Solar molten salt sleeve pipe type steam generation method and device thereof

A steam generating device and solar energy technology, applied in the field of solar energy, can solve the problems of increasing the associated power consumption of the system, temperature rise, etc., and achieve the effects of easy control and maintenance, stable state, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

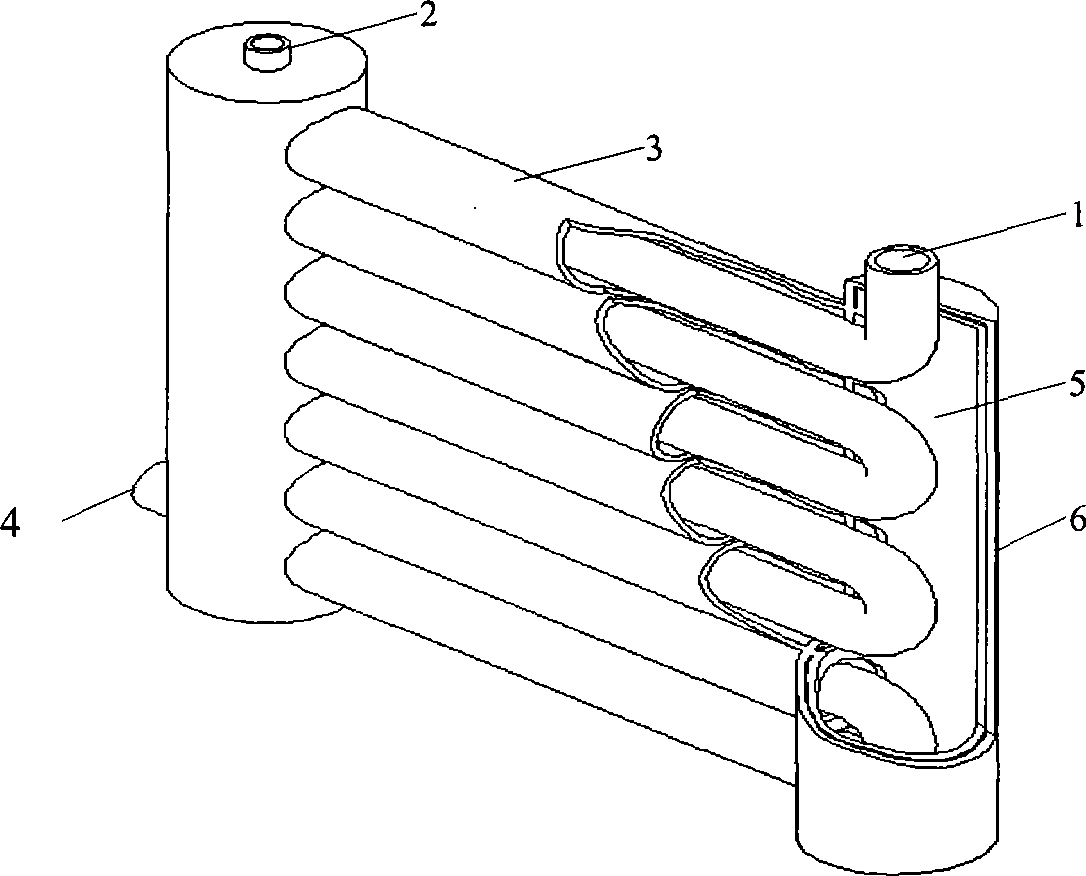

[0029] see figure 1 , figure 2 , the solar molten salt casing type steam generation method of the present invention comprises the following steps:

[0030] (1) Use the high temperature resistant selective absorption coating on the outer wall of the jacket 7 in the molten salt casing 3 to absorb radiant solar energy in real time, and transfer its heat to the molten salt medium 8 in the molten salt casing 3;

[0031] (2) transfer heat to the water or water vapor in the serpentine inner tube 9 through the molten salt medium 8 in the molten salt casing 3 until the whole device can stably generate steam;

[0032] (3) When the intensity of solar radiation fluctuates and the heat flux of solar radiation focused on the high-temperature-resistant selective absorption coating exceeds the design value, the molten salt medium 8 in the molten salt casing 3 and the salt collection tank 5 is melted and absorbed. The exotherm of heat or solidification is adjusted to maintain the stable pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com