Method for preparing lightweight energy-saving building wall material from high-content steel slag

A high-volume, steel slag technology, applied in applications, household utensils, ceramic products, etc., can solve the problem of low utilization rate of steel slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The preparation method of grinding aid early strength agent in the embodiment, the weight portion of raw material that it comprises is:

[0071] 50 parts of triethanolamine;

[0072] 50 parts of acrylic acid;

[0073] 100 parts of water;

[0074] Include the following steps:

[0075] (1) Take the raw materials according to the proportion, put into the round bottom flask and mix evenly;

[0076] (2) Put the round-bottomed flask into a magnetic stirrer with a rotating speed of 500r / min and a temperature of 70°C, add a condensing reflux device, and react for 3h;

[0077] (3) Stop heating, continue to stir, and wait for the solution to cool down to room temperature to obtain a grinding aid early-strength agent for future use.

[0078] The obtained grinding-aid early-strength agent is measured by liquid chromatography for various substance contents, and it is calculated that in the grinding-aid early-strength agent organic matter, the ester compound accounts for 71.3% by...

Embodiment 1

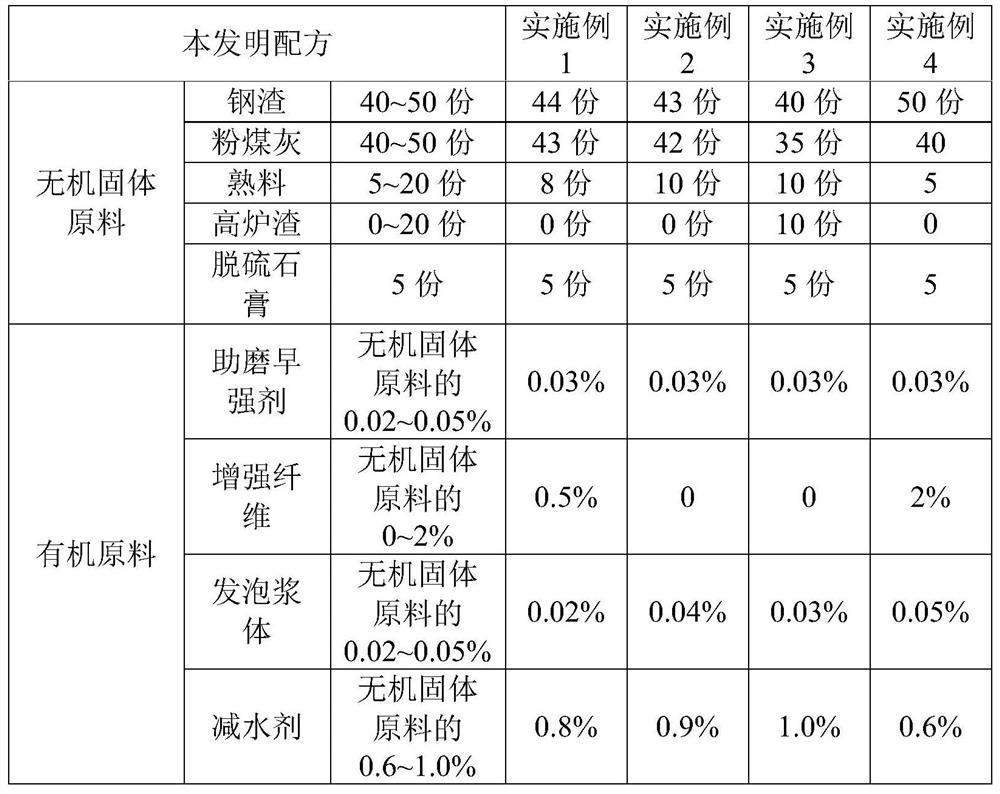

[0082] Such as figure 1 As shown, the inorganic solid raw material of the present embodiment comprises 44 parts of steel slag, 8 parts of clinker, 0 part of blast furnace slag, 43 parts of fly ash, and 5 parts of desulfurized gypsum powder; 0.03%, the specific surface area of the material after grinding is 520kg / m 2 Add glass fibers with a length of 4 to 6 mm for grinding, and the quality is 0.5% of the grinding material; the average diameter of bubbles in the foaming slurry is 1 mm, according to the requirements of 120 plates in GB / T23450-2009, and the dry density of the product after 28 days is ( 800±10)kg / m 3 design, adding the amount of foaming slurry and water reducer shown in Table 1; pouring; the specimens were cured at 30°C for 1 day, then removed from the mold, and then cured at 60°C for 4 days, and then transferred to After natural curing for 28 days, a qualified light-weight and energy-saving wall material can be prepared. The dry density of the product is 806k...

Embodiment 2

[0084] Such as figure 1 As shown, the inorganic solid raw material of the present embodiment comprises 43 parts of steel slag, 10 parts of clinker, 0 part of blast furnace slag, 42 parts of fly ash, and 5 parts of desulfurized gypsum powder; 0.03%, the specific surface area of the material after grinding is 502kg / m 2; The average diameter of bubbles in the foaming slurry is 1mm, according to the requirements of 120 plates in GB / T23450-2009, and the dry density of the product after 28 days is (800±10)kg / m 3 Design, adding the amount of foaming slurry and water reducing amount shown in Table 1; pouring, adding three layers of glass fiber mesh cloth; the specimen was demoulded after being cured at 30°C and constant humidity for 1 day, and then kept at 55°C It was cured under wet conditions for 5 days, and then transferred to natural curing for 28 days to prepare qualified lightweight energy-saving wall materials. Product dry density is 810kg / m 3 , 28d compressive strength is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com