Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

177results about How to "Avoid uneven quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

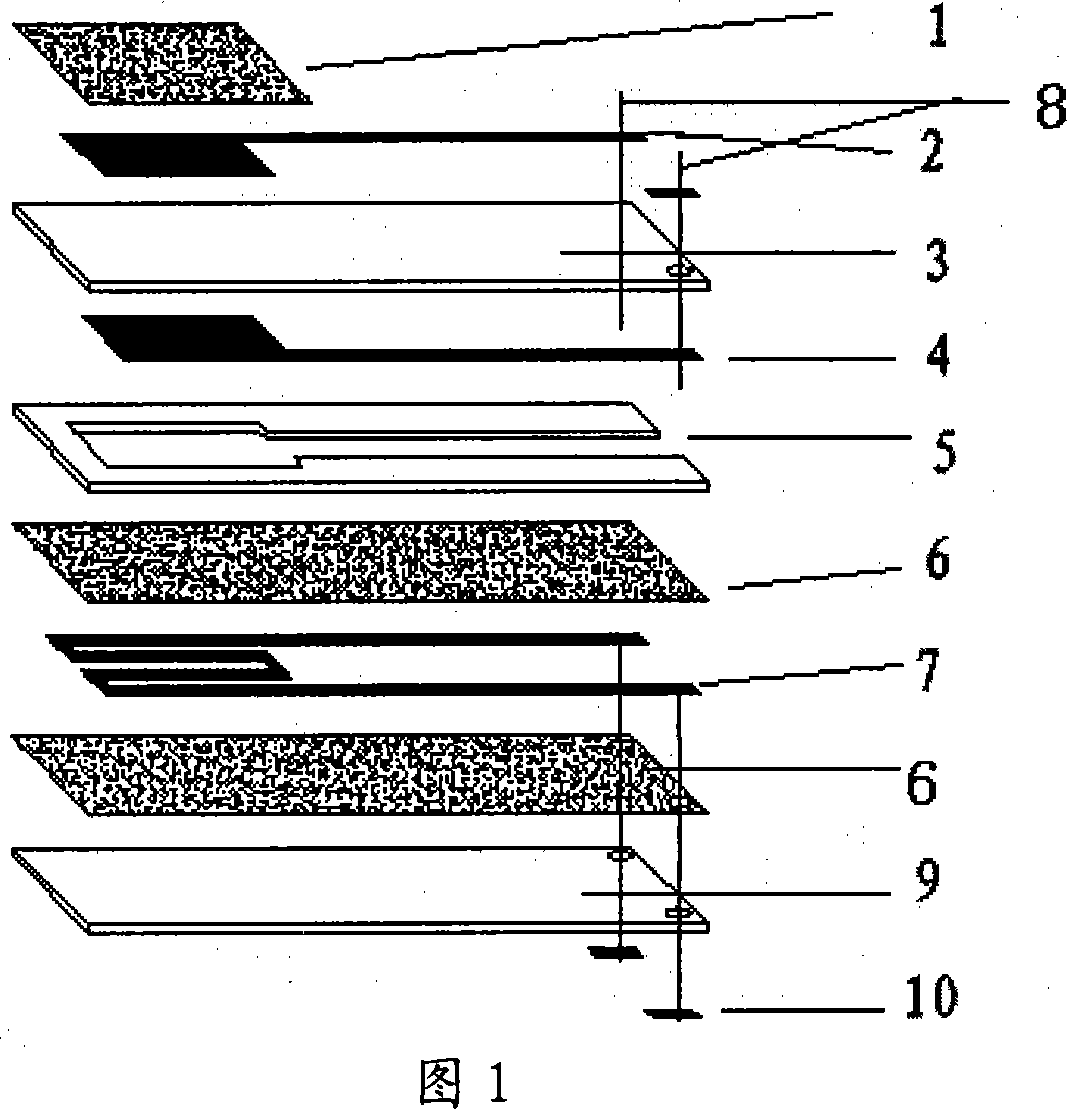

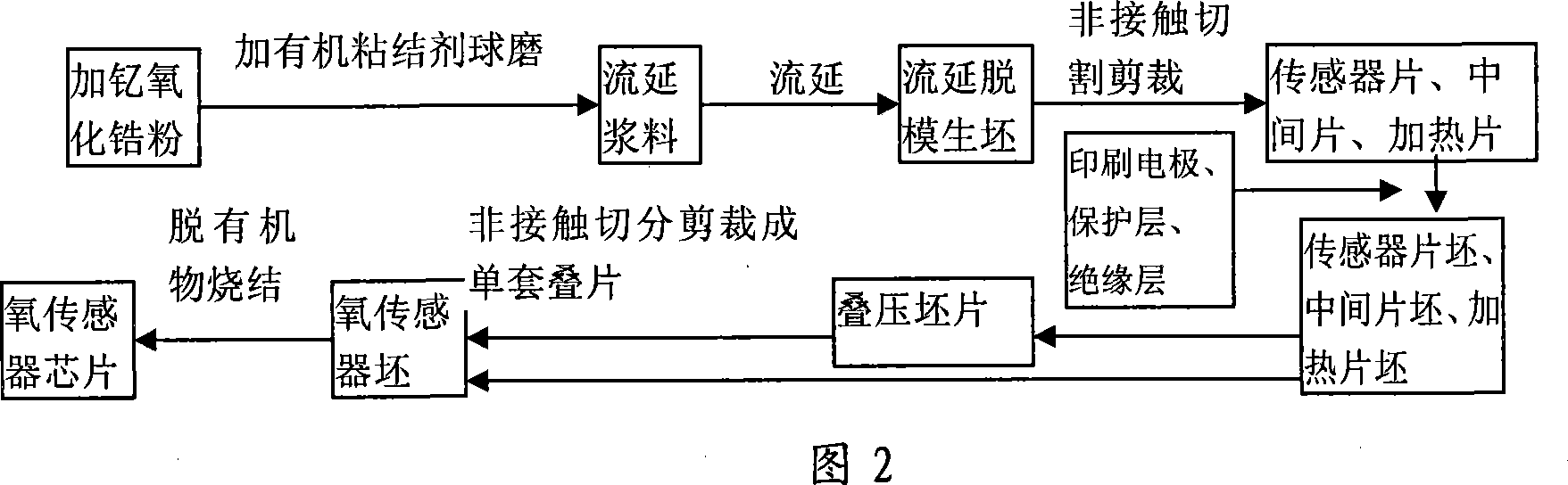

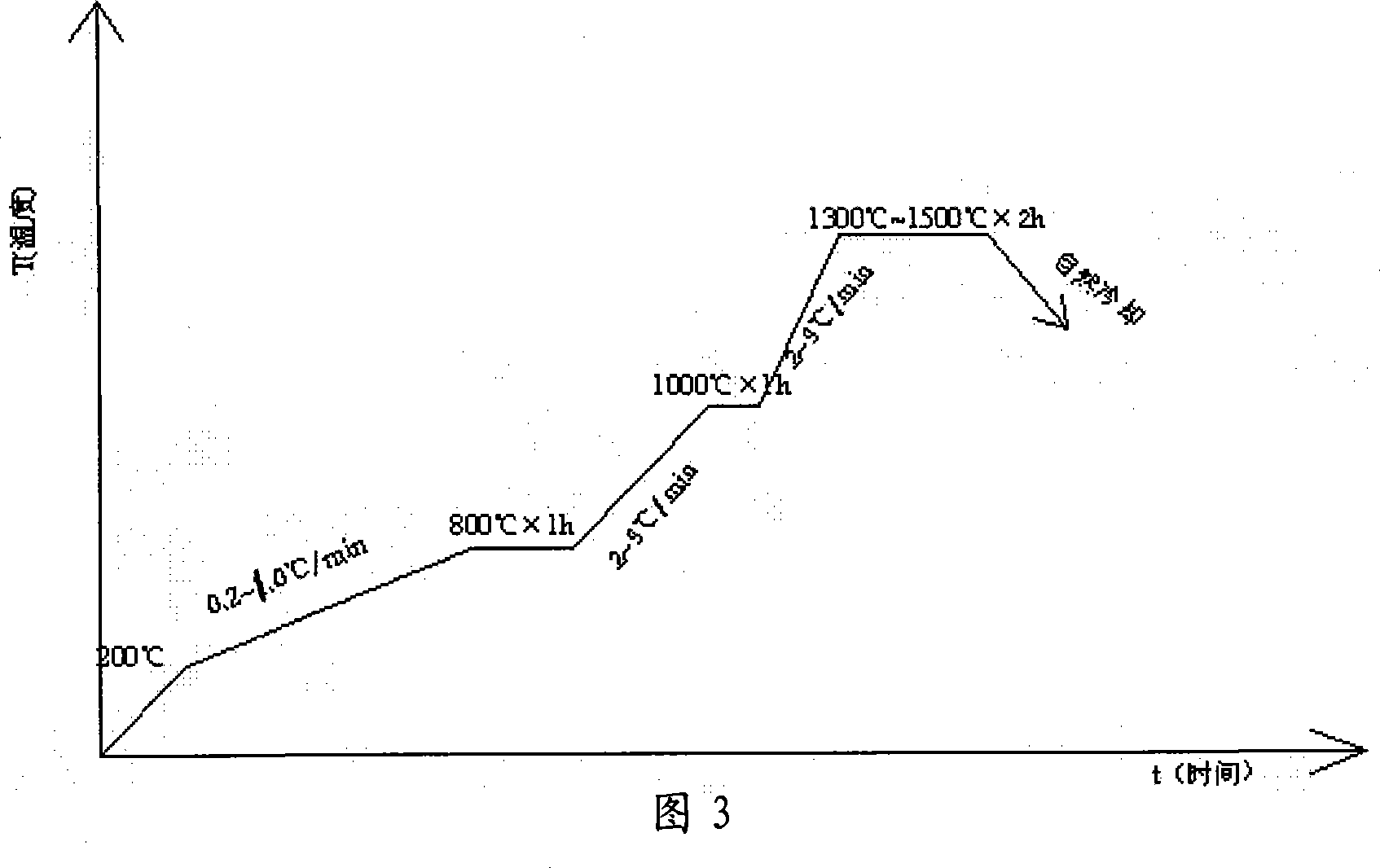

Manufacturing method of plate type oxygen sensor chip

This invention relates to one process method to control cargo motor hollow burst plane oxygen sensor chip, which comprises the following steps: processing flow paste on zircite ceramics powder mixed with yttrium and processing bright and complete film through flow and then cutting into relative sensor slices, heating slice and middle slices by non-contact cut machine; printing electrode inside sensor slice and heating resistance on heating slices; then using overlap heating type to integrate three slices into plane sensor load to remove organism under temperature of 1300 to 1500 degrees.

Owner:ZHENJIANG NERNST AUTOMOTIVE TECH

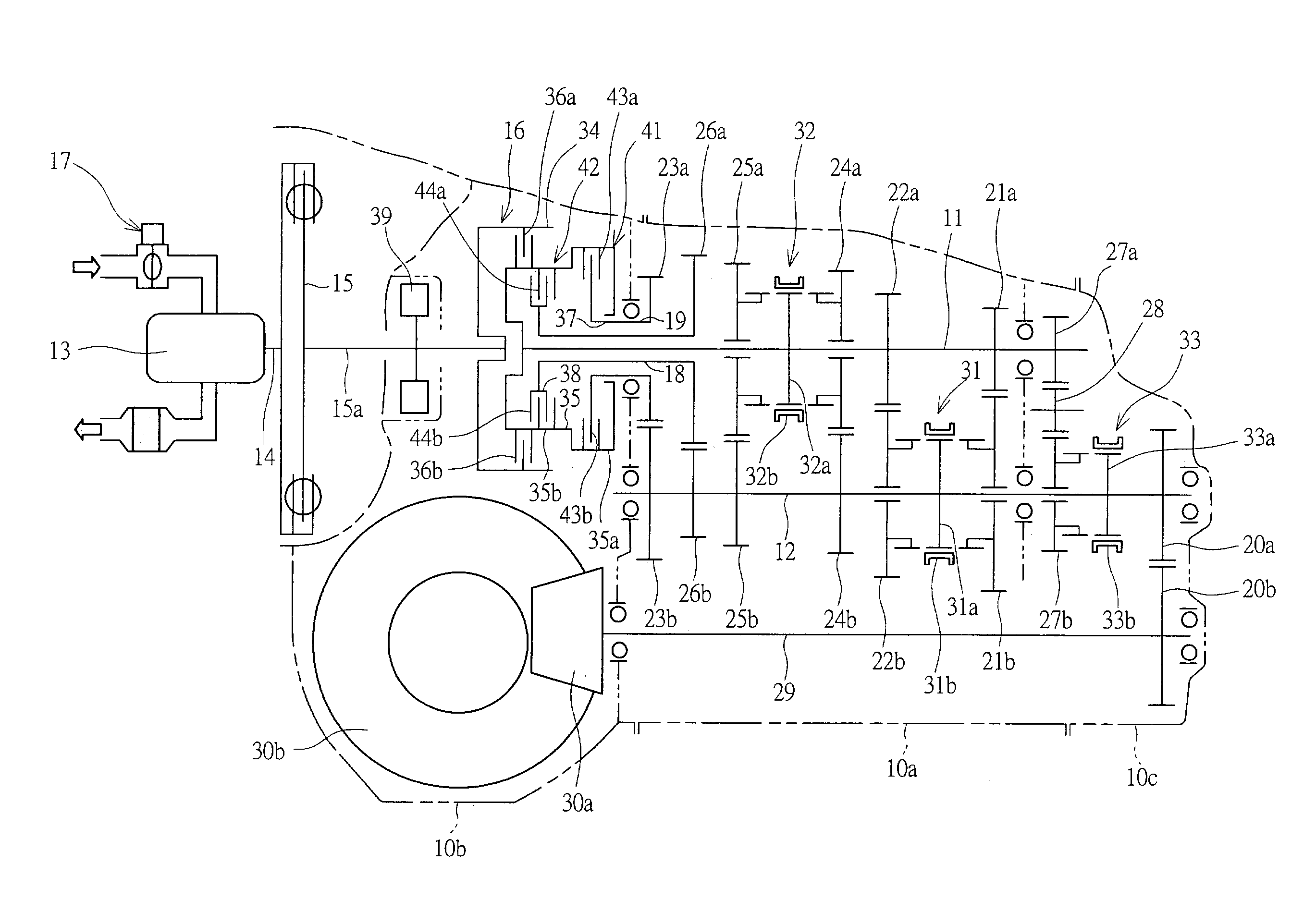

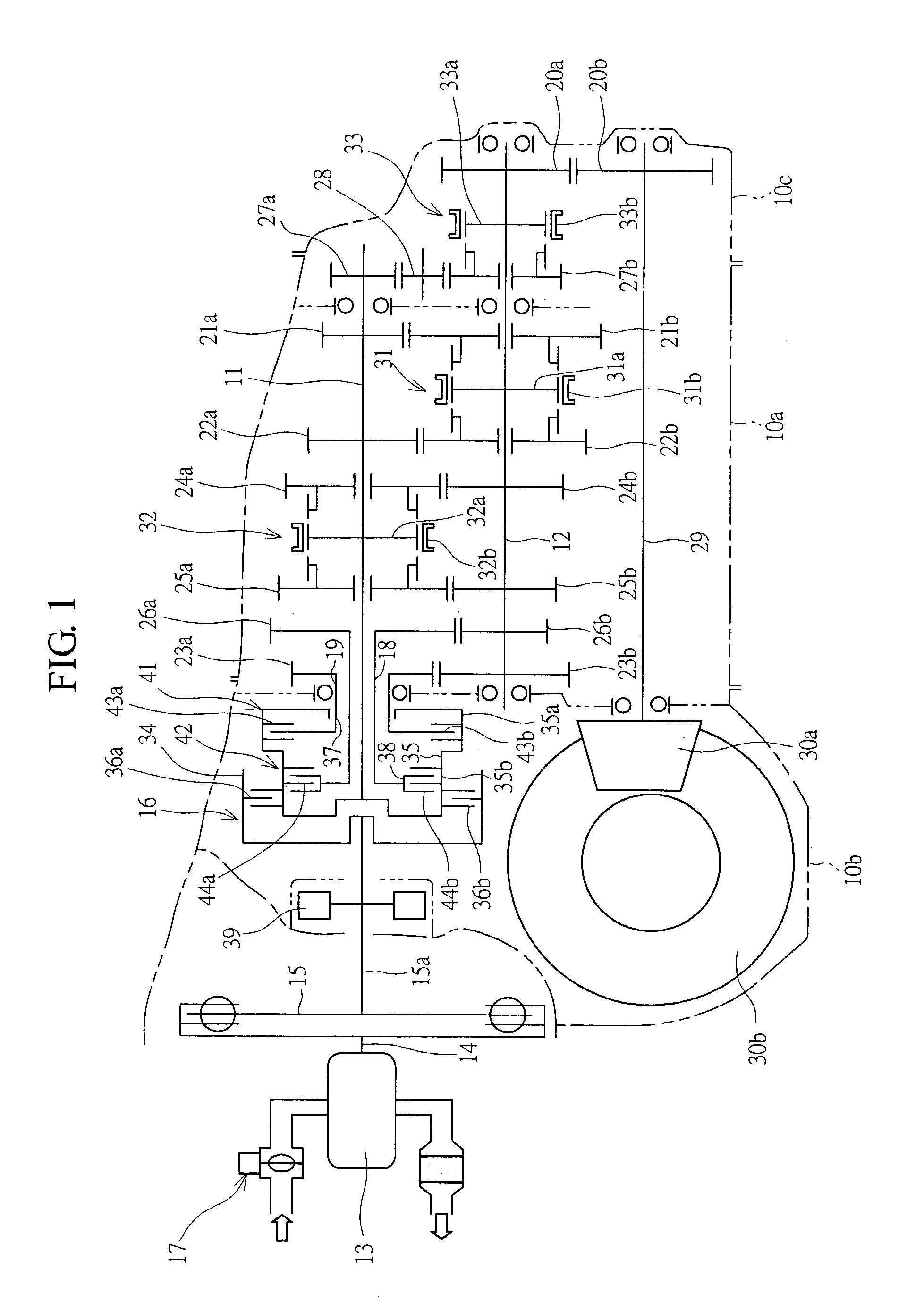

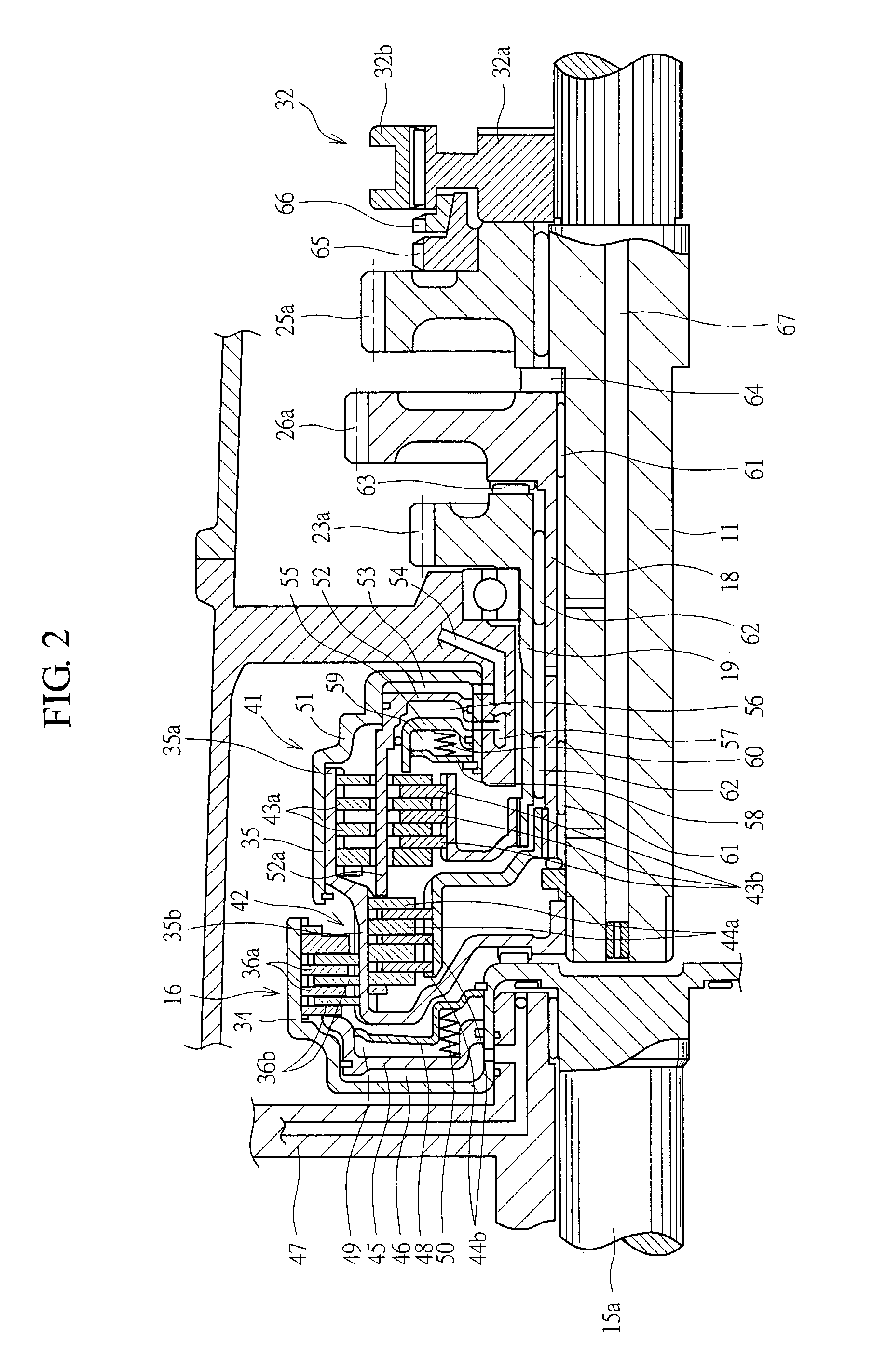

Automatic transmission

InactiveUS7021169B2Reduce gear shift shockSmooth gear shift qualityToothed gearingsControl devicesAutomatic transmissionEngineering

An automatic transmission with input shaft having drive gears and an output shaft with driven gears engaging with the drive gears are provided. A transmission gear for transmitting a power is selectively switched from transmission gear trains of the drive gears and driven gears, by a switching mechanism. An input clutch for switching engine power transmission and input shaft disconnect states is arranged between an engine crankshaft and the input shaft. Bypass clutches capable of transmitting the power to the respective transmission gear trains are provided at an end portion of the input shaft, and the engine power is transmitted to the output shaft via at least any one of the bypass clutches at a time of shifting gears. The input clutch and the plurality of bypass clutches are concentrically arranged in series between the engine and the input shaft providing size reduction.

Owner:SUBARU CORP

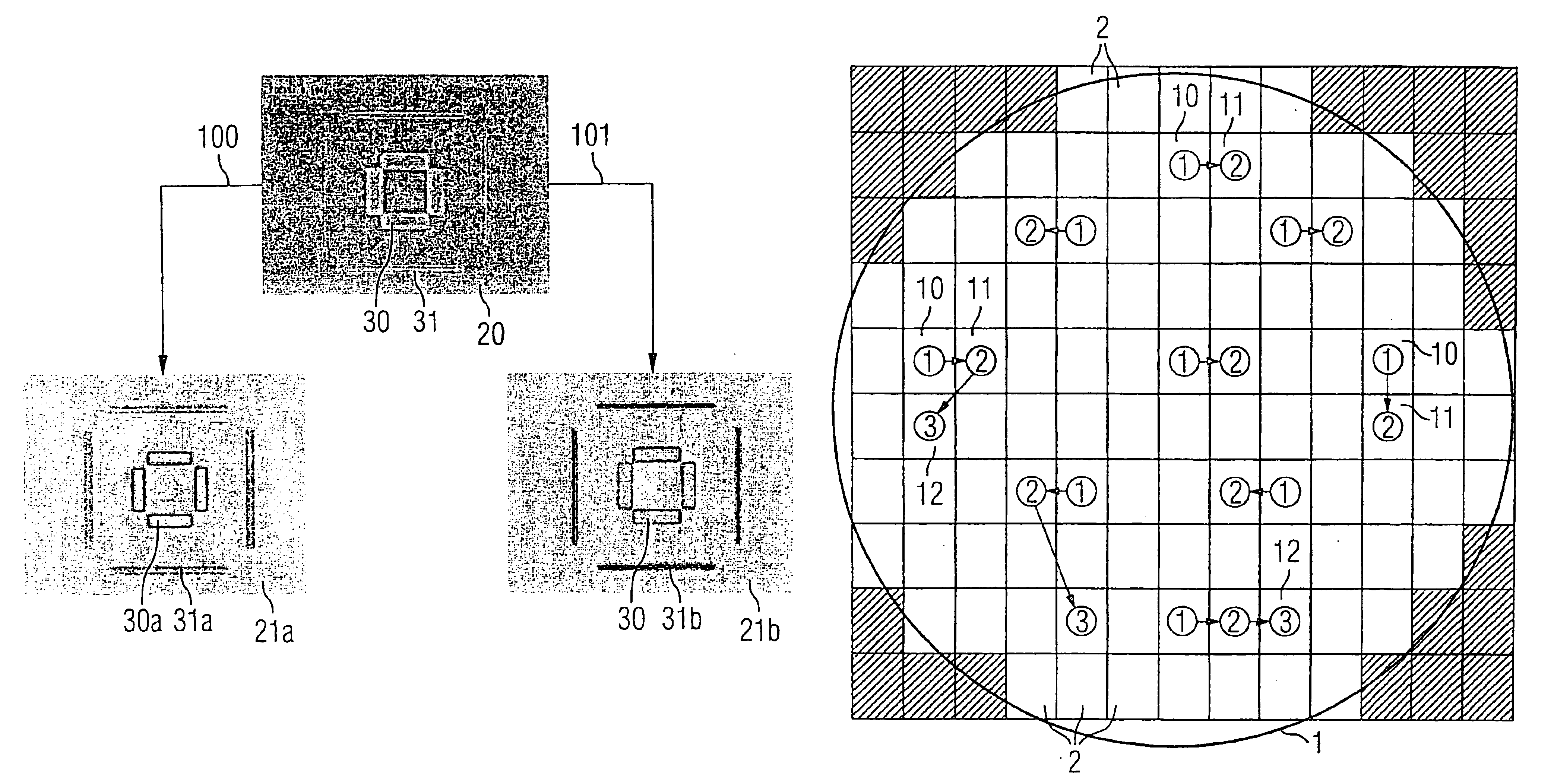

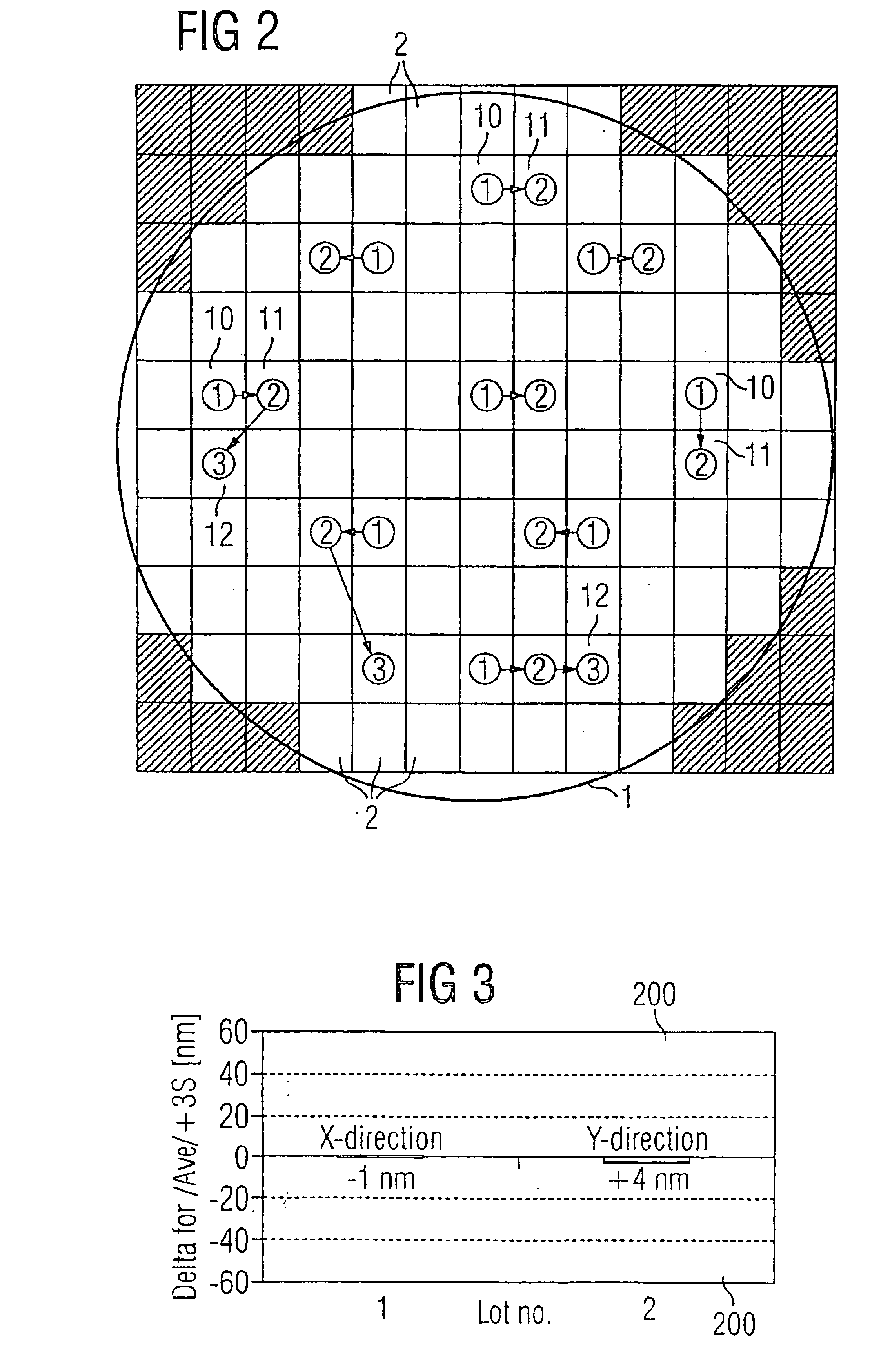

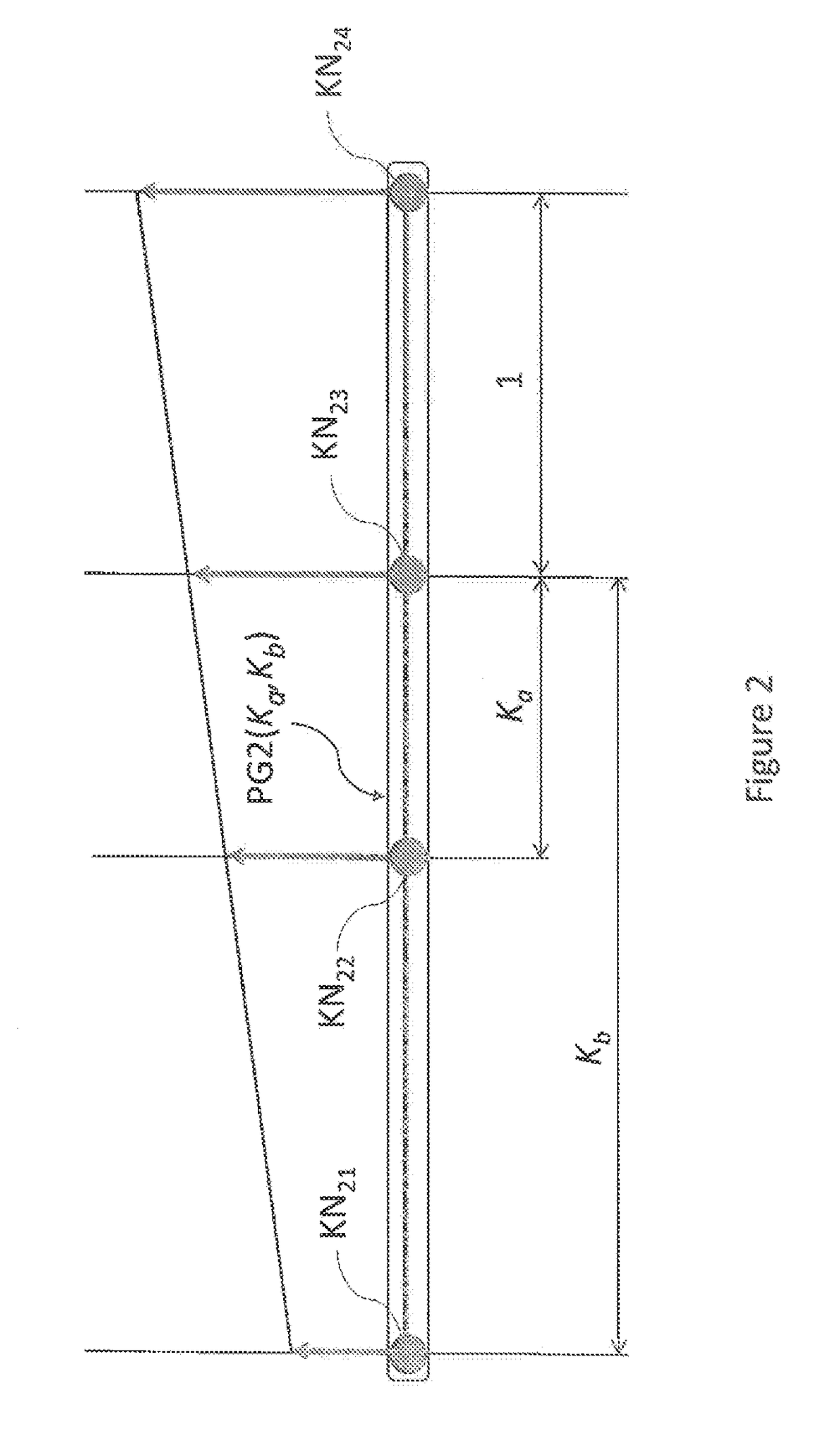

Method for performing an alignment measurement of two patterns in different layers on a semiconductor wafer

InactiveUS6908775B2Shorten the timeHigh yieldImage enhancementImage analysisSemiconductorLight field

In an alignment or overlay measurement of patterns on a semiconductor wafer an error that occurs during the measurement in one of a predefined number of alignment structures in an exposure field of a corresponding predefined set of exposure fields can be handled by selecting an alignment structure in a substitute exposure field. The latter exposure field need not be part of the predefined set of exposure fields, that is, an inter-field change may be effected. The number of alignment measurements on a wafer remains constant and the quality is increased. Alternatively, when using another alignment structure in the same exposure field—by effecting an intra-field change—the method becomes particularly advantageous when different minimum structure sizes are considered for the substitute targets. Due to the different selectivity in, say, a previous CMP process, such targets might not erode and do not cause an error in a measurement, thus providing an increased alignment or overlay quality.

Owner:QIMONDA

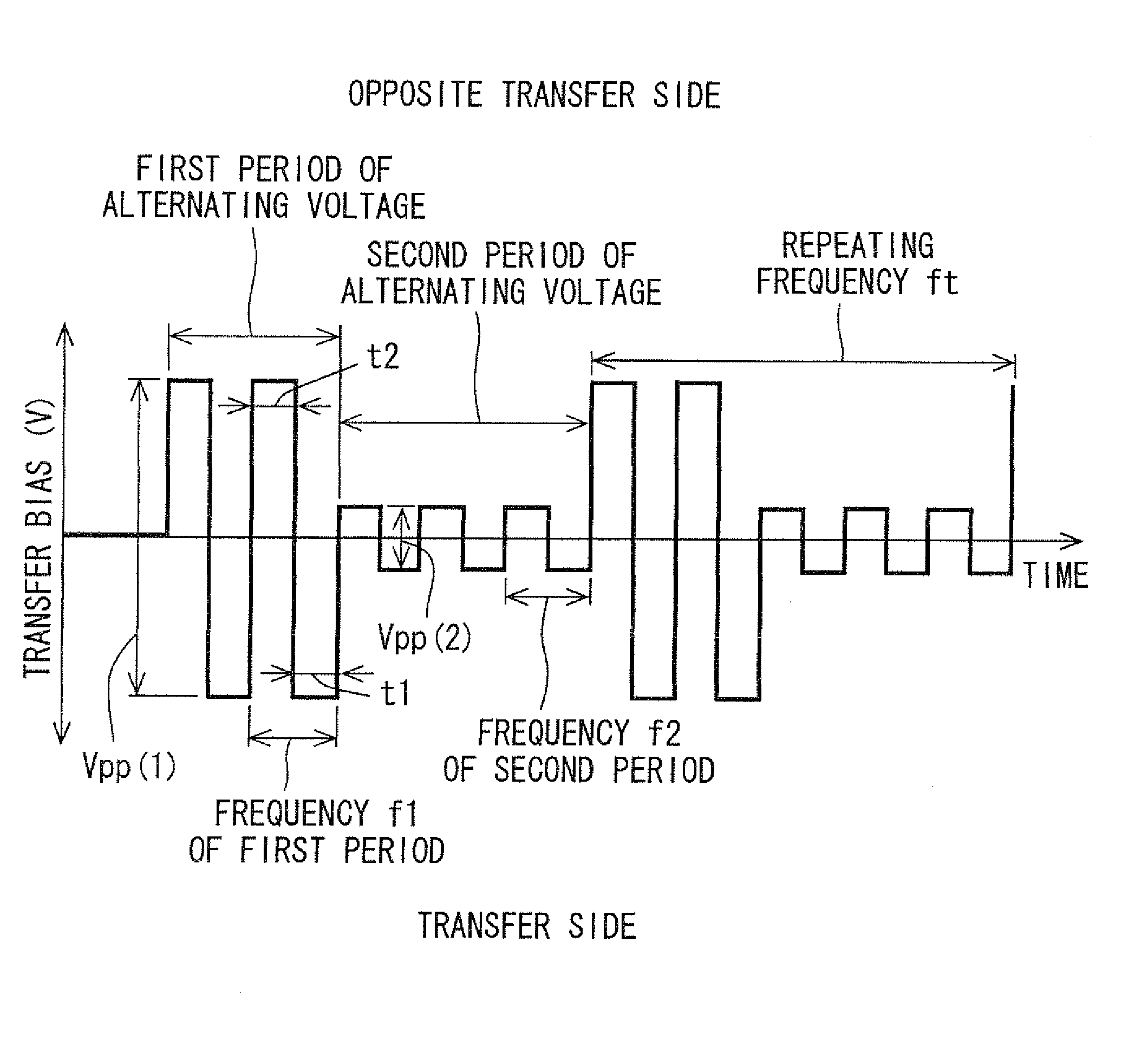

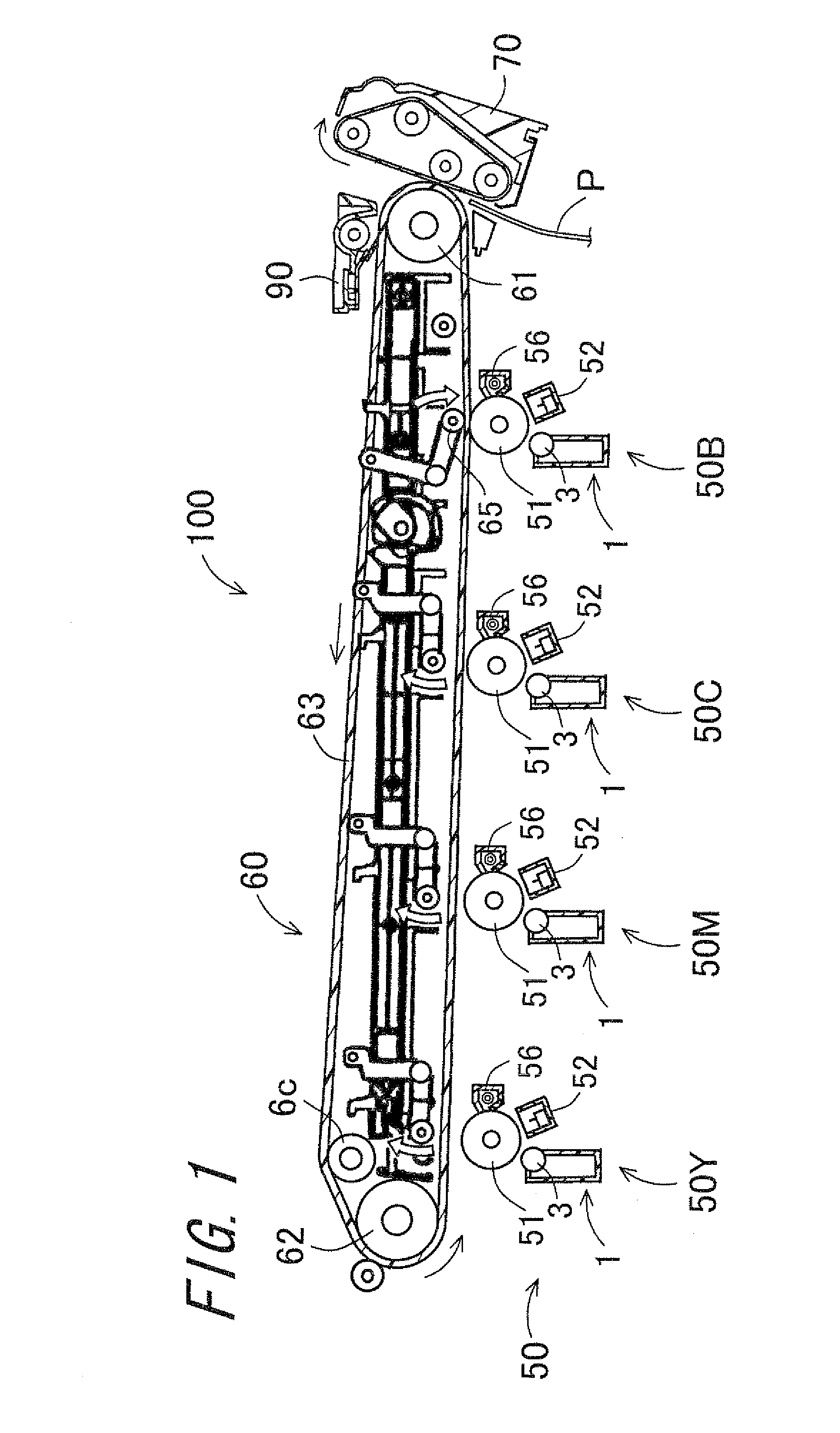

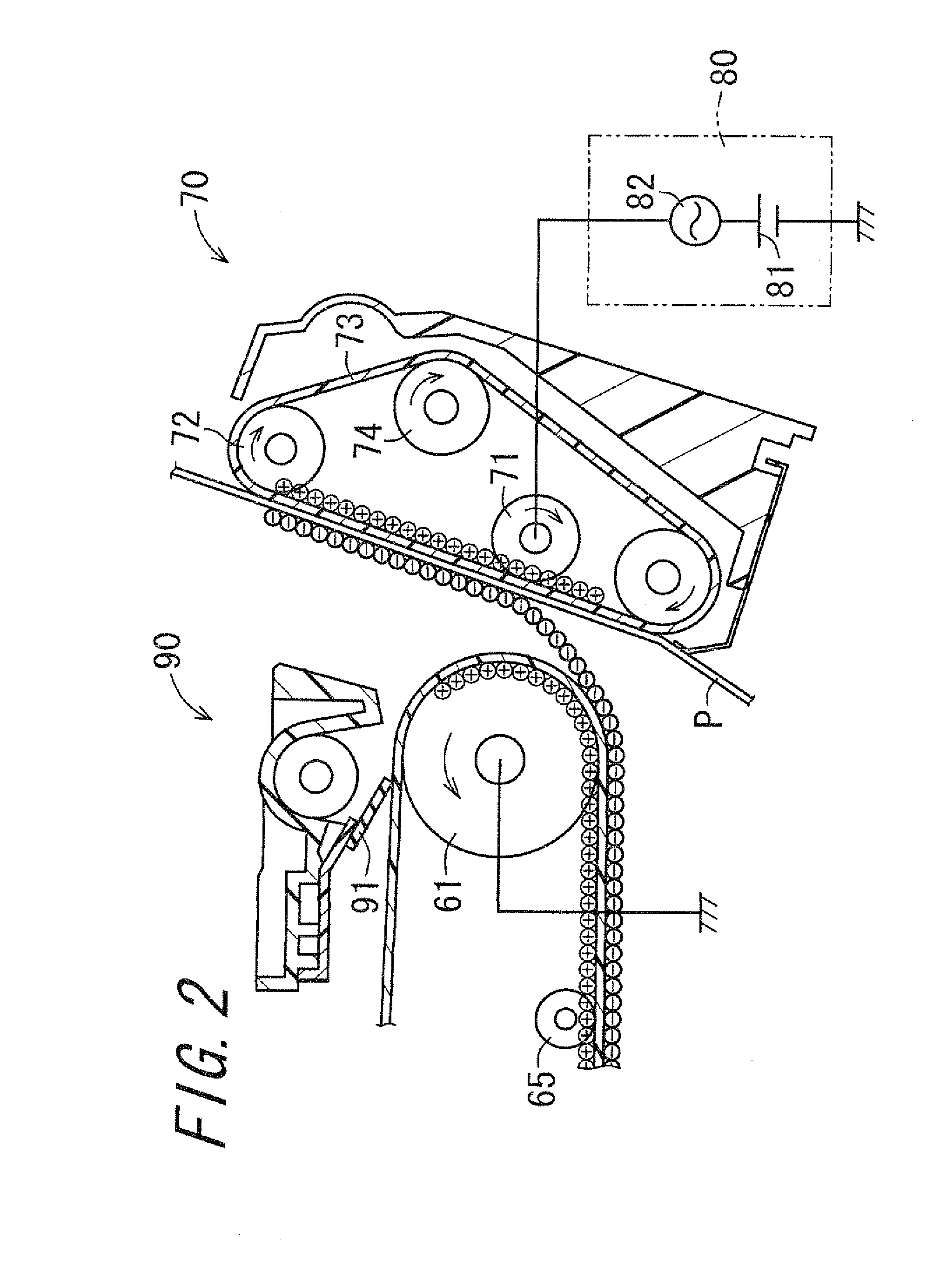

Transfer device and image forming apparatus

ActiveUS20100303518A1Avoid uneven qualityRelative density is smallElectrographic process apparatusImaging qualityEngineering

A transfer device and an image forming apparatus capable of forming an image of smooth image quality with little uneven density, are provided. An alternating voltage is applied so that a first period in which a first peak-to-peak voltage Vpp(1) is applied and a second period in which a second peak-to-peak voltage Vpp(2), lower than the first peak-to-peak voltage, is applied are alternately repeated. In the alternating voltage to be applied, a transfer side potential to shift a toner from an intermediate transfer belt to recording paper sheet and an opposite transfer side potential to shift the toner from the recording paper sheet to the intermediate transfer belt are applied so as to alternate with each other. When f1 denotes a frequency of the first period and f2 denotes a frequency of the second period, f1=f2 is satisfied.

Owner:SHARP KK

Honey processing process

InactiveCN103549250AHigh purityTargetedFood thermal treatmentMulti-step food processesHeating timeFiltration

The invention relates to a honey processing process. The honey processing process is characterized by comprising the following steps: (1) raw honey inspection; (2) (a) melting, wherein the heating temperature is 45-60 DEG C, and the heating time is 30-60 minutes or 4-8 hours according to the state of raw honey; (b) filtration, namely carrying out pressure filtration in a sealing device at the temperature higher than 40 DEG C so as to remove impurities and larger crystals; (3) vacuum concentration; (4) cooling. According to the honey processing process, the filtration step sequentially comprises rough filtration, fine filtration and refined filtration, wherein the temperature of the fine filtration is higher than that of the rough filtration, and the temperature of the refined filtration is higher than that of the fine filtration. The different processing time can be set according to different states of the raw honey, so that the pertinence is strong, not only can melting quality and the smooth operation of subsequent steps be guaranteed, but also the efficiency is increased, and the unnecessary time waste is reduced; besides, the filtration is performed three times, and the filtering temperatures are different, so that the efficiencies of each filtration process and the whole filtration are increased, and the purity of finished honey is improved.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

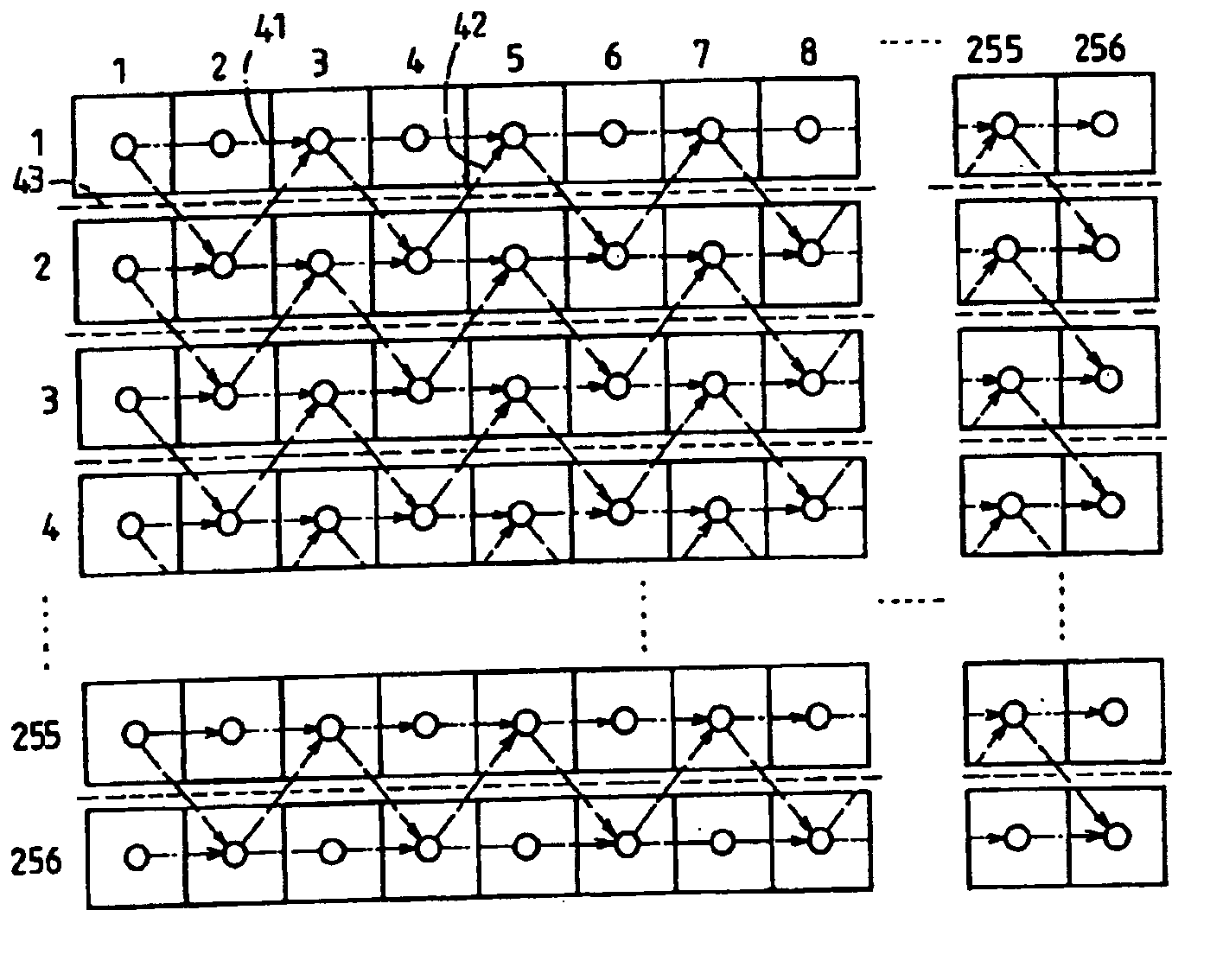

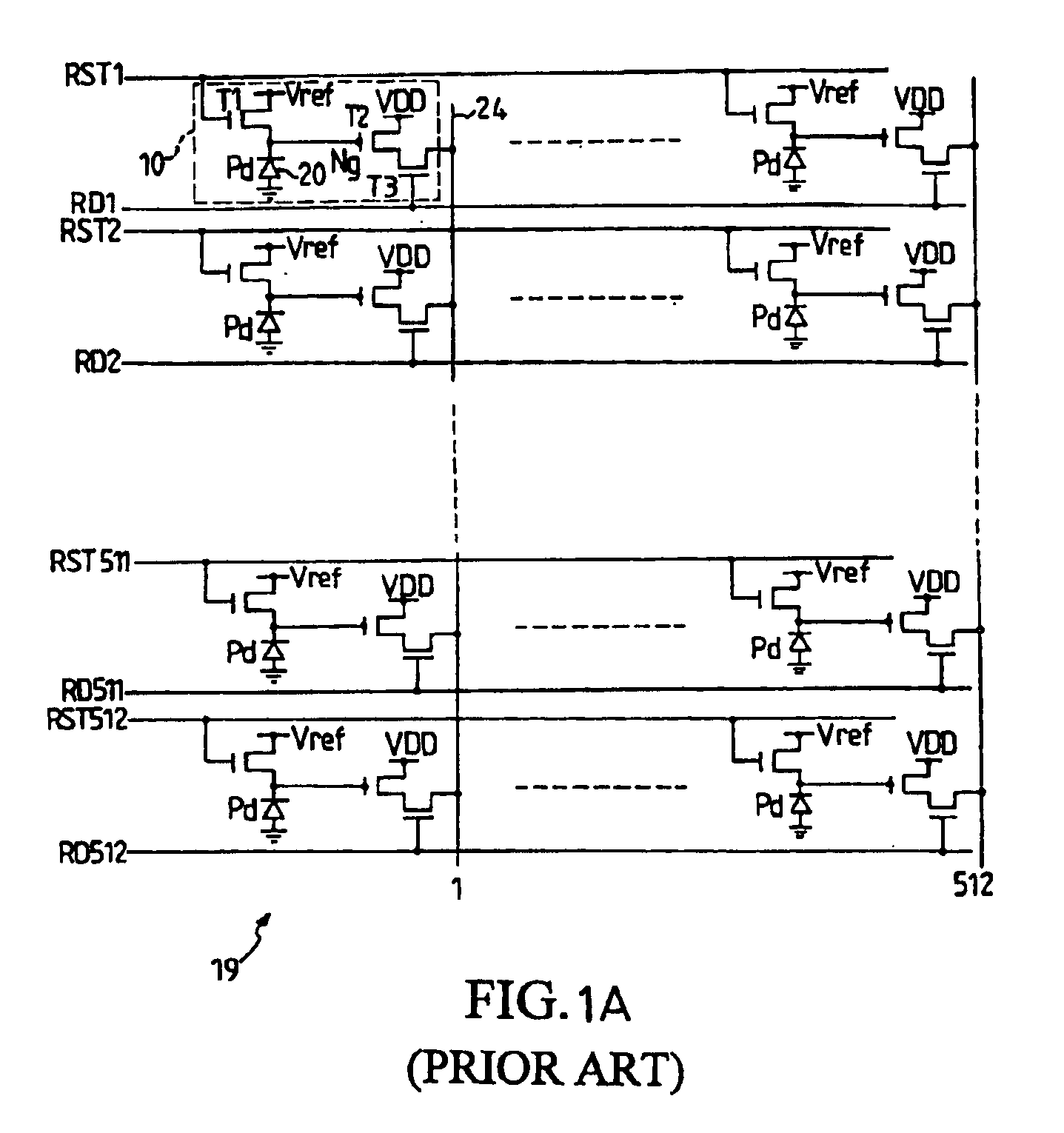

Interlaced alternating pixel design for high sensitivity CMOS Image sensors

InactiveUS6876388B1Reduce manufacturing costReduce sizing costsTelevision system detailsTelevision system scanning detailsCMOSScan line

A structure of an image sensor for sensing the light of an image impinging thereupon and for translating the image into a standard television format is disclosed. The structure comprises a plurality of first and second light detecting elements (22, 23) arranged in rows and columns and half as many rows and columns as scan lines of a television format for generating respective analog signals in proportion to the intensity of the light impinging respectively on each of the first and second light detecting elements (22, 23), wherein the first and second light detecting elements in each row are alternately disposed and activated by first read lines RDOn (n=1 . . . 256) to generate odd field signals, and wherein the first and second light detecting elements (22, 23) of two adjacent rows disposed in a zigzag or serrated manner are activated by second read lines RDEn (n=1 . . . 256) to generate even field signals.

Owner:ALCOR MICRO CORP

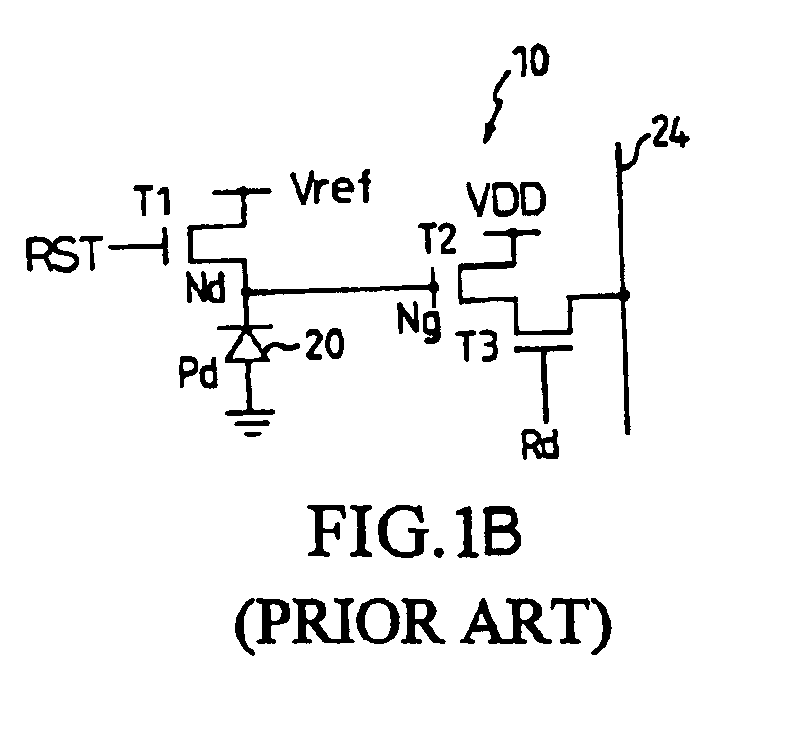

Limestone machine-made sand dry-mixed mortar and preparation method thereof

InactiveCN103922667ASolve the shortage of resourcesAddressing quality degradationCompressive resistanceProcess engineering

The invention relates to a limestone machine-made sand dry-mixed mortar and a preparation method thereof, belonging to the field of building materials. The limestone machine-made sand dry-mixed mortar comprises the following raw materials in parts by weight: 10-25 parts of cement, 5-8 parts of coal ash, 70-85 parts of machine-made sand and 0.06-0.08 part of mortar water-retention plasticizing agents, wherein the machine-made sand is limestone machine-made sand. The limestone machine-made sand dry-mixed mortar disclosed by the invention has the advantages of good cohesiveness, high water-retention rate, high compressive strength, good operability, economy, environmental protection, resource saving and the like, and is a green building material with excellent properties. The preparation method disclosed by the invention is simple and low in cost.

Owner:GUANGXI YUFENG GRP

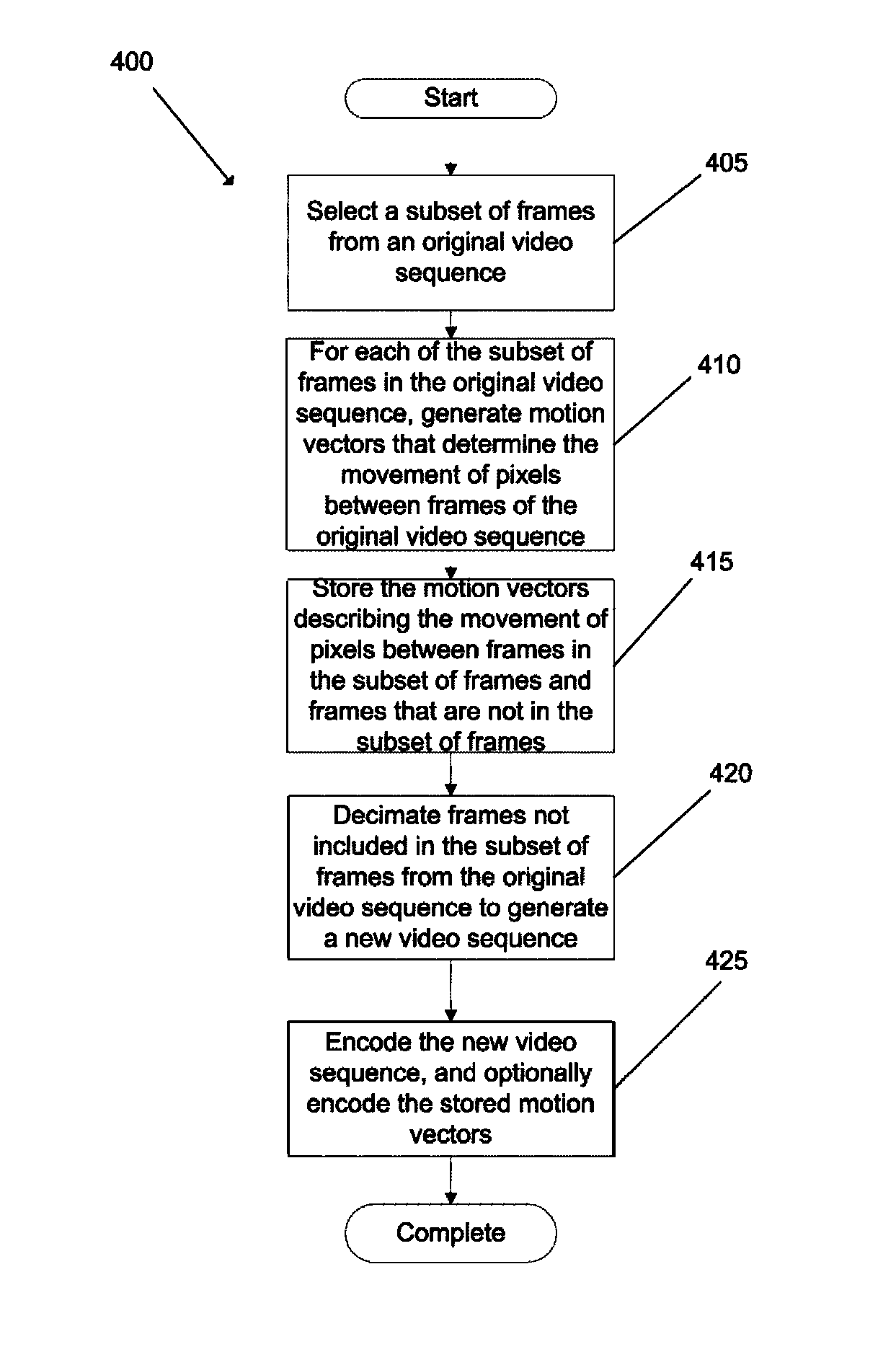

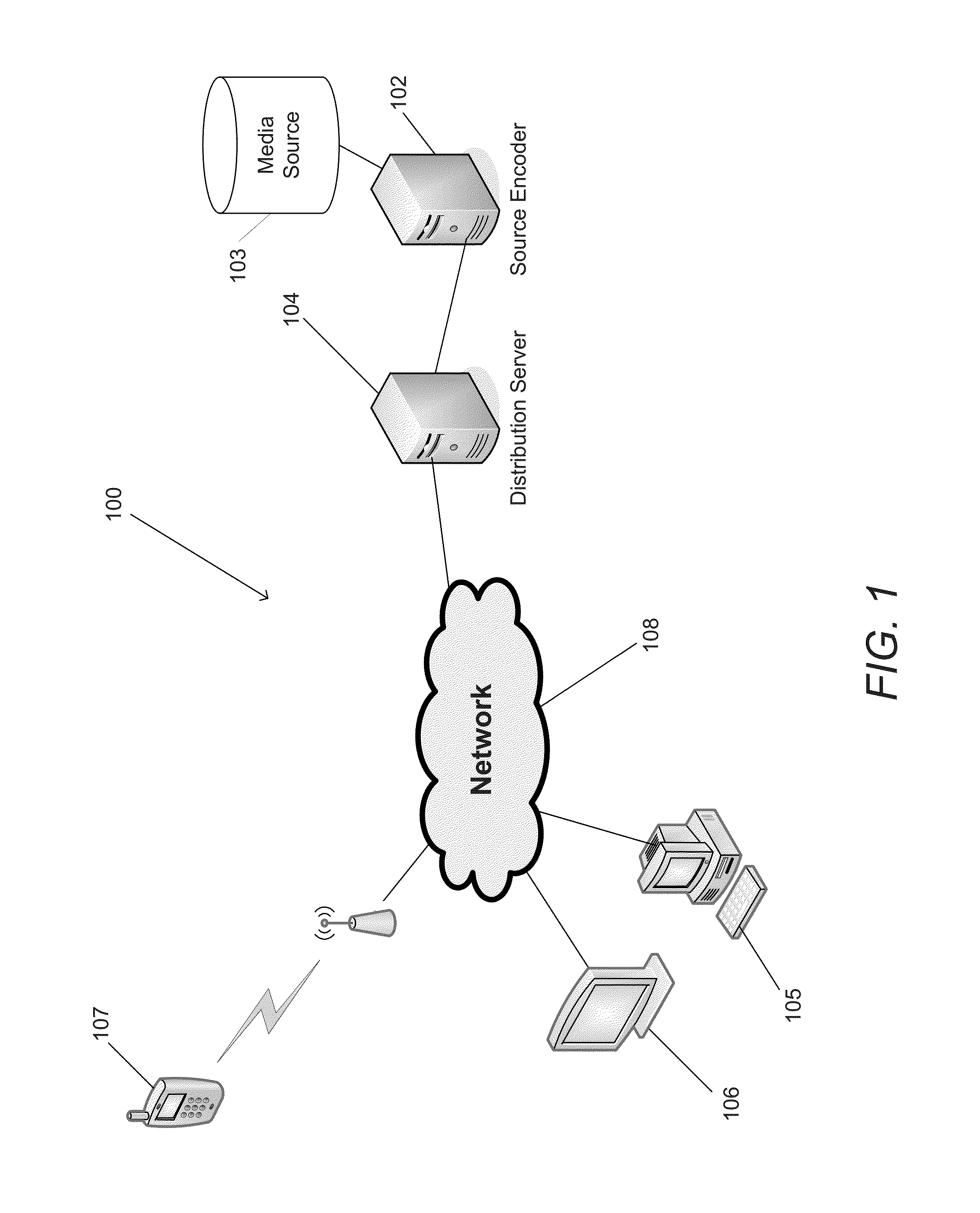

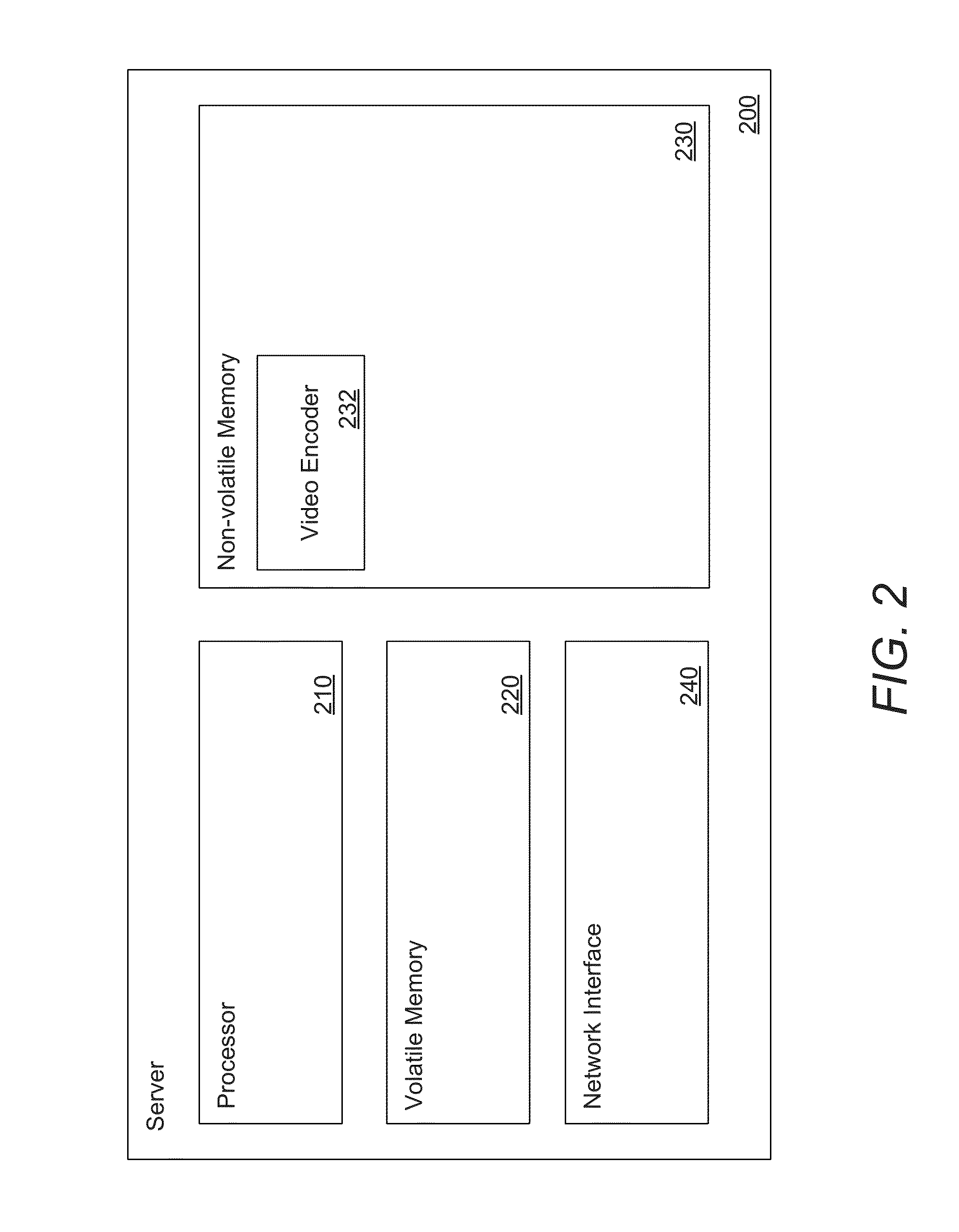

Systems and methods for motion-vector-aided video interpolation using real-time smooth video playback speed variation

ActiveUS9131202B1Stable changeShorten speedTelevision system detailsElectronic editing digitised analogue information signalsFrame rateMotion vector

Systems and methods for encoding and playing back video at adjustable playback speeds by interpolating frames to achieve smooth playback in accordance with embodiments of the invention are described. One embodiment includes a source encoder that includes a processor, memory including an encoder application, where the encoder application directs the processor to: select a subset of frames from a first video sequence; generate motion vectors describing frames from the first video sequence that are not part of the selected subset of frames, where each motion vector describes movement between a frame in the subset of frames and a frame not included in the subset of frames; store the motion vectors; decimate frames not included in the subset of frames from the first video sequence to generate a second video sequence having a nominal frame rate less than the frame rate of the first video sequence; and encode the second video sequence at the nominal frame rate.

Owner:NAUTILUS INC

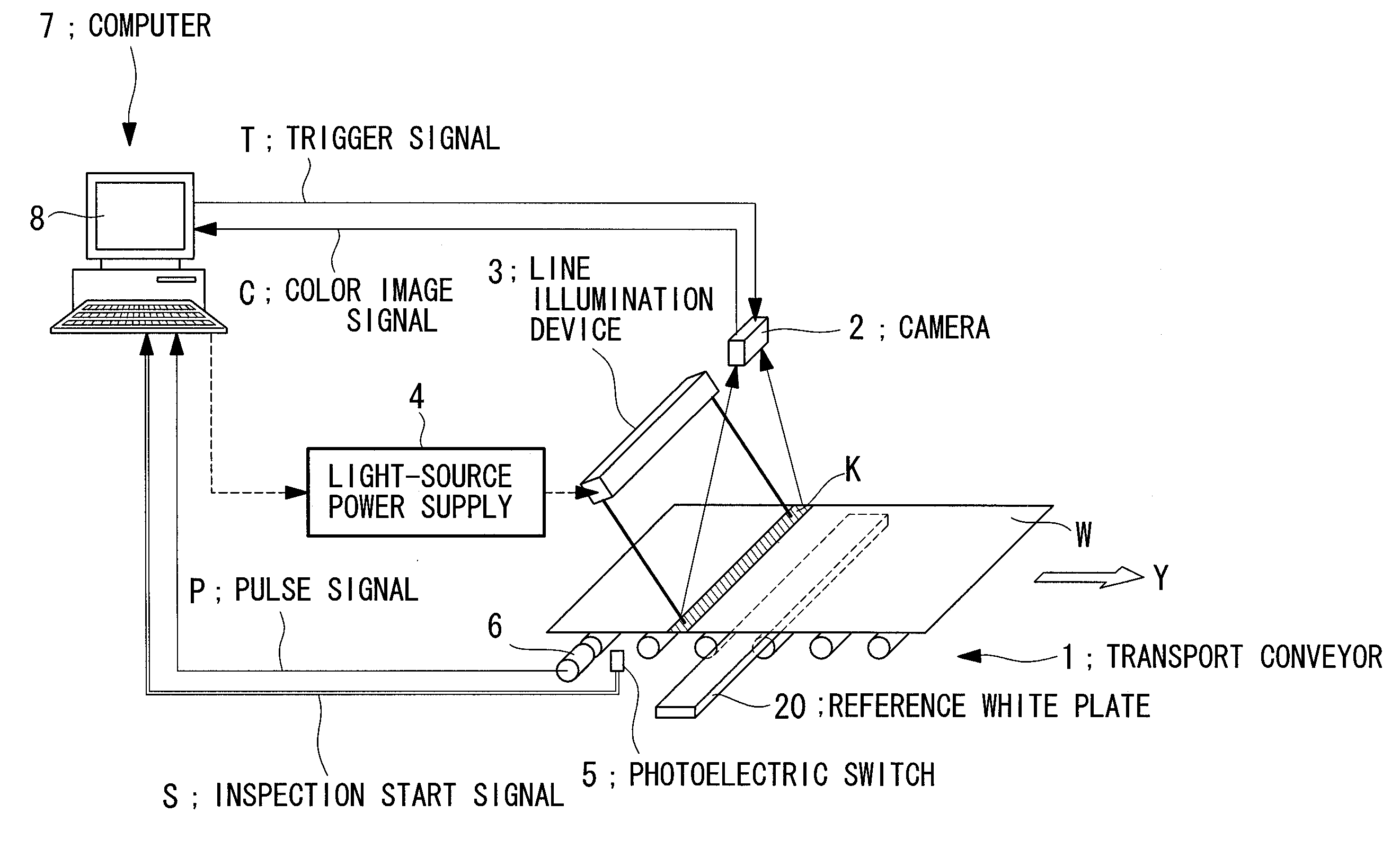

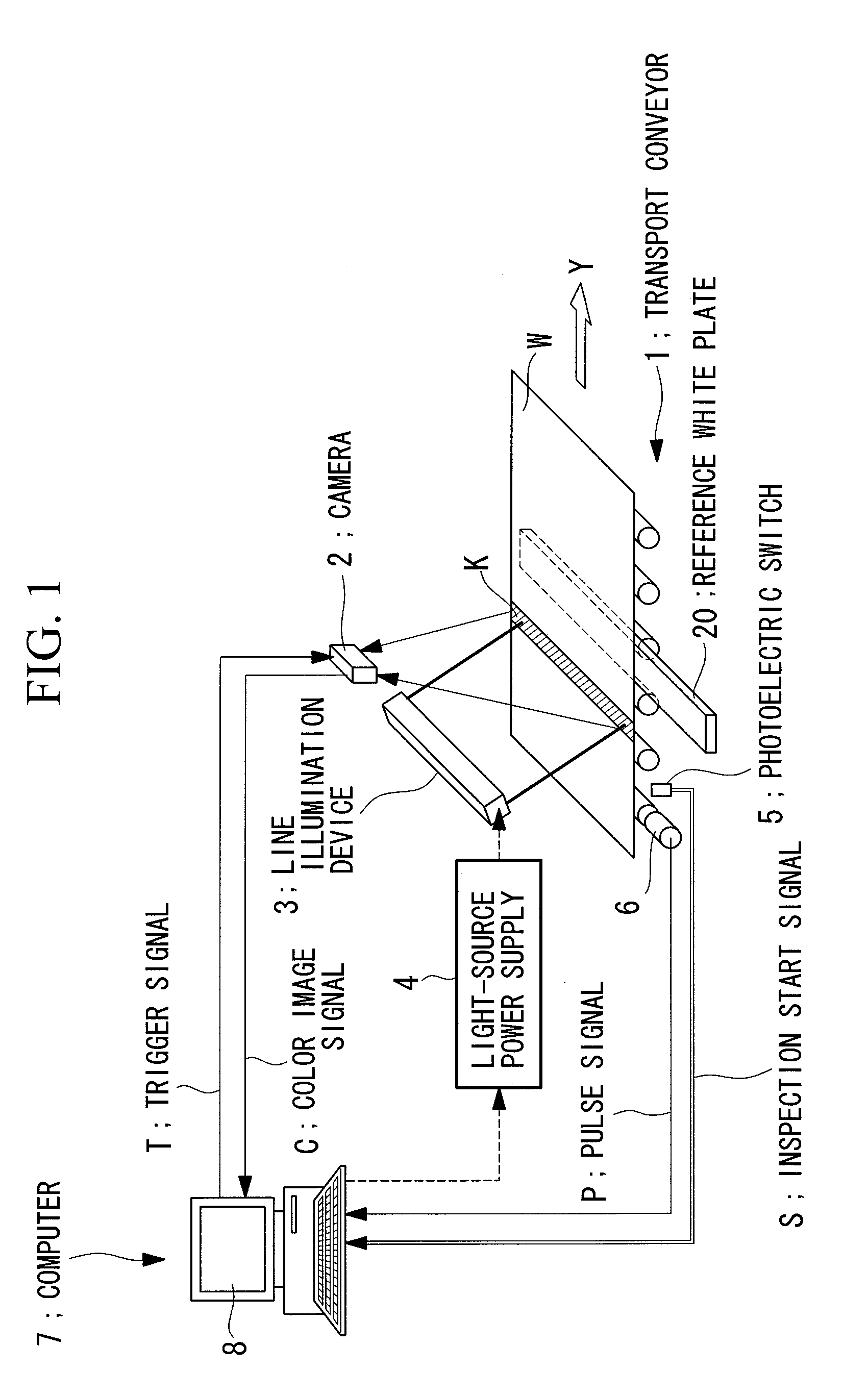

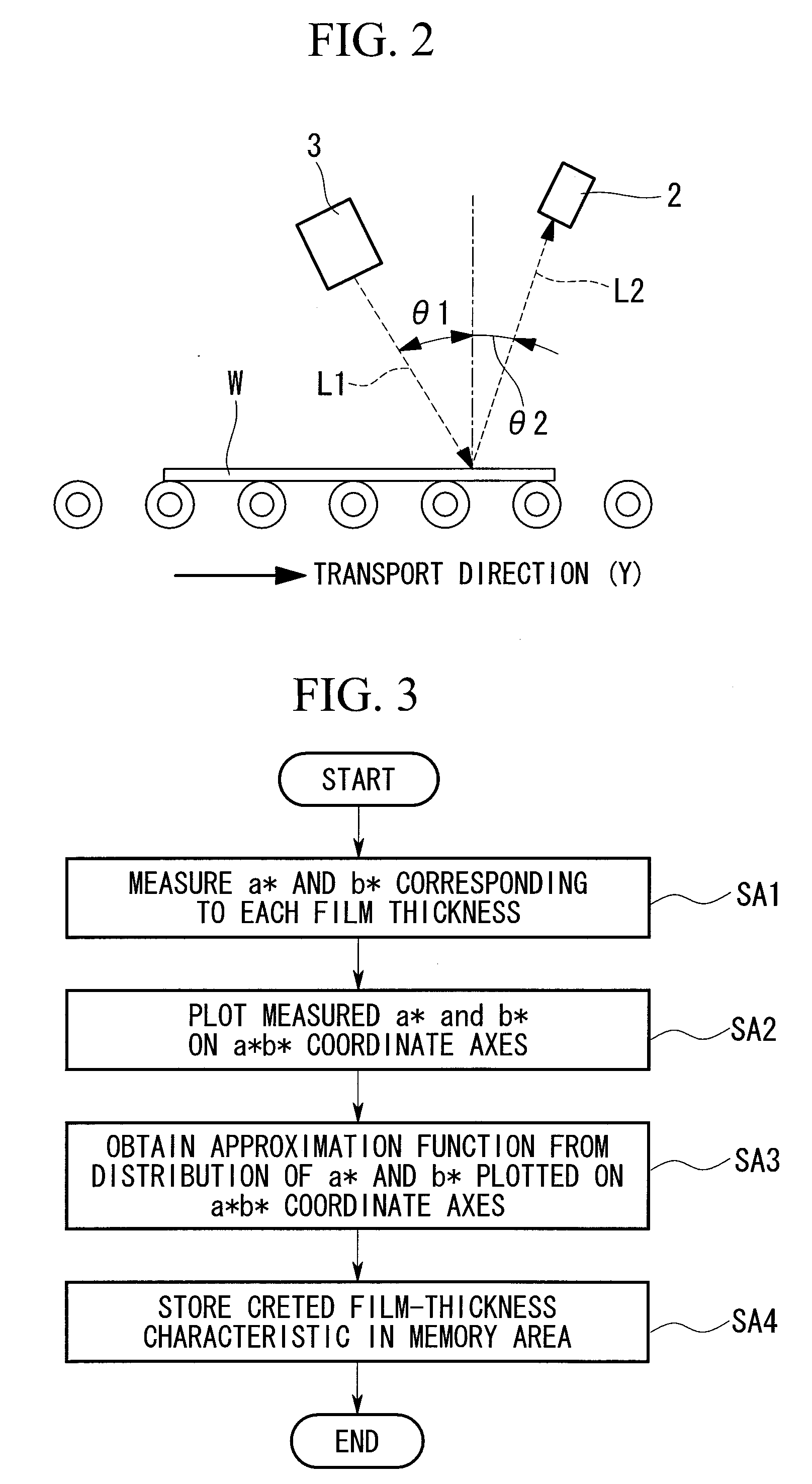

Film-thickness measurement method and apparatus therefor, and thin-film device fabrication system

InactiveUS20100177326A1Easy to measureElectricity generation efficiency can be improvedFinal product manufactureUsing optical meansTransparent conducting filmManufacturing systems

Objects are to reduce the burden on an operator and to improve fabrication efficiency. A transparent conductive film or a transparent optical film formed on a substrate W is irradiated with line illumination light by means of a line illumination device 3, line reflected light reflected at the transparent conductive film or the transparent optical film is detected with a camera, a color evaluation value of the detected reflected light is measured, and a film thickness corresponding to the measured color evaluation value is obtained using a film-thickness characteristic in which the color evaluation value is associated with the film thickness.

Owner:MITSUBISHI HEAVY IND LTD

Soft-pellet creep feed and preparation method thereof

ActiveCN103416591AImprove palatabilityEliminate lossAnimal feeding stuffAdditive ingredientBlood plasma

The invention discloses a soft-pellet creep feed and a preparation method thereof, and belongs to the field of feed formulation design and feed processing techniques. The preparation method comprises the following steps: mixing and bacillus subtilis and pickled vegetables fermentation liquor, performing fermentation in sequence to form fermented soybean meal and rice which are taken as main raw materials; adding steam fish meal, blood plasma powder, soybean meal and the like in a matched manner; utilizing a soft pelletizer to prepare pellet materials through ultramicro smashing; utilizing a syrup spray device to uniformly spray syrup on the surfaces of the pellet materials. The creep feed provided by the invention is full and balanced in nutrition, is easy to digest and intake, has stable quality, and is subjected to multiple fermentation. Moreover, feed inducing performance, soft protection performance and nutrition full value performance are improved, as a process of combining a soft manufacturing system and the syrup spray system is adopted; the incidence of hardening of medium-sized pellet feed during the preservation process is reduced; compared with a dry pellet feed, the loss of nutritional ingredient during the granulating heating and drying process is avoided, and the palatability of soft pellet feed is kept well.

Owner:LIAONING WELLHOPE AGRI TECH

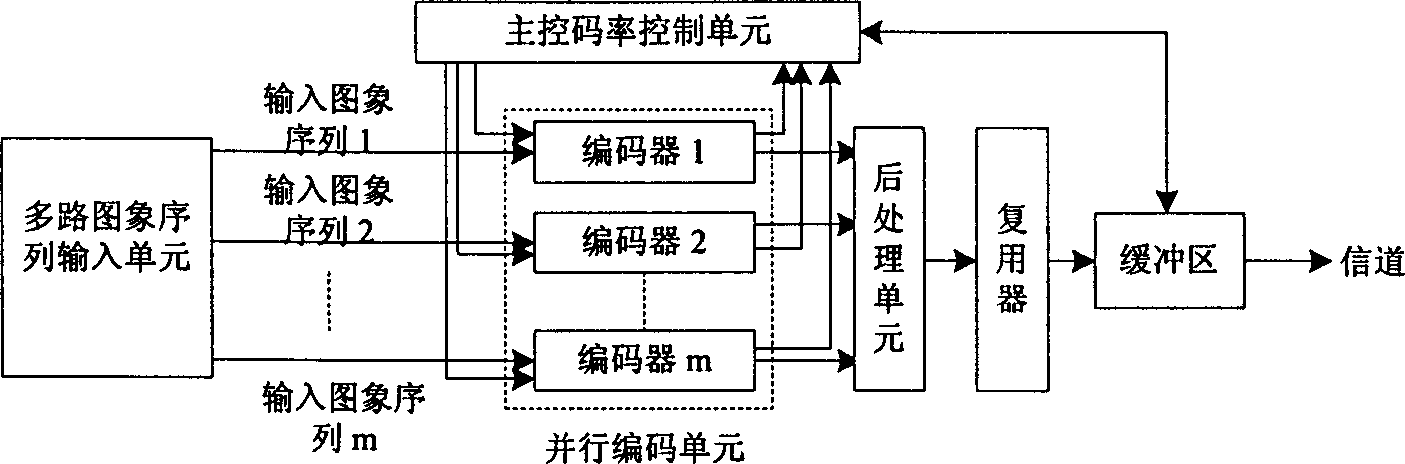

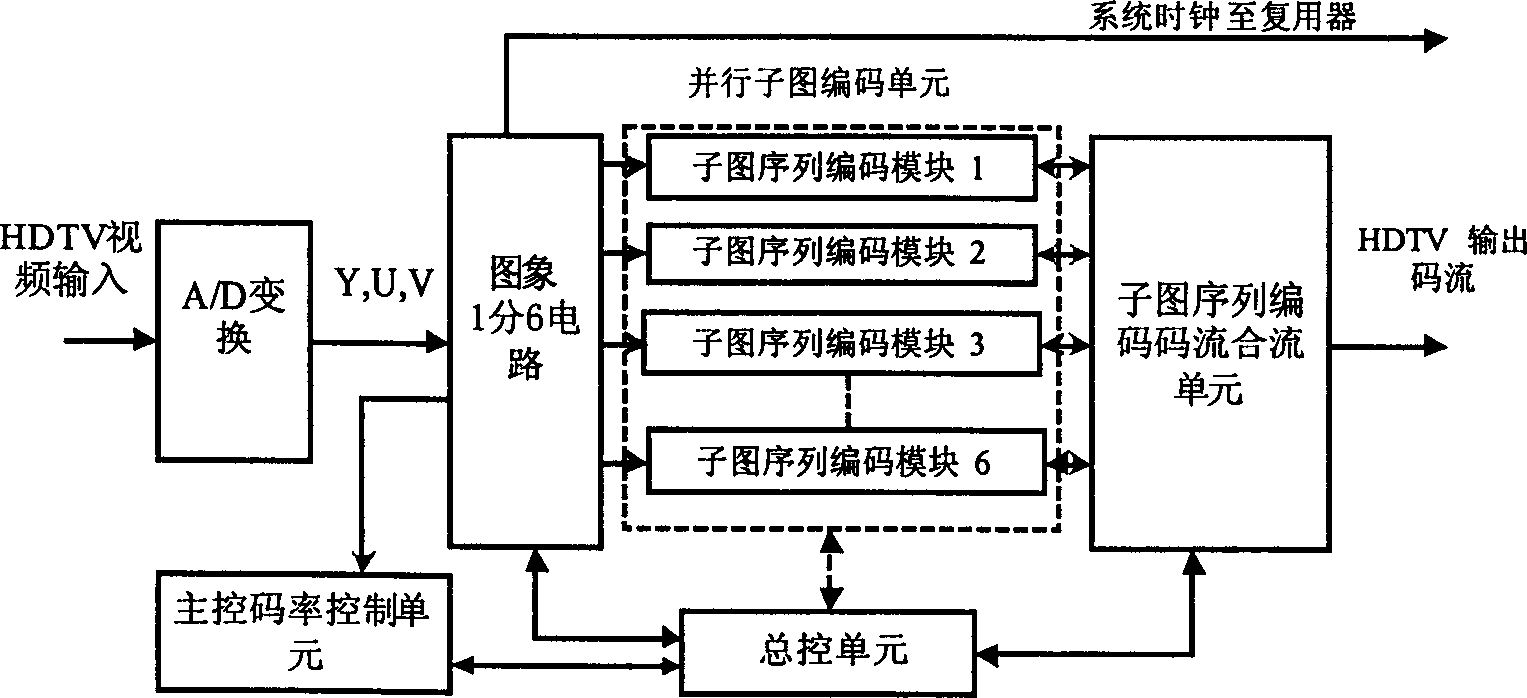

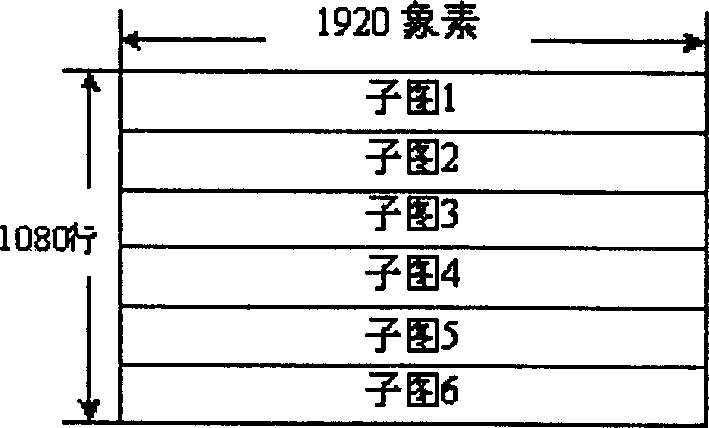

Parallel image sequence bit rate controlling method for digital TV video coder

InactiveCN1422075AAvoid uneven qualityImprove scalabilityDigital video signal modificationHigh-definition television systemsDigital videoData stream

The present invention is parallel image sequence bit rate controlling method for digital TV video coder. The input several video program sequences of different data sources or parallel image sequences of different spatial domain or frequency domain in the same data source, and the parallel encode unit is used to perform real-time MPEG-2 variable bit rate encoding of the image sequences. Super-frame is defined as the image frames of the image sequences in the same time, and super-image set is defined as the least common multiple of the image set sizes. The main control code rate control unit is used to perform layered and combined code rate control of the image frames, super-frame and super-image set, and the post-treating unit is used for code flow synthesis and code rate control of several compressed output data flows with the data being packaged in the multiplexer and fed to transmission channel via the buffering area.

Owner:SHANGHAI JIAO TONG UNIV

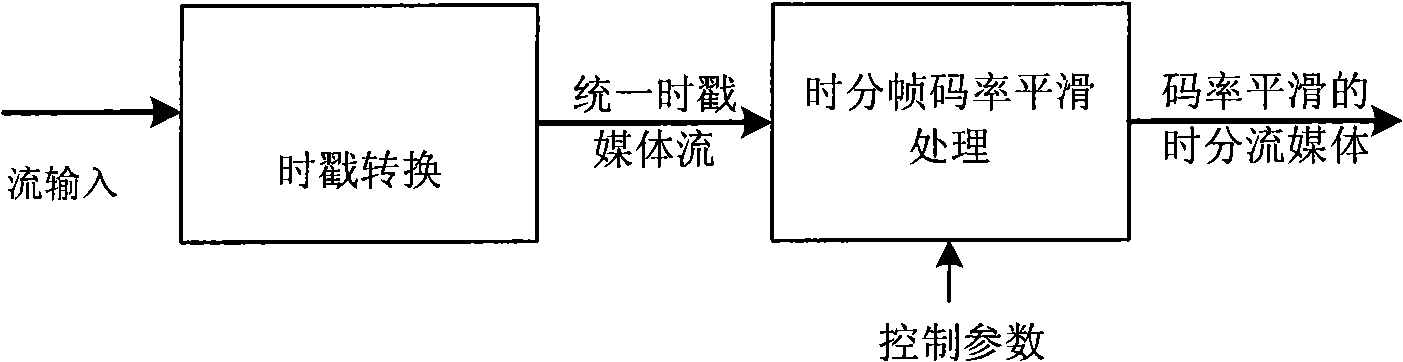

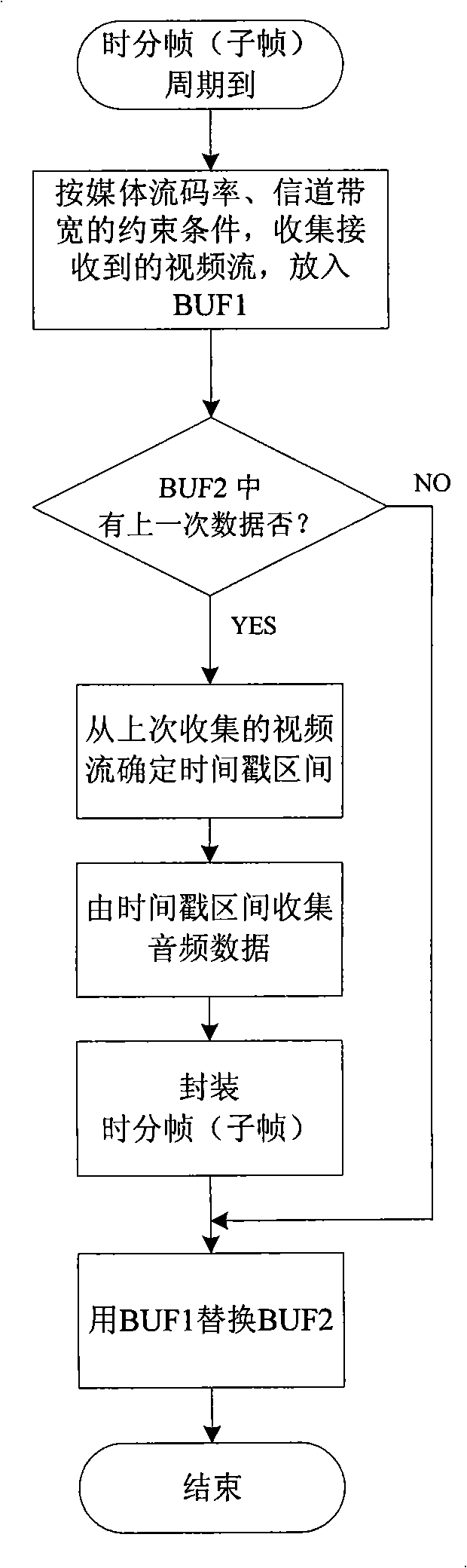

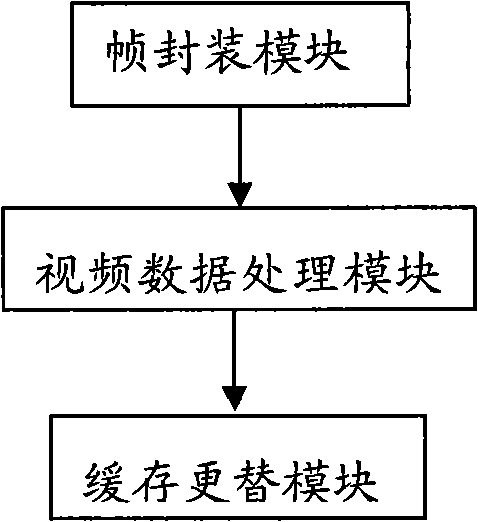

Method and apparatus for smoothing transmission code rate of time division stream media

InactiveCN101312530AAvoid uneven qualityTimestamp range is smallPulse modulation television signal transmissionTransmissionAudio MediaStreaming data

The invention provides a method for smoothing the transmission bit rate of time division flow media and a device. The method comprises: the time division frame / sub frame period arrives, packaging the time division frame / sub frame; inputting video stream data into a buffer region, collecting the video stream data packed into the next sub frame, taking out the video stream data to be arranged into the buffer region; if at the system initial state, the last video data is not buffered, adopting the buffer region to directly replace the buffer region to start a next period; if the buffer region has the video data of last time, adopting its media time stamp interval to attain audio media data, packaging the video and audio media data into the frame / sub frame structure, and adopting said buffer region to replace the buffer region. The invention can effectively smooth the bit rate of time division flow media, thus is adaptive to the transmission channel demanding a limited bit rate.

Owner:GLOBAL INNOVATION AGGREGATORS LLC

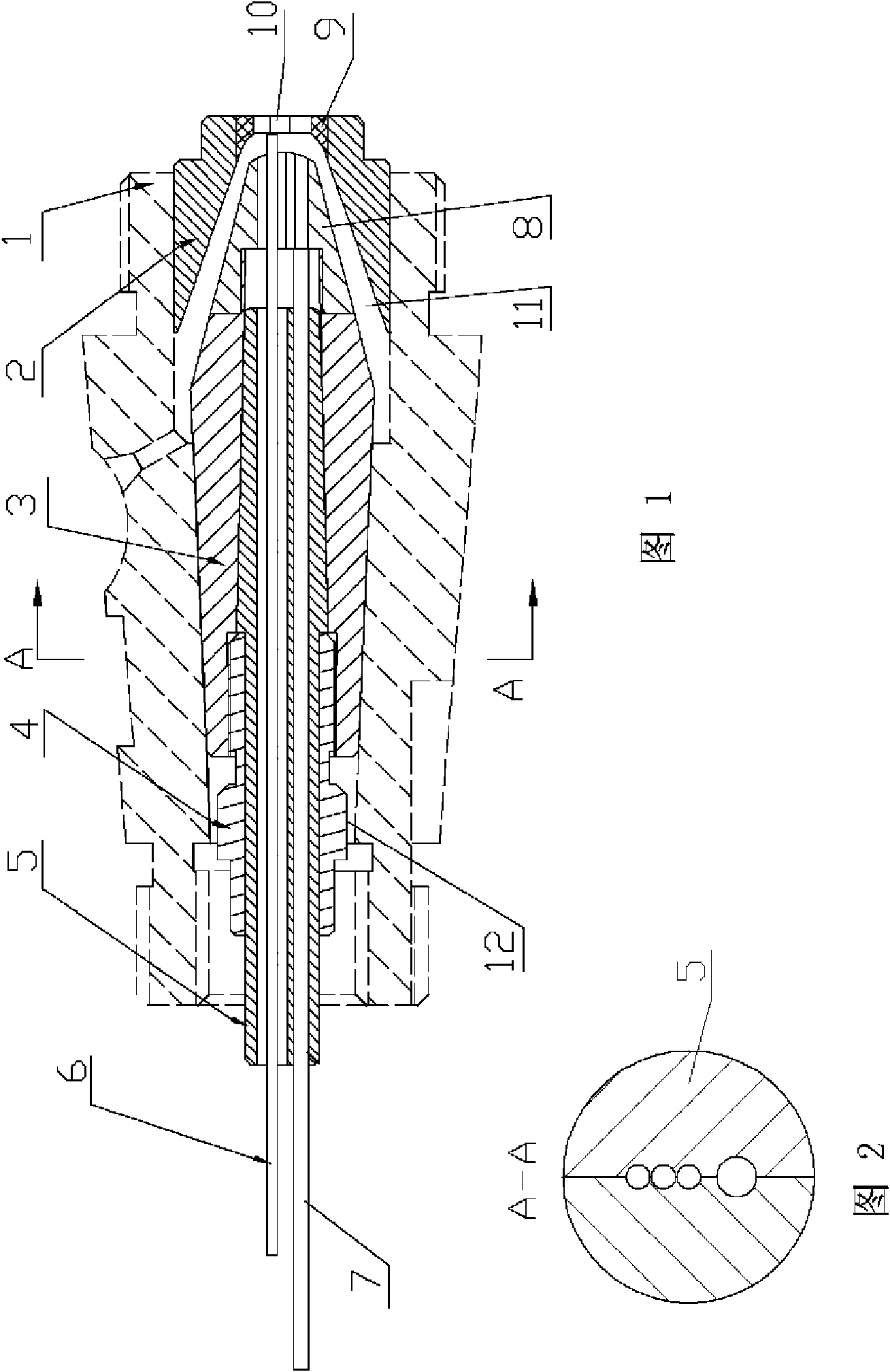

Optical fiber cabling die

ActiveCN101655593AAvoid damage or breakageImprove assembly accuracyFibre mechanical structuresEngineeringOptical fiber cable

The invention relates to an optical fiber cabling die which comprises a die sleeve and a die core. A die core plug-in is inserted in an axial conical hole in the center of the die core and internallyand axially provided with at least one optical fiber channel and at least one reinforcer channel; an optical fiber guiding protective tube is fixedly mounted in each optical fiber channel; the die sleeve is provided with a conical hole; the front end of the die core is in a conical shape and is matched with the conical hole of the die sleeve to form a conical flow passage which is communicated with the reinforcer channels; the front end of die core plug-in is arranged in the die core; each optical fiber guiding protective tube penetrates through both ends of the die core plug-in; and the frontend of each optical fiber guiding protective tube extends forwards to a position between an inner port and an outer port of an extrusion hole of the die sleeve. The optical fiber cabling die processes a bare optical fiber into an optical fiber and enables melted plastics to not only tightly wrap the reinforcer, but also avoid damaging the bare optical fiber in a cabling process, thereby ensuringthe quality of the processed optical fiber.

Owner:河南仕佳通信科技有限公司

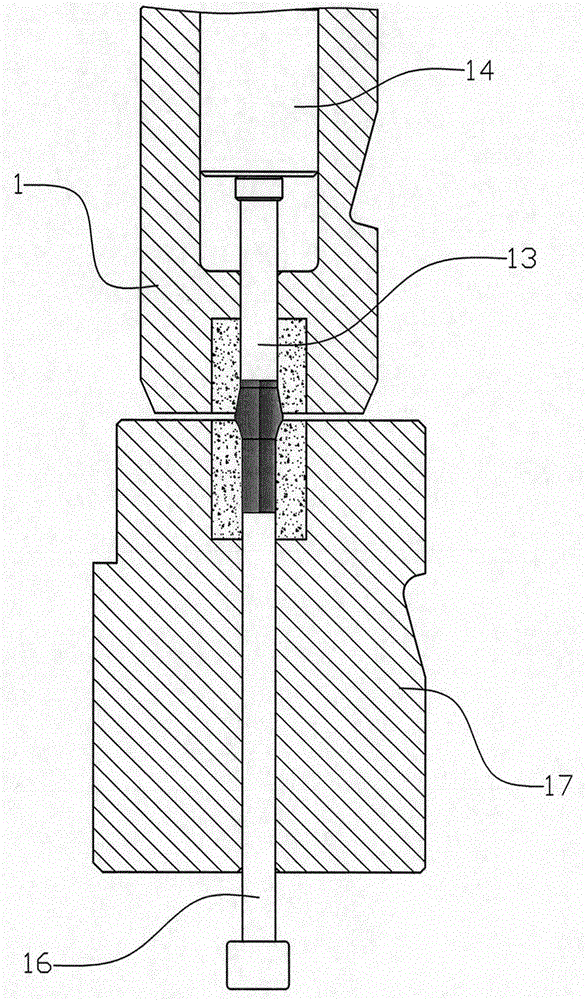

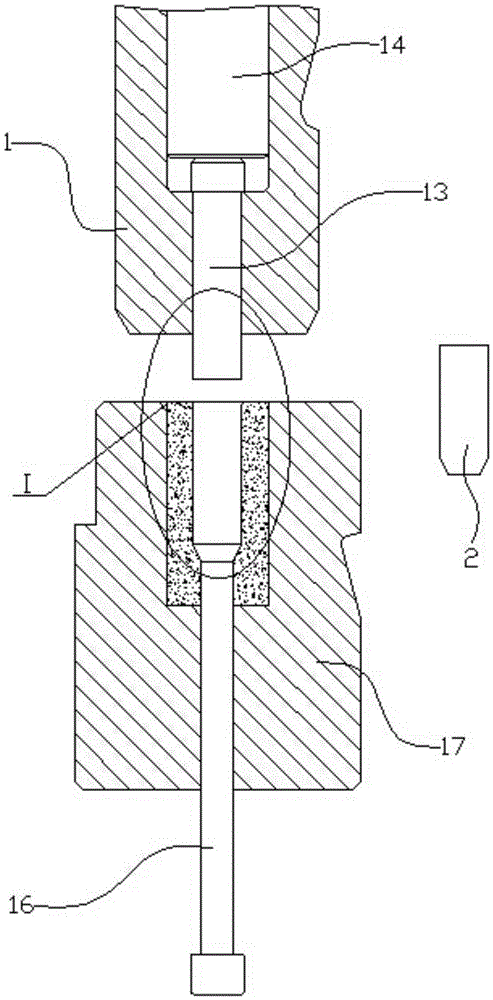

Part cold heading machining method

ActiveCN104525811AIncrease profitEfficient removalForging/hammering/pressing machinesEngineeringMachining process

A part cold heading machining method includes the steps that firstly, a part blank is extruded by a first stamping die (1) to obtain sizes required by head taper and rod necking; secondly, a part (2) obtained in the first step is extruded by a second stamping die (3) to obtain the contour and size of the head of the part; thirdly, the part (2) obtained in the second step is extruded by a third stamping die (4), and a trimming die of a bottom die conducts reverse cutting on the part (2) obtained in the second step to obtain the needed shape and the needed size of the contour of the neck of the part; fourthly, upper and lower double cutting is carried out on the periphery of the head of the part (2) machined in the third step through a fourth stamping die to obtain the shape and size of the contour of the head of the burr-free part, and the whole part cold heading machining process is completed. The part cold heading machining method has the advantages that the utilization rate of materials is high, the materials are saved, cost is saved, the procedures are simple, the dies can conduct one-shot machining forming as long as the part is placed at an appointed position, efficiency is high, adjustability is high, the reject rate is lowered, burrs can be effectively removed, and the application effect is good.

Owner:ZHOUSHAN 7412 FACTORY

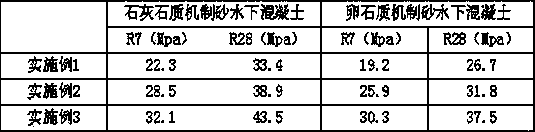

Underwater concrete containing limestone machine-made sand and preparation method thereof

ActiveCN103936363ASolve the shortage of resourcesAddressing quality degradationSolid waste managementArchitectural engineeringCrushed stone

The invention relates to an underwater concrete containing limestone machine-made sand and a preparation method thereof, and belongs to the field of construction materials. The concrete comprises the following raw materials in parts by weight: 5 to 20 parts of cement, 1 to 7 parts of mineral powder, 0 to 5 parts of coat ash, 35 to 45 parts of broken stone, 30 to 40 parts of machine-made sand, 5 to 8 parts of water, and 0.1 to 0.8 part of water reducer; wherein the machine-made sand is limestone machine-made sand. The concrete has the advantages of good cohesiveness, fluidity, and water retaining performance, high strength, good durability, simple production technology, low cost, and good economic and social profits.

Owner:GUANGXI YUFENG GRP

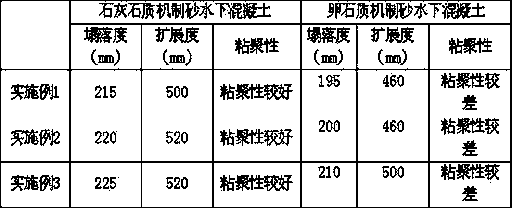

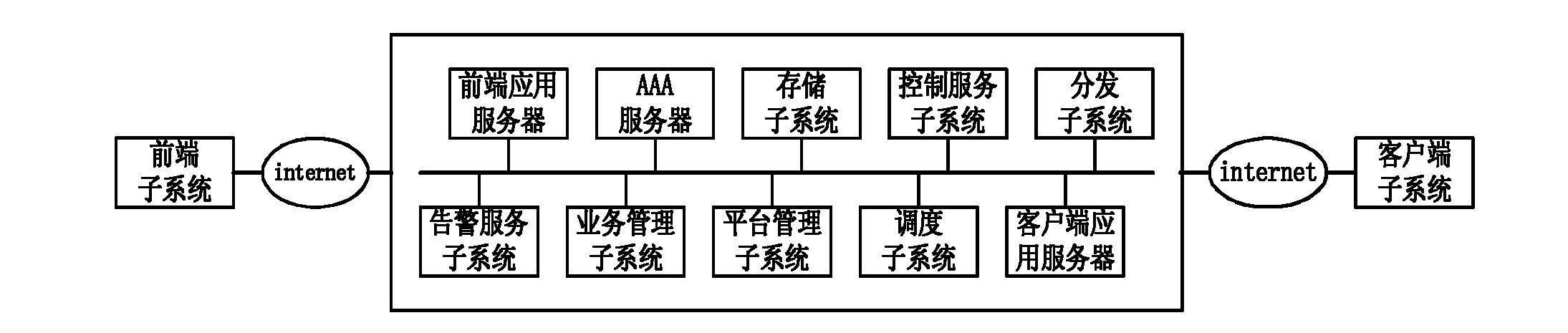

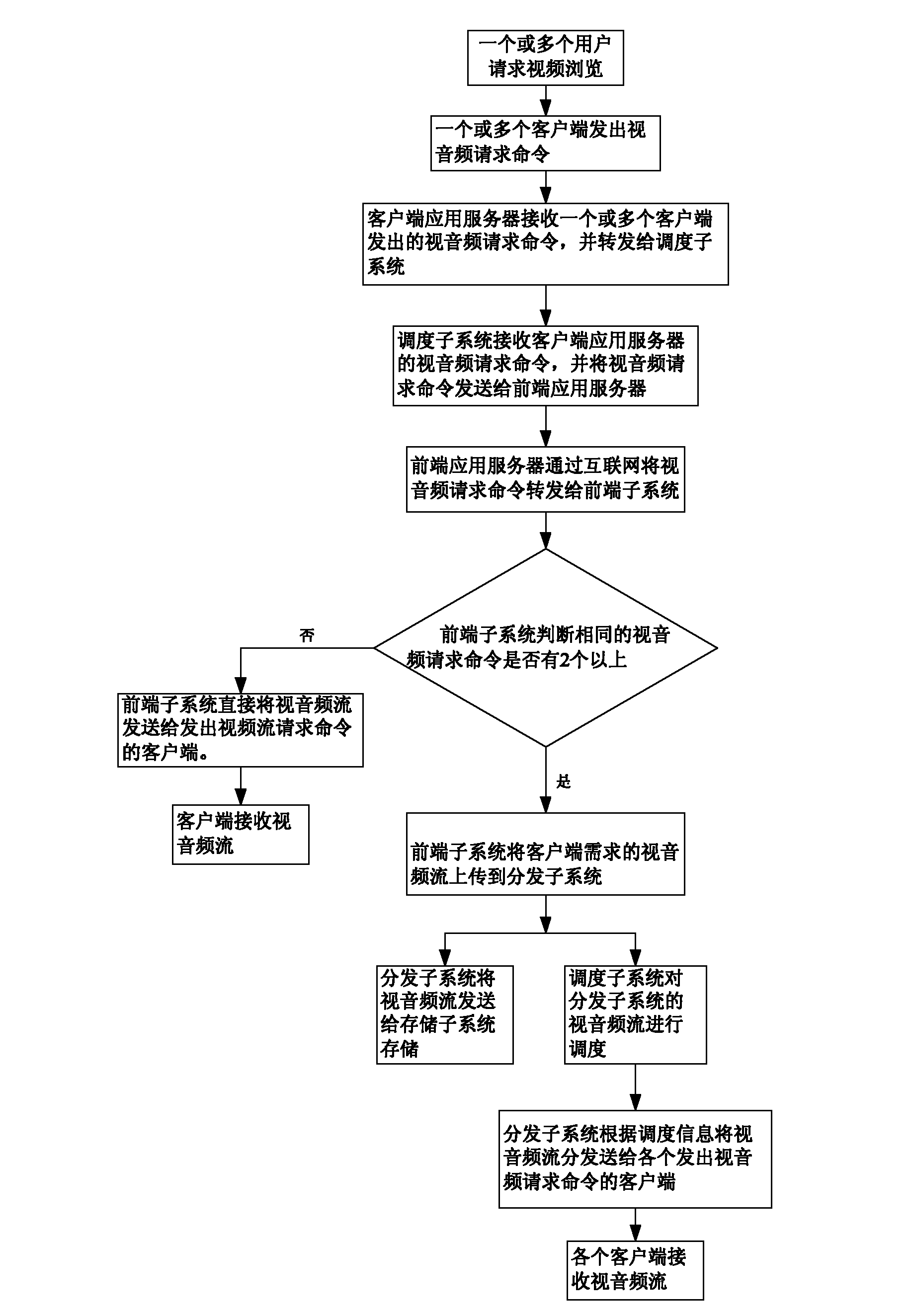

Internet-based video-audio transmission system and video-audio stream distribution method thereof

InactiveCN102665116ADoes not cause a bottleneckImprove usabilityTransmissionSelective content distributionApplication serverDistribution method

The invention discloses an Internet-based video-audio transmission system and a video-audio stream distribution method thereof. The system comprises a front-end subsystem, a client subsystem, and a central service platform; besides, the central service platform includes a client application server, a service management subsystem, an alarm service subsystem, an authentication, authorization, accounting (AAA) server, a platform management subsystem, a scheduling subsystem, a storage subsystem, a distribution subsystem, a control service subsystem, and a front-end application server. In addition, the invention also discloses a video-audio stream distribution method of the Internet-based video-audio transmission system. The scheduling subsystem carries out reasonable scheduling on videos and audios of the distribution subsystem according to a current using situation of the system; and the distribution subsystem sends video and audio streams to a client terminal having demand; according to scheduling information of the scheduling subsystem. According to the invention, the system and the method thereof have the following advantages: simultaneous access to and use of a same video-audio stream by multiple users is supported; it is convenient to manage the system; and the application range is wide, and so on.

Owner:GUANGDONG BAIYUN UNIV

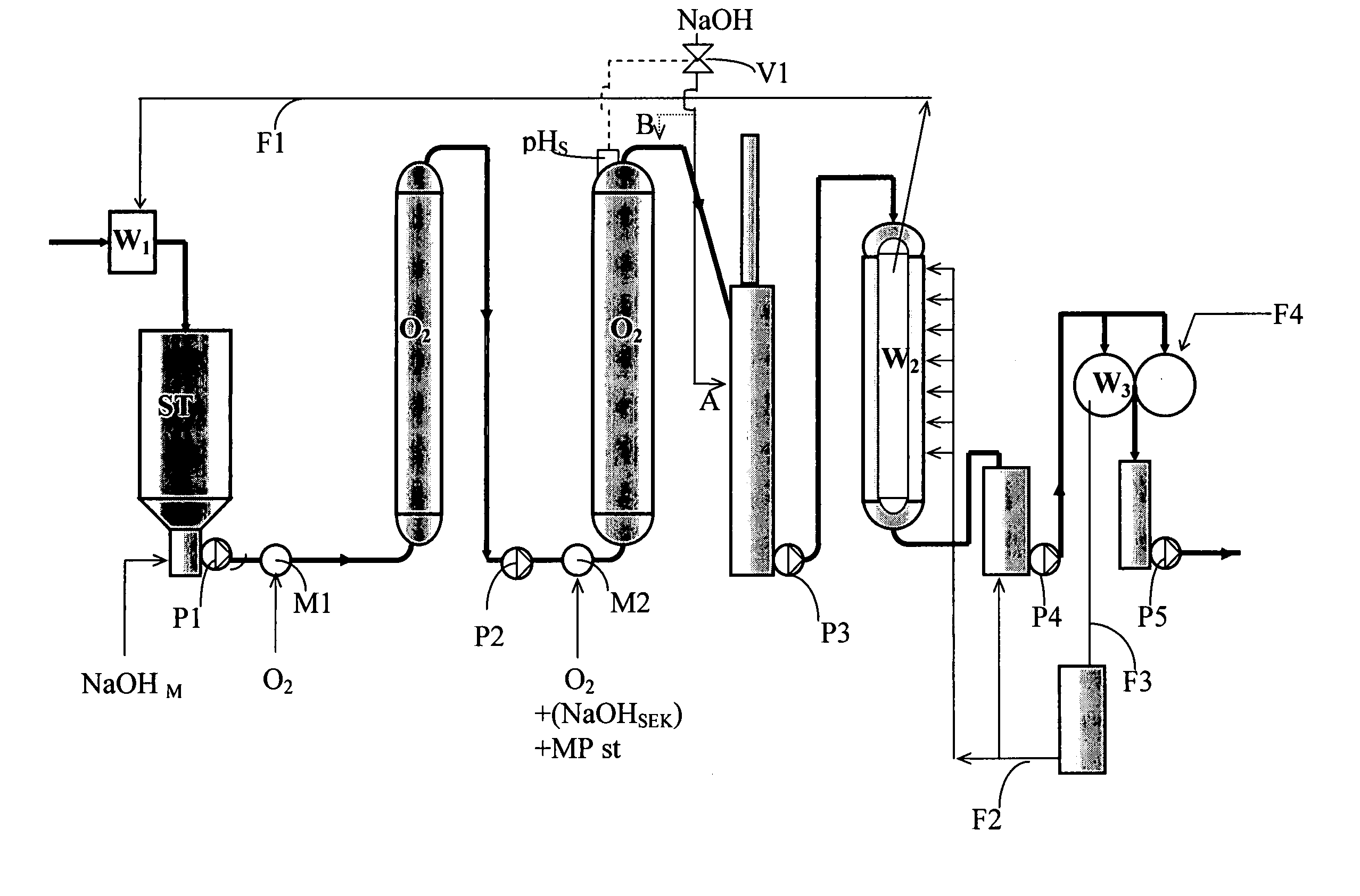

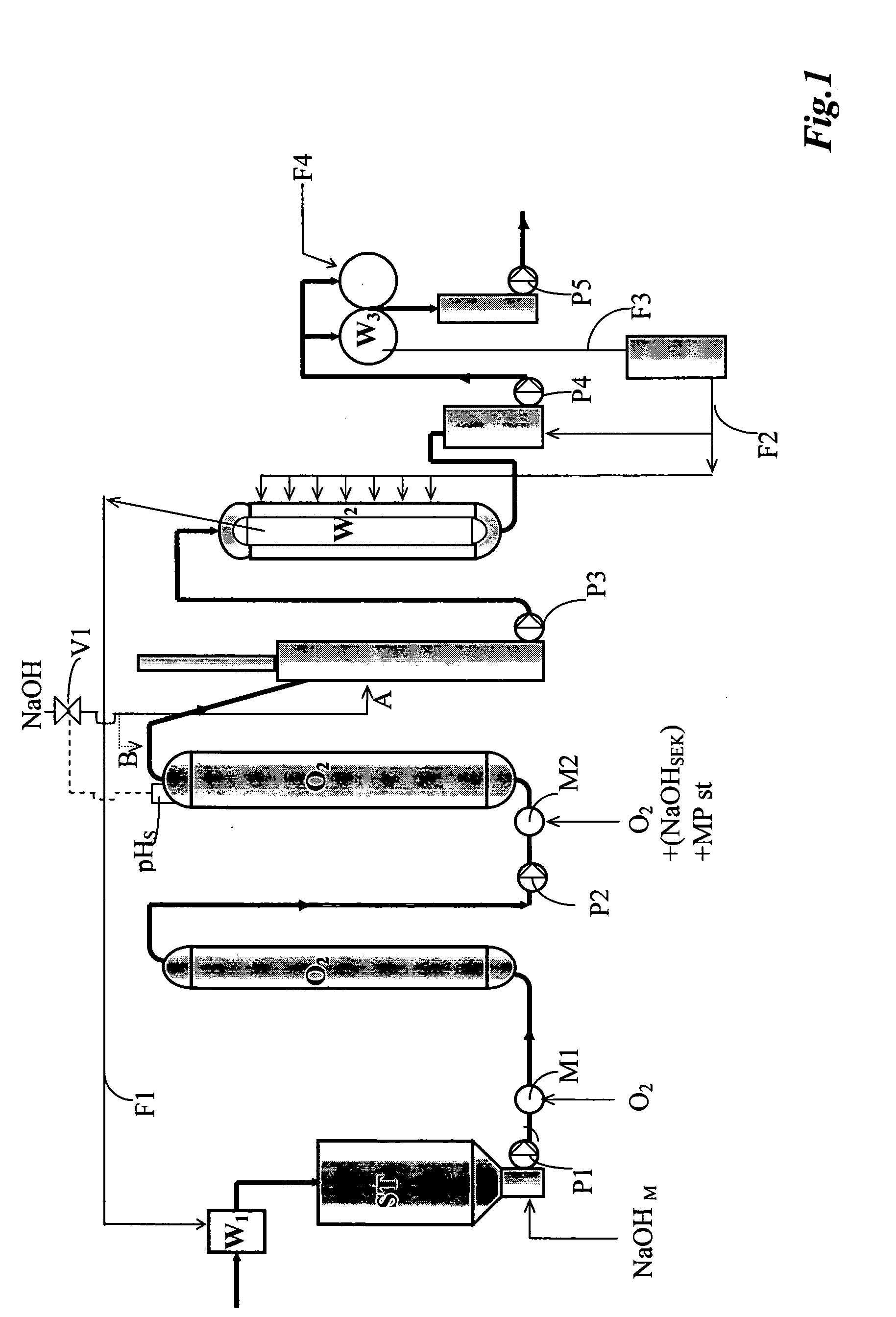

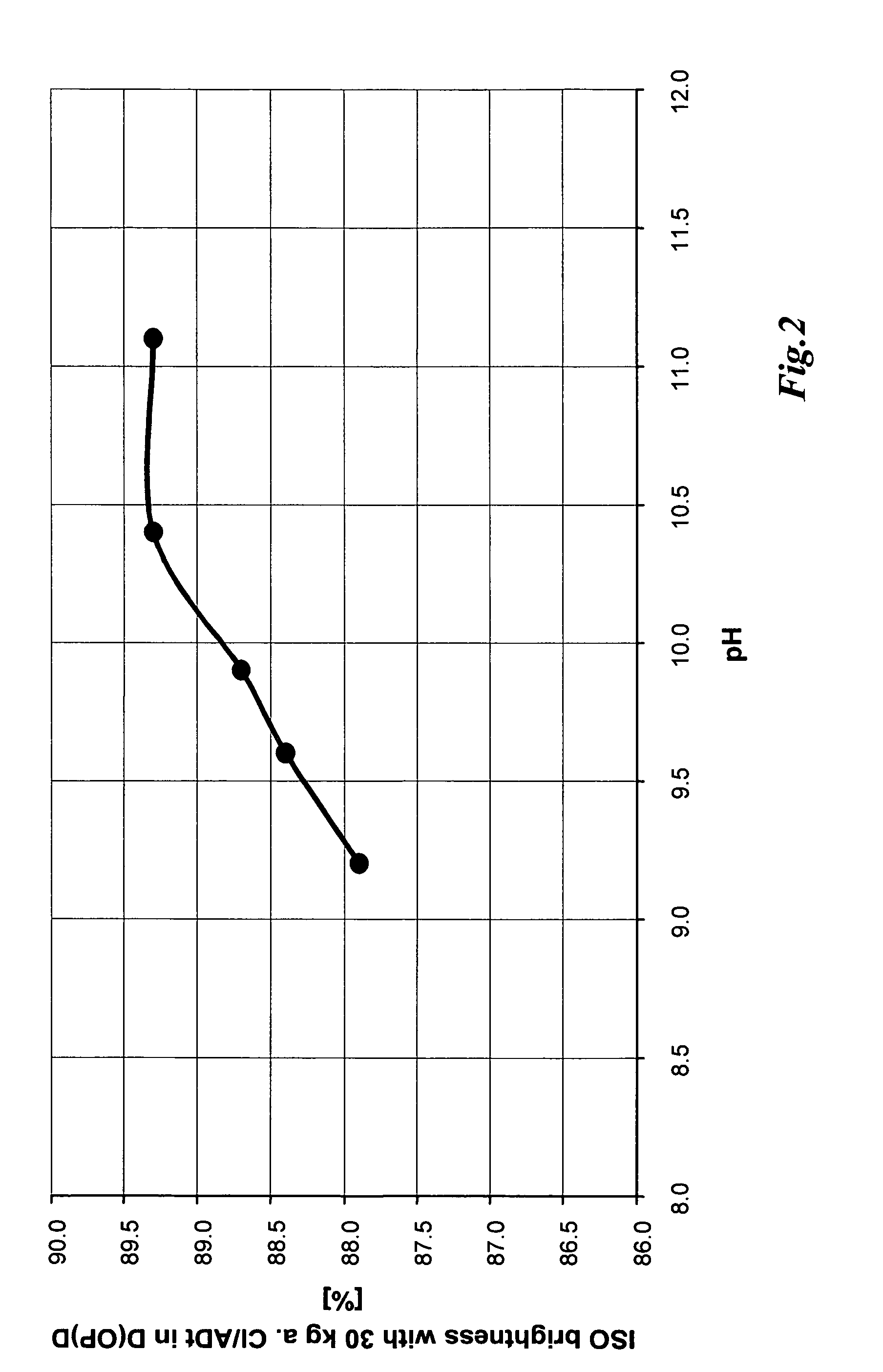

Method and arrangement for oxygen delignification of cellulose pulp

InactiveUS7156952B2High strengthLow and even alkali profileWashing/displacing pulp-treating liquorsDigestersOxygenCellulose pulp

The invention relates to a method and arrangement for alkaline oxygen delignification of cellulose pulp. By adding alkali in the final phase of the oxygen delignification one can ensure that an optimal predetermined end-pH is obtained. This provides advantages in the subsequent bleaching since the bleachability is substantially improved in the form of reduced need for bleaching chemicals.

Owner:GL&V MANAGEMENT HUNGARY KFT LUXEMBOURG BRANCH

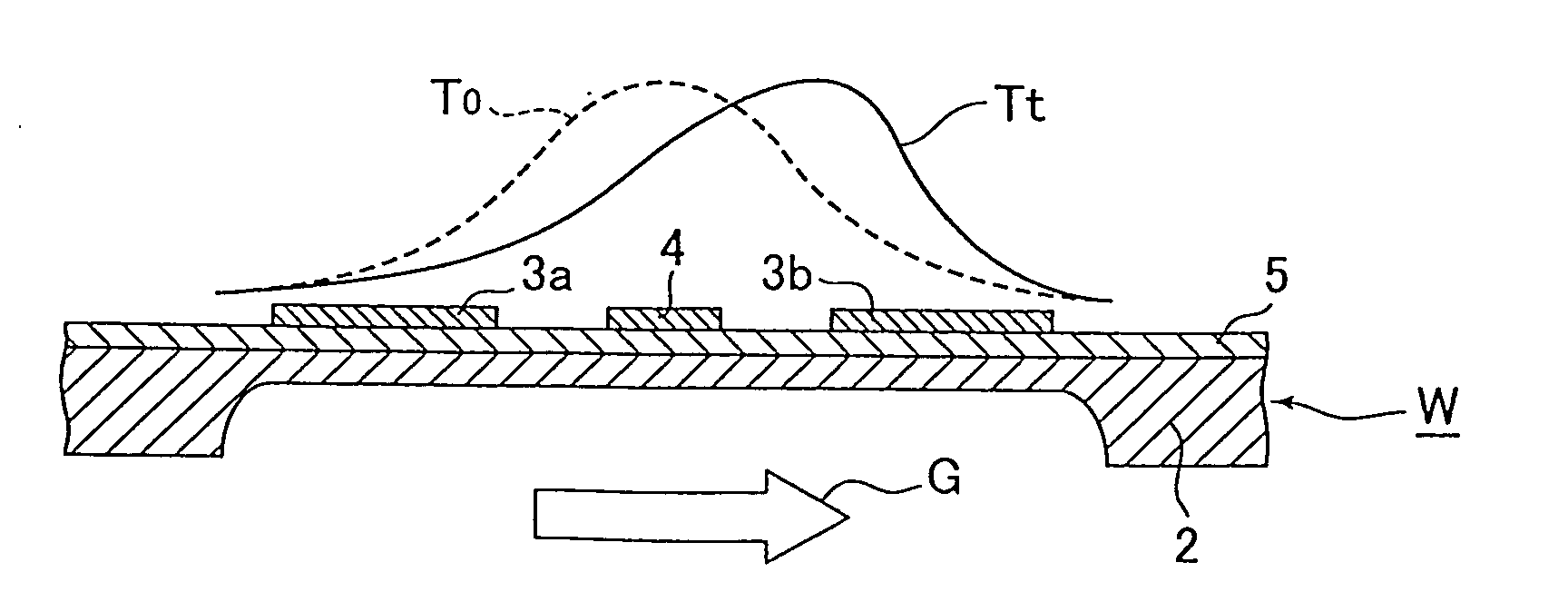

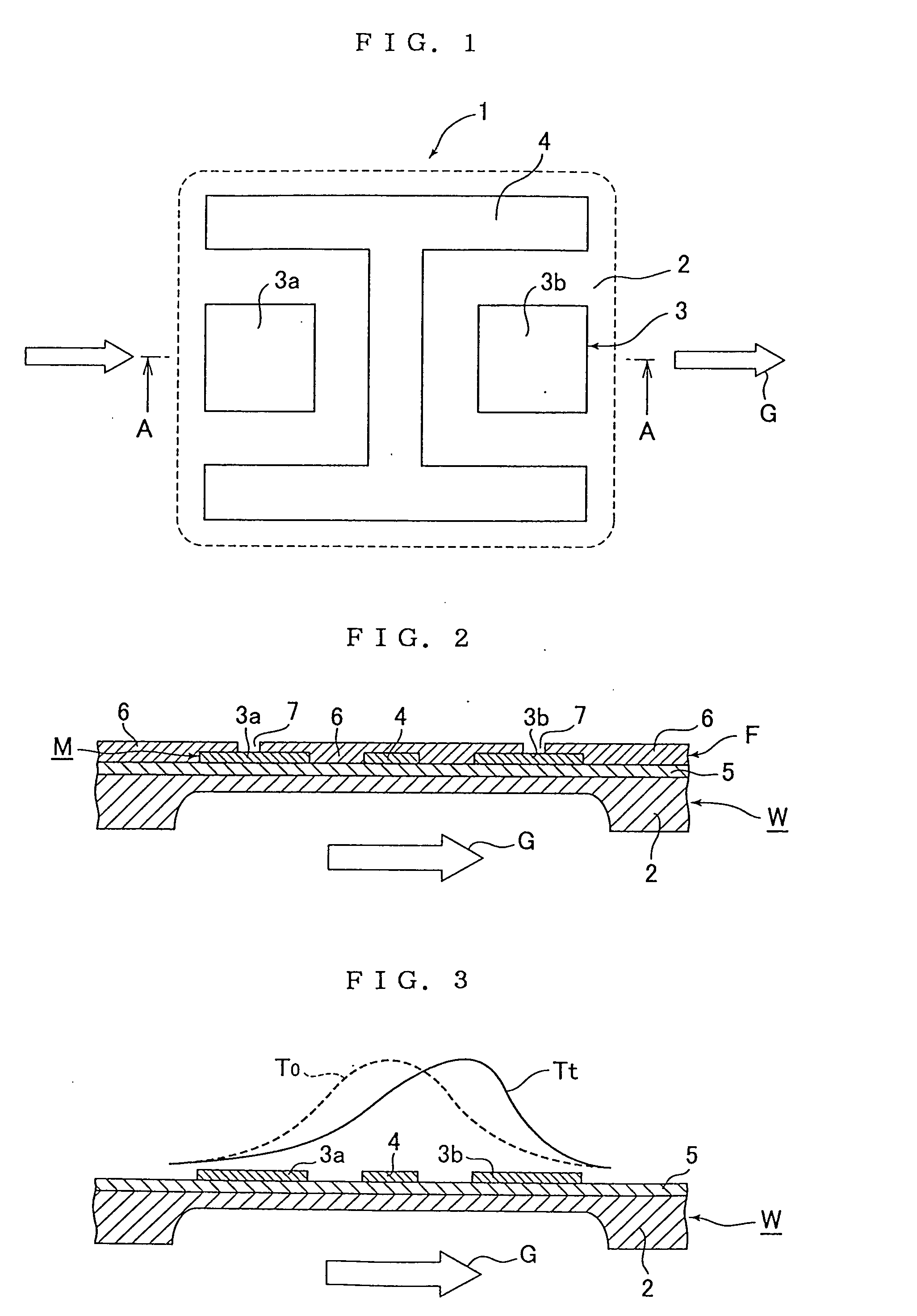

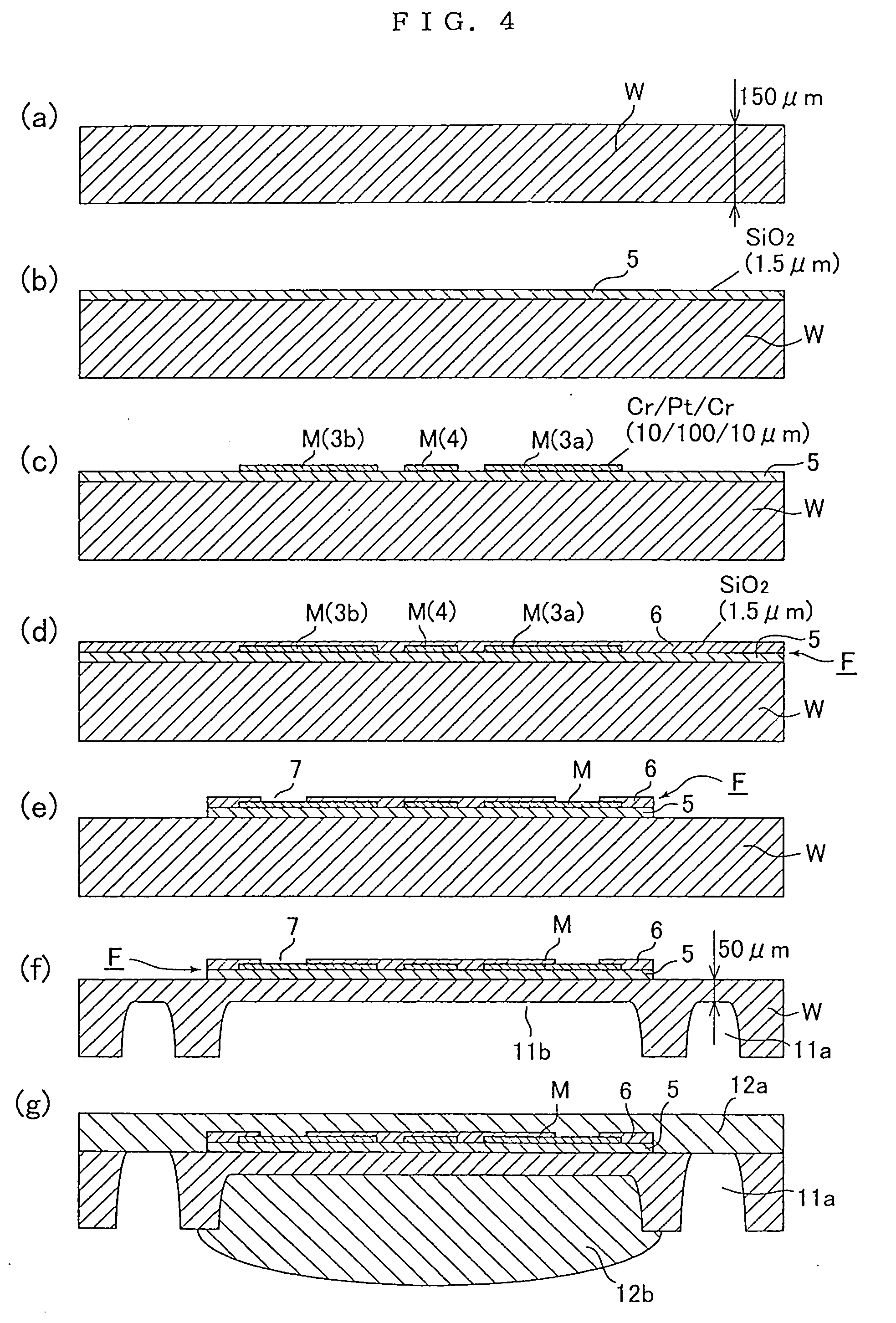

Thermal type mass flow rate sensor made of corrosion resistant metal, and fluid supply equipment using the same

ActiveUS20060053878A1Improve corrosion resistanceQuick responseVolume/mass flow by thermal effectsEtchingStream flow

A corrosion resistant thermal type mass flow rate sensor, and a fluid supply device employing the sensor, are provided thus allowing enhanced corrosion resistance of the thermal type mass flow rate sensor, improve responsiveness, to be achieved particle-free, and to prevent unevenness of product qualities. A thermal type mass flow rate sensor is constituted with a sensor part 1 comprising a corrosion resistant metal substrate 2 formed as a thin plate by applying electrolytic etching on the rear face side of a corrosion resistant metal material W, thin film F forming a temperature sensor 3 and a heater 4 mounted on the rear face side of the corrosion resistant metal substrate 2, and a sensor base 13 hermetically fitted by welding to the outer periphery of the corrosion resistant metal substrate 2 of the afore-mentioned sensor part 1 fitted into a fixture groove 13a.

Owner:FUJIKIN INC

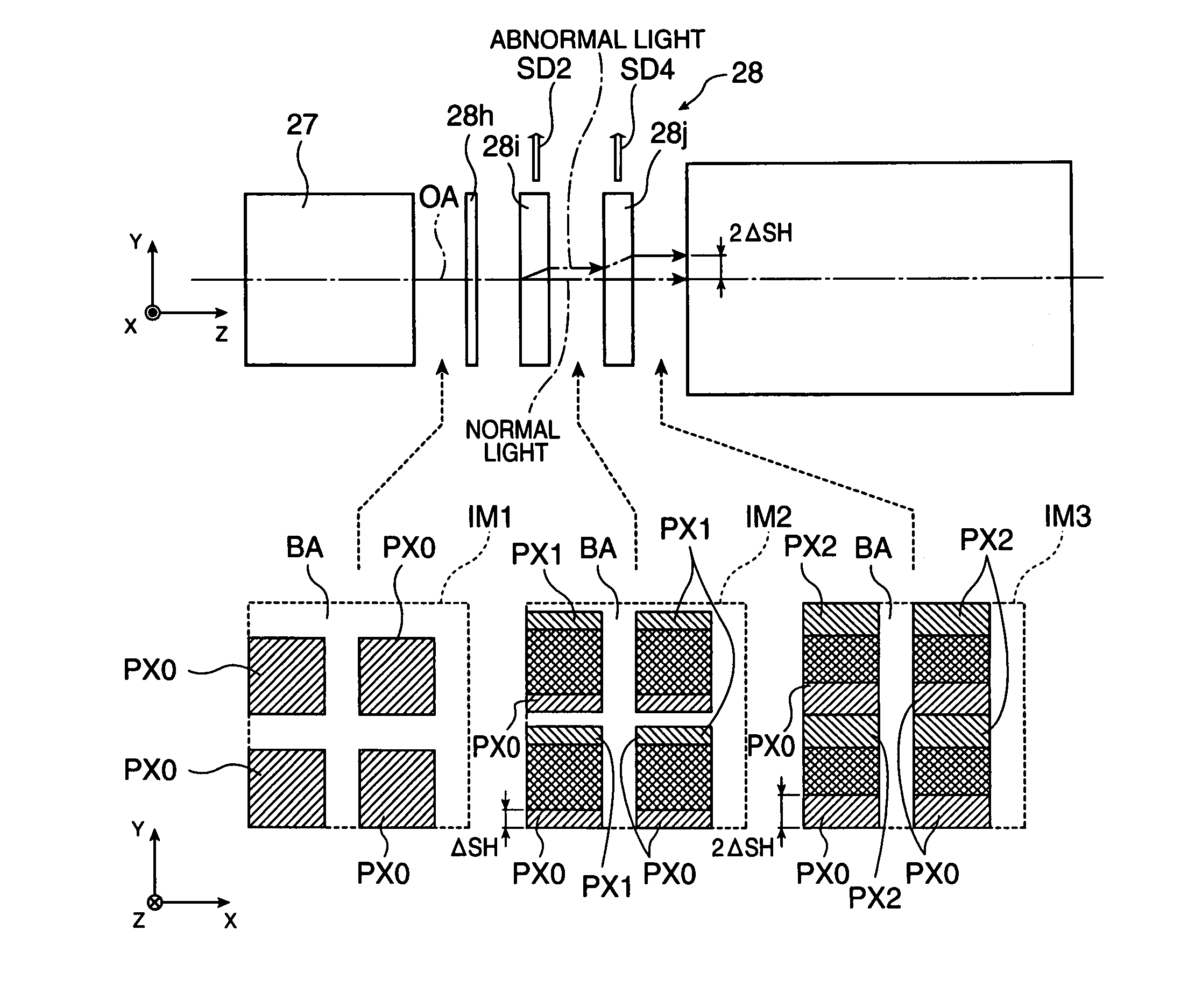

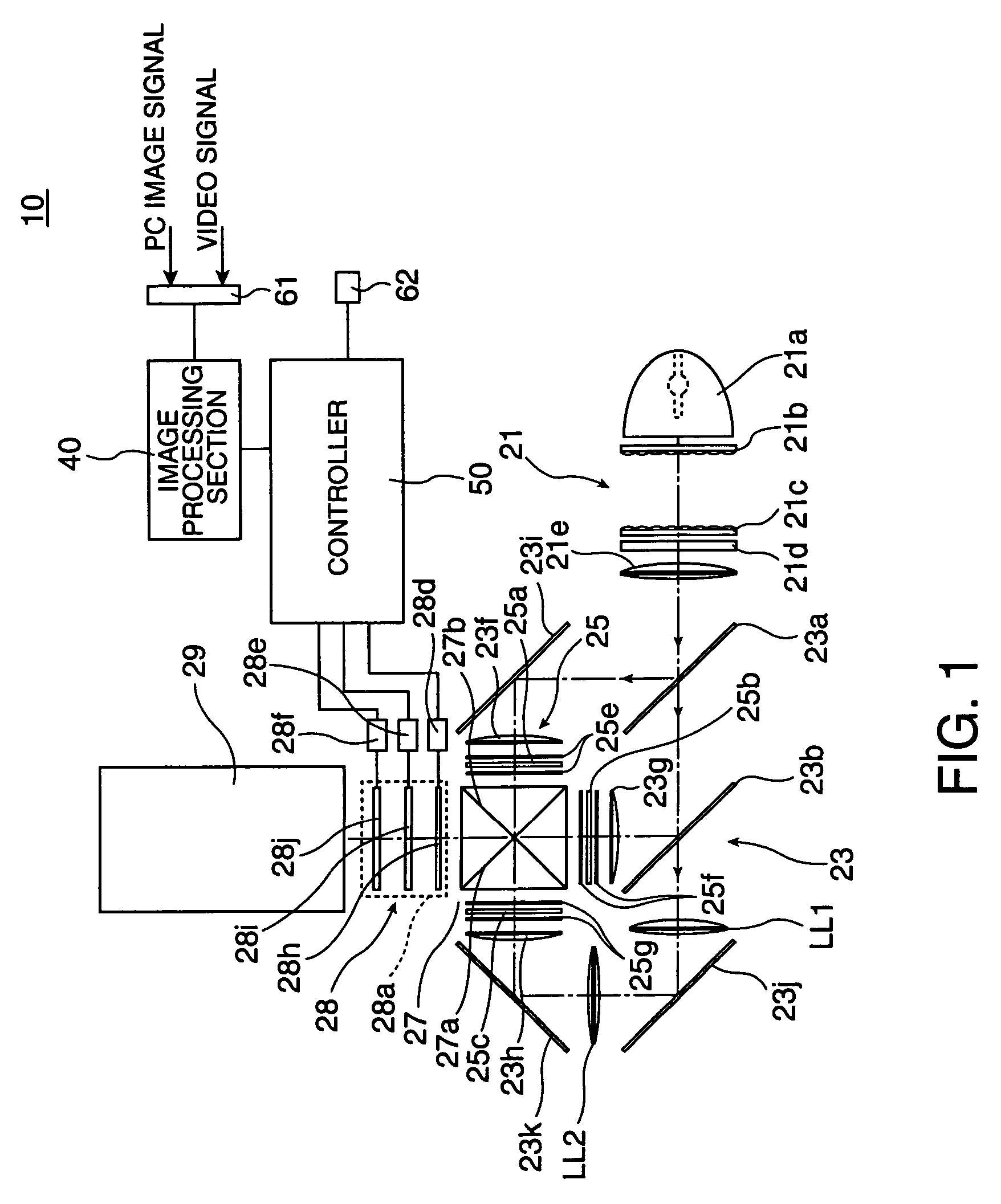

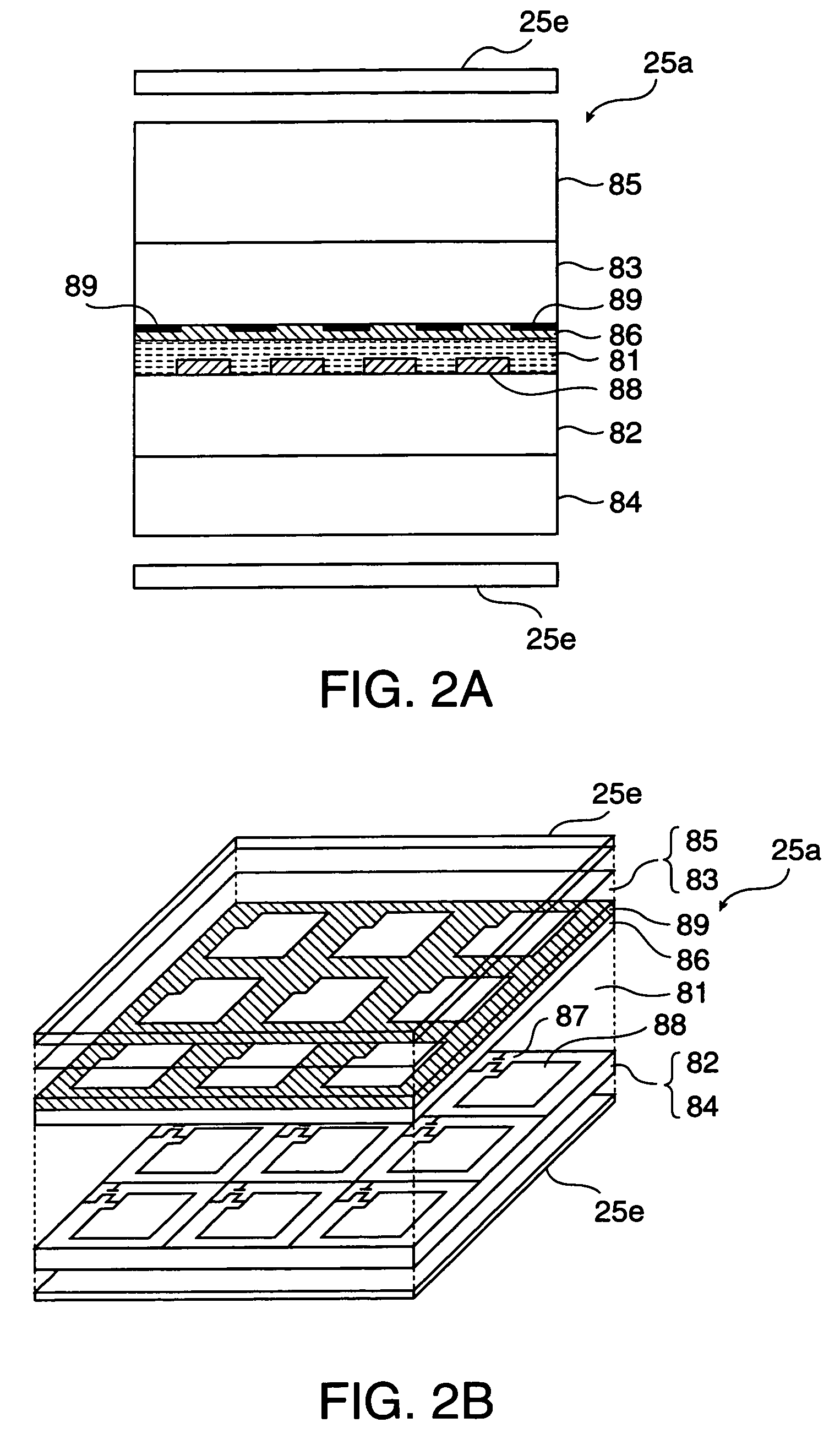

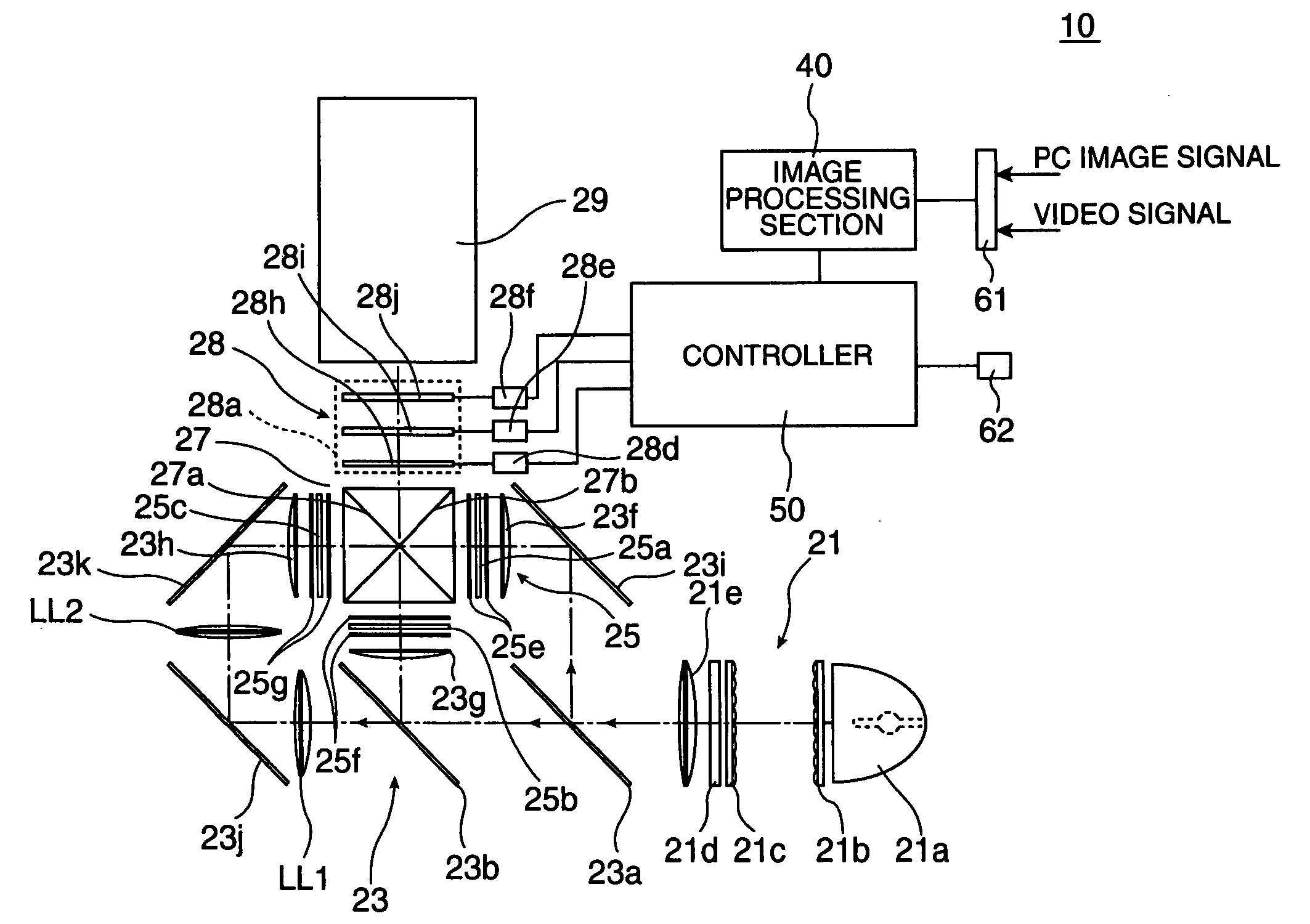

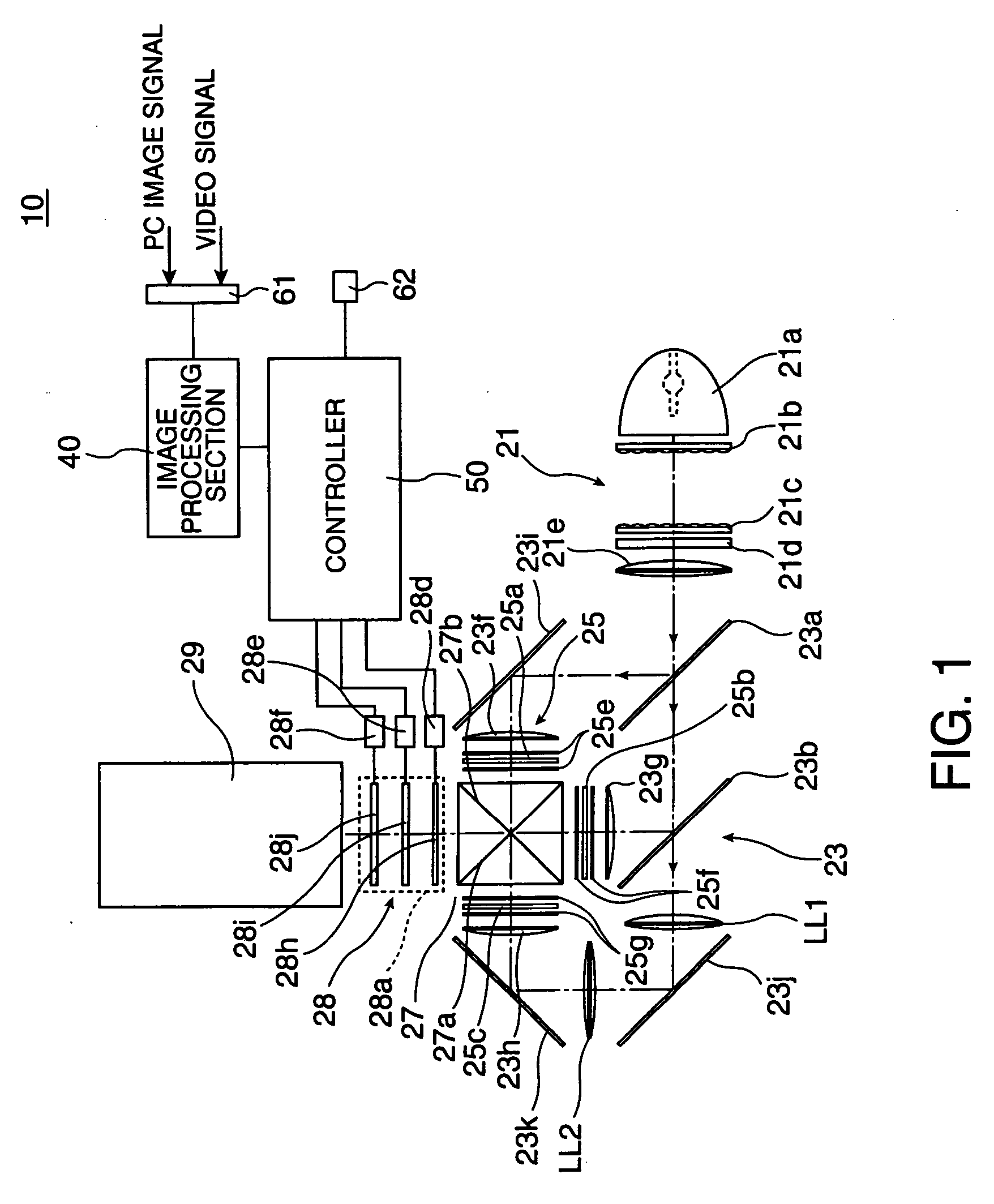

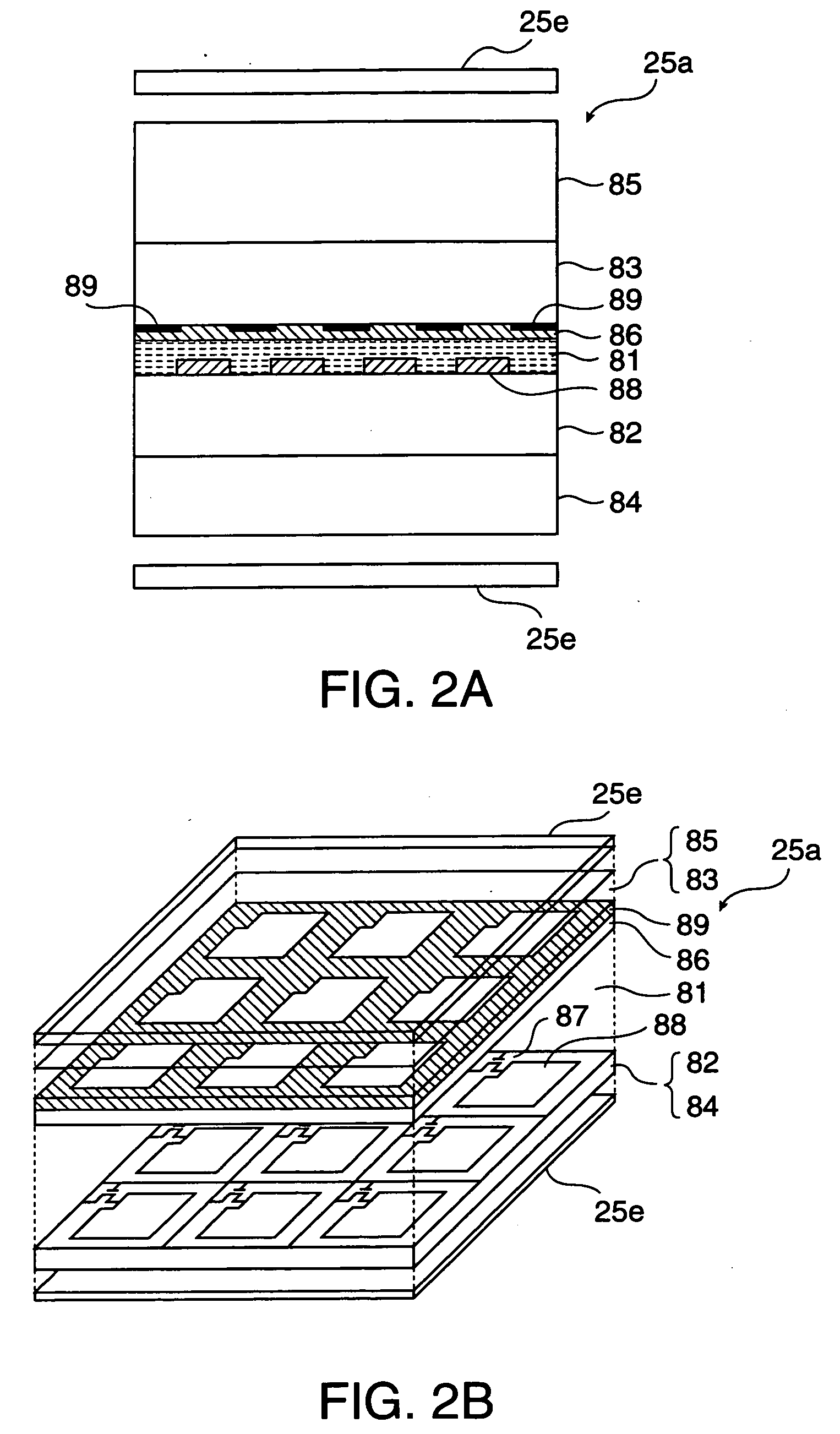

Projector

InactiveUS7021766B2Avoid uneven qualityHigh resolutionStatic indicating devicesProjectorsStable stateImaging quality

An object of the invention is to form a projecting image of smooth image quality inconspicuous in a joint in a stable state. With respect to image light passing through a second birefringent plate 28j set to a first state, an image light portion branched by a first birefringent plate 28i is further branched in the Y-direction. An image IM3 constructed by an original pixel PX0, a pixel PX2 corresponding to its branching image, and a black matrix area BA is formed on a screen. With respect to the image light passing through a second birefringent plate 28j set to a second state, the image light once branched by the first birefringent plate 28i is returned in the −Y direction. As this result, an image constructed by the black matrix area BA and an image provided by overlapping the branching image of the original pixel PX0 with the original pixel PX0 is formed on the screen. Namely, the same image IM3′ as an original image IM1 is formed on the screen.

Owner:SEIKO EPSON CORP

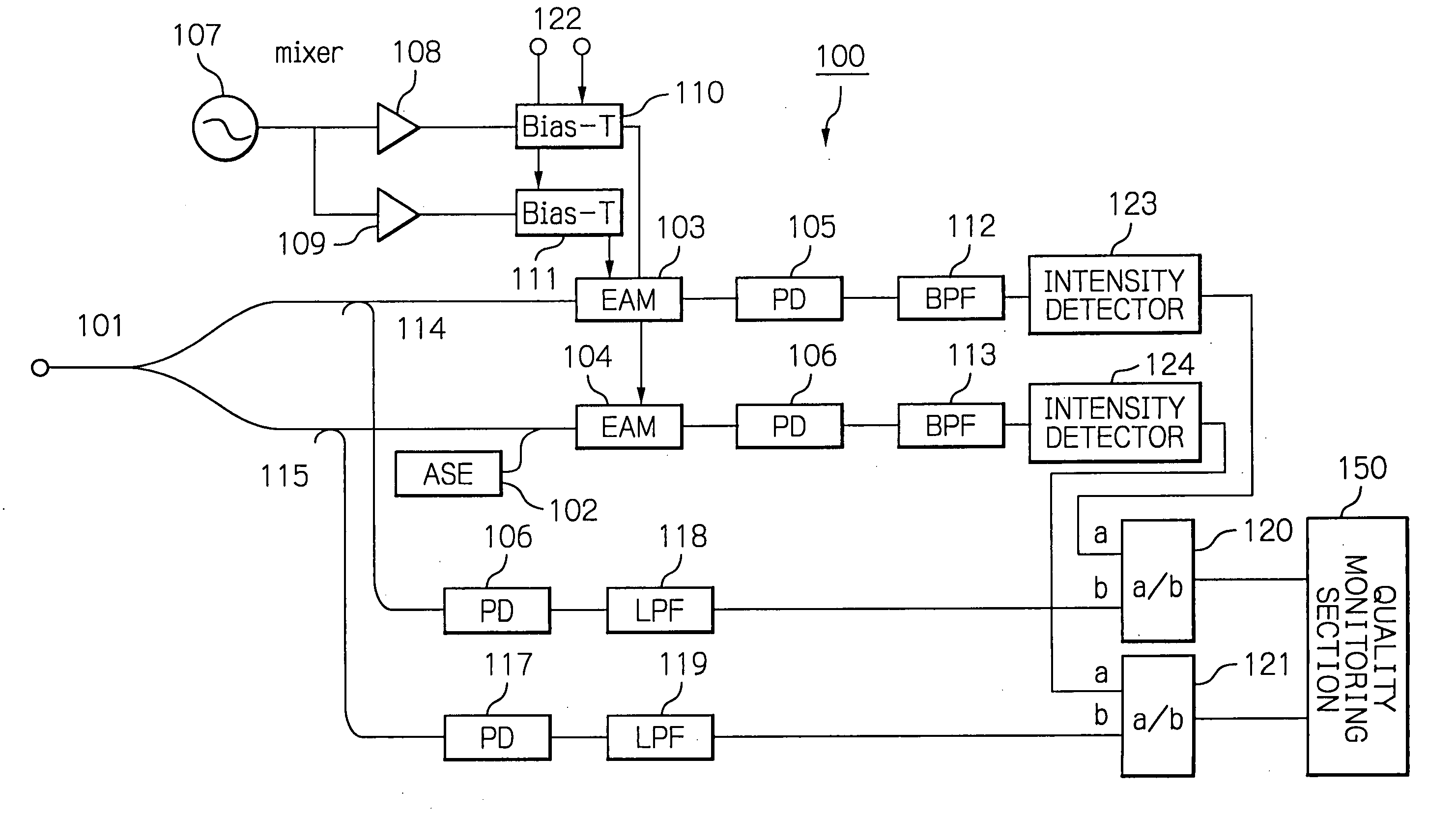

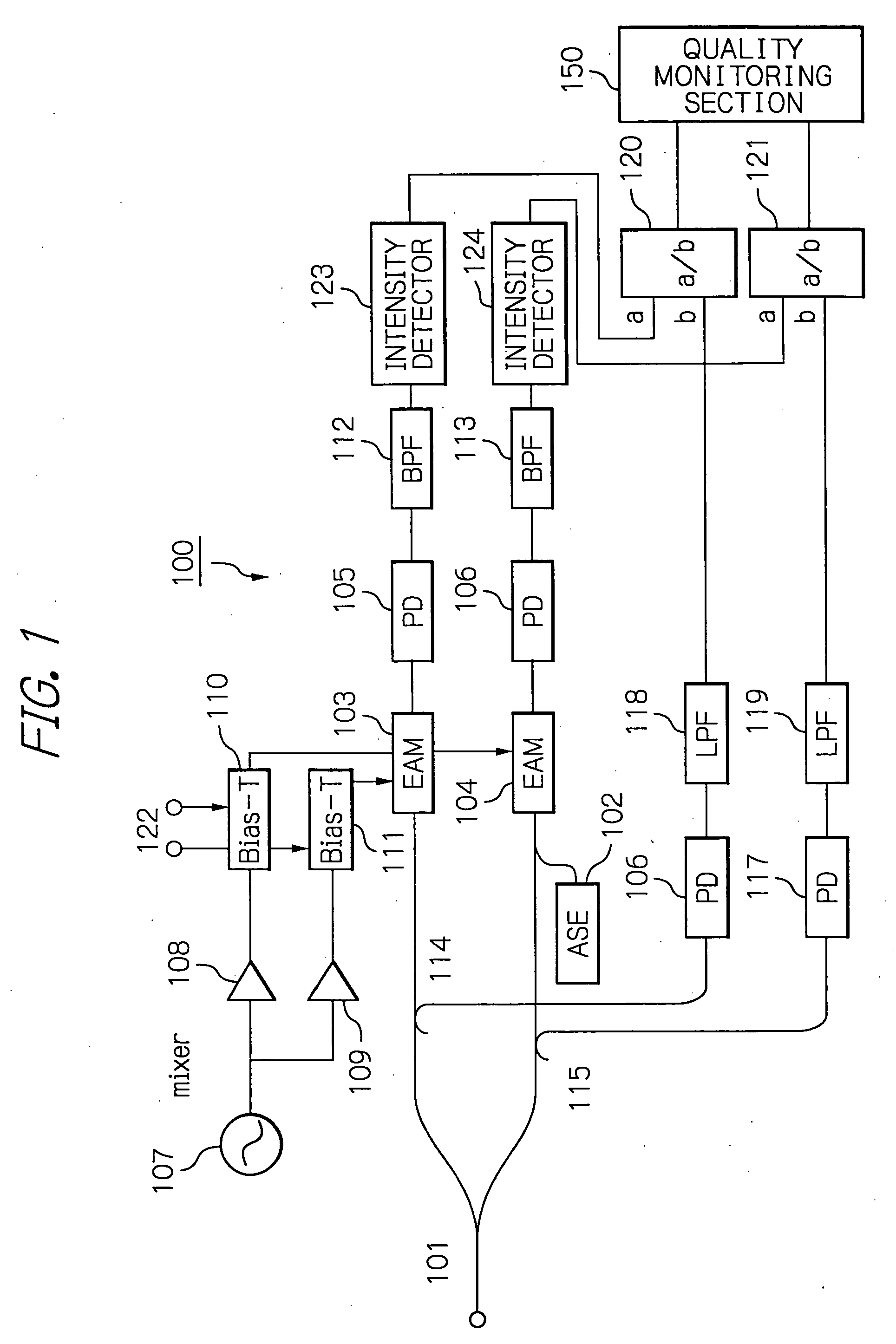

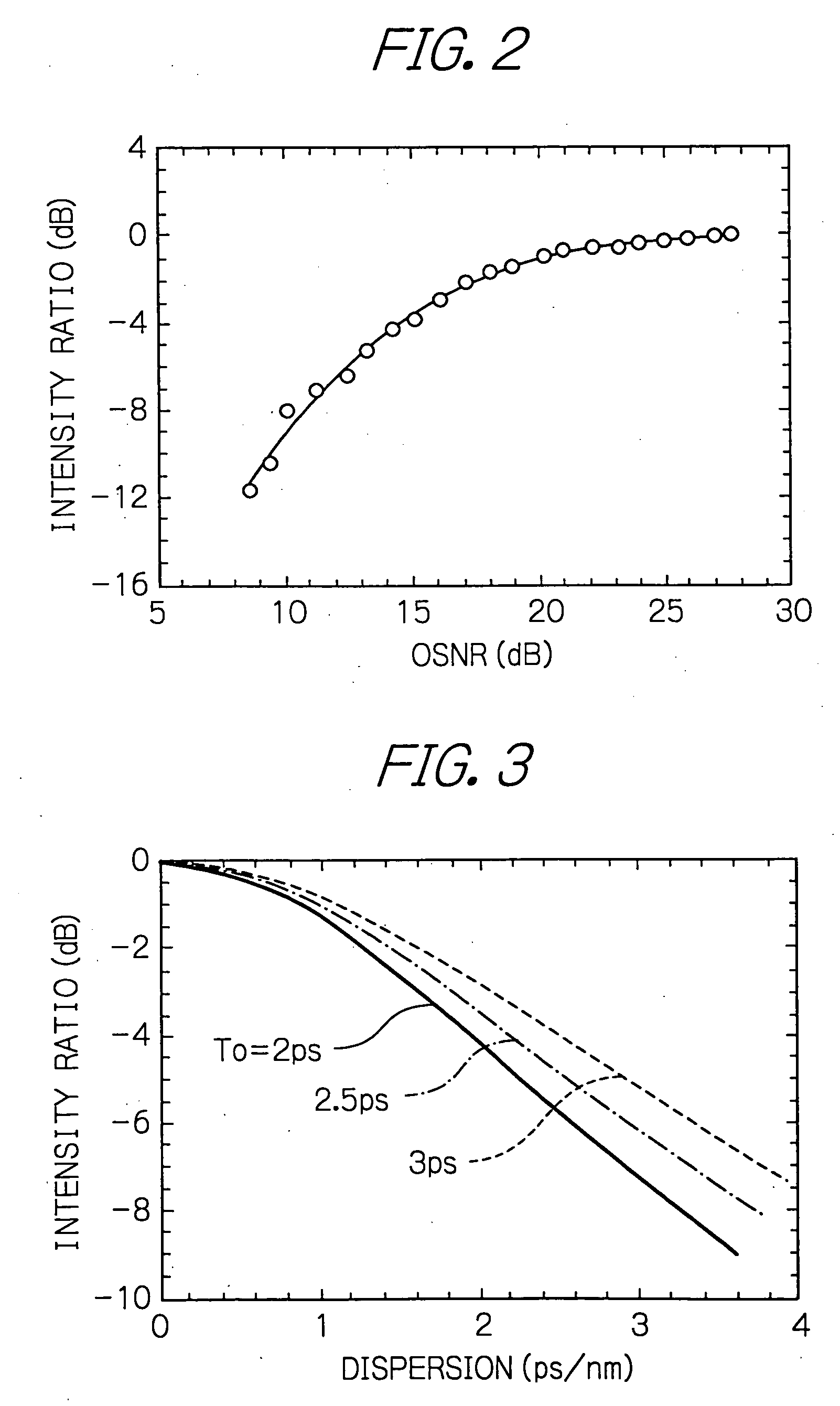

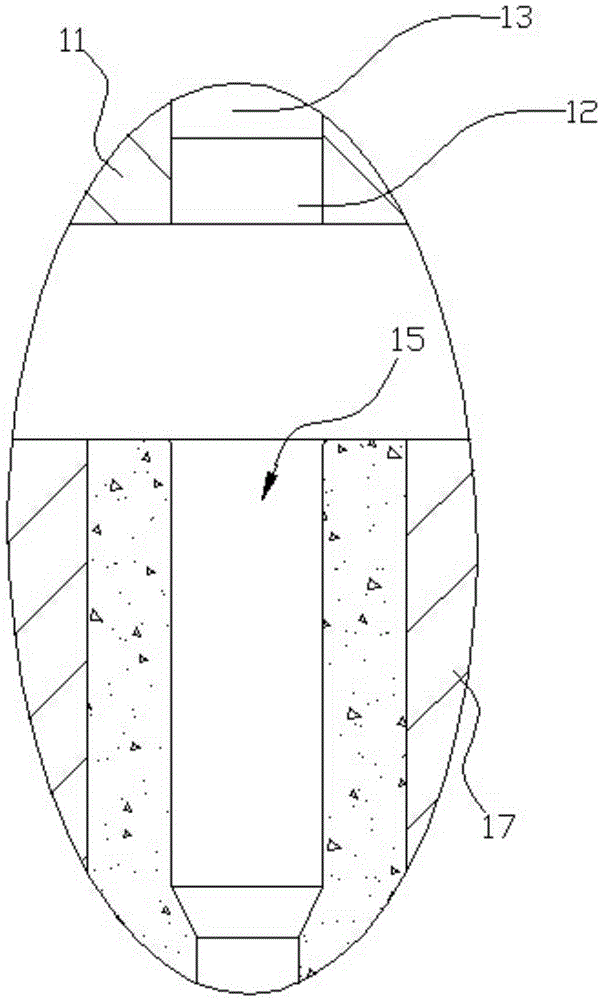

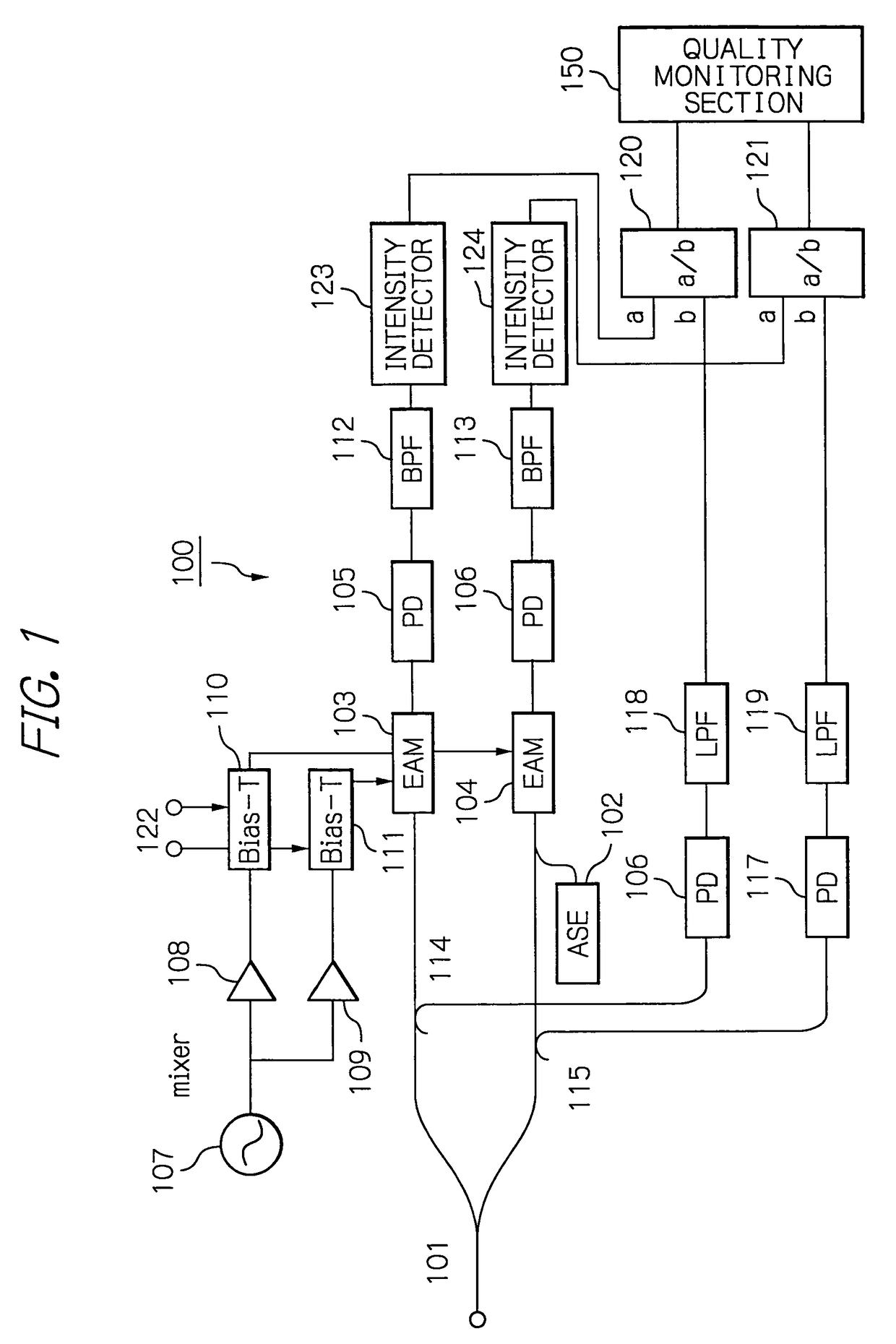

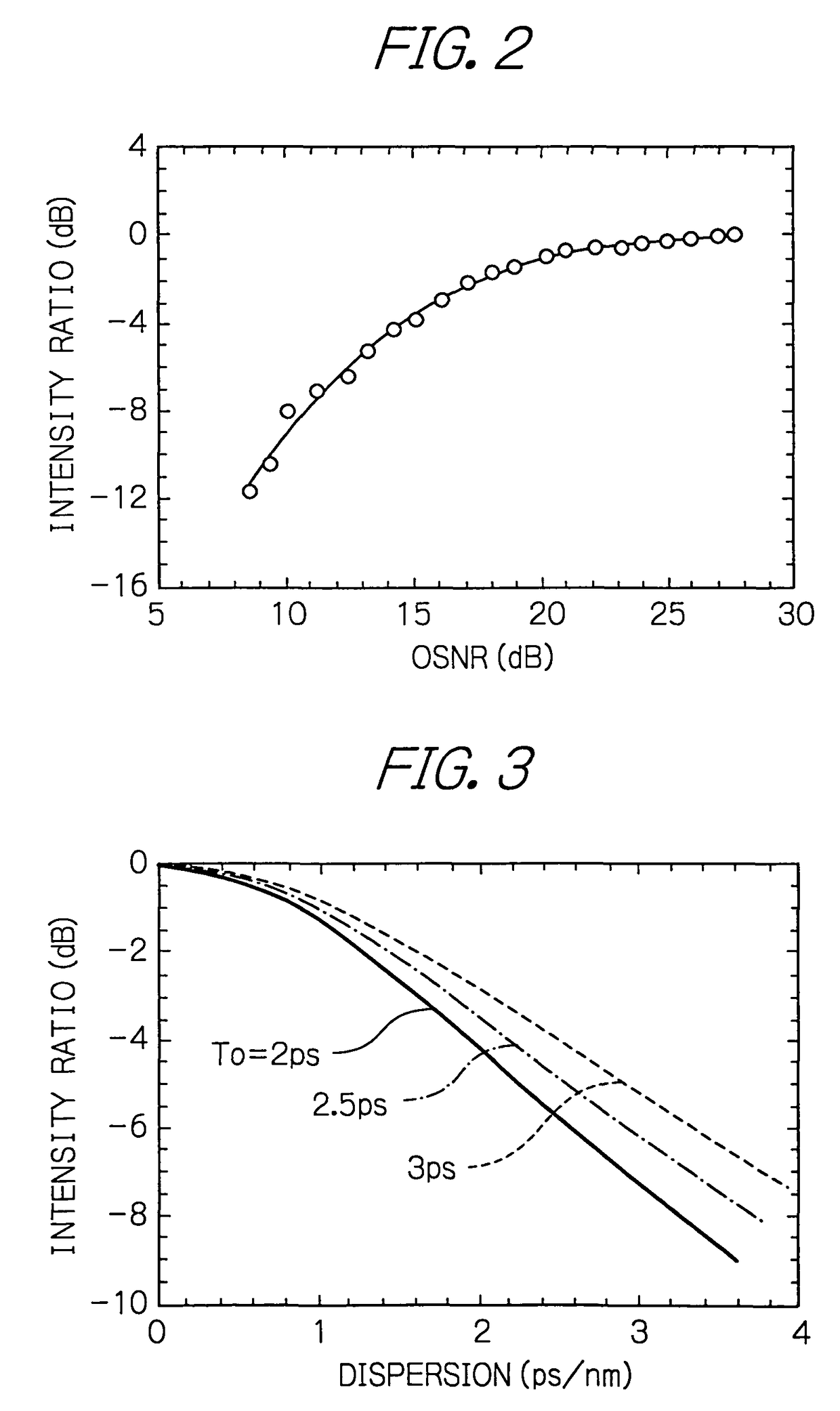

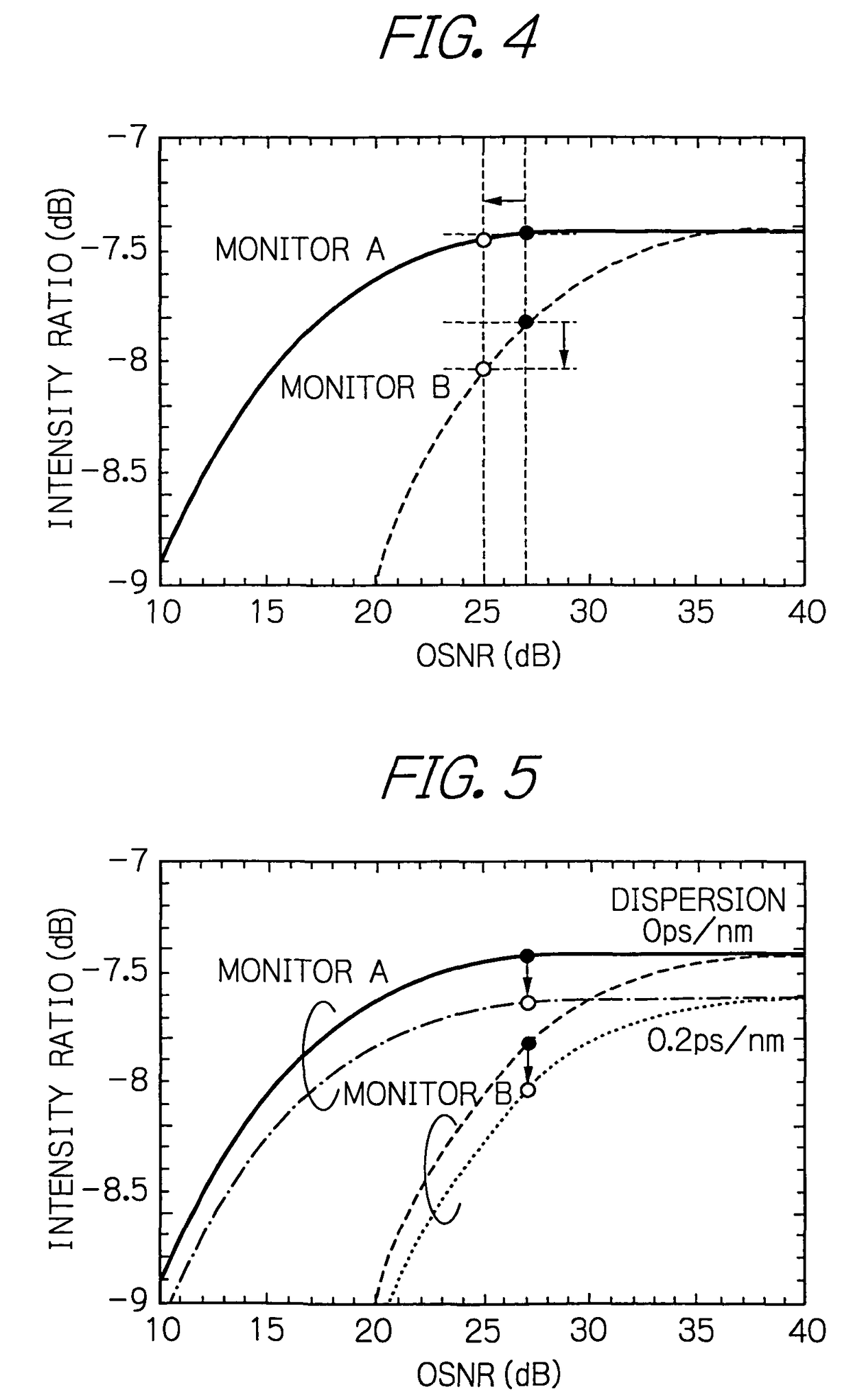

Optical signal quality monitor for a high-bit rate signal

InactiveUS20090016712A1Avoid uneven qualityAppropriately qualitySagnac effect gyrometersSpeed measurement using gyroscopic effectsSignal qualityBand-pass filter

An optical signal quality monitor includes a splitter splitting an input optical signal into two signals; a low-frequency converter converting one split optical signal to a low frequency signal by modulating the optical signal with a frequency offset signal; and an intensity ratio calculator calculating an intensity ratio between the low frequency signal and the other split optical signal, thereby appropriately confirming the quality of a high-bit rate optical signal. The monitor includes plural processing lines, each line including the splitter, the low-frequency converter, and the intensity ratio calculator. At least one line includes an optical noise superimposer superimposing optical noise on the one split signal before inputted to the converter or an optical band-pass filter transmitting the one split signal before inputted to the converter. The monitor includes a polarization state changer changing the polarization state of the input signal before inputted to the splitter.

Owner:OKI ELECTRIC IND CO LTD

Projector

InactiveUS20050057726A1Stable stateAvoid uneven qualityStatic indicating devicesProjectorsStable stateImaging quality

An object of the invention is to form a projecting image of smooth image quality inconspicuous in a joint in a stable state. With respect to image light passing through a second birefringent plate 28j set to a first state, an image light portion branched by a first birefringent plate 28i is further branched in the Y-direction. An image IM3 constructed by an original pixel PX0, a pixel PX2 corresponding to its branching image, and a black matrix area BA is formed on a screen. With respect to the image light passing through a second birefringent plate 28j set to a second state, the image light once branched by the first birefringent plate 28i is returned in the −Y direction. As this result, an image constructed by the black matrix area BA and an image provided by overlapping the branching image of the original pixel PX0 with the original pixel PX0 is formed on the screen. Namely, the same image IM3′ as an original image IM1 is formed on the screen.

Owner:SEIKO EPSON CORP

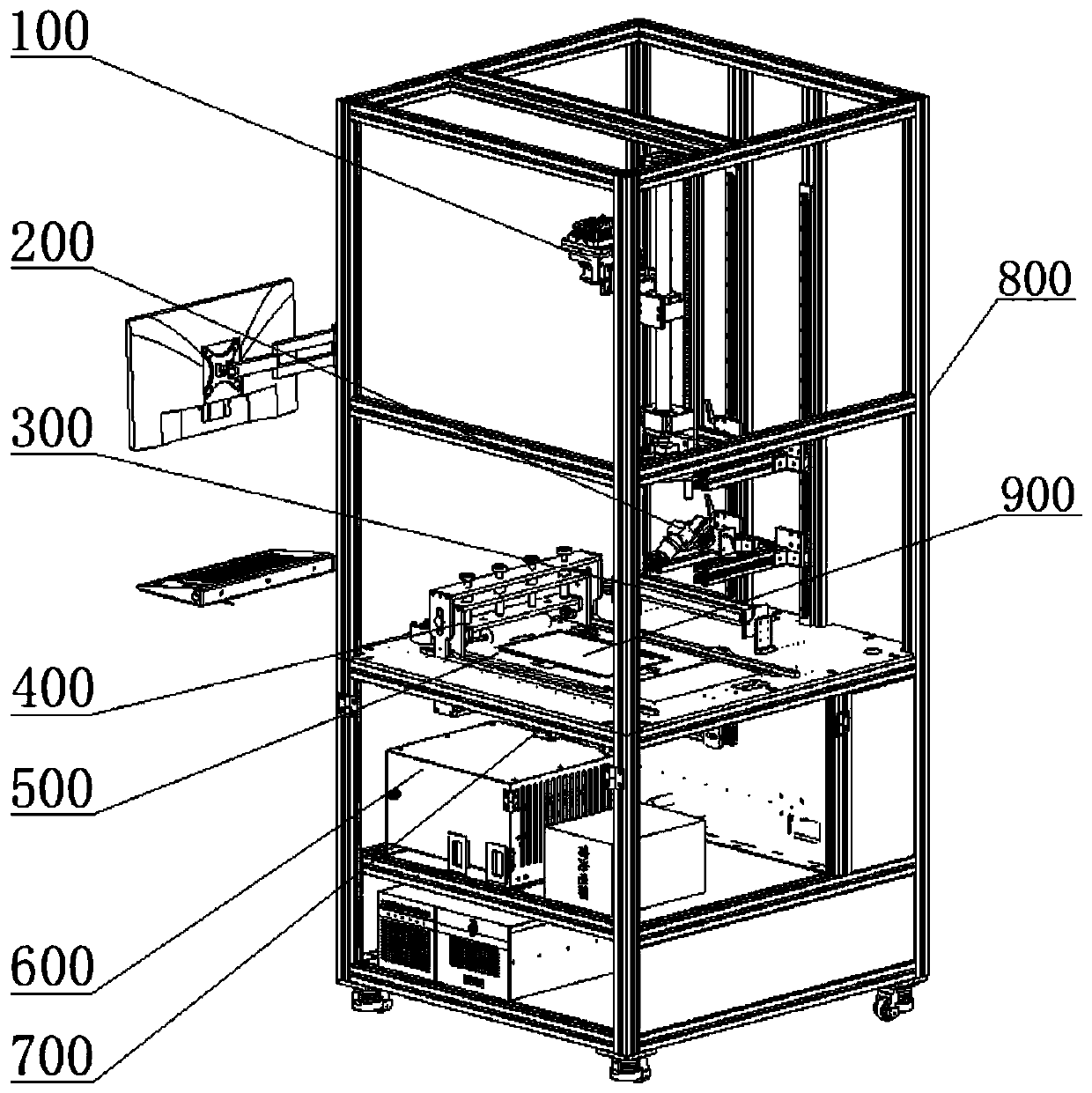

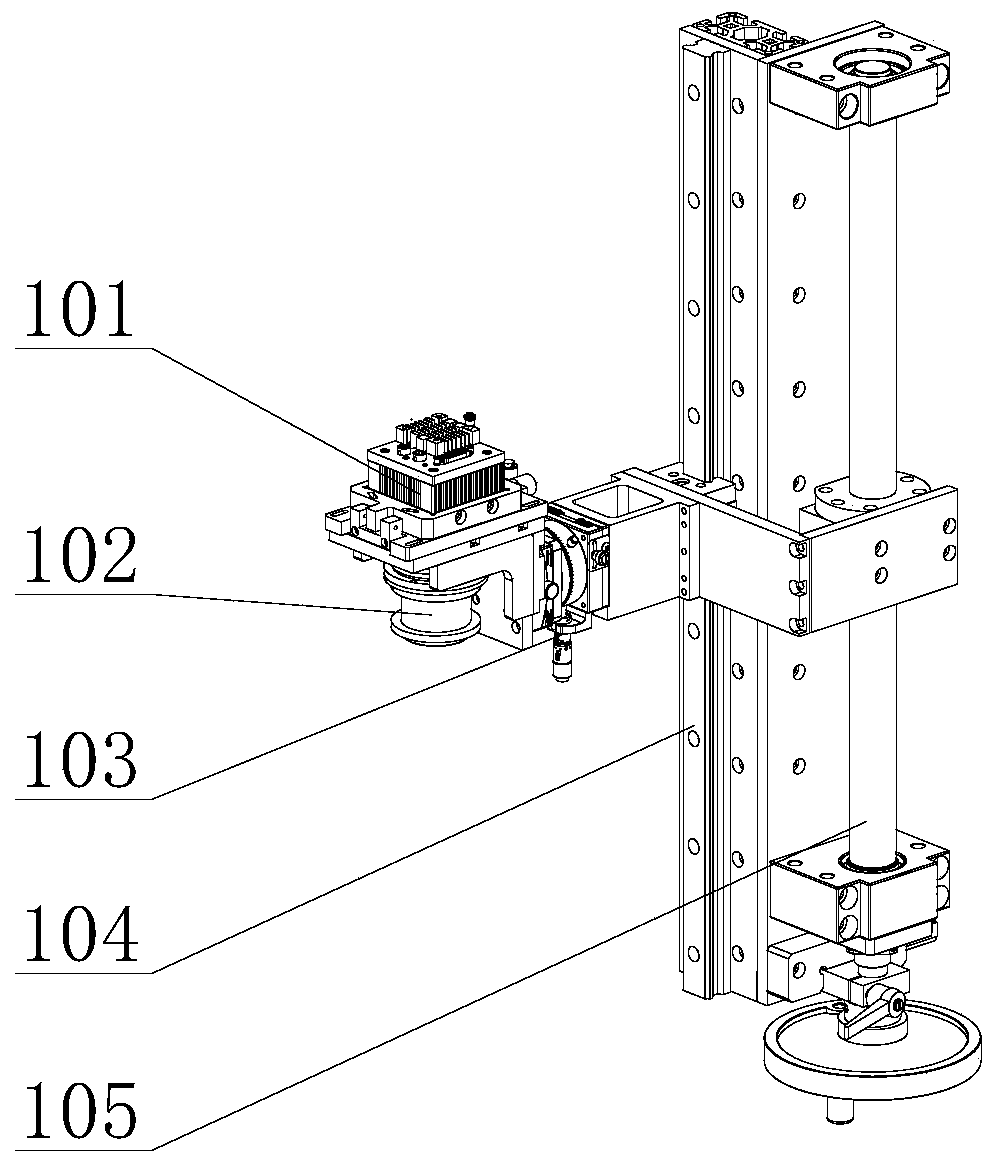

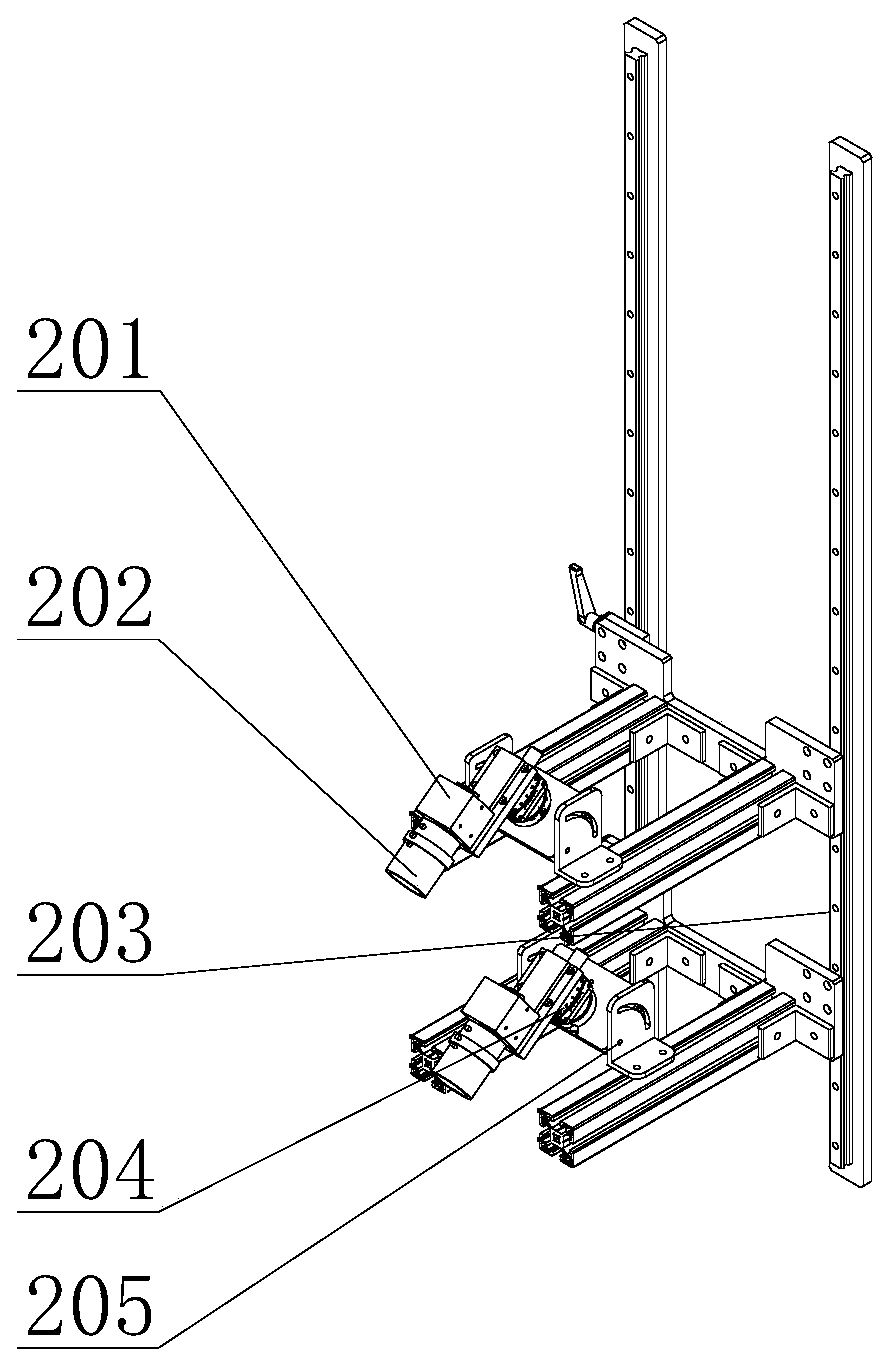

Multi-camera standard machine for defect detection of backlight module

The invention discloses a multi-camera standard machine for defect detection of a backlight module. The multi-camera standard machine comprises a rack, a tool module, an automatic code-reading module,a side light source illumination module, a camera detection module, a dedusting module and an automatic optical detection module, the tool module comprises a tool, a crimping member and a cylinder, the automatic code-reading module is used for reading a bar code pasted on the backlight module and transmitting the information to the automatic optical detection module, the dedusting module is usedfor dedusting the surface of the backlight module, the camera detection module comprises a fin-tuning slide table assembly and a camera, the camera shoots the backlight module, converts an obtained optical image to a digital signal and transmits the digital signal to the automatic optical detection module, and the automatic optical detection module performs analysis and comparison with a saved standard image so that defect detection of the backlight module is realized and whether the backlight module is qualified is determined. According to the multi-camera standard machine, the accuracy and the efficiency of defect detection of the backlight module and the yield of the backlight module of the whole production line are improved, and the labor and time costs are greatly reduced.

Owner:WUHAN JINGLI ELECTRONICS TECH +1

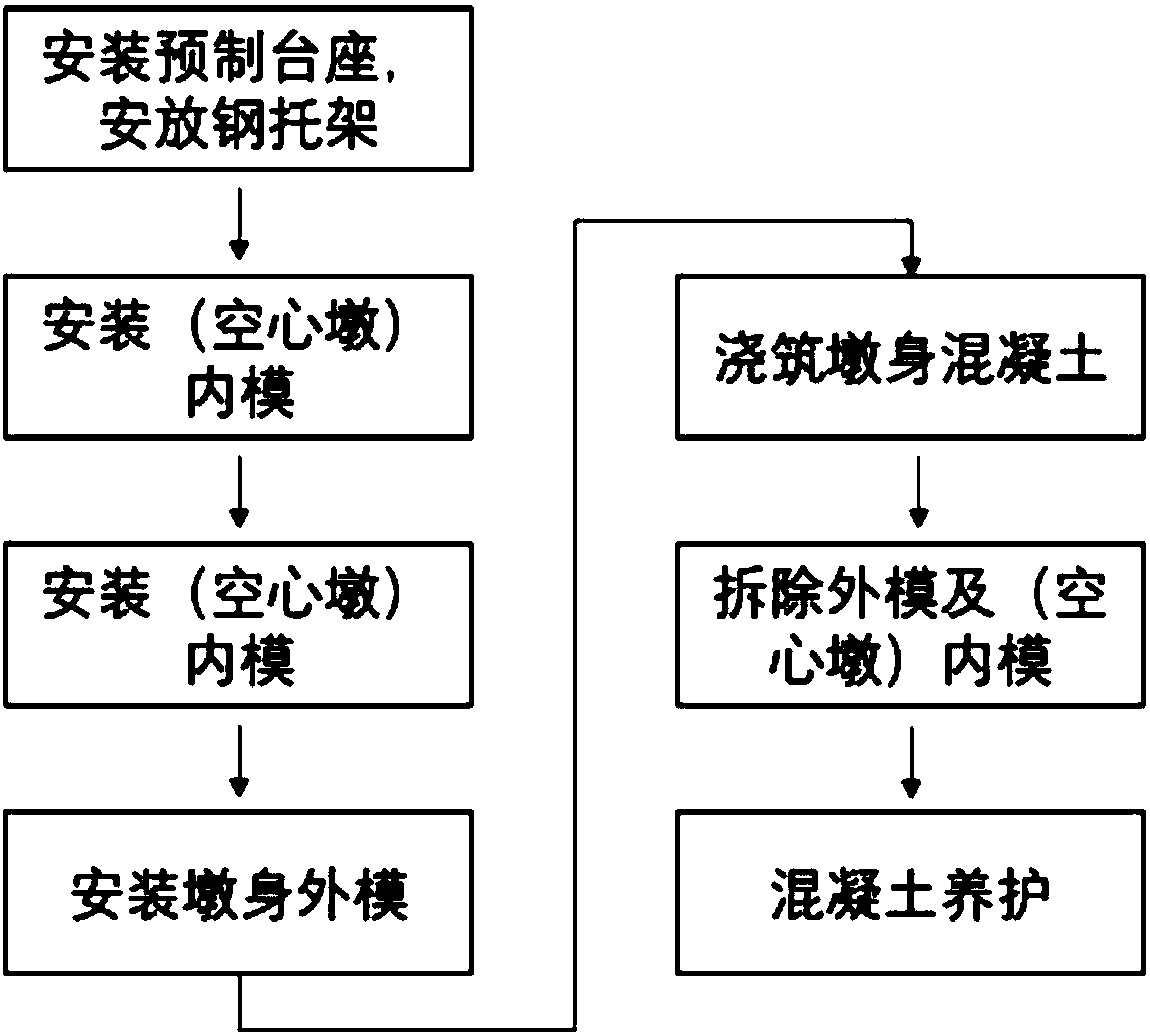

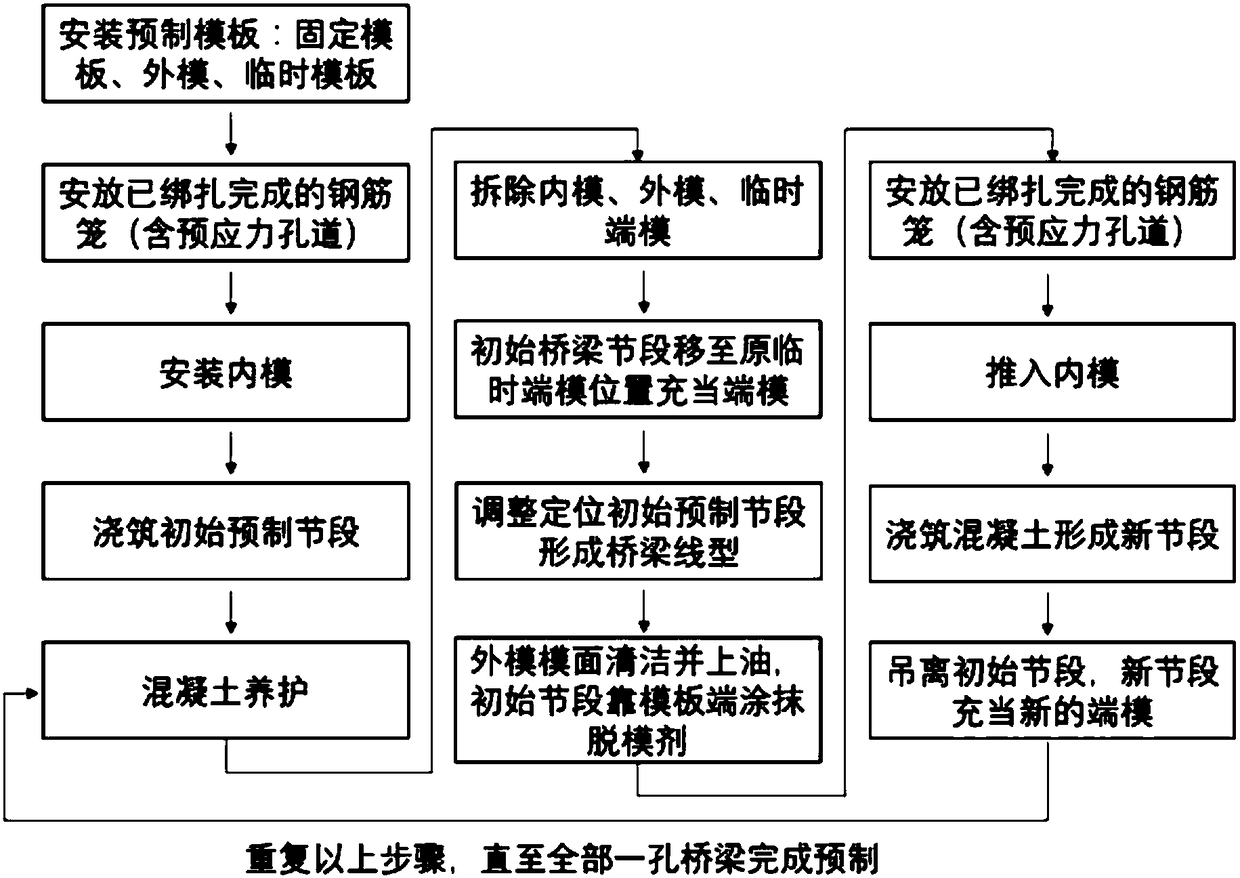

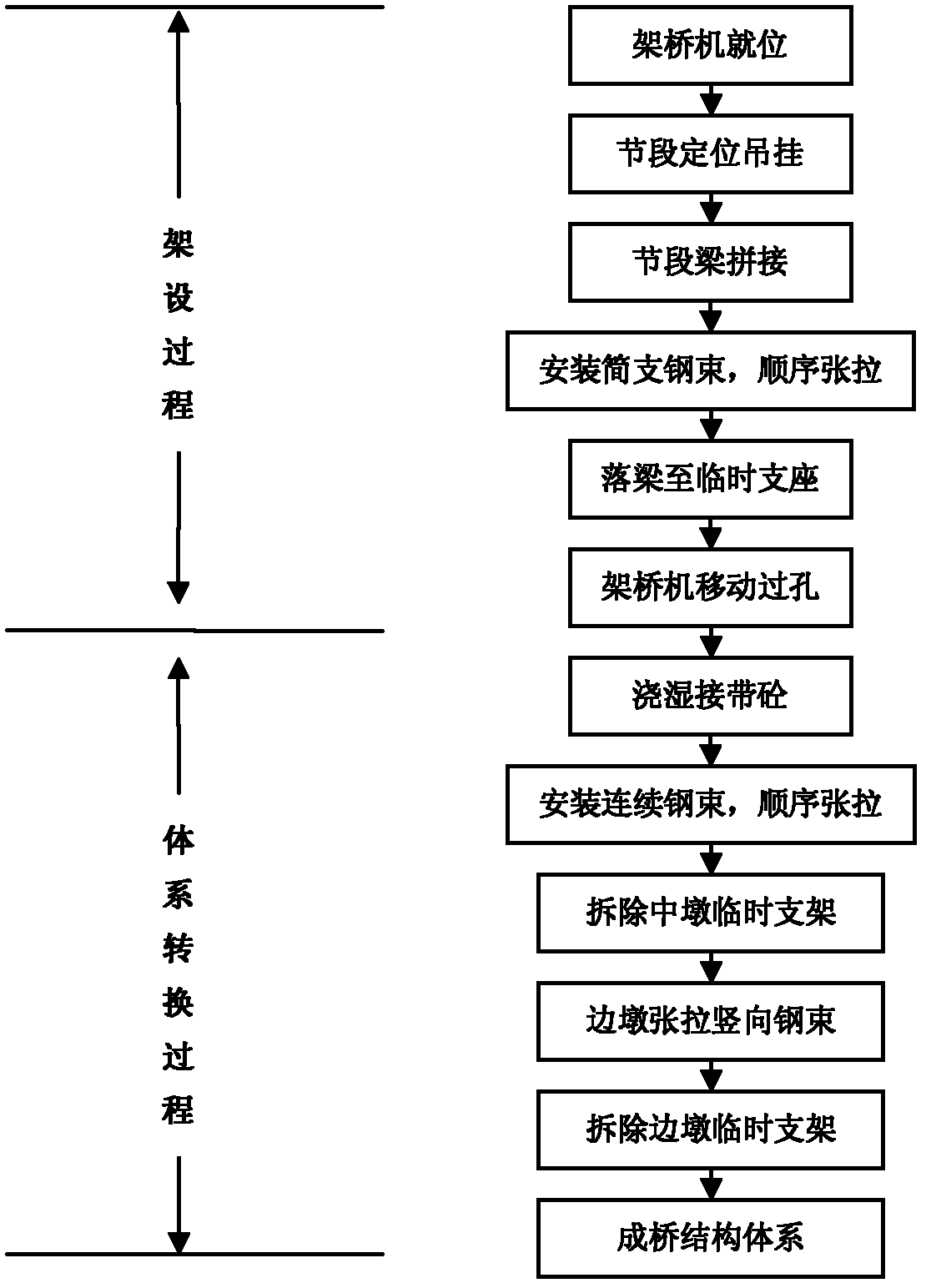

Support-free full-bridge segment prefabricating method based on cantilever balanced assembling

InactiveCN108149580AImprove efficiencyShorten the construction periodBridge erection/assemblyRigid frameSystem transformation

The invention provides a support-free full-bridge segment prefabricating method based on cantilever balanced assembling. The support-free full-bridge segment prefabricating method based on cantileverbalanced assembling comprises a segment prefabricating stage and an assembling stage; in the assembling stage, prefabricated piers are assembled at first; then a pier top prefabricated segment is mounted to a pier top and is fixed to the pier top; segments are assembled symmetrically one by one along a bridge span direction by a cantilever assembling method, and when every segment is assembled, prestressing force is applied and thus the segment and a formed portion form a whole body; and finally, after a cantilever is assembled to a midspan, closure is implemented by post-pouring of concrete,and after closure is implemented, continuous prestressing force is tensioned to form the support-free prestressing force concrete continuous rigid frame bridge. By construction processes such as system transformation, a cast-in-situ scheme of a free-support-system bridge is changed into segmented assembling by the cantilever assembling method, the efficiency is improved greatly in the prefabricating stage and the assembling stage, the construction period is shortened, the construction processes are green, and the method is environmentally friendly.

Owner:瀚阳国际工程咨询有限公司

Multimode electromechanical variable speed transmission apparatus with smooth mode shifting and method of controlling the same

InactiveUS20180037104A1Improve power transfer efficiencyExtended operational speed ratio rangeHybrid vehiclesGas pressure propulsion mountingPower splitElectric machine

A multi-mode electro-mechanical variable speed transmission capable of providing two power split operation modes and at least one fixed output-to-input speed ratio operation mode. The transmission includes an input shaft, an output system, at least one planetary gear set having at least a first, second and third co-axial rotatable components, two electric machines, and at least one torque transfer device. The first co-axial rotatable component couples to the first electric machine with a constant speed ratio; the second co-axial rotatable component couples to the output system with a constant speed ratio; and the third co-axial rotatable component couples to the input shaft with a constant speed ratio; the second electric machine selectively couples to two different co-axial rotatable components of the planetary gear set with two different speed ratios. The transmission is configured to unload the torque transfer device, adjust engine power, shift one of the electric machines to a freewheeling state, and actively synchronize the speed of the electric machines with the speed of one of the engagement positions of the torque transfer device.

Owner:AI XIAOLIN +2

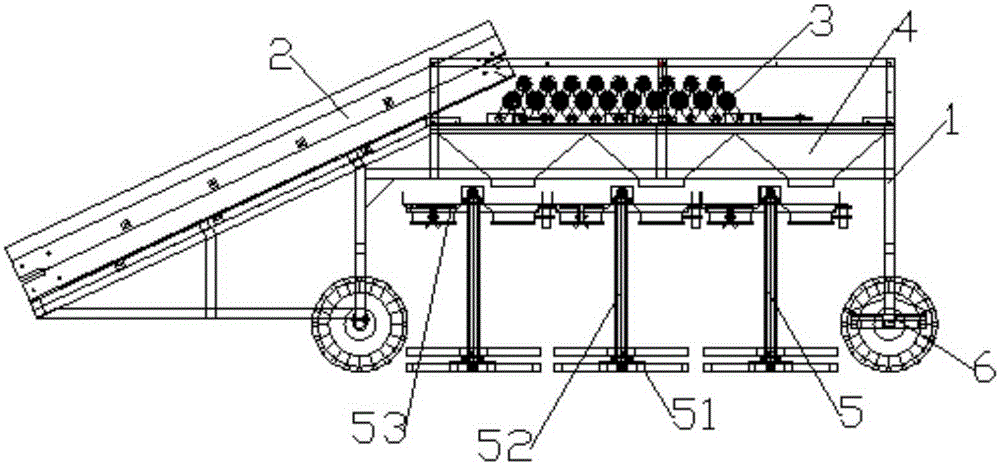

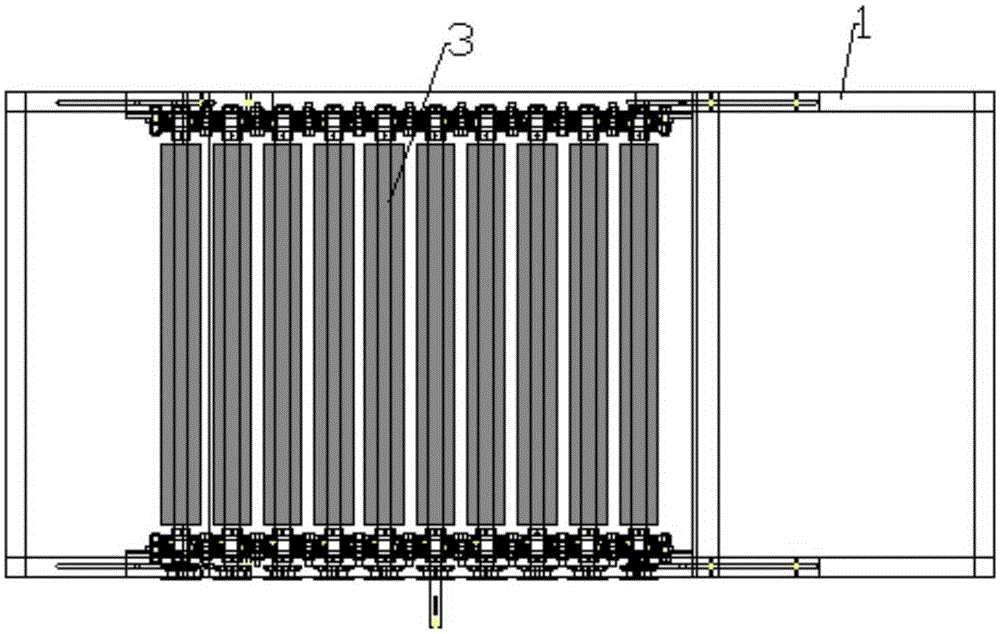

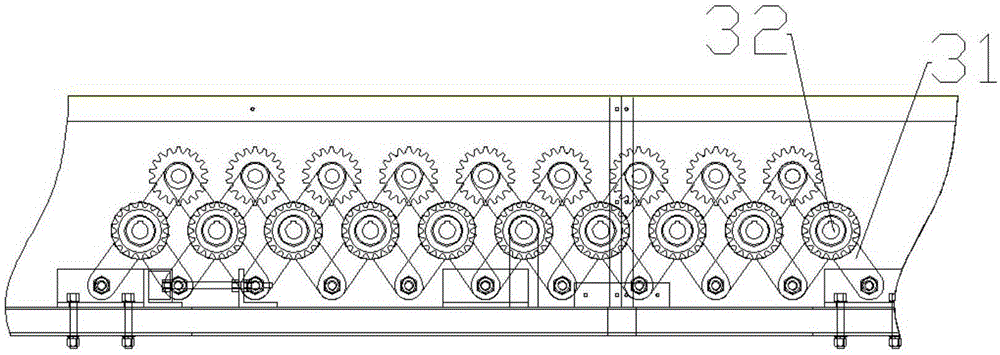

Grading packaging machine of integrated sorting machine for potatoes and other underground tuber crops

InactiveCN105173133ARealize automatic size classificationAvoid the problem of uneven quality of products of the same levelSievingConveyorsEngineeringSolanum tuberosum

The invention provides a grading packaging machine of an integrated sorting machine for potatoes and other underground tuber crops. The grading packaging machine comprises a grading packaging machine frame, an inclination belt, a grading machine, a stock bin, a packaging rotary disc, a packaging bag and a wheel assembly. By means of the technical scheme, size grading of the potatoes and other underground tuber crops is realized, the problem that the quality of products in the same grade is not uniform is avoided, and work efficiency is improved.

Owner:赵东明

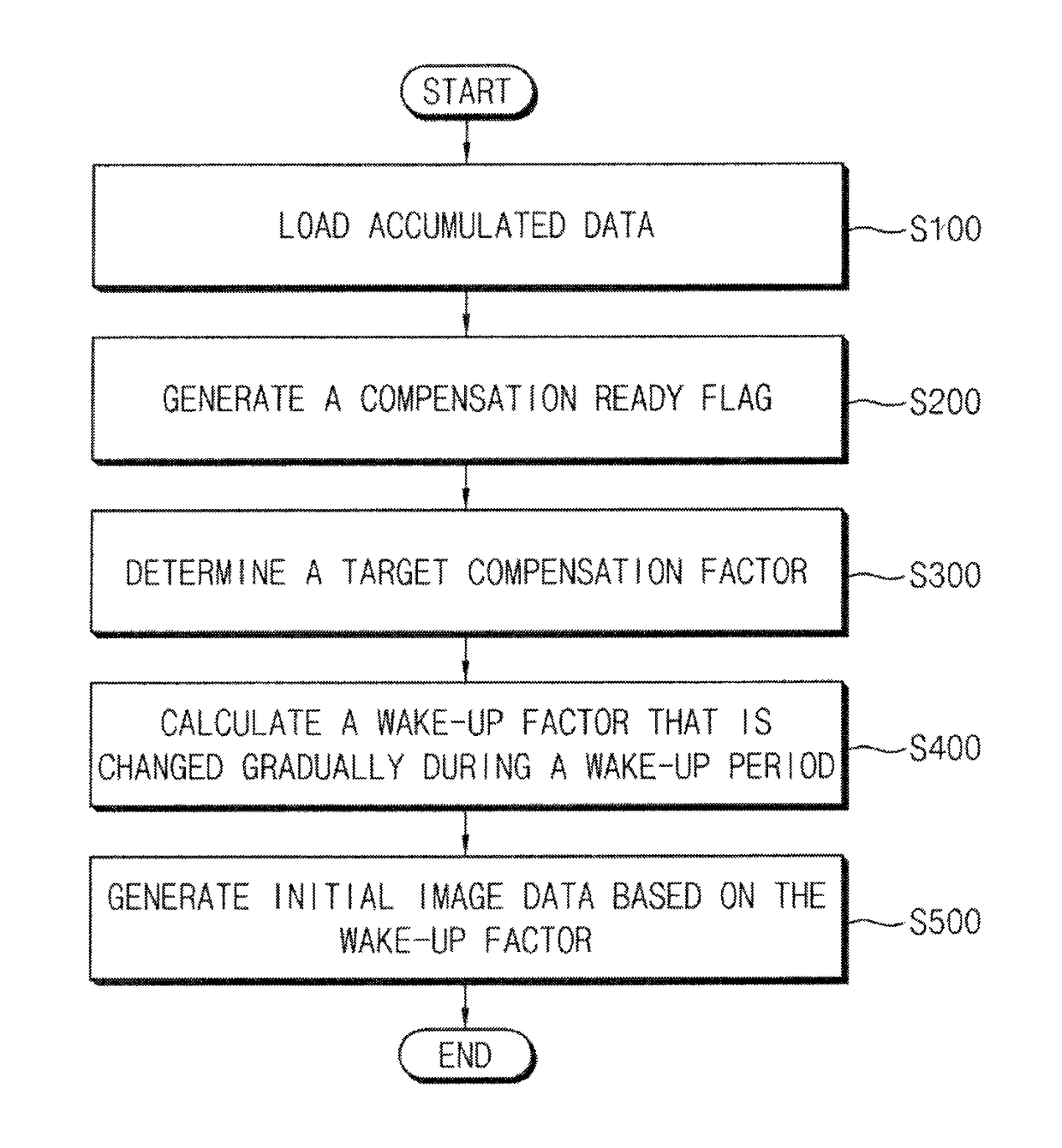

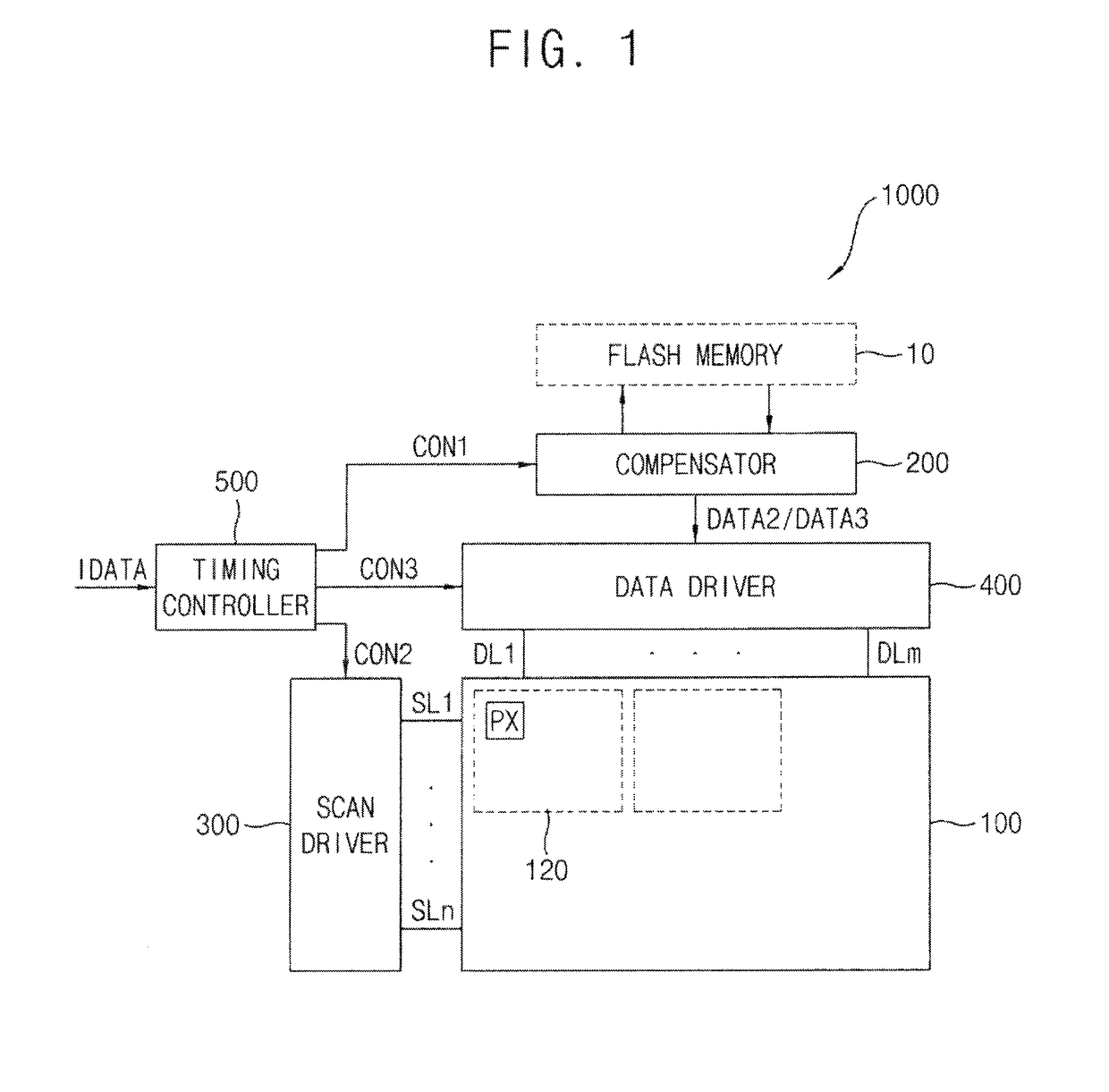

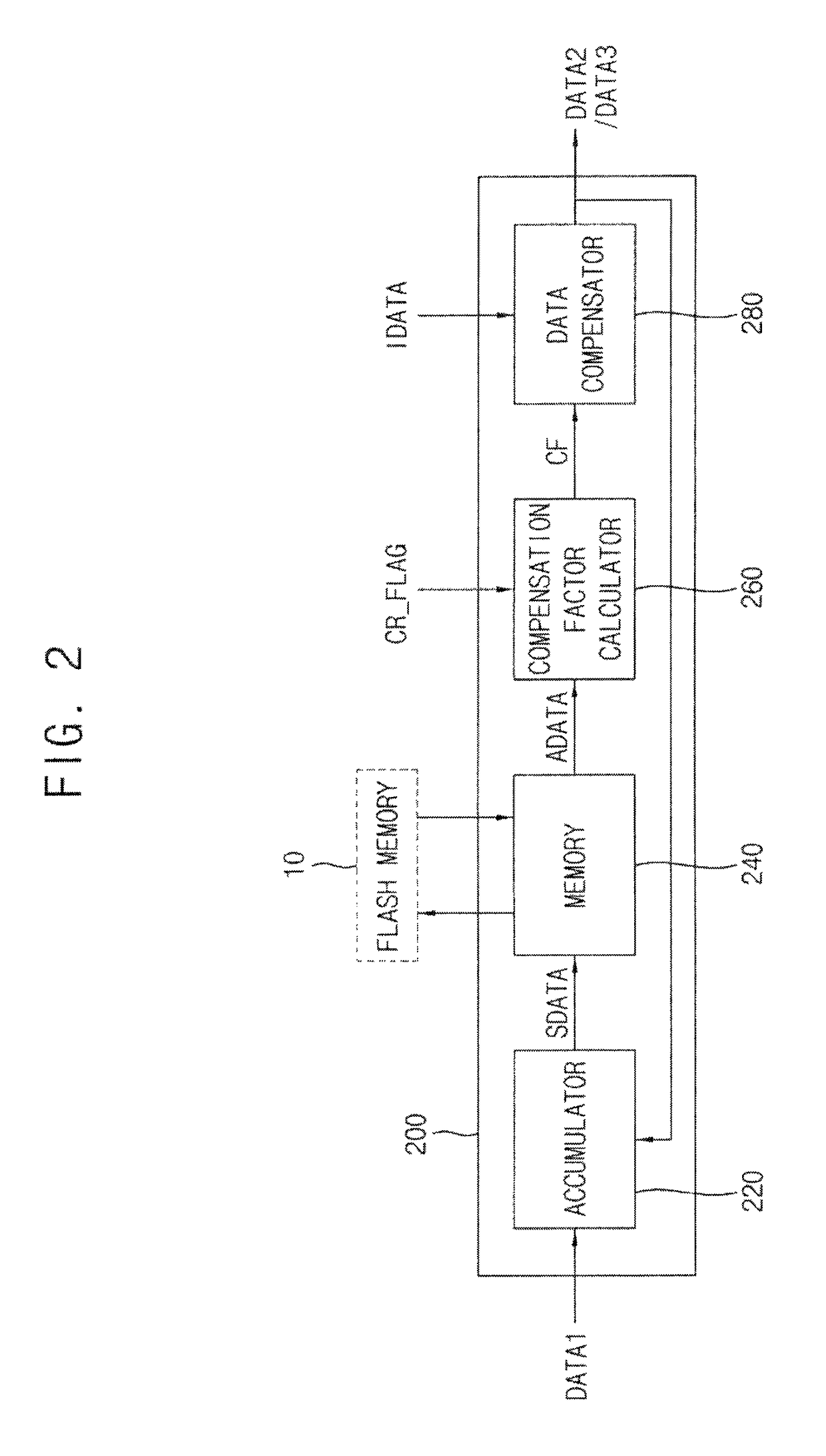

Degradation compensating device, organic light emitting display device having the same, and method for driving organic light emitting display device

ActiveUS9940872B2Avoid uneven qualitySmooth changeStatic indicating devicesDisplay deviceComputer science

A degradation compensating device includes an accumulator configured to accumulate stress data every pixel block, a memory configured to receive the stress data from the accumulator, and to load accumulated data from an external flash memory when a display device power is turned on, the accumulated data being a total sum of the stress data, a compensation factor calculator configured to determine a target compensation factor based on the accumulated data to compensate image data, and to apply an initial compensation factor to the target compensation factor during a wake-up period after loading the accumulated data is completed, the initial compensation factor being changed gradually during the wake-up period, and a data compensator configured to generate image compensation data based on the target compensation factor, and to generate initial image data based on a wake-up factor that is an adjusted target compensation factor based on the initial compensation factor.

Owner:SAMSUNG DISPLAY CO LTD

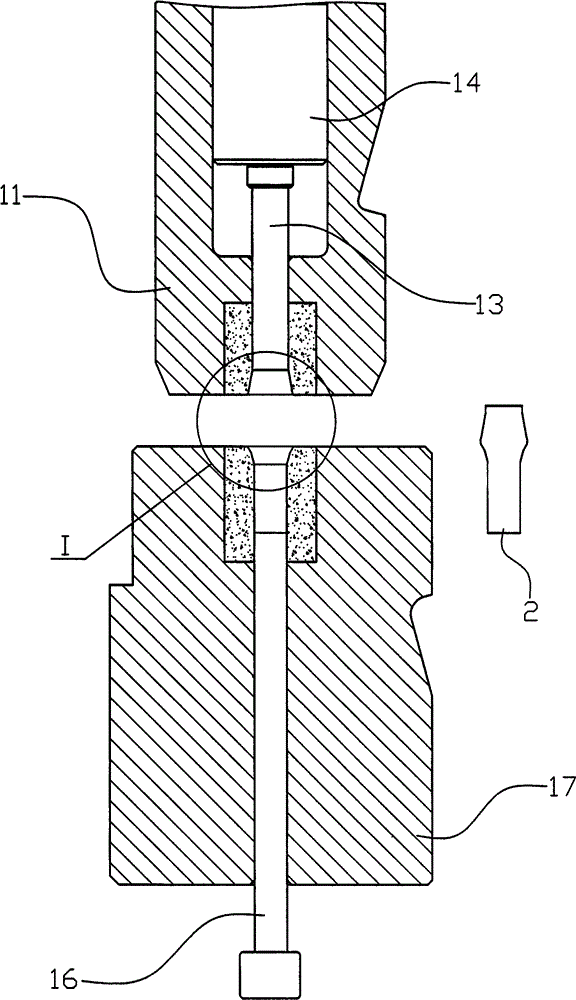

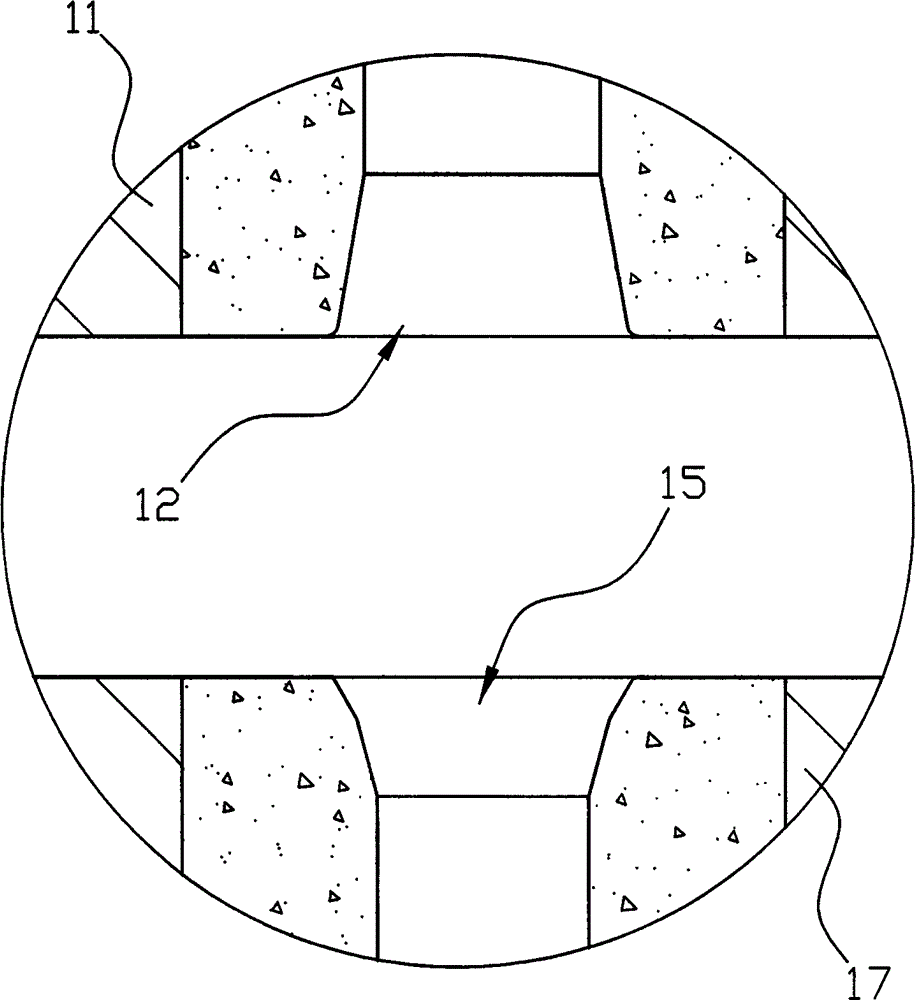

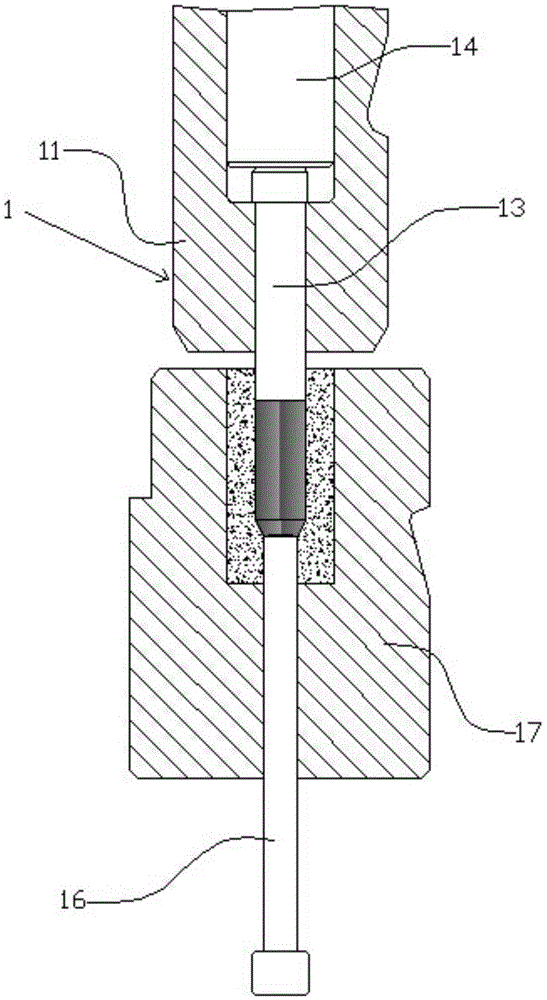

Plastic forming method of draw-hole bolt

ActiveCN105618665AEven by forceExtended service lifeBoltsForging/hammering/pressing machinesHead shapeMechanical engineering

The invention provides a plastic forming method of a draw-hole bolt and belongs to part cold heading methods. The plastic forming method comprises the steps that firstly, the tail taper and required dimension of a rod part are obtained by squeezing a part blank through a first stamping die (1); secondly, a bottom hole and the required dimension of the rod part are obtained by squeezing the part (2) in the first step through a second stamping die (3); thirdly, the head taper and the required dimension of upsetting depth and pumping depth of the rod part are obtained by squeezing the part (2) in the second step through a third stamping die (4); fourthly, the required dimension for flattening the head portion, drawing down the rod part and further hole drawing is obtained by squeezing the part (2) machined in the third step through a fourth stamping die (5); and fifthly, the head shape is obtained by squeezing the part (2) machined in the fourth step through a fifth stamping die (6). The plastic forming method of the draw-hole bolt has the advantages that the bottom hole is squeezed effectively, the procedures are simple, machining is convenient, the material utilization rate is high, and the service life of the dies is long.

Owner:丽水市知源科技有限公司

Optical signal quality monitor for a high-bit rate signal

InactiveUS8121475B2Appropriately qualityAvoid uneven qualityWavelength-division multiplex systemsSpeed measurement using gyroscopic effectsSignal qualityBand-pass filter

An optical signal quality monitor includes a splitter splitting an input optical signal into two signals; a low-frequency converter converting one split optical signal to a low frequency signal by modulating the optical signal with a frequency offset signal; and an intensity ratio calculator calculating an intensity ratio between the low frequency signal and the other split optical signal, thereby appropriately confirming the quality of a high-bit rate optical signal. The monitor includes plural processing lines, each line including the splitter, the low-frequency converter, and the intensity ratio calculator. At least one line includes an optical noise superimposer superimposing optical noise on the one split signal before inputted to the converter or an optical band-pass filter transmitting the one split signal before inputted to the converter. The monitor includes a polarization state changer changing the polarization state of the input signal before inputted to the splitter.

Owner:OKI ELECTRIC IND CO LTD

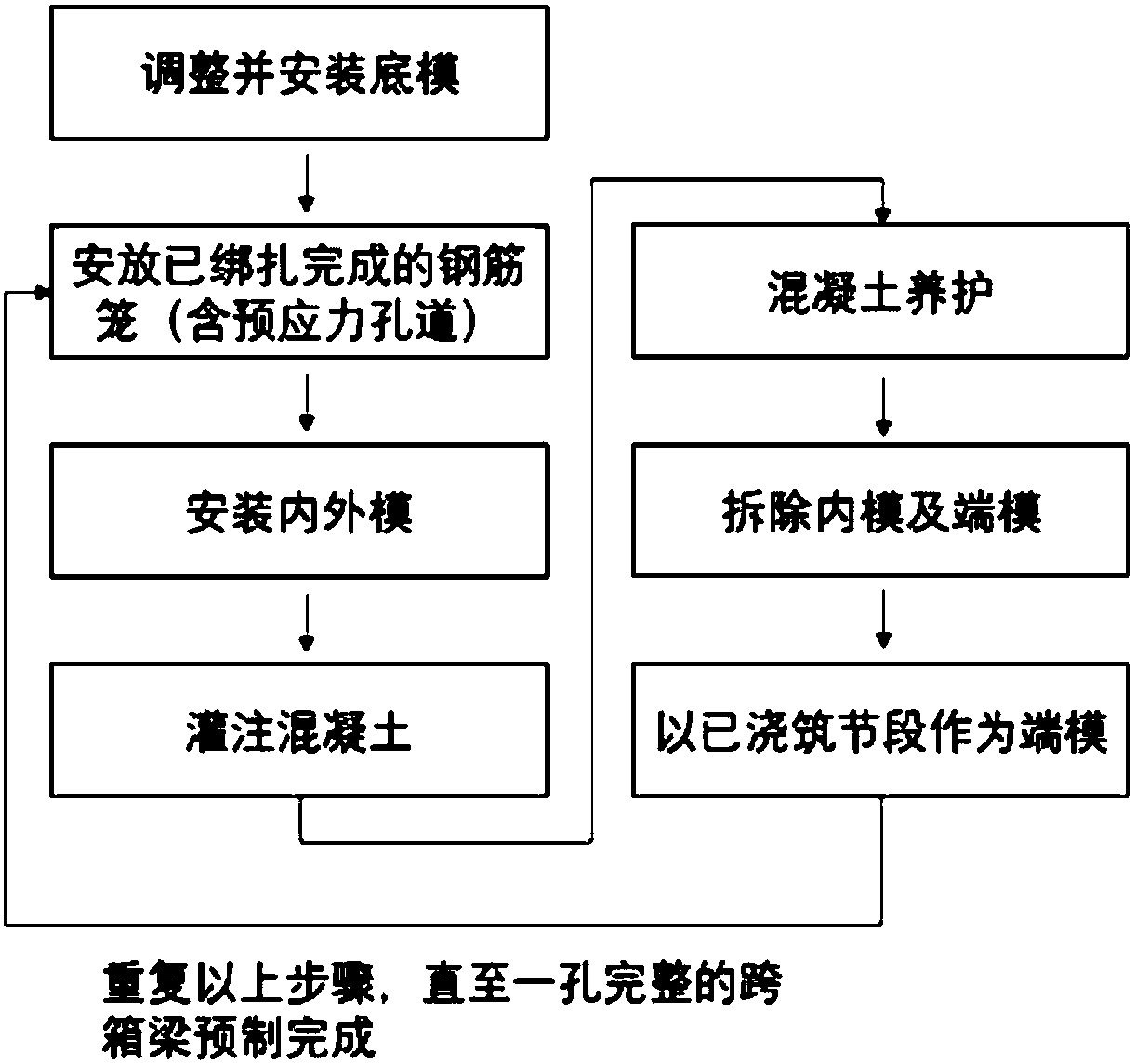

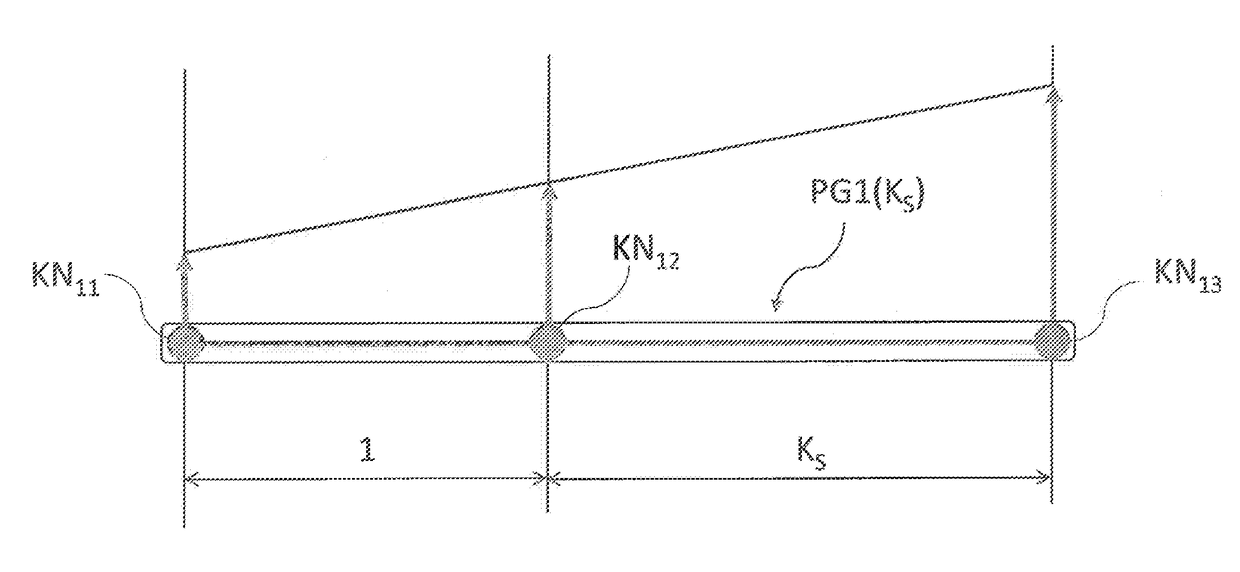

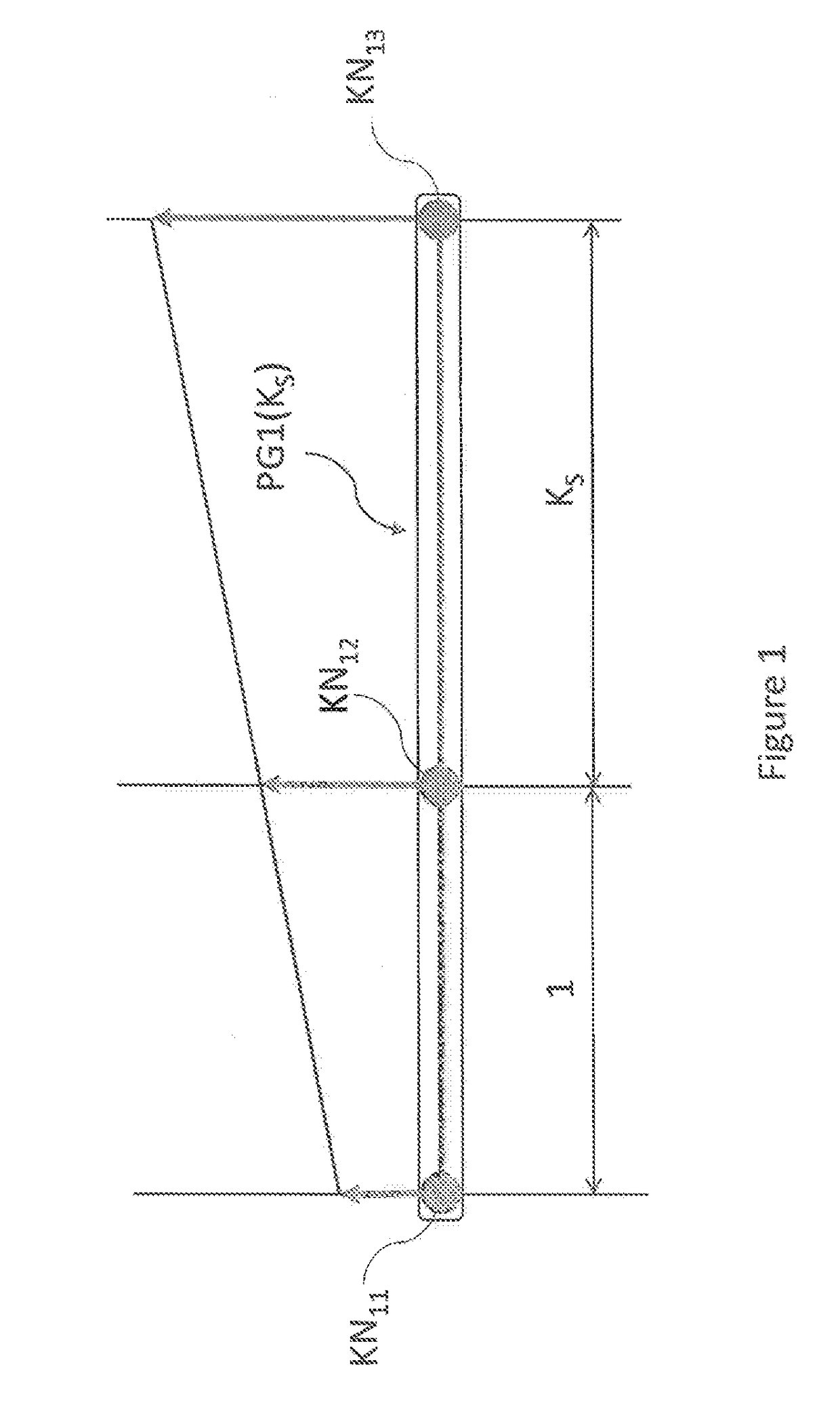

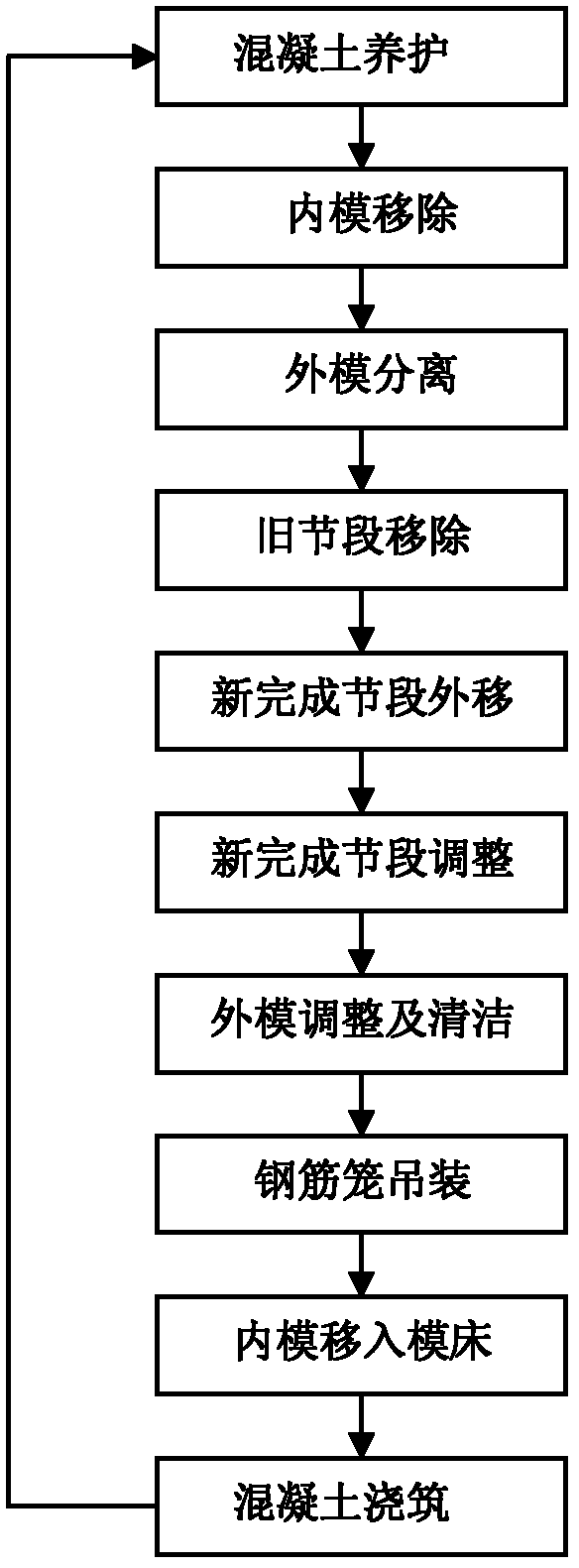

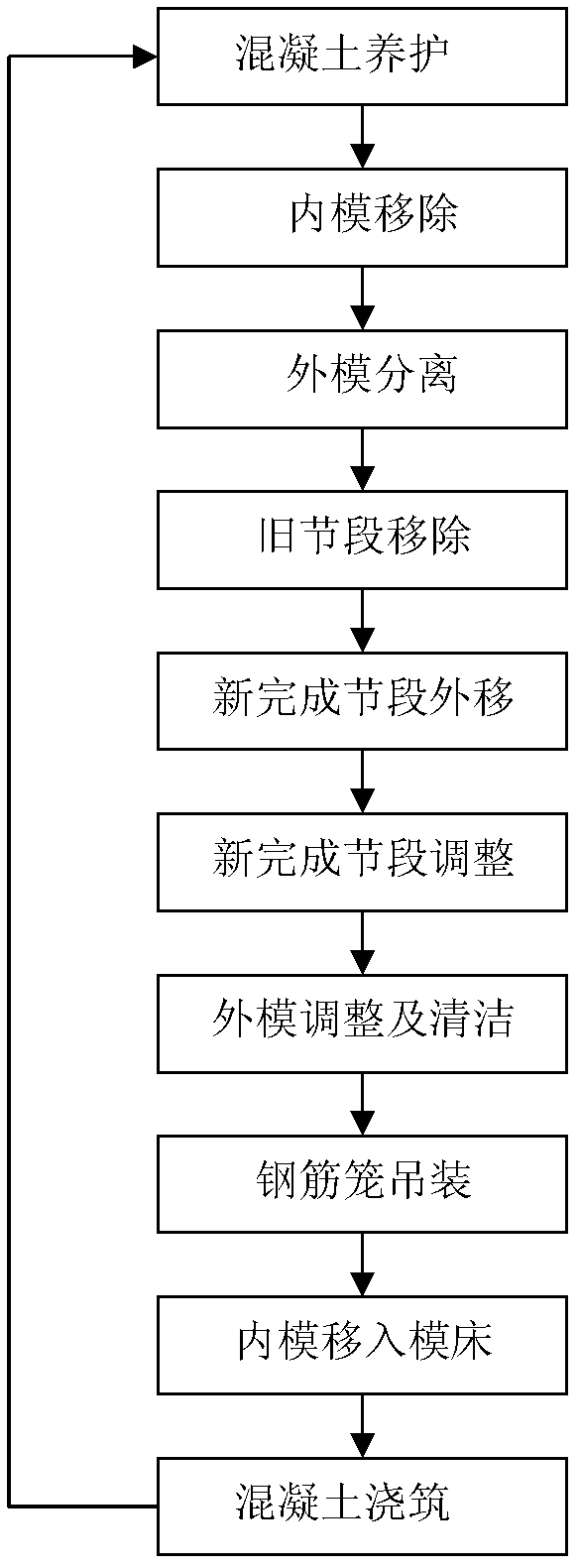

Manufacture method for prefabricating support-free system bridge sections

ActiveCN102493345AReduces the effects of shrinkage and creepQuality assuranceBridge erection/assemblyRebarStressed state

The invention discloses a manufacture method for prefabricating support-free system bridge sections, which comprises a first portion and a second portion. The first portion is that the section prefabricating technology is adopted to manufacture girder portions and bridge piers. The second portion comprises the steps of assembling bridge pier sections to be prefabricated, using the bridge piers as supports of a bridge girder erection machine and assembling the girder portions through the bridge girder erection machine, namely hanging sections to be prefabricated of the girder portions in positions through the bridge girder erection machine; then assembling the sections together through prestressing tendons to form simply supported girders, tying steel bars at the positions of wet connection gaps, pouring concrete, and stretching and drawing continuous tendons to form a continuous structure; and finally pouring concrete of side pier top sections and concrete of side piers, and stretching and drawing vertical prestressing tendons of the side piers to form a rigid framework. The section prefabricating technology is adopted to divide a whole concrete structure of a continuous rigid framework bridge, factorizing section manufacture is performed in a zero-stress state, the construction of the concrete structure is transferred from outside operation at heights to factory operation, and standardizing production can be performed.

Owner:瀚阳国际工程咨询有限公司

Method for mechanochemically synthesizing magnesium lithium silicate

ActiveCN104760966AGuaranteed uniformitySmall particle sizeSilicon compoundsSlurryTemperature resistance

The invention discloses a method for mechanochemically synthesizing magnesium lithium silicate, which comprises the following steps: 1) synthesizing a magnesium lithium silicate precursor, and controlling the temperature of the precursor at 30-99 DEG C; and 2) feeding the precursor into a wet-process superfine treatment device, grinding at 90-99 DEG C for 5-90 minutes, and drying the obtained slurry to obtain the target product magnesium lithium silicate. The diameter of the grinding medium spheres used by the wet-process superfine treatment device is 0.1-5mm, and the linear speed of the grinding medium spheres is 8-20 m / s. The magnesium lithium silicate is synthesized by using high temperature and high pressure instantaneously generated by the grinding medium, so the requirements for high temperature resistance and high pressure resistance of the device are low. The superfine treatment device in peculiar structure can perform continuous production, and can solve the problem in batch production in the traditional hydrothermal reaction kettle. Compared with the traditional hydrothermal synthesis, the method disclosed by the invention has the advantages of lower cost and higher safety, and can easily implement industrialization.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com