Water-based damping coating, and preparation method and application thereof

A damping coating, water-based technology, applied in the field of damping coatings, can solve the problems of the damping coating being difficult to meet the use requirements, the coating peeling off damping performance, limiting the use of subways, etc. Good anti-corrosion and mildew-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

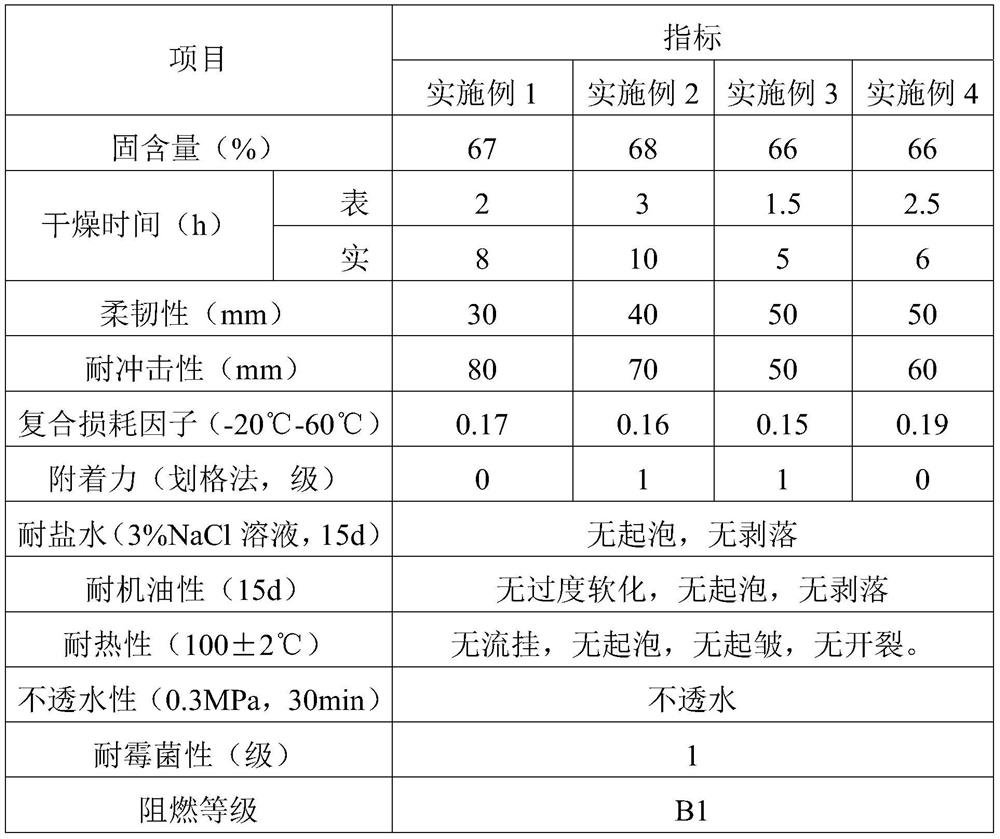

Examples

Embodiment 1

[0033] A water-based damping paint, comprising the following raw materials in parts by weight: 25-50 parts of water-based emulsion, 0.5-2.0 parts of anti-corrosion and anti-mold agent, 15-25 parts of flake functional filler, 10-20 parts of auxiliary filler, 5-20 parts 20 parts of rust inhibitor, 3-10 parts of inorganic fiber, 2-5 parts of anti-settling agent, 5-15 parts of flame retardant, 2-5 parts of film-forming aid, 0.5-1 part of dispersant , 0.2 to 1 part of defoamer, 0.5 to 1 part of substrate wetting agent, 0.3 to 1.5 parts of rheological modifier, and 2 to 5 parts of antifreeze.

[0034] It should be noted that in the examples of this application, 10 parts of styrene-butadiene latex and 15 parts of pure acrylic emulsion are used for the water-based emulsion. The water-based emulsion has excellent water resistance and has different glass transition temperatures. The solid content of the water-based emulsion is ≥ 45%. The emulsion particle size is less than 1 μm.

[003...

Embodiment 2

[0056] A water-based damping paint, comprising the following raw materials in parts by weight: 25-50 parts of water-based emulsion, 0.5-2.0 parts of anti-corrosion and anti-mold agent, 15-25 parts of flake functional filler, 10-20 parts of auxiliary filler, 5-20 parts 20 parts of rust inhibitor, 3-10 parts of inorganic fiber, 2-5 parts of anti-settling agent, 5-15 parts of flame retardant, 2-5 parts of film-forming aid, 0.5-1 part of dispersant , 0.2 to 1 part of defoamer, 0.5 to 1 part of substrate wetting agent, 0.3 to 1.5 parts of rheological modifier, and 2 to 5 parts of antifreeze.

[0057] It should be noted that in the examples of the present application, 10 parts of chlorine partial emulsion and 20 parts of silicon-acrylic emulsion are used for the aqueous emulsion, the solid content of the aqueous emulsion is ≥ 45%, and the particle size of the emulsion is less than 1 μm.

[0058] In the embodiment of the present application, 1 part of organically modified nano-silver...

Embodiment 3

[0076] A water-based damping paint, comprising the following raw materials in parts by weight: 25-50 parts of water-based emulsion, 0.5-2.0 parts of anti-corrosion and anti-mold agent, 15-25 parts of flake functional filler, 10-20 parts of auxiliary filler, 5-20 parts 20 parts of rust inhibitor, 3-10 parts of inorganic fiber, 2-5 parts of anti-settling agent, 5-15 parts of flame retardant, 2-5 parts of film-forming aid, 0.5-1 part of dispersant , 0.2 to 1 part of defoamer, 0.5 to 1 part of substrate wetting agent, 0.3 to 1.5 parts of rheological modifier, and 2 to 5 parts of antifreeze.

[0077] It should be noted that in the examples of the present application, 25 parts of styrene-acrylic emulsion and 25 parts of non-ionic polyurethane emulsion are used for the aqueous emulsion, the solid content of the aqueous emulsion is ≥ 45%, and the particle size of the emulsion is less than 1 μm.

[0078] In the embodiment of the present application, 1 part of nano-zinc oxide and 1 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com