Preparation method of PVC (polrvinyl chloride) resin with high porosity and low film coverage rate

A technology of polyvinyl chloride resin and porosity, which is applied in the field of preparation of polyvinyl chloride resin with low polymerization degree, high porosity and low film coverage, and can solve the problem of unapplicable technology, coarse resin particles, and methods of reducing sticky matter And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

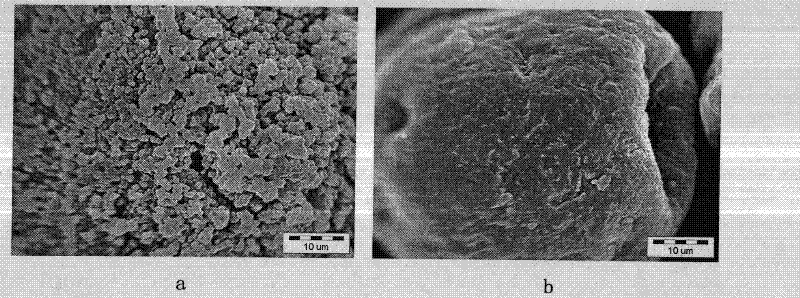

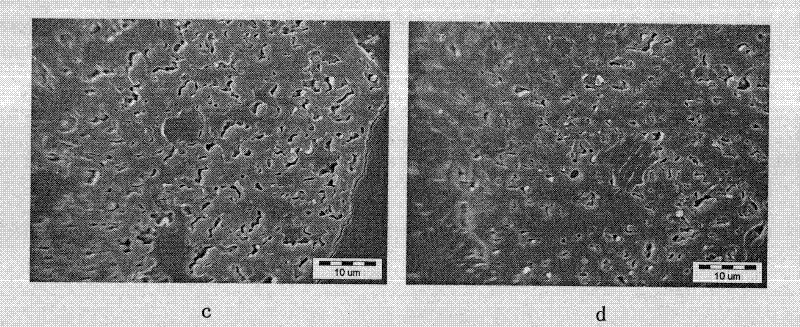

Image

Examples

Embodiment 1

[0052] The polymerization reaction is carried out in a kettle with a volume of 5 L, where the stirring is a two-layer flat paddle, the bottom tube and the galvanic sleeve are used as baffles. The technical conditions and process are briefly described as follows: firstly 2.1Kg desalted water, PVA (I) 0.19g, PVA (II) 0.68g, HPMC 0.68g, 0.7g sorbitan monostearate (HLB 4.7), 0.10g 2-mercaptoethanol, 0.5g azobisisoheptanonitrile, 0.5g NH 4 HCO 3 Put it into the kettle, start stirring after the pressure test, add 1.4Kg of VCM after vacuuming to -0.90MPa, raise the temperature to 62°C to start polymerization, keep the polymerization temperature until the polymerization pressure drops by 0.15MPa, add 0.3g diethylhydroxylamine to terminate the reaction, and automatically After the monomer is recovered by pressure, the material is discharged, and the PVC resin is obtained after centrifugal drying.

[0053] Above dispersant PVA (I) is alcoholysis degree 80% (mol fraction), the polyviny...

Embodiment 2

[0056] Change the add-on of dispersant PVA (I) into 0.26g, change the add-on of dispersant PVA (II) into 1.60g, change the add-on of dispersant HPMC into 0.40g, and other process conditions are the same as embodiment 1, and its test results are as follows : K value 58, apparent density 0.42 (g / ml), 100 g resin plasticizer absorbs 33 g, average particle size 110.0 (μm), distribution width 1.20.

Embodiment 3

[0058] Change the add-on of dispersant PVA (I) into 0.22g, change the add-on of dispersant PVA (II) into 1.10g, change the add-on of dispersant HPMC into 0.40g, and other processing conditions are the same as embodiment 1, and its test results are as follows : K value 57, apparent density 0.46 (g / ml), 100 g resin plasticizer absorbs 30 g, average particle size 113.0 (μm), distribution width 1.20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com