Polyvinyl alcohol, preparation method and applications

A technology of polyvinyl alcohol and vinyl, which is applied in the field of polyvinyl alcohol and its preparation, can solve the problems that the dispersibility of PVA cannot be fully exerted, the stability of the viscosity of PVA solution is unfavorable, and the effect of auxiliary dispersant is affected, so as to shorten the plastic Curing time, excellent resin processability, regular shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

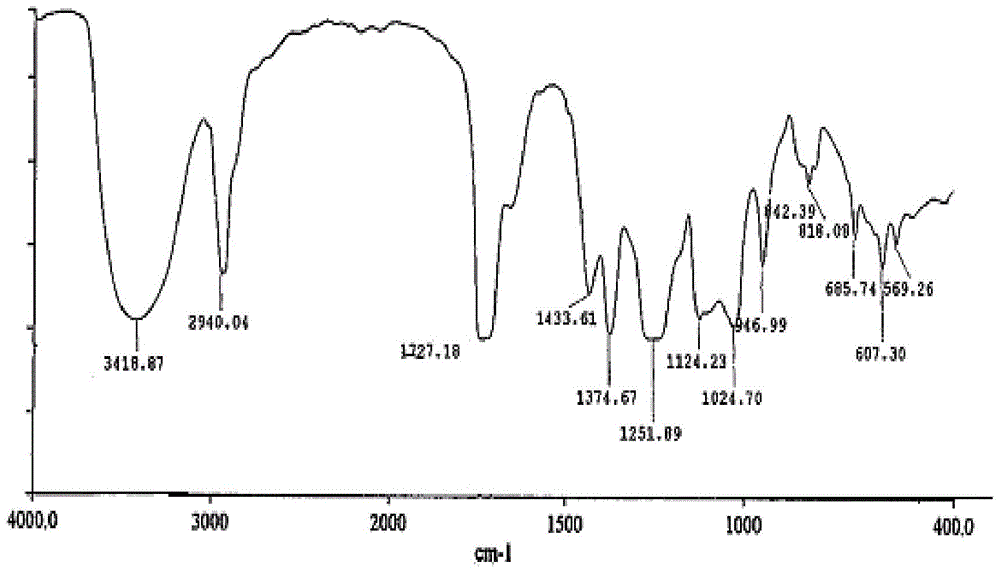

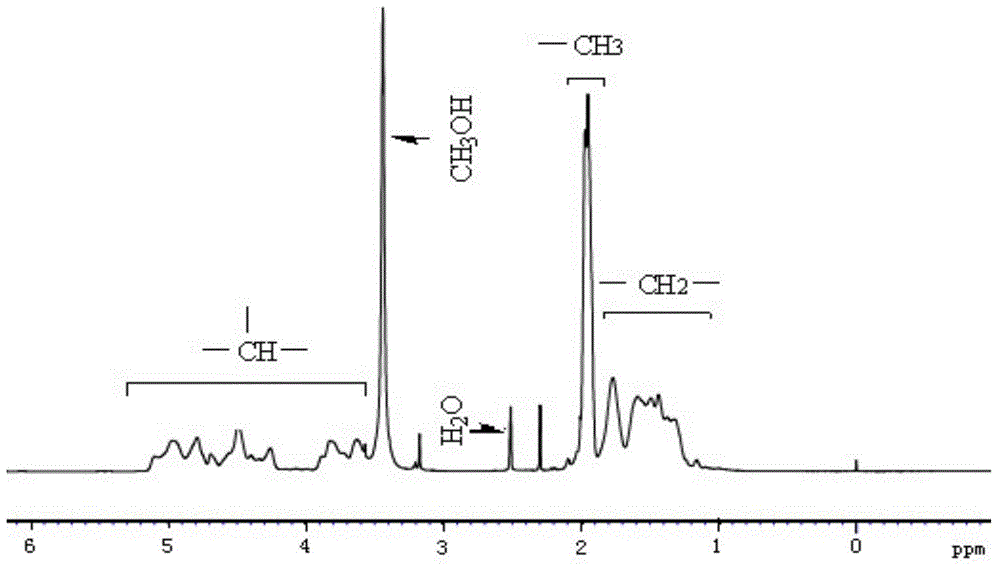

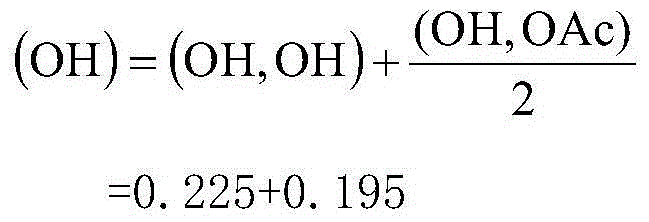

[0028] In the presence of 1.65 parts of AIBN, 100 parts of vinyl acetate are solution-polymerized in 150 parts of methanol. The polymerization temperature is 60°C. When the polymerization reaction is over, switch and blow out the residual sheet to obtain polyvinyl acetate resin. Take a part of polyvinyl acetate Resin is adjusted into the methanol solution that concentration is 45wt%, carrying out alcoholysis with the p-toluenesulfonic acid methanol solution of 30wt% with concentration, when alcoholysis degree reaches required value, spray with the methanol solution of 40g / L sodium hydroxide The reaction is terminated by leaching to obtain polyvinyl alcohol with low degree of polymerization and low degree of alcoholysis of the present invention. The degree of polymerization is 380, the degree of alcoholysis is 42.3 (mol / mol), the degree of block is 0.80, and its concentration is 34.5wt% alcohol The measured viscosity of the solution at 25°C is 98mPa.s, and the viscosity stabilit...

Embodiment 2

[0045] The alcohol solution with a concentration of 34.5 wt% prepared by the polyvinyl alcohol with low degree of polymerization and low degree of alcoholysis prepared in Example 1 is used as an auxiliary dispersant for suspension polymerization of vinyl polymers; it is used for suspension polymerization of vinyl chloride : Add 200 parts of soft water in the autoclave, add 0.08 part of the above-mentioned auxiliary dispersing agent while stirring at 350rpm, alcoholysis degree is 80mol% polyvinyl alcohol 0.03 part, 0.2 part of lauryl peroxide, then add 150 parts of vinyl chloride monomer, when the temperature is raised to 60°C, carry out suspension polymerization to obtain polyvinyl chloride resin. Using the resin obtained in Example B1, its apparent density is 0.53g / ml, and the number of fish eyes is 6 / 400cm 2 , the absorption rate of plasticizer is 27g / 100g, the 250um sieve residue is less than 2.0, and the residual vinyl chloride is 1.6mg / Kg, meeting the requirements of inte...

Embodiment 3-8

[0058] Embodiment 3-8, comparative example 1-4

[0059] A3-A7 in Table 1: medium chain transfer agents are respectively vinyl polyoxyethylene ether, isopropanol, acetaldehyde, valeraldehyde, ethanol, the medium chain transfer agents of comparative examples 2-3 are acetaldehyde, dodecyl sulfide Alcohol; Catalyst in A3-A8 is respectively sulfuric acid, hydrochloric acid, benzenesulfonic acid, 2-methyl-5-propanebenzenesulfonic acid, 1,5-naphthalene disulfonic acid, 2,7-benzenedisulfonic acid; comparative example Catalyst is sodium hydroxide among 1-4; The initiator among the embodiment A3-A5 and comparative example 2-4 is AIBN, and among the embodiment A6-A8, initiator is respectively dipropyl peroxydicarbonate, EHP, Peroxypivalic acid-pivalic acid ester, comparative example 1 initiator is peroxypivalic acid-pivalic acid ester. Using the relevant parameters described in Tables 1 and 2 and in combination with the conventional production process, according to the methods of Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com