Production technology of two-nozzle atomization aluminium powder

A production process and double-nozzle technology, which is applied in the field of aluminum powder production process, can solve the problems of increased investment costs and production and operation costs, and achieve the effects of high heating efficiency, guaranteed temperature and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

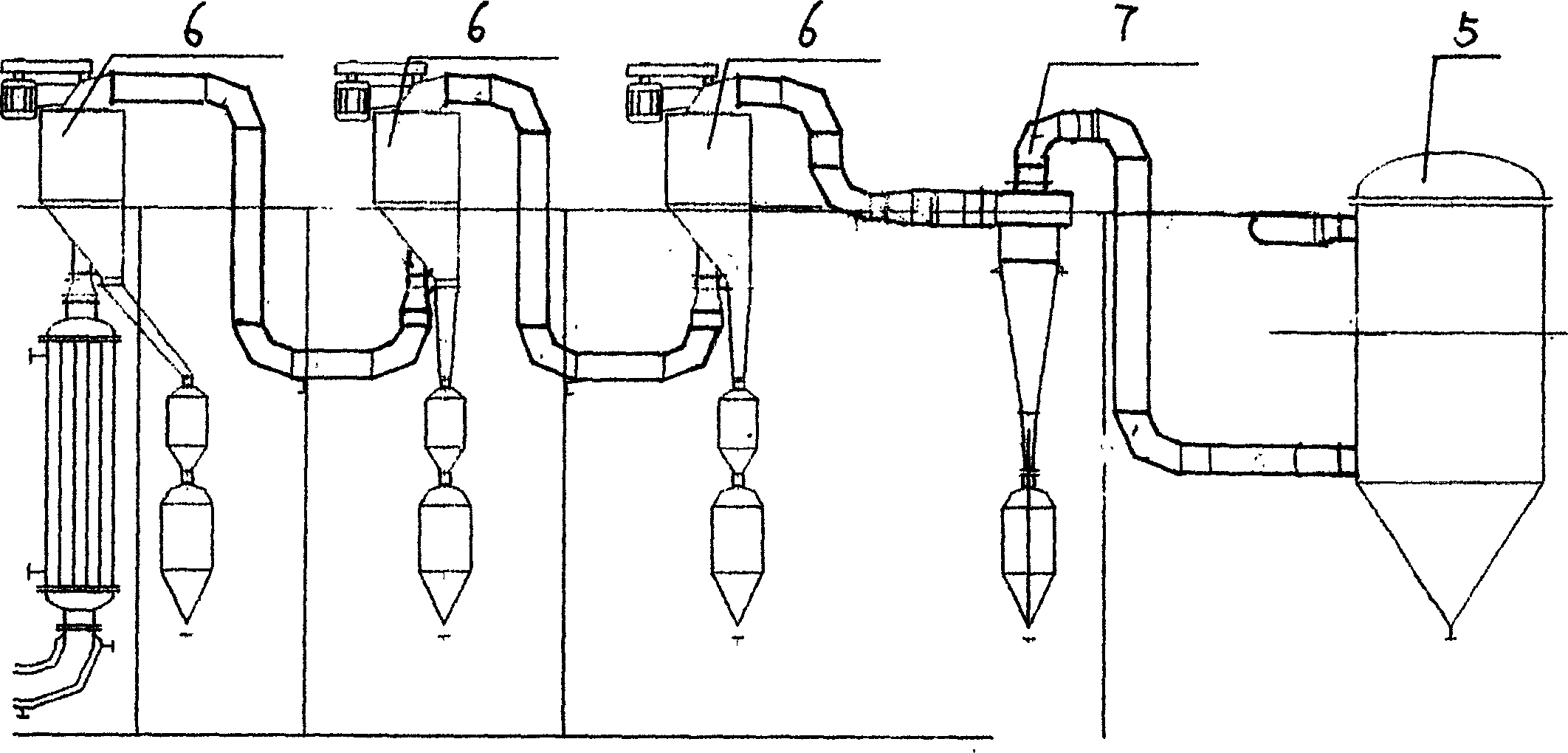

[0033] See figure 1 , double-nozzle atomized aluminum powder production process, this process uses a double-nozzle atomization chamber 1, and is equipped with two silicon carbide rods to heat the aluminum melting furnace 2 to melt the aluminum ingots, and the melted liquid aluminum enters the double-nozzle atomization chamber for further processing Atomization treatment, high-temperature and high-pressure nitrogen is blown into the atomization chamber through the air compressor, and after cooling, the liquid aluminum liquid becomes granular. Enter classification system 3 to carry out classification then; Classification system adopts three-stage centrifugal classifier 6 to add the mode of one-stage cyclone collector 7 ( image 3 ), the cyclone collector 7 is connected to the dust collector 5; the circulation system adopts double balance tanks 4 and double fans, and is connected to the dust collector 5;

[0034] Its working parameters are:

[0035] 1) Spray chamber

[0036] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com