Polyamide powder and preparation method thereof

A polyamide powder and polyamide technology, applied in the field of polyamide powder and its preparation, can solve the problems of damage to the anti-oxidation effect of materials, yellowing of powder, and poor performance of parts, and achieve easy removal, recycling and reuse, loose packing The effect of high density and high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of polyamide powder, comprising the following steps:

[0041] Dissolution and heat preservation: Add 1 weight part of PA12 and 10 volume parts of formamide into a reaction kettle protected by nitrogen, stir at a speed of 500r / min, heat the mixture to 40°C higher than the precipitation temperature of PA12 powder and keep it for 1 Hour, the reactor pressure is 1.0MPa.

[0042] Cool down to make powder: cool down to 125°C at a rate of 0.5°C / min, then cool down to a PA12 precipitation temperature of 100°C at a rate of 0.18°C / min, and finally cool down to room temperature at a rate of 2.8°C / min to precipitate PA12 precipitates.

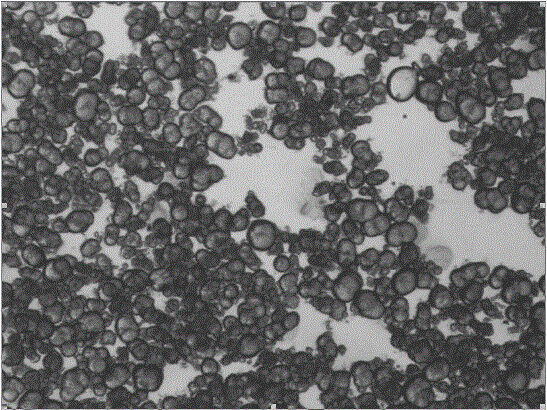

[0043] Drying: The precipitated polyamide is centrifuged and dried to obtain PA12 powder particles. The obtained polyamide powder material powder particles are spherical particles with good sphericity, uniform particles and concentrated particle size. 65.3 μm, D75 is 80 μm, and D90 is 98.2 μm.

Embodiment 2

[0045] A preparation method of polyamide powder, comprising the following steps:

[0046] Dissolution and heat preservation: PA6 pellets and 1% titanium dioxide are dissolved in formamide and added to a reactor protected by nitrogen, stirred at a speed of 450r / min, and the mixture is heated to 40°C higher than the precipitation temperature of PA6 powder and kept for 0.5 hours. Reactor pressure is 1.2MPa.

[0047] Cool down to make powder: cool down at a rate of 0.5°C / min to a temperature 20°C higher than the precipitation temperature of PA6 powder, then cool down to the precipitation temperature of PA6 powder at a rate of 0.4°C / min, and finally cool down at a rate of 5°C / min to At room temperature, PA6 was precipitated out.

[0048] Drying: The precipitated polyamide is centrifuged and dried to obtain PA6 powder particles. The appearance of the obtained polyamide powder material is spherical particles with good sphericity, uniform particles and concentrated particle size. Th...

Embodiment 3

[0050] A preparation method of polyamide powder, comprising the following steps:

[0051] Dissolution and heat preservation: Dissolve PA11 pellets, 0.1% titanium dioxide, and 1% fumed silica in formamide and add them to a reaction kettle protected by nitrogen gas, stir at a speed of 500r / min, and heat the mixture until PA11 powder is precipitated The temperature was kept at 25° C. for 1.5 hours, and the pressure of the reactor was 0.8 MPa.

[0052] Cooling powder: Cool down at a rate of 2.0°C / min to a temperature 20°C higher than the precipitation temperature of PA11 powder, then cool down at a rate of 0.1°C / min to the precipitation temperature of PA11 powder, and finally cool down at a rate of 1°C / min to At room temperature, the precipitation of PA11 was obtained.

[0053] Drying: The precipitated polyamide is centrifuged and dried to obtain PA11 powder particles. The appearance of the obtained polyamide powder material shows that the powder particles are spherical particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com