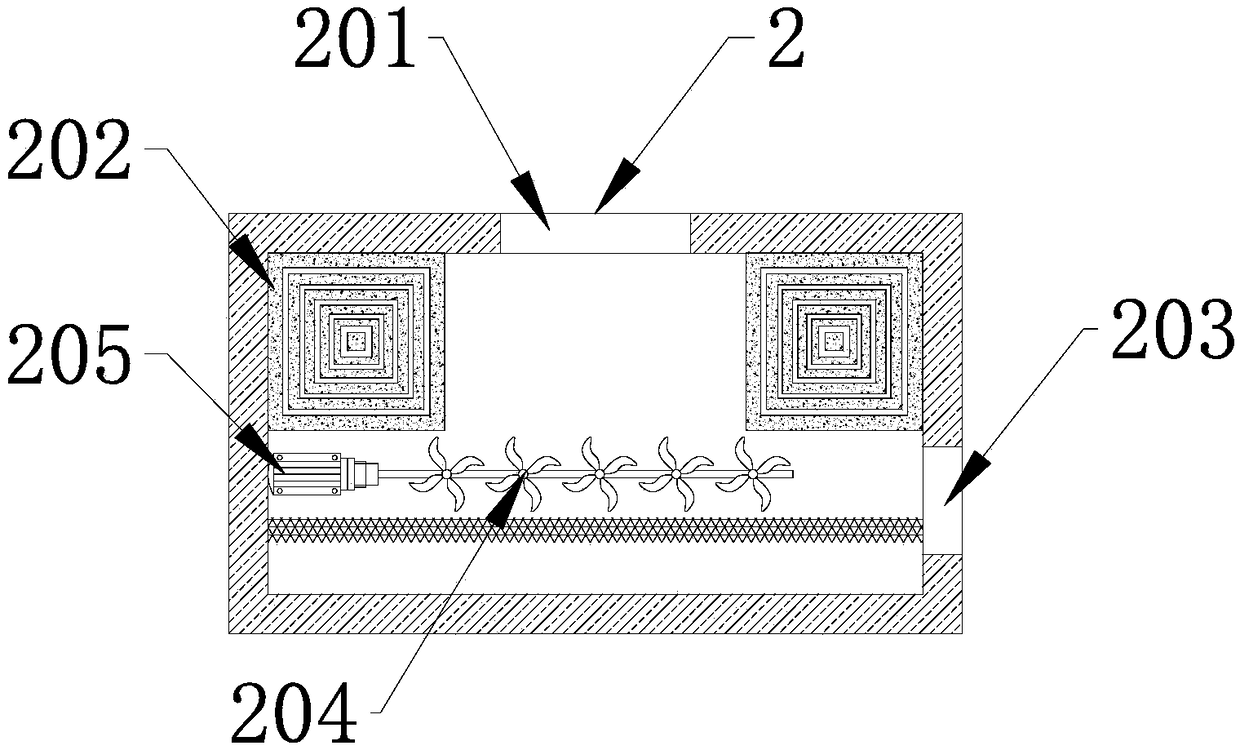

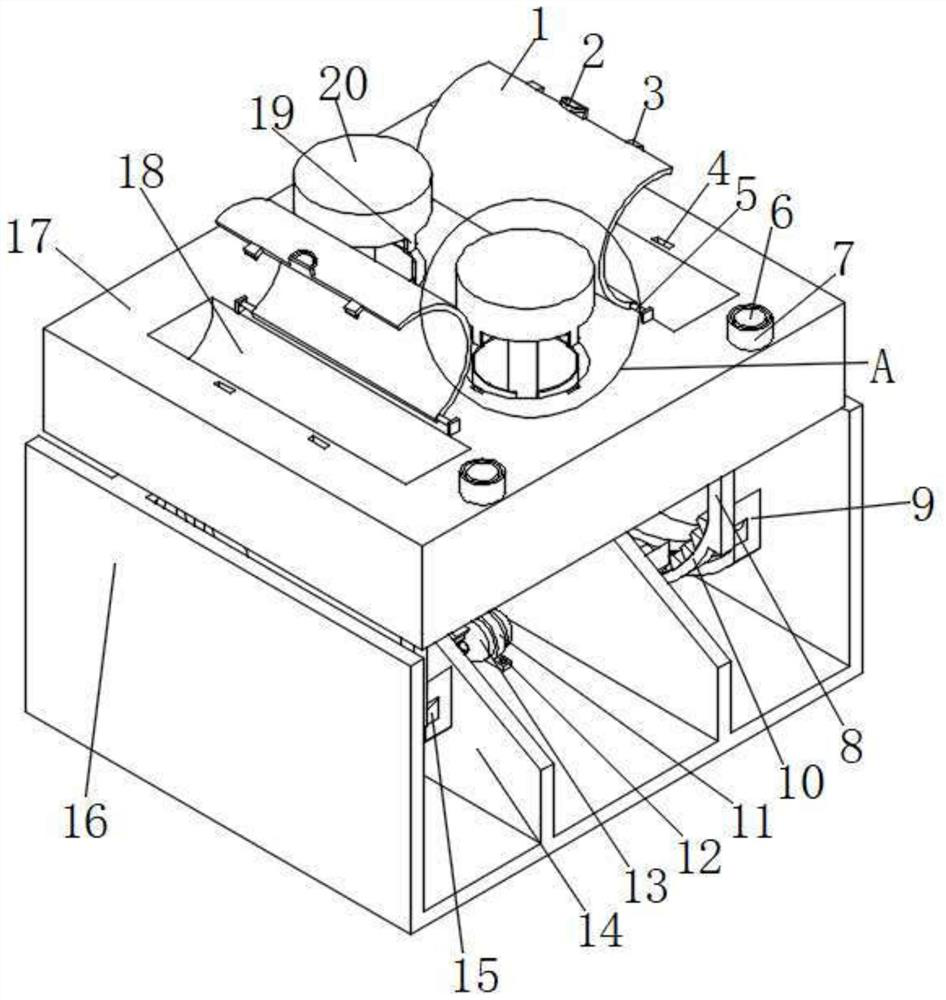

Intelligent indoor temperature adjusting system

InactiveCN104295517AMultiple optionsEmbody noveltyPower-operated mechanismPump controlEngineeringTemperature sensing

The invention discloses an intelligent indoor temperature adjusting system. The intelligent indoor temperature adjusting system comprises an intelligent fan unit, an intelligent window unit and a user control unit. Firstly, a pyroelectric infrared detecting module and a temperature sensing module are adopted by the system to control the opening and the closing of an intelligent window and turning off and turning on of an intelligent fan according to the temperature of an environment so that the ventilation problem caused after an air conditioner is turned off in a timed mode can be solved, and the trouble that people wake up due to stuffiness after the air conditioner is turned off can be relieved; secondly, the speed of the fan is intelligently adjusted, the situation that people get ill due to the fact that too much air is blown to people is effectively avoided, whether a user is close to the fan or not can be automatically detected at the same time, if the user is not within a detection area, and the fan will be automatically turned off so as to achieve the energy-saving purpose; finally, the system achieves the sound control function, voice prompts of the user can be identified, relevant action is made, thievery prevention conducted after the window is opened is achieved with a pyroelectric infrared detecting method, the window is closed in time, and the safety of lives and properties is guaranteed.

Owner:JINAN UNIVERSITY

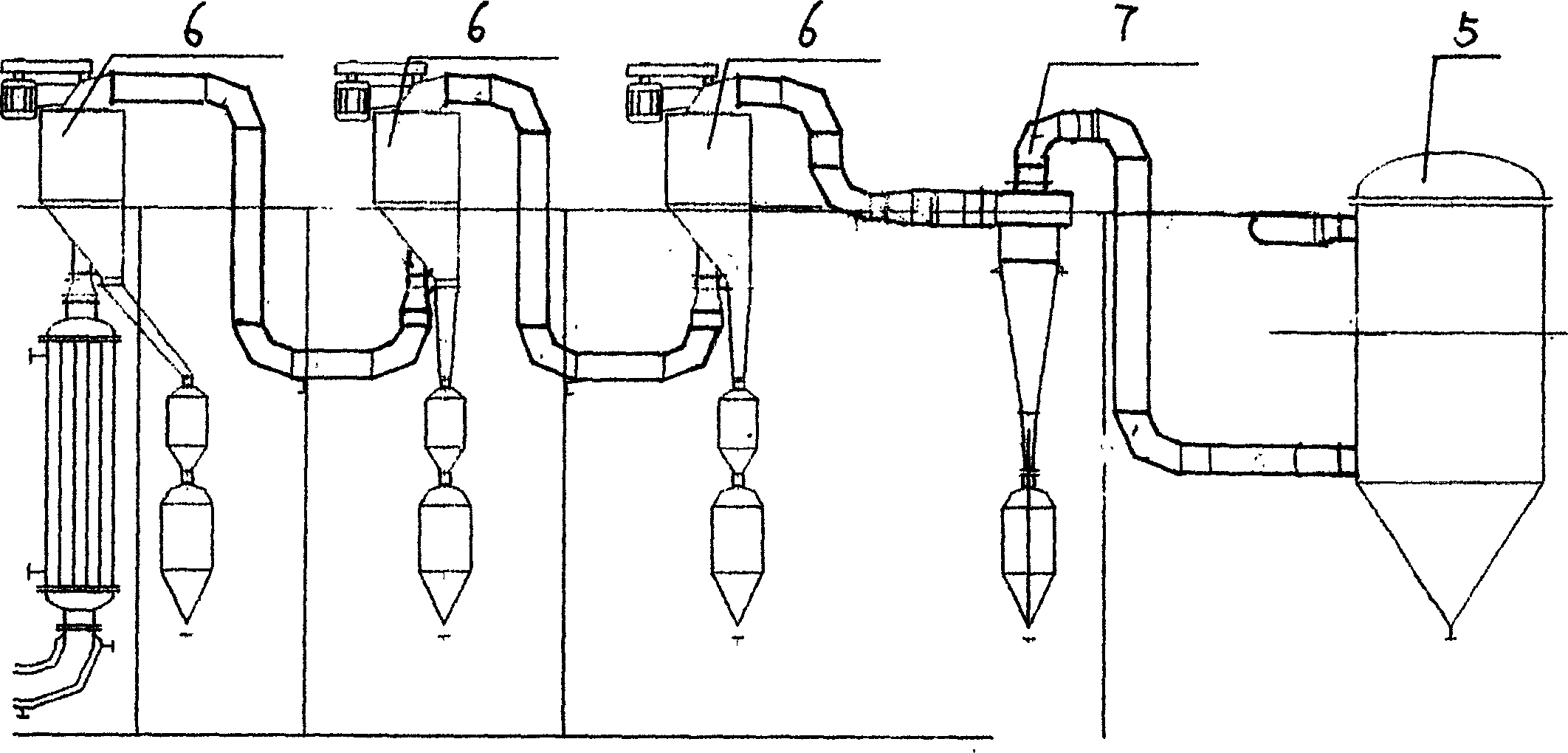

Production technology of two-nozzle atomization aluminium powder

The double nozzle atomizing aluminum powder production process includes the following steps: smelting aluminum ingot in aluminum smelting furnace with two heating silicon carbon rods, atomizing the liquid aluminum in double nozzle atomizing chamber, blowing high temperature and high pressure nitrogen with air compressor into the atomizing chamber to cooling liquid aluminum into aluminum grains, grading in a grading system comprising three stages centrifugal grading machine and one cyclonic collector, and circulating through a circulating system comprising double balance tank and double blower. The present invention has greatly raised production capacity, saving in investment and low production cost.

Owner:鞍钢实业微细铝粉有限公司

Method for chemical modification, pigment dyeing and overflow sand washing of fiber

InactiveCN101736579AEmbody noveltyEmbody creativityBiochemical fibre treatmentDry-cleaning apparatus for textilesFiber ChemistryCellulose fiber

The inventions discloses a method for chemical modification, pigment dyeing and overflow sand wash of a fiber and application thereof to garment dyeing. The method comprises the following steps of: carrying out an anode chemical modification reaction on a cellulosic fiber of a fiber product by using a cation denaturing agent under the non-alkali condition of a fiber product; and then carrying out pigment dyeing and overflow sand wash treatment to enable the fiber product to form the traditional stone washing old-coped effect. Compared with the traditional processing technology, the invention has the advantages that: the hand feeling and the firmness of the products can be improved by modifying the fiber for pigment dyeing, and meanwhile, the technology can be simplified, the process can be shortened, and the consumption and the pollution can be reduced. The invention solves the quality problems on the hand feeling, the firmness, the color reproducibility and the like in traditional garment stone milling treatment.

Owner:鞍山博亿印染有限责任公司

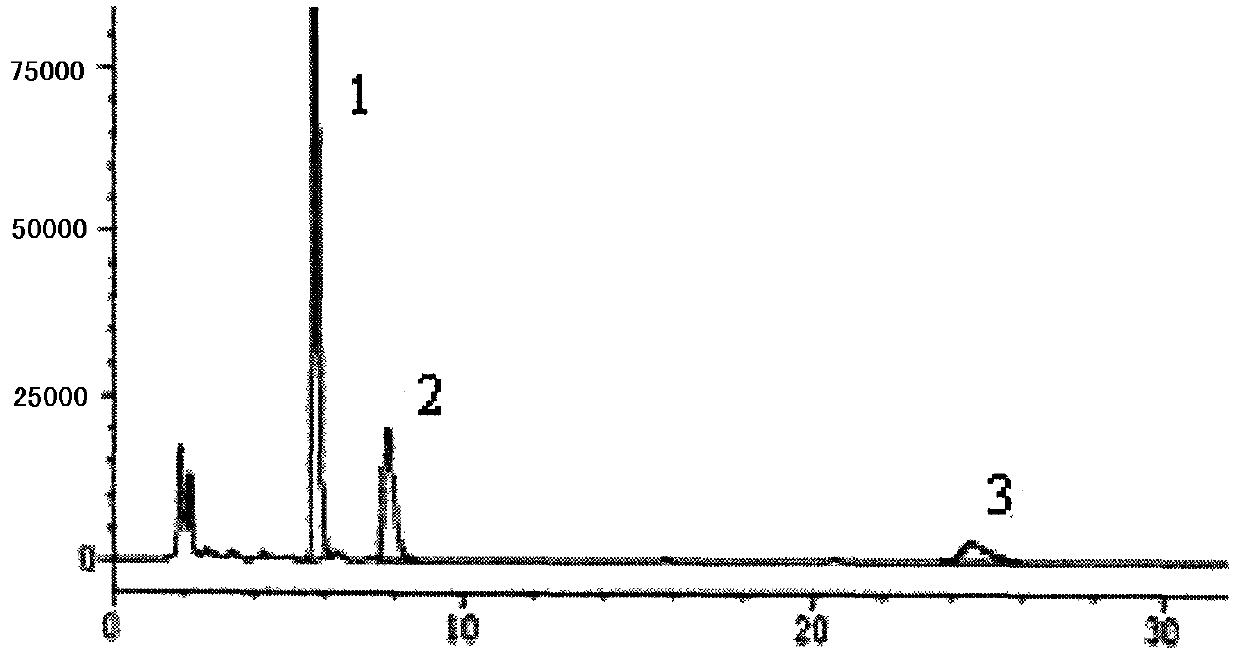

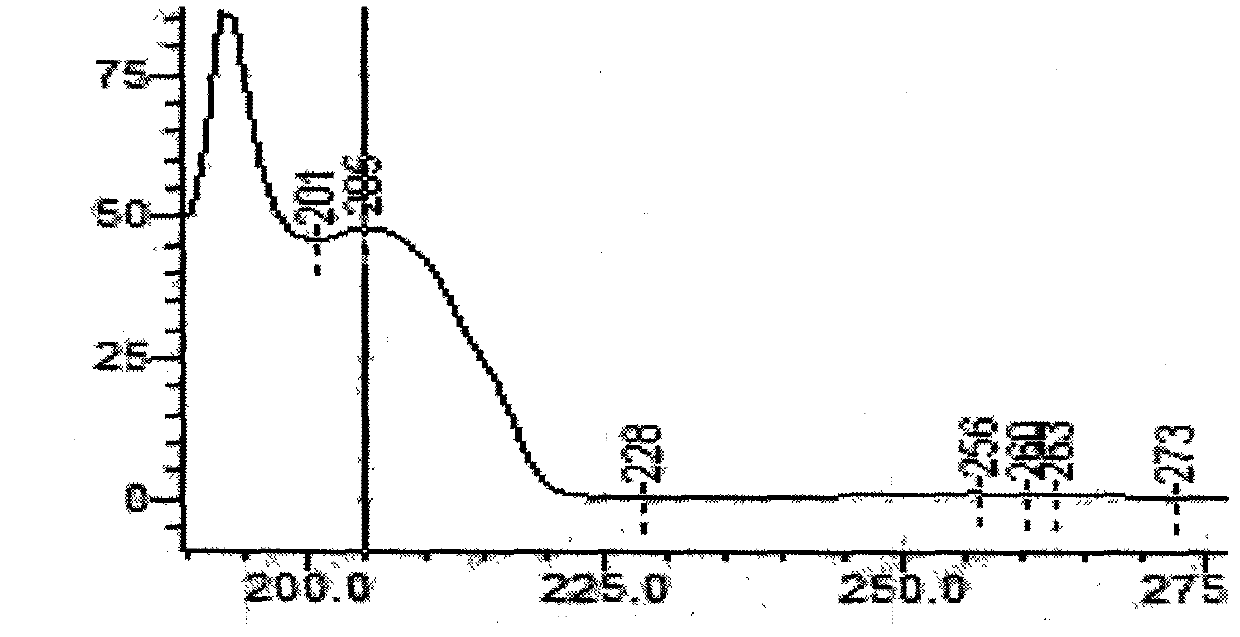

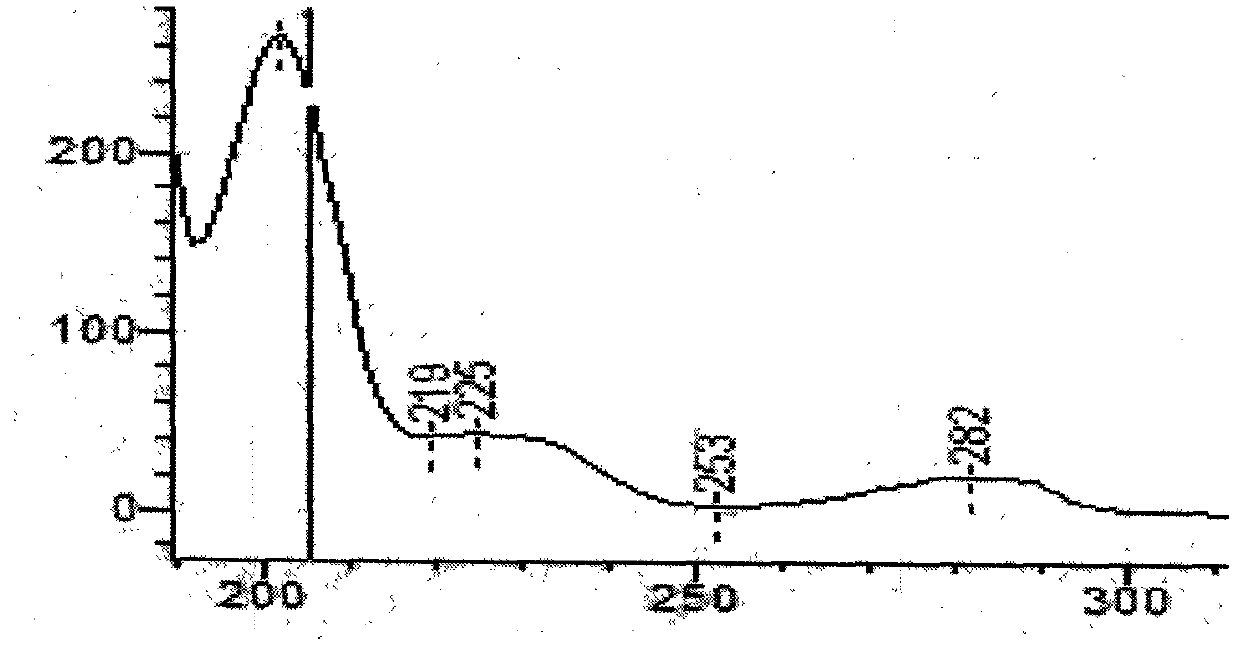

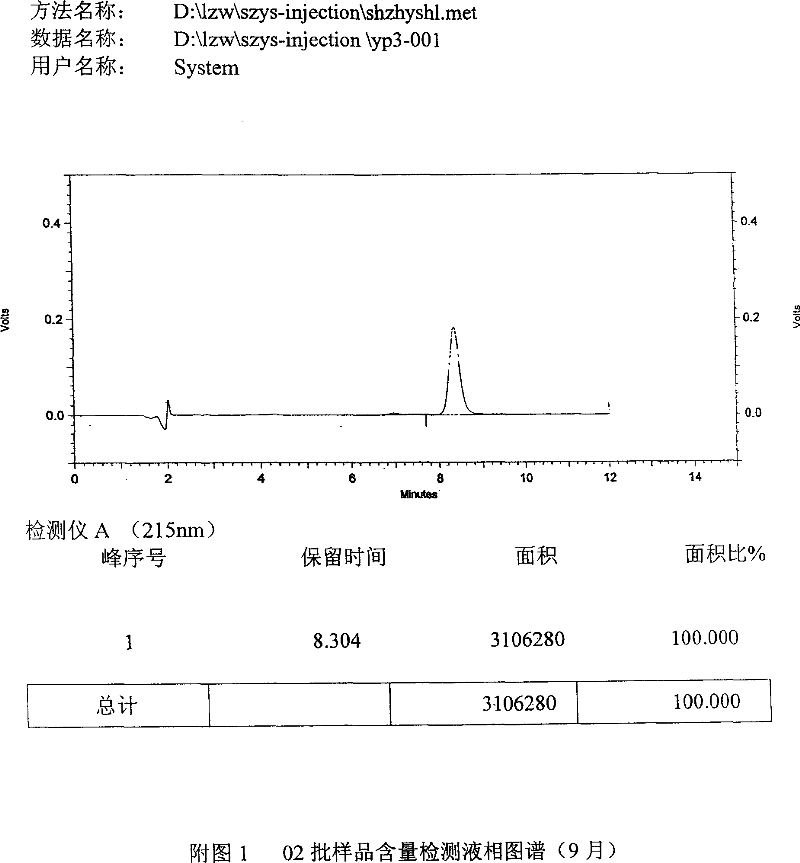

Method for simultaneously determining three alkaloids in granules for eliminating phlegm and stopping cough for children

ActiveCN102662024AQuality improvementGood peak separationComponent separationEmetine HydrochloridePhosphoric acid

The invention relates to a method for simultaneously determining three alkaloids in granules for eliminating the phlegm and stopping the cough for children. The method is characterized in that the HPLC (High Performance Liquid Chromatography) method is employed for the first time, an ordinary gradient elution and reversed-phase chromatographic column are adopted, and acetonitrile, methanol and 0.1% phosphoric acid in the volume ratio of (1.5-2.5) : (12.5-11) : (86-86.5) are taken as the mobile phase; the detection wavelength is 205 nm; and the contents of ephedrine hydrochloride, cephaeline hydrochloride and emetine hydrochloride in the granules for eliminating the phlegm and stopping the cough for children are determined simultaneously, so as to end the history of no HPLC determining method for emetine and no quantitative determining indexes for granules for eliminating the phlegm and stopping the cough for children. The method provided by the invention comprises the steps of performing an ultrasonic treatment to a sample with methanol, sucking a certain amount of subsequent filtrate, removing impurities with an alumina column, and determining. The method has the benefits that crest separation of the three alkaloids is excellent, the baseline is stable, and 30 min is required to finish the determining; the quality control aim of being simple, convenient, quick, scientific, standard and multi-component quantitive by one maker is realized; and safety and effectiveness of taking granules for eliminating the phlegm and stopping the cough for children are ensured.

Owner:JING JING PHARMA

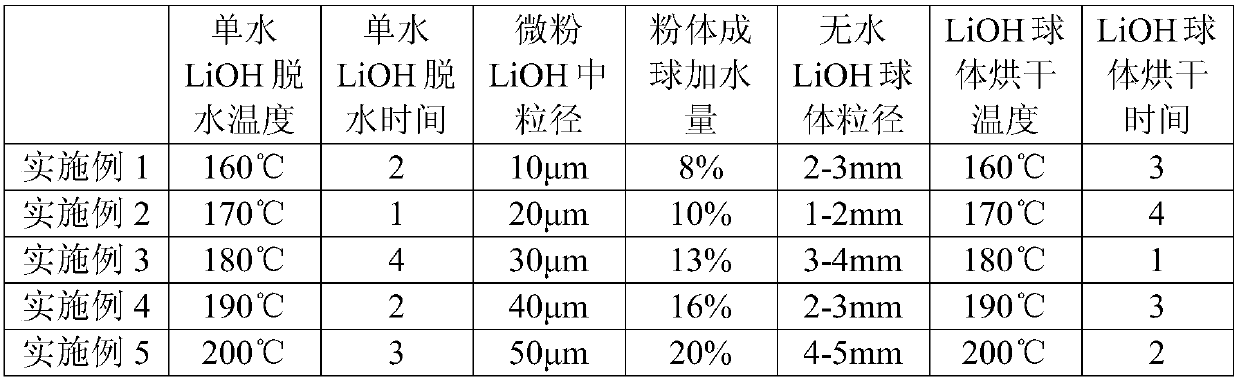

Method for industrially producing anhydrous lithium hydroxide balls

ActiveCN109553118AAchieve recyclingPrevent hardeningCarbon compoundsLithium oxides/hydroxidesLithium hydroxidePhysical chemistry

The invention provides a method for industrially producing anhydrous lithium hydroxide balls, comprising the steps of dehydration drying, fine powder, ball forming of powder, sieving, drying, and thelike. Medicine grains, which do not cause powder falling and do not have irritating smell, are prepared from anhydrous lithium hydroxide by a powder forming process. When the anhydrous lithium hydroxide balls are applied to a CO2 absorbent, the absorption efficiency of carbon dioxide by the absorbent is tested to be 85% or more according to a coal standard MT454-2008.

Owner:GANFENG LITHIUM CO LTD

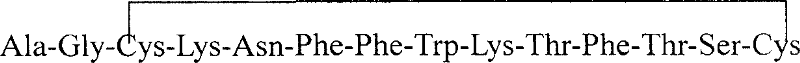

Somatostation a aqua prepn and its prepn process and application

ActiveCN100336557CSimple production processHigh activityMetabolism disorderAerosol deliveryPediatricsDisease

The present invention relates to one kind of somatostation aqua preparation and its preparation process and application in preparing medicine for preventing and treating serious acute esophagus varicose hemorrhage, acute gastric and duodenal ulcer hemorrhage, acute erosive gastritis, acute hemorrhagic gastritis, etc. The preparation consists of somatostation in 0.1-1000 mg each 0.1-500 ml, medicinal supplementary material, which may be mannitol, polyglycol, cyclodextrin, etc., and water. The preparation process includes compounding, sterilizing, packing, and other steps. The somatostation aqua preparation has high stability, easy preparation and other features, and has wide application foreground in preparing medicine for preventing and treating serious acute esophagus varicose hemorrhage, acute gastric and duodenal ulcer hemorrhage, acute erosive gastritis, acute hemorrhagic gastritis, etc.

Owner:BEIJING SL PHARMA

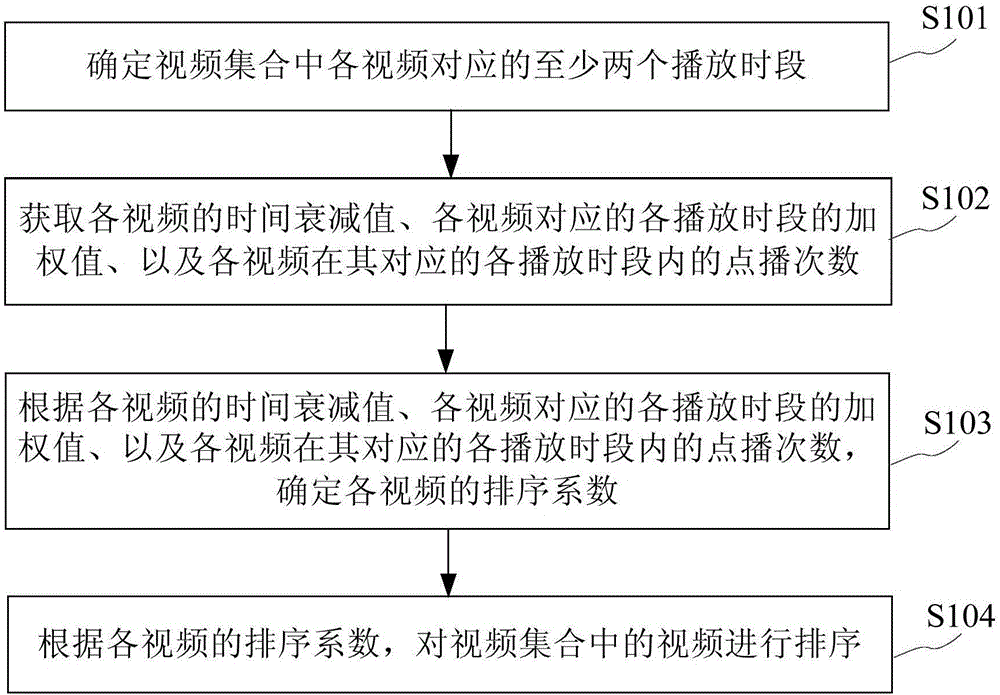

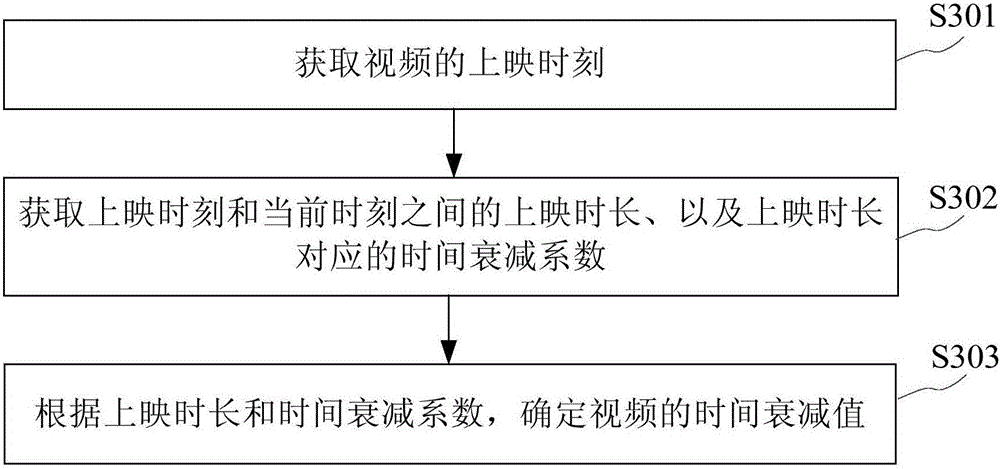

Video sequencing method and device based on video on-demand volume

ActiveCN105828181AReflect the length of the showEmbody noveltySelective content distributionUltrasound attenuationRanking

An embodiment of the invention provides a video sequencing method and device based on video on-demand volume. The method includes the steps of: determining at least two playing periods of time corresponding to each video in a video set, the video set including at least one video; obtaining a time attenuation value of each video, a weighted value of each playing period of time corresponding to each video and the on-demand number of times of each video in corresponding each playing period of time; determining a sequencing coefficient of the videos according to the time attenuation value of each video, the weighted value of each playing period of time corresponding to each video and the on-demand number of times of each video in corresponding each playing period of time; and sequencing the videos in the video set according to the sequencing coefficient of each video. The video sequencing method is used for improving the precision of video ranking.

Owner:JUHAOKAN TECH CO LTD

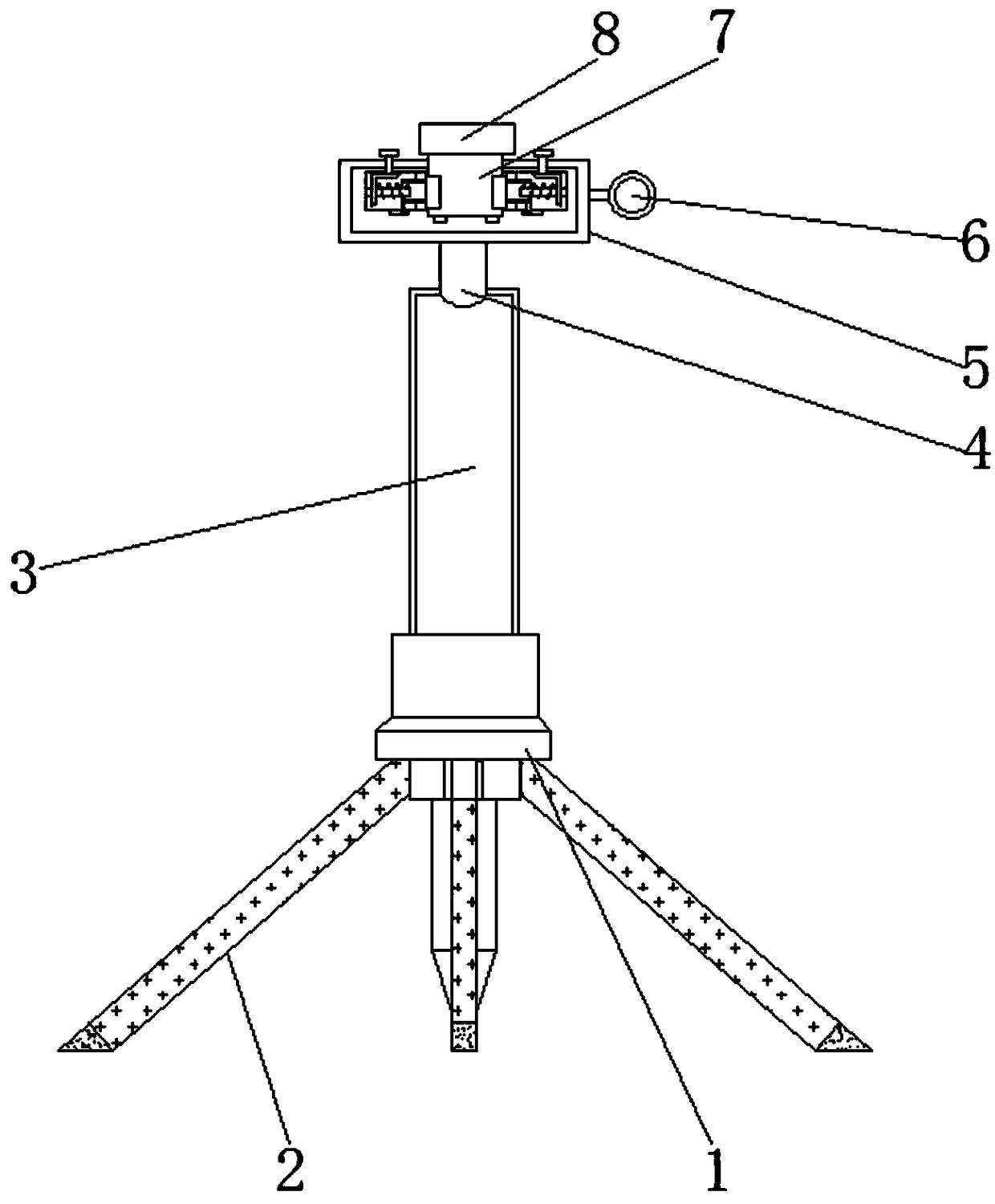

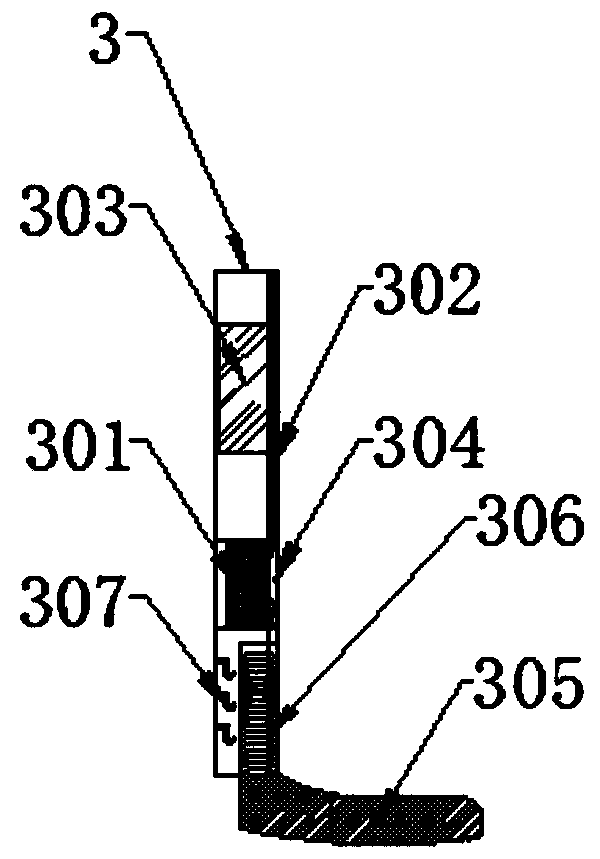

Height-adjustable mounting bracket for communication equipment

InactiveCN108966048AQuick installationEmbody practicalitySelection arrangementsArchitectural engineeringPulley

The invention discloses a height-adjustable mounting bracket for communication equipment. The mounting bracket comprises a base, wherein a connecting block is welded at the top outer wall of the base,and a connecting column is welded at the middle location of the top outer wall of the connecting block, sliding rails are formed at inner walls at two sides of the connecting column, and the inner wall of the bottom of each sliding rail is slidingly connected with a sliding wheel, and the sliding wheels are matched with the sliding rails in specification; a connecting rod is arranged at the outerwall of one side of each pulley, and a telescopic rod is welded at the outer wall of one end of the connecting rod; a circular groove is formed in the connecting column, and the telescopic rod is inserted into the circular groove; a first groove is formed on the outer wall of one side of the telescopic rod, and a spring is welded at the inner wall of the bottom of the first groove. The height ofthe mounting bracket can be quickly adjusted, so that the people can conveniently and quickly mount the communication equipment, the practicability and the novelty of the device are reflected, the alarm lamp and like communication equipment can be dismounted more easily, and the maintenance can be timely performed when the communication equipment is in fault.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

Anti-fall face protection device for cobra breeding

The invention discloses an anti-fall face protection device for cobra breeding, including a main body of the protection device, a hood and a mask, wherein the hood is fixedly connected to the top of the main body; the mask is fixedly connected to the bottom of the main body; the bottom end of the mask is fixedly connected with a chin top bracket; an adjustment spring is fixedly connected to the inner bottom of the mask; an adjusting hook is fixedly connected to one side of the inner bottom of the mask, the bottom end of the hood is fixedly connected with an adjusting cap ring, the adjusting cap ring plays a very good role in preventing the main body from falling off, and the chin supports the upward pressure, so that the head of the cobra farmer and the hood form a stable supporting structure, thus effectively guaranteeing the anti-fall effect of the main body; the nasal support embodies the humanization of the main body and improves the comfort of the main body of the protection device; the isolation film fully embodies the safety of the main body of the protection device and is suitable for the use of face protection, so that the anti-fall face protection device for cobra breeding has a wide development prospect in the future.

Owner:宋小魁

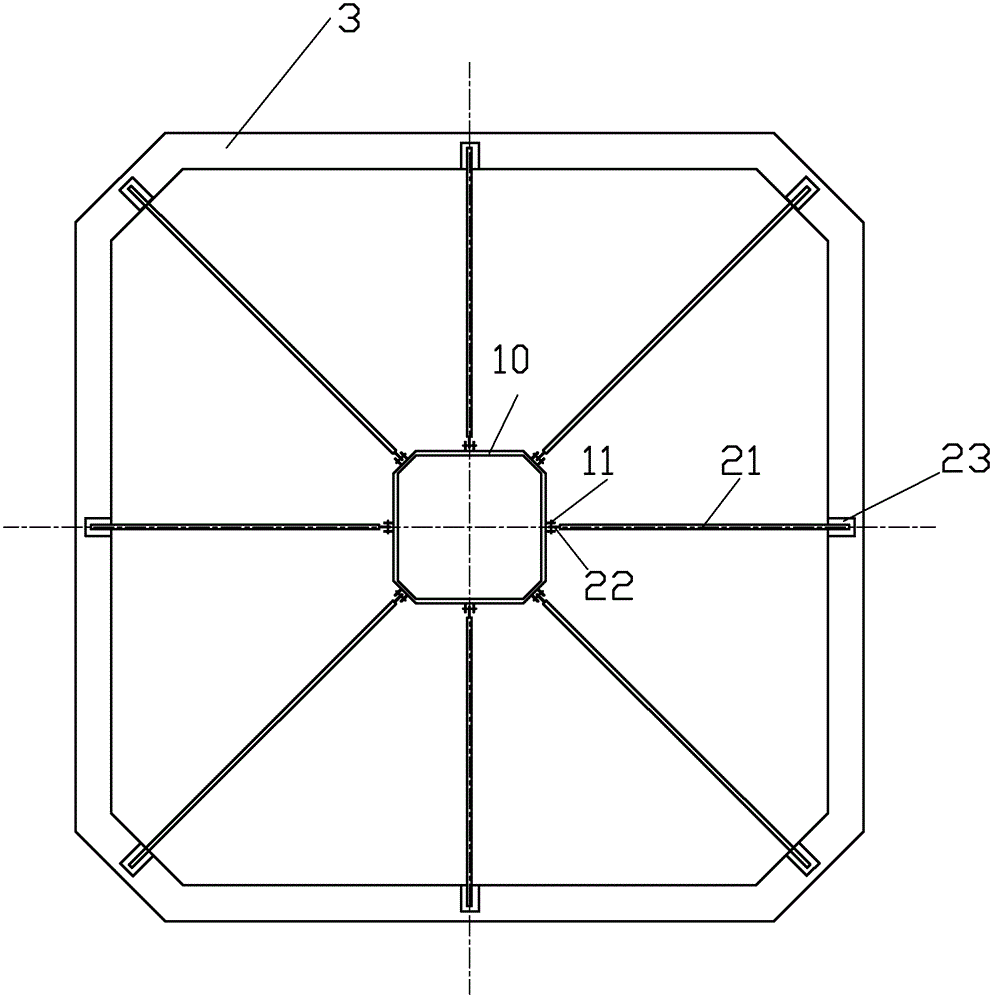

An anti-jump net heat preservation cover support for aquaculture fish pond

InactiveCN102257975ASmall footprintEmbody noveltyClimate change adaptationPisciculture and aquariaDual purposeEngineering

The invention relates to the technical field of auxiliary devices for aquaculture, in particular to an anti-jump net and insulation cover integrated support for preventing fish from jumping away from a factory fish pond. The support is characterized in that a connecting ring (10) is arranged above a fish pond (3); a plurality of hinge pedestals (1) are arranged on the circumference of the connecting ring (10); each hinge pedestal (1) is connected with all support rods (21) by hinge pins (22) arranged at the upper ends of the support rods (21) in a rotary manner; the lower end of each support rod (21) is fixedly connected with a supporting angle-shaped plate (23) in a shape of angle steel; and the right-angled bend of each supporting angle-shaped plate (23) is supported at the top surface and inner wall on the circumference of the fish pond (3). The support is neat, light and flexible, is convenient to collect after being folded or dismantled, has lower cost, can be repeatedly used, isan anti-jump net and insulation cover dual-purpose support suitable for the factory fish pond and is an auxiliary device specially for aquaculture.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

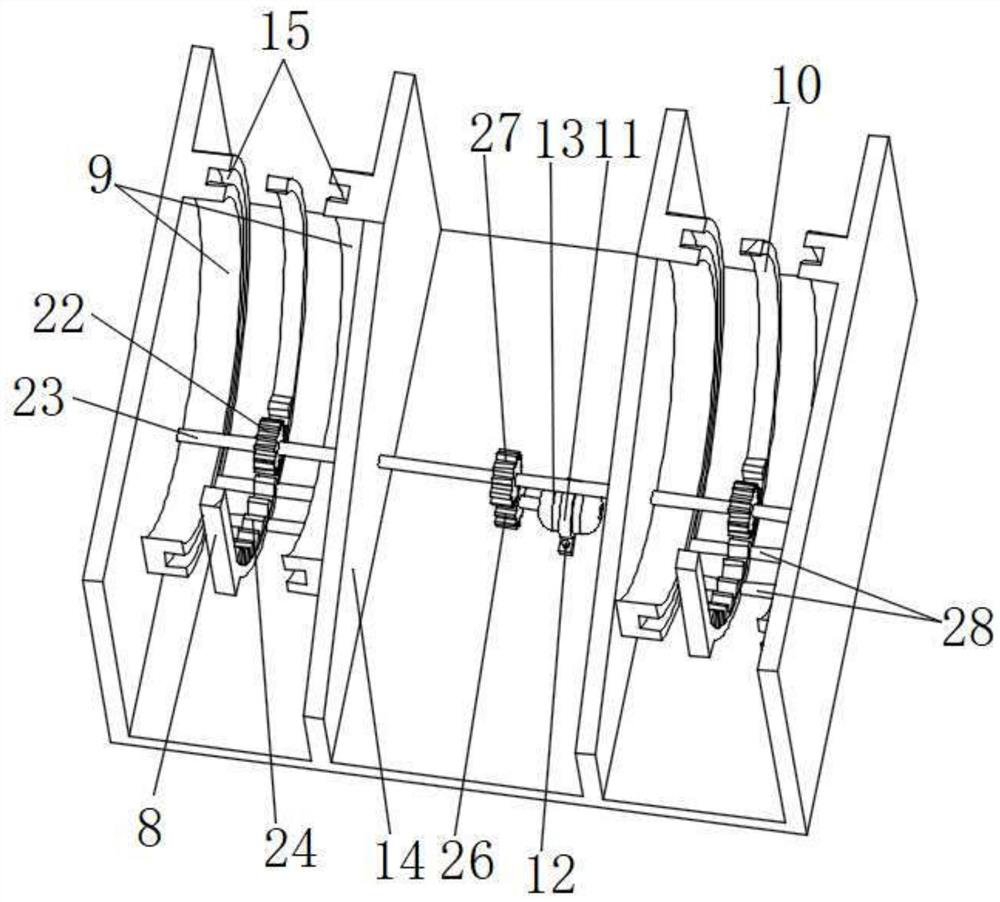

Driving control signal collecting device for groove wheel of seeding machine or fertilization seeding machine

PendingCN106818003AStrong noveltyCreativeDevices using optical meansFertiliser equipmentsSeederControl signal

The present invention relates to an improved device of a seeding machine or a fertilization seeding machine in agricultural machines, and discloses a driving control signal collecting device for a seed or fertilizer discharge groove wheel of the seeding machine or the fertilization seeding machine, roller wheels are arranged on the seeding machine or the fertilization seeding machine, the roller wheels are contacted with the ground, the roller wheels rotate along with the forward moving of the seeding machine or the fertilization seeding machine, and electrical signals which are outputted while the roller wheels rotate are transmitted to a driving control device of the groove wheel (12) of the seeding machine or the fertilization seeding machine. A rotating shaft (8) of the roller wheels collects the electrical signals by a rotation speed sensor to transmit to the driving control device of the groove wheel (12) of the seeding machine or the fertilization seeding machine. The rotating shaft (8) of the roller wheels is provided with a grating disc (4), an infrared probe (10) on the side of the grating disc (4) collects the electrical signals to transmit to the driving control device of the groove wheel (12) of the seeding machine or the fertilization seeding machine. The driving control signal collecting device has the advantage of simple structure, the whole driving control signal collecting device combines two technical characteristics, the driving control signal collecting device can sensitively and accurately reflect and collect actual operation conditions of the seeding machine or the fertilization seeding machine, also can conveniently and quickly transfer the actual operation conditions to the driving control device of the groove wheel of the seeding machine or the fertilization seeding machine to obtain accurate signals so as to achieve the purpose of the driving control signal collecting device.

Owner:彭卓敏

Intelligent management system and method for tunnel engineering

PendingCN111997690AEmergency escapeEmbody wisdomMining devicesMeasurement devicesEnvironmental resource managementIdentity recognition

The invention provides an intelligent management system and method for tunnel engineering. The intelligent management system comprises an identity recognition device, a temperature measuring device, apositioning device, a communication device, a fire alarm device, an environment monitoring device and a monitoring device. The identity recognition device is arranged in a tunnel and a tunnel entrance and / or exit. The temperature measuring device is used for identifying the body temperature of a person entering the tunnel and / or ambient temperature. The positioning device is used for positioningthe positions of people in the tunnel in real time. The communication device is used for realizing the conversation between people in the tunnel and between the people and a monitoring room. The firealarm device and the environment monitoring device are used for fire and harmful gas safety alarming. The monitoring device is used for real-time monitoring of information. The intelligent managementsystem and method for tunnel engineering comprehensively use intelligent sensors, human face recognition, personnel precise positioning, mobile Internet, big data cloud platforms and APP new generation technology, multiple types of emerging technologies are integrated to the intelligent management system, and intelligence, advancement and novelty are fully embodied.

Owner:SHANGHAI INSTALLATION ENG GRP

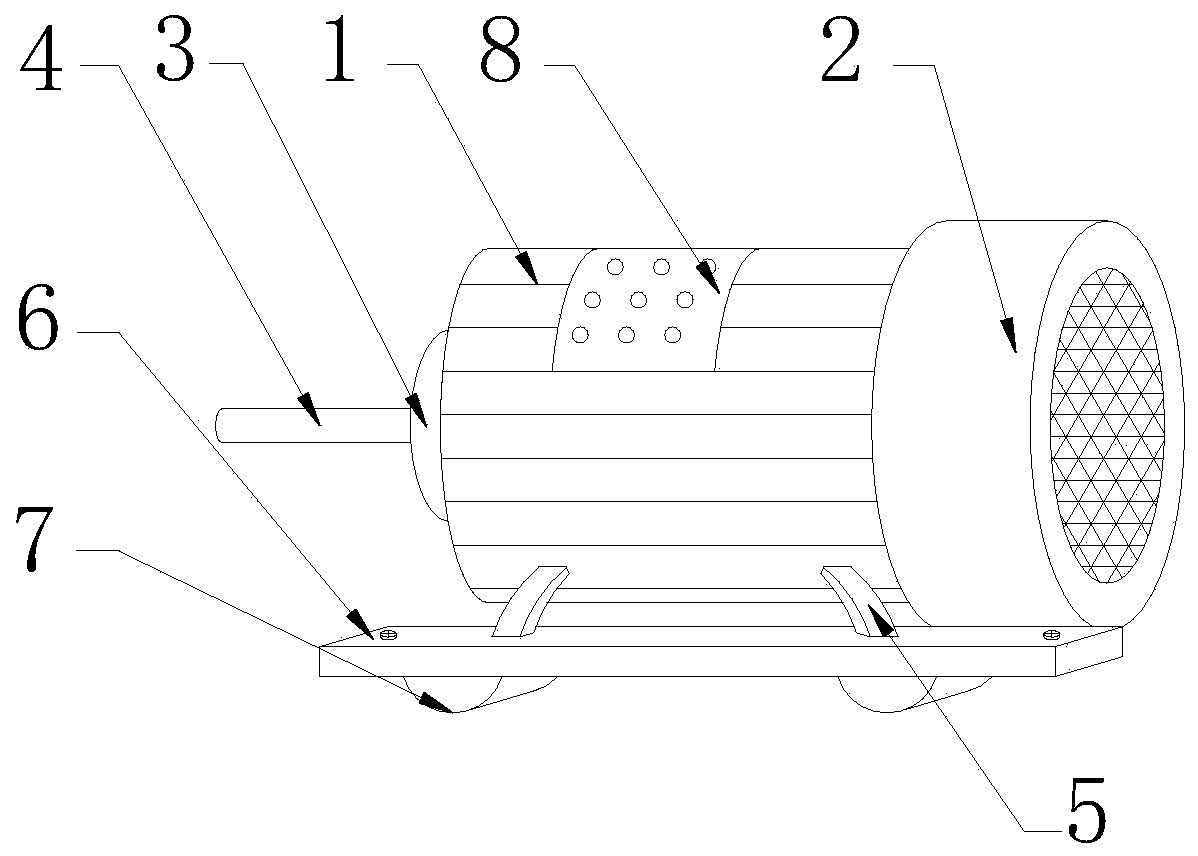

Generator convenient for thermal dissipation

InactiveCN110048540AImprove securityGood heat insulationCooling/ventillation arrangementSupports/enclosures/casingsThermal insulationOperability

The invention discloses a generator convenient for thermal dissipation. The generator comprises a generator main body, a thermal dissipation end board and a front end cover, a water injection cavity is embedded into the top end of the generator main body, a water diversion film is tightly attached to the middle part of the interior of the water injection cavity, the bottom end of the water injection cavity is fixedly connected with a thermal conduction pipe, the bottom end of the thermal conduction pipe is fixedly connected with a superheated steam outlet, the periphery of the generator main body is fixedly connected with a reflector, a rubber sleeve is tightly attached to the top end of the generator main body, the rubber sleeve has good thermal insulation capability, thus scald risk is avoided, the reflector well ensures the practicability of the generator, a shock absorption support can buffer shock generated by the generator main body to a certain degree, operability of the generator is well improved, the service life of the generator is well prolonged through the superheated steam outlet, the thermal dissipation performance of the generator is further improved through the cooling fan, and the generator is suitable for being used and has wide development prospects in the future.

Owner:诸暨市合纵科技有限公司

Manufacturing method of phosphogypsum ball

The present invention relates to a preparation method of phosphogypsum sphere which can be substituted for natural gypsum in cement industrial. Said method includes the following steps: (1), raw material selection: selecting naturally dried rejected material of phosphate fertilizer plant, screening, removing impurity, its grain size is less than 10mm; (2), adding modifying agent alkaline substance, uniformly mixing them, drying in drying kiln, in the drying process making the impurities of water, water-soluble phosphorus pentoxide, sulfate radical and phosphate radical be volatilized; and (3), pressing sphere and forming.

Owner:朱成书

Fluoroplastic product processing calender

The invention discloses a fluoroplastic product processing calender. The fluoroplastic product processing calender comprises a calender main body, a horizontal worktable and a multi-directional flattening roller. The top of the calender main body is movably connected with the horizontal worktable, one side of the horizontal worktable is connected with the multi-directional flattening roller in a penetrating mode, one side of the calender main body is connected with a temperature-controlled processing electric furnace in a penetrating mode, a tungsten heating plate is fixedly connected with a middle part of the temperature-controlled processing electric furnace, driving motors are fixedly connected with both ends of the multi-directional flattening roller. The rolling speed of the flattening roller is improved by the driving motors, embodying the practicability of the fluoroplastic product processing calender. A transverse flattening roller makes the surface of a fluoroplastic product more flat and improves the flatness of the fluoroplastic product. The heating plate has a high melting point and has good stability and can adapt to different heating environments. A flattening rollerspring well embodies novelty of the fluoroplastic product processing calender. The fluoroplastic product processing calender is suitable for the field of processing of fluoroplastics and has broad development prospects in the future.

Owner:湖州博创氟材科技有限公司

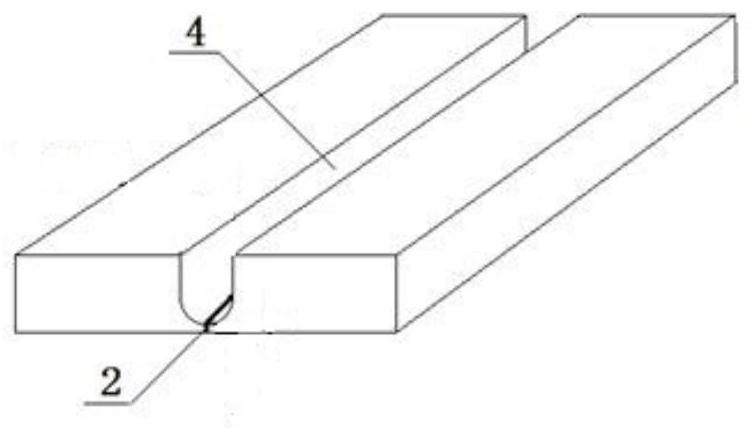

Method for repairing cracks of circular saw blade through welding

InactiveCN112676678AEasy and flexible operationEasy to operateArc welding apparatusSawing tools dressing arrangementsCircular sawEconomic benefits

The invention discloses a method for repairing cracks of a circular saw blade through welding, and particularly provides a manual arc welding process method capable of repairing crack defects of the circular saw blade at a lower preheating temperature. The method is characterized in that a welding material is a flat welding electrode capable of realizing narrow-direction strip conveying method welding and wide-direction strip conveying method welding; narrow and small grooves are welded; weld joint stress is eliminated through vibration impact; a bottoming weld joint and a filling weld joint are welded through a narrow-direction strip conveying method, and a cap weld joint is welded through a wide-direction strip conveying method; and the preheating temperature of the circular saw blade is 100 DEG C, and the welding repair temperature is kept at 80-100 DEG C. According to the method, the problem that the welding preheating temperature is too high is effectively solved, meanwhile, the welding operation is as simple, convenient and feasible as common welding, effective welding repair of the cracks on the circular saw web can be achieved, and the method has very high practical value and economic benefits.

Owner:日照唐晟锯业有限公司

Mould for spheroidal graphite iron casting

The invention discloses a mould for a spheroidal graphite iron casting. The mould for the spheroidal graphite iron casting comprises a mould main body, a processing box and a support column. The top of the mould main body is fixedly connected with the processing box. The bottom of the processing box is fixedly connected with the support column. The middle portion of one side in the processing boxis connected with a feeding channel in a penetrated mode. The middle portion of the top in the processing box is fixedly connected with a graphite treatment box. The middle portion of the other side in the processing box is fixedly connected with a spheroidizing agent treatment box. A top cover is connected to the top of the processing box in an embedded mode and can be dismantled to clean the interior of the mould main body and eliminate a failure of an internal device conveniently. An extraction fan facilitates to draw fresh air from the outside into the mould main body and discharge internal exhaust gas of the casting. A cooling box makes the casting in the forming mould be cooled quickly and improves the quality of the casting greatly. The mould for the spheroidal graphite iron castingis convenient to use, has high security, is suitable for the technical field of spheroidal graphite iron, and has broad prospects for development in the future.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

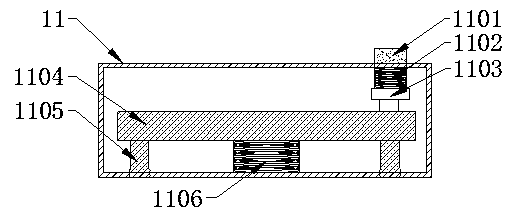

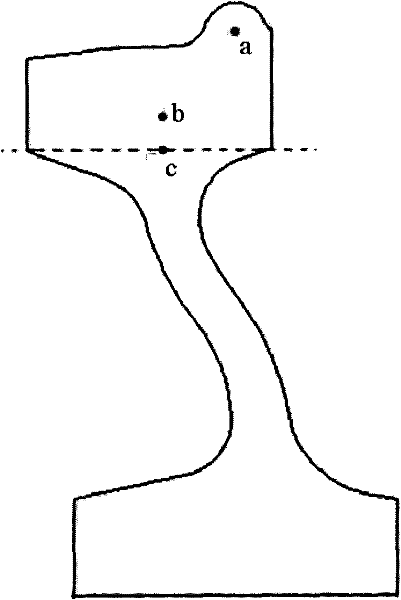

Railway wheel heat treatment heating furnace and heat treatment process thereof

ActiveCN101818239BHigh strengthImprove toughnessIncreasing energy efficiencyFurnace typesEnvironmental resistanceHigh intensity

The invention discloses a railway wheel heat treatment heating furnace. An induction heating device therein has the structure that the periphery of the tread of a railway wheel is provided with an induction heating coil, the corresponding positions of the inner side surface of the rim of the railway wheel and the inner side surface of the rim to a transition area are respectively provided with aninduction heating compensation coil. The invention also discloses a heat treatment process thereof of the heat treatment heating furnace. The above technical scheme realizes the technical target of high strength and high toughness of the rim as well as low strength and high toughness of a wheel disk. The two-phase region has high heating speed and short austenite temperature region, is favorable for evenly refining crystalline grains and improves rim toughness. The invention can realize quick heating of the wheel rim position, and the wheel disk position temperate is below Ac3 while the rim position is totally austenitized. The invention has the advantages of quick starting, high heating speed, easy control of temperature, high heating efficiency, favorable technical repeatability, favorable workpiece surface quality, environmental protection and the like.

Owner:MAANSHAN IRON & STEEL CO LTD

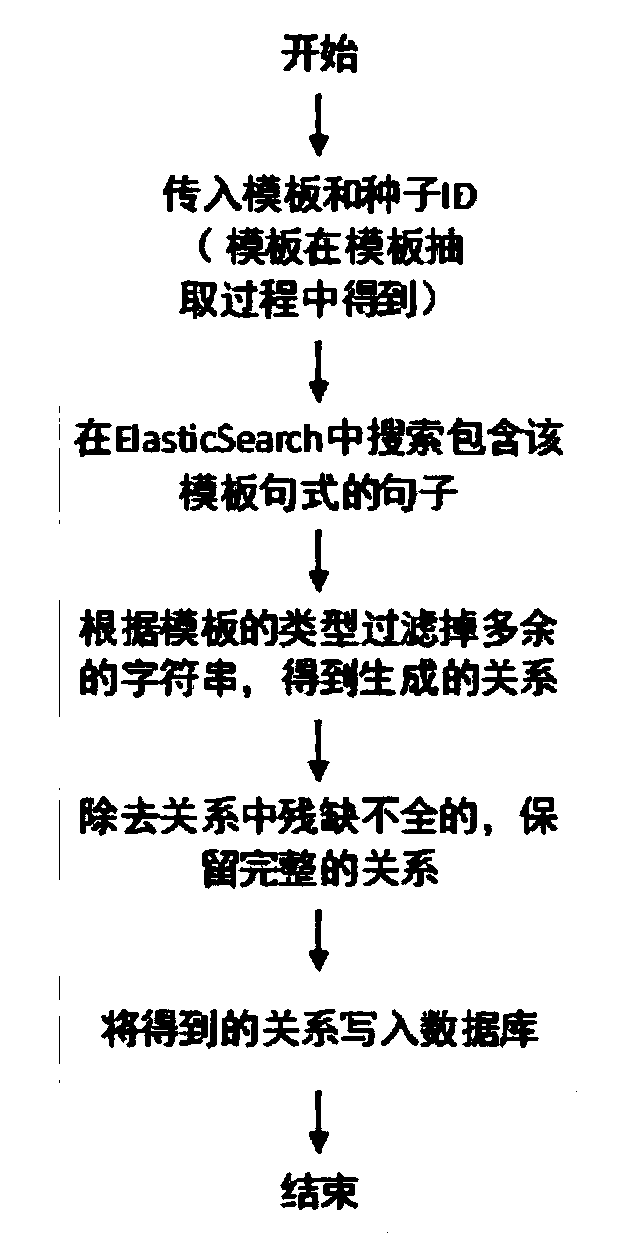

Relation pair library table construction method

ActiveCN110413726AGuaranteed accuracyEmbody noveltyText database indexingText database queryingNatural language processingInitial Seed

The invention relates to the technical field of character processing, and provides a relation pair library table construction method. The method aims to manually specify several initial seeds. After that, a system searches for sentence pattern templates meeting the requirement for manually providing the seeds. New seeds are found through the obtained templates. The iteration is conducted continuously. Finally, the purpose of one-reverse-three is achieved. A large number of triples meeting the manually specified relation are found. According to the main scheme, the method comprises the steps ofinputting multiple relation pairs to form a relation pair set; according to the two entities in the relationship pair, searching for literature statements containing the entities in a search server;replacing two entity words in the sentence with entity placeholders arg0 and arg1 to form a sentence pattern template; and comparing whether the relationship pairs corresponding to the sentence pattern templates conform to the two input relationship pairs at the same time, if so, leaving the sentence pattern templates, searching sentences containing the left sentence pattern templates in the search server, and finding out the corresponding parts of arg0 and arg1 to obtain the generated relationship pairs.

Owner:北京中科瑞通信息科技有限公司

Anti-jump net and insulation cover integrated support in fish pond

InactiveCN102257975BSmall footprintEmbody noveltyClimate change adaptationPisciculture and aquariaEngineeringDual purpose

The invention relates to the technical field of auxiliary devices for aquaculture, in particular to an anti-jump net and insulation cover integrated support for preventing fish from jumping away from a factory fish pond. The support is characterized in that a connecting ring (10) is arranged above a fish pond (3); a plurality of hinge pedestals (1) are arranged on the circumference of the connecting ring (10); each hinge pedestal (1) is connected with all support rods (21) by hinge pins (22) arranged at the upper ends of the support rods (21) in a rotary manner; the lower end of each support rod (21) is fixedly connected with a supporting angle-shaped plate (23) in a shape of angle steel; and the right-angled bend of each supporting angle-shaped plate (23) is supported at the top surface and inner wall on the circumference of the fish pond (3). The support is neat, light and flexible, is convenient to collect after being folded or dismantled, has lower cost, can be repeatedly used, isan anti-jump net and insulation cover dual-purpose support suitable for the factory fish pond and is an auxiliary device specially for aquaculture.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Stretching type grid visible automobile sun visor and double-shaft sun visor

The invention relates to a stretching type grid visible automobile sun shield and a double-shaft automobile sun shield, which structurally comprise a double-plate fixing universal shaft 1, a rotating transverse shaft 2, a grid main plate 3, a double-groove buckle 4, an opening and closing lock 5, a telescopic bracket 6, a joint outer longitudinal edge 7, an outer transverse edge 8, a hole grid 9, a hole grid 10, an observation window 11, an inner longitudinal edge 12, a plate a rotating transverse shaft (13), a plate b rotating transverse shaft 2, a plate a fixing universal shaft a and a plate b universal shaft b, by means of the special structure, capable of being compressed and unfolded, of the grid, the sunshade area is enlarged, a part of direct strong light can be filtered out, the sunshade area can be enlarged when the sunshade plate is used on one side of a vehicle door, and observation of a rearview is not affected by using the movable window; after the grid main plate is opened, the two sun shields can be jointed through the joint outer longitudinal edges of the two sun shields, strong light emitted from a front windshield is completely shielded, the temperature in an automobile after parking is reduced, novelty, practicability and scientificity are embodied, and the unicity of a common automobile sun shield is broken through in the aspect of automobile trim.

Owner:刘海

Rolled steel integral wheel for large-size railway vehicle and production method thereof

ActiveCN103469091BReduce difficultyEmbody noveltyFurnace typesHeat treatment furnacesChemical compositionRoom temperature

The present invention provides a steel for large-sized rolling steel integral wheel for railway, the mass percent of its chemical composition is: C 0.46-0.55%, Si0.20-0.37%, Mn0.70-0.85%, Ni0.10-0.25%, Cr0.24~0.32%, Als0.020~0.040%, P≤0.008%, S≤0.008%. The heat treatment process is as follows: heat the wheel after rolling and slow cooling according to the conventional process to 860-880°C with the furnace, keep it warm for 3-3.5 hours, then take it out of the furnace and air-cool it to room temperature, then raise the temperature of the wheel to 840-860°C with the furnace, keep it warm After 3.5-4 hours, immediately cool down to below 550°C after leaving the furnace, then air-cool to room temperature at a cooling rate of 2°C / s-5°C / s, then put the cooled wheel into a furnace at 480-500°C, and keep it warm for 4.5-5 hours. Remove from the oven and air cool.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

A method for industrially producing anhydrous lithium hydroxide balls

ActiveCN109553118BAchieve recyclingPrevent hardeningCarbon compoundsLithium oxides/hydroxidesLithium hydroxidePhysical chemistry

The invention provides a method for industrially producing anhydrous lithium hydroxide balls, comprising the steps of dehydration drying, fine powder, ball forming of powder, sieving, drying, and thelike. Medicine grains, which do not cause powder falling and do not have irritating smell, are prepared from anhydrous lithium hydroxide by a powder forming process. When the anhydrous lithium hydroxide balls are applied to a CO2 absorbent, the absorption efficiency of carbon dioxide by the absorbent is tested to be 85% or more according to a coal standard MT454-2008.

Owner:GANFENG LITHIUM CO LTD

Thymosin alpha-1 aqua prepn and its prepn process and application

ActiveCN100342909CSimple production processImprove stabilityPeptide/protein ingredientsDigestive systemDiseaseMANNITOL/SORBITOL

The present invention relates to one kind of thymosin alpha-1 aqua preparation and its preparation process and application in preparing medicine for treating chronic viral hepatitis and other immunological damage diseases. The preparation consists of thymic pentapeptide in 0.1-1000 mg each 0.1-500 ml, medicinal supplementary material, which may be mannitol, polyglycol, cyclodextrin, etc., and water. The preparation process includes compounding, sterilizing, packing, and other steps. The thymosin alpha-1 aqua preparation has high stability, easy preparation and other features, and has wide application foreground in preparing medicine for treating chronic viral hepatitis and other immunological damage diseases.

Owner:北京双鹭立生医药科技有限公司

Video sorting method and device based on video-on-demand volume

ActiveCN105828181BReflect the length of the showEmbody noveltySelective content distributionUltrasound attenuationRanking

An embodiment of the invention provides a video sequencing method and device based on video on-demand volume. The method includes the steps of: determining at least two playing periods of time corresponding to each video in a video set, the video set including at least one video; obtaining a time attenuation value of each video, a weighted value of each playing period of time corresponding to each video and the on-demand number of times of each video in corresponding each playing period of time; determining a sequencing coefficient of the videos according to the time attenuation value of each video, the weighted value of each playing period of time corresponding to each video and the on-demand number of times of each video in corresponding each playing period of time; and sequencing the videos in the video set according to the sequencing coefficient of each video. The video sequencing method is used for improving the precision of video ranking.

Owner:JUHAOKAN TECH CO LTD

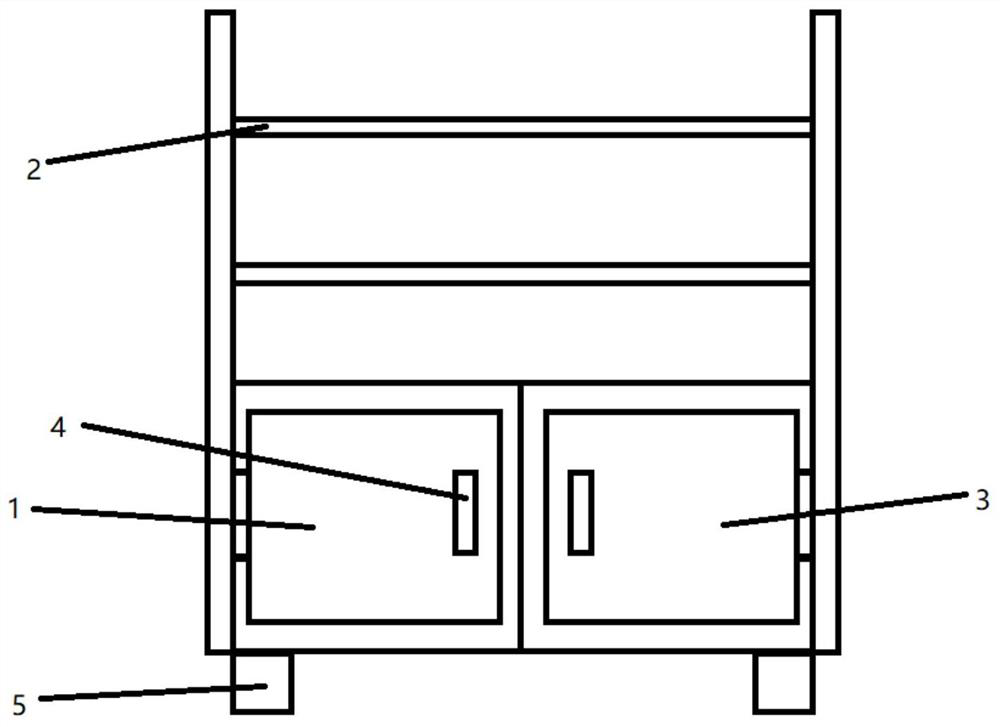

Hardware product classification cabinet

InactiveCN112401587AEasy to countEasy to checkShow cabinetsShow shelvesComputer hardwareEmbedded system

The invention discloses a hardware product classification cabinet. The hardware product classification cabinet comprises a storage cabinet, a placement frame, a box door, a handle and a supporting base. The device is simple in structure and reasonable in design, and the problems that the placement space is small, hardware products of different sizes cannot be stored in a classified mode, purchasers cannot conveniently find and know the hardware products, and the sales rate is reduced are solved.

Owner:扬州远洋针业有限公司

Method for simultaneously determining three alkaloids in granules for eliminating phlegm and stopping cough for children

ActiveCN102662024BQuality improvementGood peak separationComponent separationEmetine HydrochloridePhosphoric acid

The invention relates to a method for simultaneously determining three alkaloids in granules for eliminating the phlegm and stopping the cough for children. The method is characterized in that the HPLC (High Performance Liquid Chromatography) method is employed for the first time, an ordinary gradient elution and reversed-phase chromatographic column are adopted, and acetonitrile, methanol and 0.1% phosphoric acid in the volume ratio of (1.5-2.5) : (12.5-11) : (86-86.5) are taken as the mobile phase; the detection wavelength is 205 nm; and the contents of ephedrine hydrochloride, cephaeline hydrochloride and emetine hydrochloride in the granules for eliminating the phlegm and stopping the cough for children are determined simultaneously, so as to end the history of no HPLC determining method for emetine and no quantitative determining indexes for granules for eliminating the phlegm and stopping the cough for children. The method provided by the invention comprises the steps of performing an ultrasonic treatment to a sample with methanol, sucking a certain amount of subsequent filtrate, removing impurities with an alumina column, and determining. The method has the benefits that crest separation of the three alkaloids is excellent, the baseline is stable, and 30 min is required to finish the determining; the quality control aim of being simple, convenient, quick, scientific, standard and multi-component quantitive by one maker is realized; and safety and effectiveness of taking granules for eliminating the phlegm and stopping the cough for children are ensured.

Owner:JING JING PHARMA

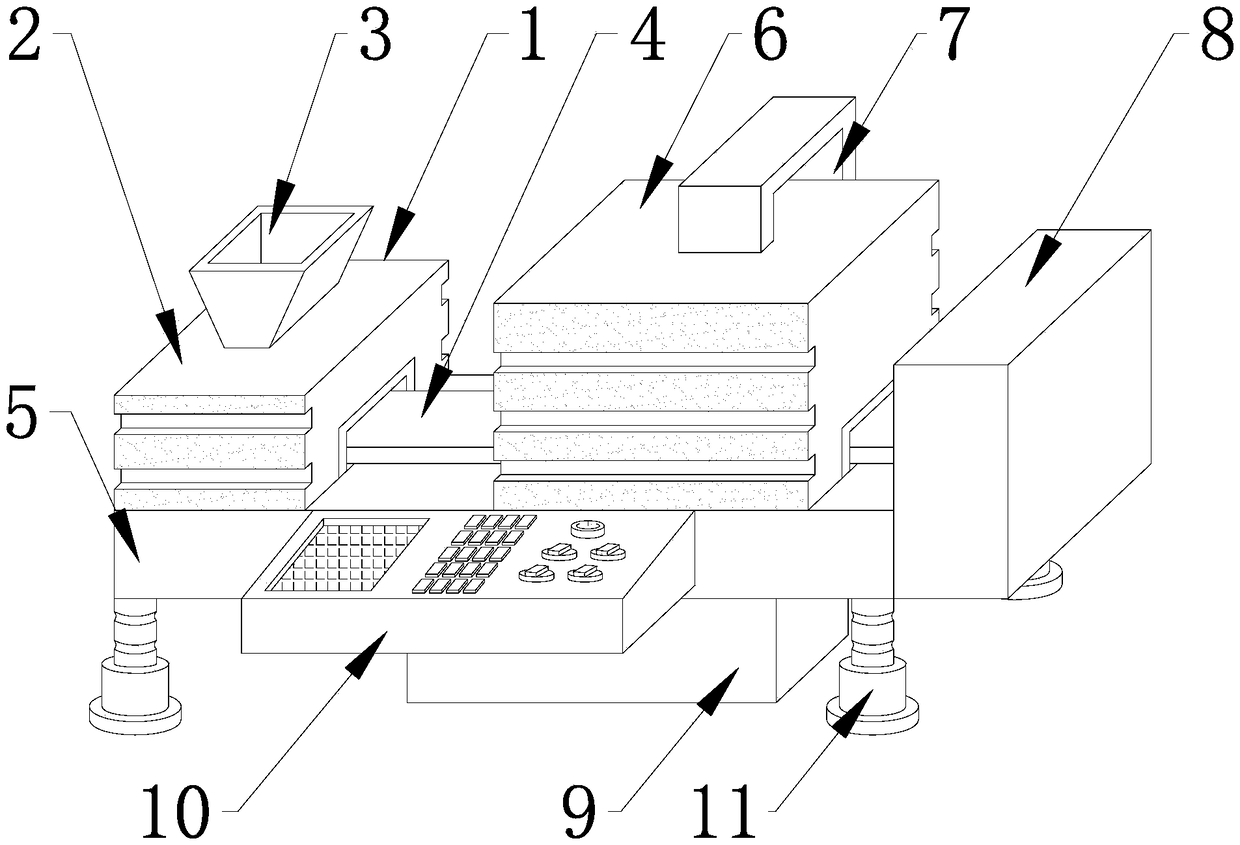

Upward pressing type tableting machine

The invention discloses an upward pressing type tableting machine. The upward pressing type tableting machine comprises a tableting machine main body, a treatment box and a worktable; the bottom of the tableting machine main body is fixedly connected with the worktable; the top end of one side of the worktable is fixedly connected with the treatment box; the bottom of the other side of the treatment box is connected with a conveying belt in a penetrated manner; the middle part of the front of the worktable is fixedly connected with a console; the middle part of the top in the treatment box isconnected with a feed inlet in a penetrated manner; and the top end of the other side of the worktable is fixedly connected with a tableting box. Internal components of the tableting box can rapidly perform tableting treatment on raw materials, which reflects the high efficiency of the tableting machine main body. The treatment box enables the raw materials to be subjected to tableting treatment better through internal treatment, which reflects the inventiveness of the tableting machine main body. A stabilizing base enables the tableting machine main body to work stably, which reflects the stability of the tableting machine main body. The upward pressing tableting machine is convenient to use and suitable for the technical field of tableting, and has a wide development prospect in the future.

Owner:孝感市智强医疗器械有限公司

Skin care product packaging box

InactiveCN112572985AEasy to displayAvoid damageNon-removalbe lids/coversDischarging meansGear wheelEngineering

The invention discloses a skin care product packaging box, and belongs to the technical field of packaging boxes. The skin care product packaging box comprises a bottom frame, two supporting plates are symmetrically and fixedly connected to the upper end of the bottom frame, and fixing rings are fixedly connected to the supporting plates and side plates of the bottom frame. Sliding rails are arranged in the fixing rings, sliding columns are slidably connected to the sliding rails, and annular brackets are fixedly connected to the middles of the sliding columns. The upper sides of the front ends of the annular brackets are fixedly connected with supporting rods, the front portions of the annular brackets are fixedly connected with gear racks, and the gear racks are connected with third gears in a meshing mode. The centers of the third gears are fixedly connected with rotating shafts, the middle ends of the rotating shafts are fixedly connected with second gears, and the lower ends of the second gears are connected with first gears in a meshing mode. According to the device, a simple mechanical structure is adopted, the base can be tilted by a certain angle, and novelty is achieved;meanwhile, manufacturers can conveniently display skin care products to people, the high grade of the skin care products is embodied; and meanwhile, end covers are arranged in containing grooves of the skin care products to guarantee the stability of the skin care products and prevent the skin care products from being damaged in the transportation process, and buttons are further arranged. One ends of the skin care products are conveniently warped up and is convenient to take.

Owner:厦门正庚年工业设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com