Preparation method and application of Ni0.8Co0.1Mn0.1(OH)2 material with high tap density

A technology of tap density and positive electrode materials, which is applied in the field of lithium-ion battery materials, can solve the problems of low tap density and poor sphericity, and achieve the effect of uniform particle size distribution and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The Ni of embodiment 1 high tap density 0.8 co 0.1 mn 0.1 (OH) 2 material preparation

[0024] Nickel sulfate, cobalt sulfate, and manganese sulfate are prepared into a solution a with a concentration of 2mol / L in a molar ratio of 8:1:1, and industrial concentrated ammonia is diluted into a solution b with a concentration of 4mol / L. Dilute to a solution c with a concentration of 5 mol / L, and prepare a solution d of 3 mol / L with sodium hydroxide; dissolve an appropriate amount of ascorbic acid in water to form a solution e. Then solution b and solution e were successively poured into a 25L reactor as the bottom liquid, the stirring rate was set at 200r / min, and the temperature of the reactor was set at 60°C. Nitrogen was passed into the reactor as a protective gas, and the flow rate of nitrogen was set at 100mL / min. When the temperature rises to the set temperature, increase the stirring rate to 800r / min, and start pumping solution a, the addition rate is set to 3mL...

Embodiment 1I

[0028] Table 1 Embodiment 1ICP test

[0029]

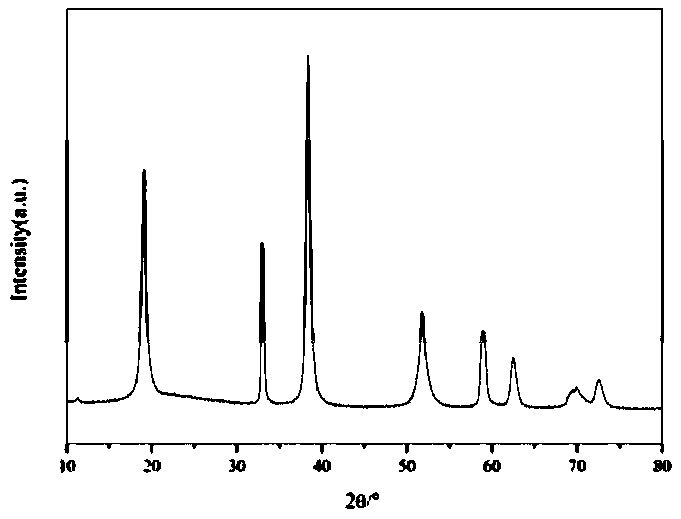

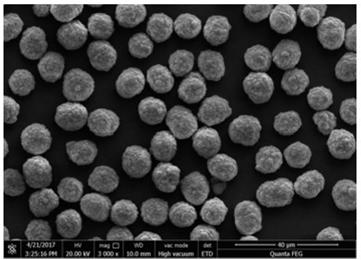

[0030] image 3 It is the SEM picture of the sample of Example 1. Obviously, the sphericity of the sample in the example is very high, the uniformity is good, and the particle size is basically about 10 microns. Tap density up to 2.29g / cm 3 After mixing the lithium source, the electrochemical performance of the high-nickel ternary cathode material is as follows: Figure 5 Shown: The discharge specific capacity at 0.1C is as high as 203.6.mAh g -1 , the first Coulombic efficiency is as high as 89.70%, and the capacity retention rate after 500 cycles under 3.0-4.2V, 1C / 1C charge-discharge system is 95%, and the cycle performance is excellent.

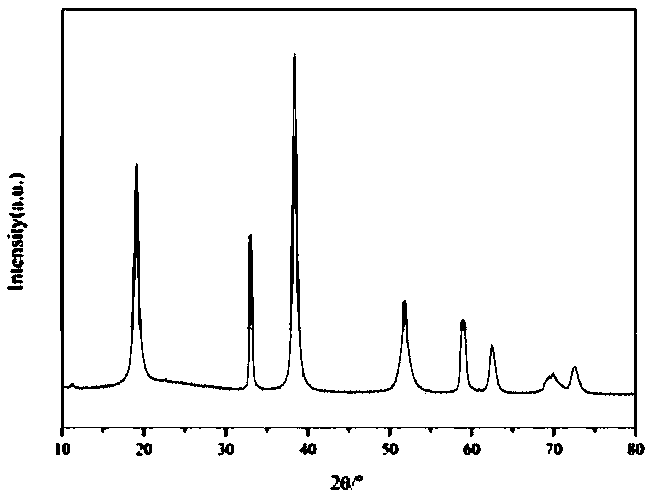

Embodiment 2

[0031] Ni of embodiment 2 high tap density 0.8 co 0.1 mn 0.1 (OH) 2 material preparation

[0032] Nickel sulfate, cobalt sulfate, and manganese sulfate are prepared into a solution a with a concentration of 2mol / L in a molar ratio of 8:1:1, and industrial concentrated ammonia is diluted into a solution b with a concentration of 5mol / L. Dilute to a solution c with a concentration of 7mol / L, and prepare a solution d of 3mol / L with sodium hydroxide; dissolve an appropriate amount of ascorbic acid in water to form a solution e. Then solution b and solution e were successively poured into a 25L reactor as the bottom liquid, the stirring rate was set at 200r / min, and the temperature of the reactor was set at 50°C. Nitrogen was passed into the reactor as a protective gas, and the flow rate of nitrogen was set at 100mL / min. When the temperature rises to the set temperature, increase the stirring rate to 800r / min, and start pumping solution a, the addition rate is set to 3mL / min; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com