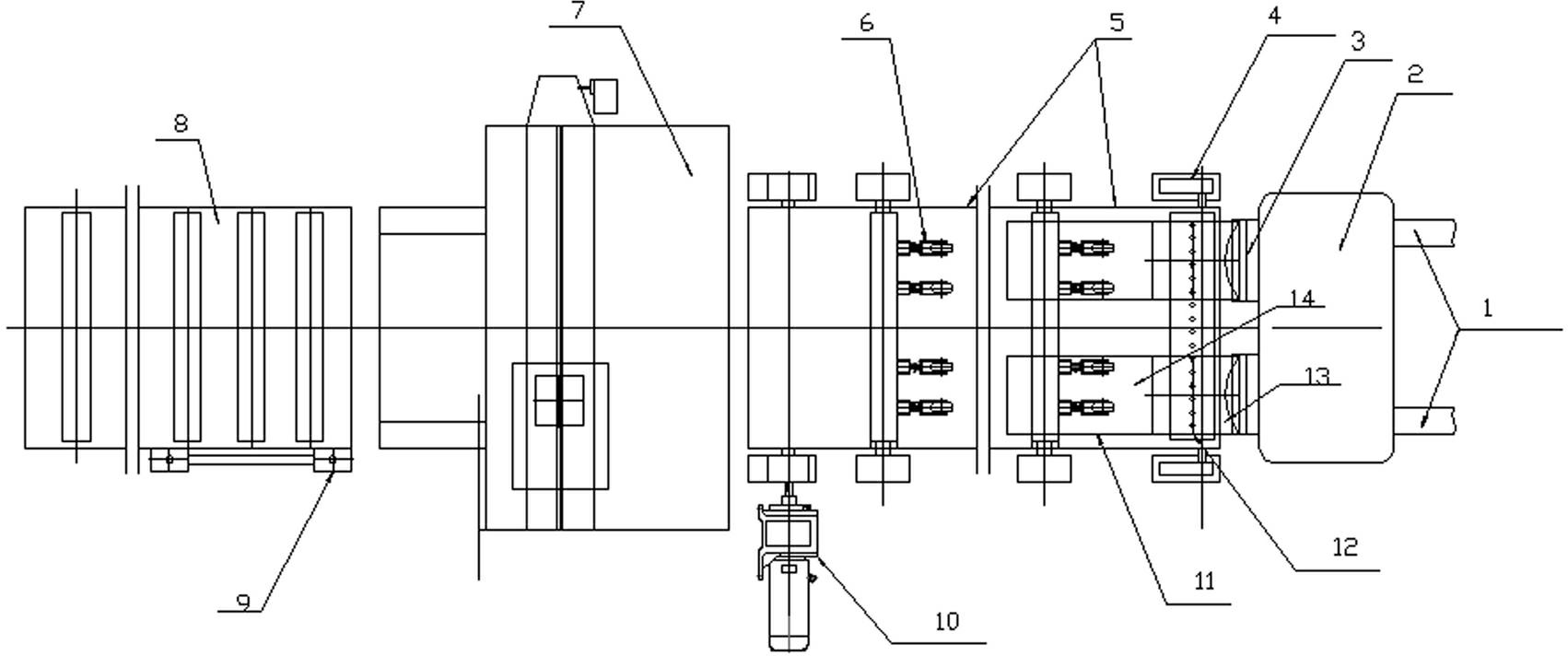

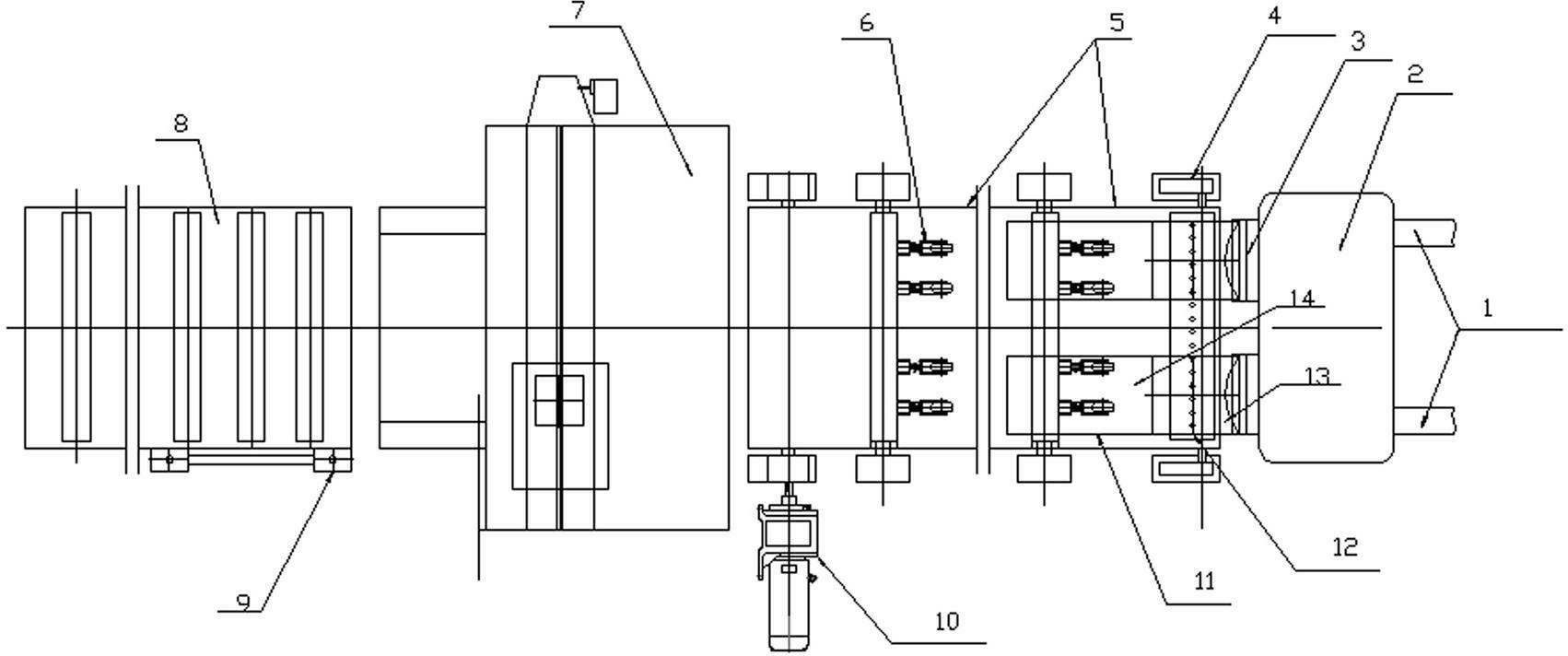

Broad-width horizontal multiple continuous casting device

A horizontal and wide-width technology, applied in the field of wide-width horizontal multi-strand continuous casting devices, to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] An aluminum plant uses a 3-meter-wide chain plate machine to cast 850×300mm T-shaped ingots, corresponding to a 3-meter-long tundish, and 3 groups of 850×300 T-shaped crystallizers are installed on the ladle. Two sets of spring compression wheels are installed on the chain plate machine. Install cooling spray water at a position 300mm away from the crystallizer outlet for cooling. The wide-width horizontal chain conveyor is connected with the synchronous sawing mechanism, and a photoelectric sensor is installed. For a given length, the synchronous saw is triggered and the clamping device is installed on the mechanism to clamp the ingot, so that the ingot is synchronized with the synchronous saw and the mechanism, and at the same time Start the circular saw to saw the ingot. When the synchronous saw is in contact with the traveling roller table, the synchronous saw control system is triggered, and the synchronous saw system exits the sawing state and returns to the init...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com