Efficient embossing and disinfecting integrated napkin machine

A technology of napkin machine and embossing, which is applied in mechanical processing/deformation, chemical instruments and methods, and dust removal, etc. It can solve the problems of paper towel sterilization, affecting production efficiency, and easy deformation of paper towels, so as to achieve good sterilization and disinfection and improve Embossing efficiency, the effect of increasing the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

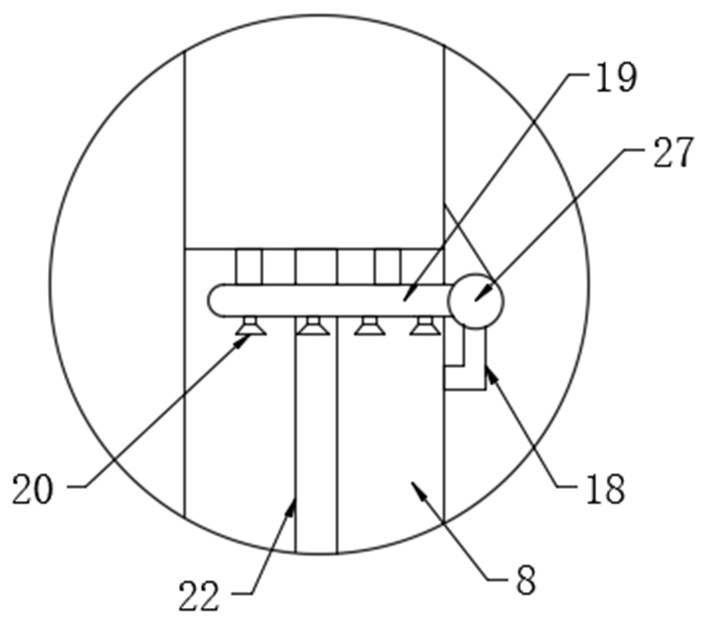

[0027] Such as Figure 1-6 As shown, the present invention provides a technical solution: a high-efficiency embossing and disinfection integrated napkin machine, including a base 1, a paper disc roller 2, a humidifying mechanism, an embossing mechanism, a hot pressing mechanism, a disinfection mechanism, a folding mechanism and a cutting mechanism. The paper mechanism, the paper disc roller 2 is rotatably installed on one end of the base 1, the embossing mechanism is located on the side of the paper disc roller 2, the humidifying mechanism is located above the embossing mechanism, and the hot pressing mechanism is located on the side of the embossing mechanism. side, the disinfection mechanism is located on the side of the hot pressing mechanism, the folding mechanism is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com