Technological method and device for preparing high-purity spherical superfine/nanoscale powdered materials in plasma atomization mode

A technology of nano powder and process method, applied in the direction of nano technology, which can solve the problems of low chemical purity, particle size not reaching ultrafine and nano level, high production cost, etc., and achieve the effect of high purity and concentrated particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0013] Specific embodiments: the process and equipment for producing high-purity ultra-fine metal Ti-6Al-4V (TC4) spherical powder using coiled wire raw materials.

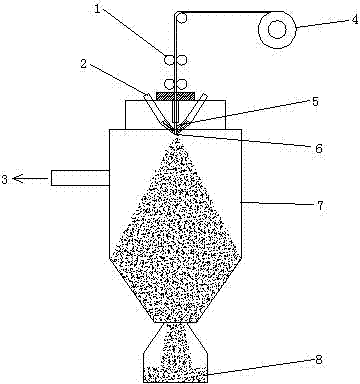

[0014] 1. Establish a plasma atomization equipment system, the whole system is mainly composed of 60kw plasma power supply, 2 symmetrical plasma moments 2, argon gas source, atomization tower 7, vacuum system 3, roller metal coil wire conveying system 1, gas powder Separation system, powder collection system, gas purification and recycling system, etc.; the symmetrical plasma rectangle forms the focus area of high-temperature plasma concentration 6, see figure 1 .

[0015] 2. In order to prevent oxidation of the titanium alloy material during heating, the air in the atomization tower is drawn out first, and argon gas is introduced for protection and cooling.

[0016] 3. Select commercialized Ti-6Al-4V (TC4) coiled wire with a diameter of 5mm, and send it to the high-temperature argon plasma focus area th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com