Method for industrially producing anhydrous lithium hydroxide balls

A technology of anhydrous lithium hydroxide and monohydrate lithium hydroxide, applied in chemical instruments and methods, lithium oxide;/hydroxide, inorganic chemistry, etc., can solve the problem of low mechanical strength of ordinary LiOH particles, high dust rate, Easy to break and other problems, to achieve the effect of smooth air circulation, improved absorption efficiency, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

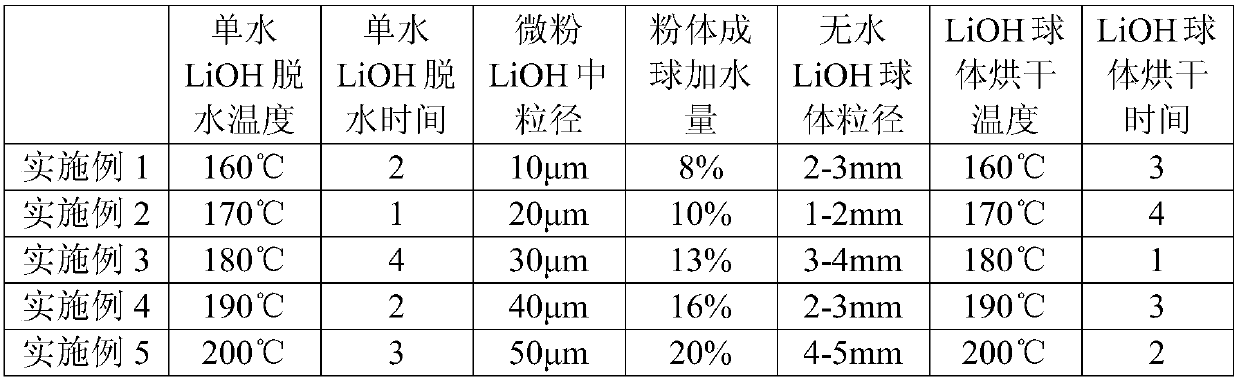

Embodiment 1

[0037] 100Kg of industrial-grade lithium hydroxide monohydrate was vacuum-dried at 160°C for 2 hours to obtain anhydrous LiOH with a main LiOH content of 97.3%. The anhydrous LiOH is pulverized to a fine powder anhydrous LiOH whose middle particle diameter D50 is 10 microns by a nitrogen jet mill. The micro-powder anhydrous LiOH is transported to the disk pelletizer under the protection of nitrogen by air flow, and the powder is formed into balls. The water addition amount of the spray water adding device is controlled to be 8%, and the balls are transported to the square vibrating screen to obtain anhydrous powder with a particle size of 2-3mm. Lithium hydroxide spheres, the small particle spheres that do not meet the particle size requirements are transported to the disc pelletizer to continue pelletizing into balls. Dry the qualified spherical lithium hydroxide wet material in a vacuum dryer at a drying temperature of 160 degrees for a drying time of 3 hours to obtain spher...

Embodiment 2

[0039] 80Kg of industrial-grade lithium hydroxide monohydrate was vacuum-dried at 170°C for 1 hour to obtain anhydrous LiOH with a main LiOH content of 97.5%. The anhydrous LiOH is pulverized to a fine powder anhydrous LiOH whose middle particle diameter D50 is 20 microns by a nitrogen jet mill. The micro-powder anhydrous LiOH is transported to the disc pelletizer under the protection of nitrogen by air flow, and the powder is formed into balls. The water addition amount of the spray water adding device is controlled to be 10%, and the balls are transported to the square vibrating screen to obtain anhydrous powder with a particle size of 1-2mm. Lithium hydroxide spheres, the small particle spheres that do not meet the particle size requirements are transported to the disc pelletizer to continue pelletizing into balls. The qualified spherical lithium hydroxide wet material was dried in a vacuum dryer at a drying temperature of 170 degrees for a drying time of 4 hours to obtain ...

Embodiment 3

[0041] 90Kg of industrial-grade lithium hydroxide monohydrate was vacuum-dried at 180°C for 4 hours to obtain anhydrous LiOH with a main LiOH content of 97.1%. The anhydrous LiOH is pulverized to a fine powder anhydrous LiOH whose middle particle diameter D50 is 30 microns by a nitrogen jet mill. The micro-powder anhydrous LiOH is transported to the disc pelletizer under the protection of nitrogen by air flow, and the powder is formed into balls. The water addition amount of the spray water adding device is controlled to be 13%, and the balls are transported to the square vibrating screen to obtain anhydrous powder with a particle size of 3-4mm. Lithium hydroxide spheres, the small particle spheres that do not meet the particle size requirements are transported to the disc pelletizer to continue pelletizing into balls. Dry the qualified spherical lithium hydroxide wet material in a vacuum dryer at a drying temperature of 180°C and a drying time of 1 hour to obtain spherical an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com