Continuous casting and rolling productive technology for figured steel

A technology of continuous casting and rolling, production technology, applied in the direction of metal rolling, etc., can solve the problems of difficult control of surface quality, large drawing resistance, difficult pouring, etc., and achieve the effect of compact structure, good product quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] specific implementation plan

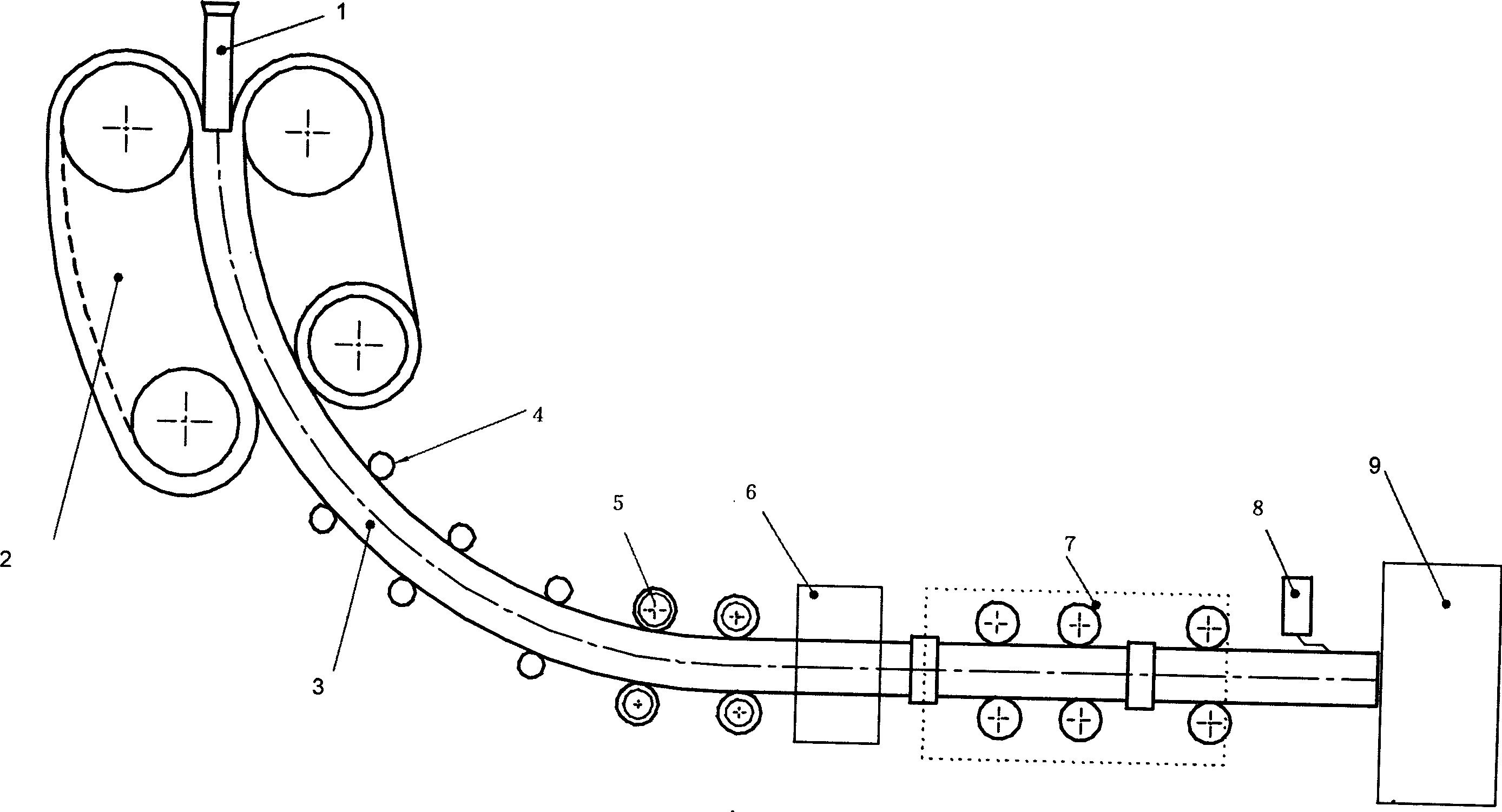

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and with the accompanying drawings as examples.

[0038] The continuous casting and rolling production process of special-shaped steel in the present invention is a combination of ultra-high-speed near-net-shape continuous casting technology and a new generation of steel material production technology. The process flow is: molten steel supply—steel receiving area—continuous casting ——Secondary cooling zone——Straightening—Tunnel-type billet temperature-controlled furnace—Finish rolling.

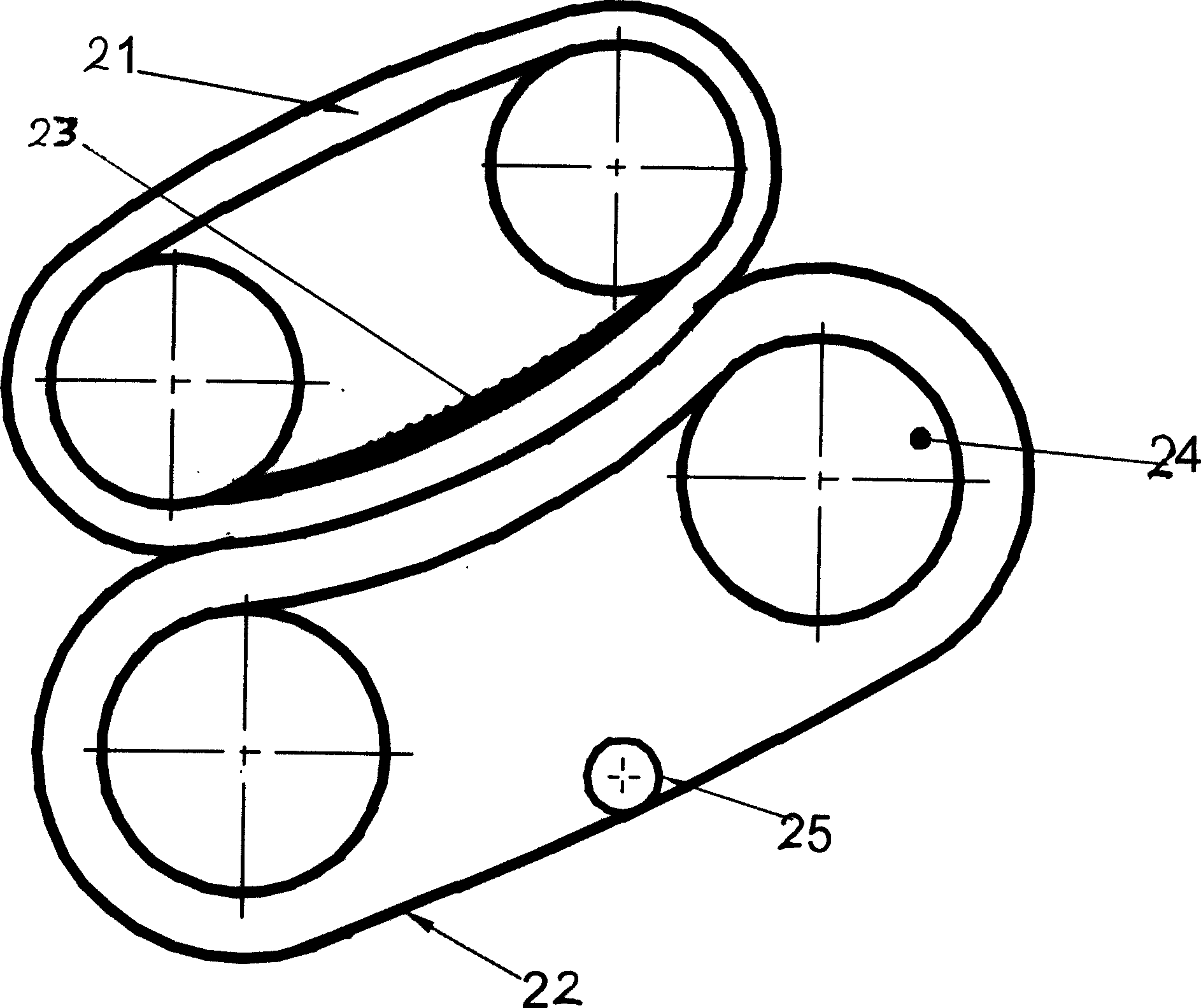

[0039] The so-called ultra-high-speed near-net shape continuous casting is carried out in an arc-shaped synchronous motion mold, single-strand continuous casting, casting speed 10-120m / min, casting radius 2.50-4.50m, the best casting radius is 3m. In order to prevent secondary oxidation during pouring, it is necessary to protect the ladle wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com