Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

198results about How to "Meet the requirements of industrialization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

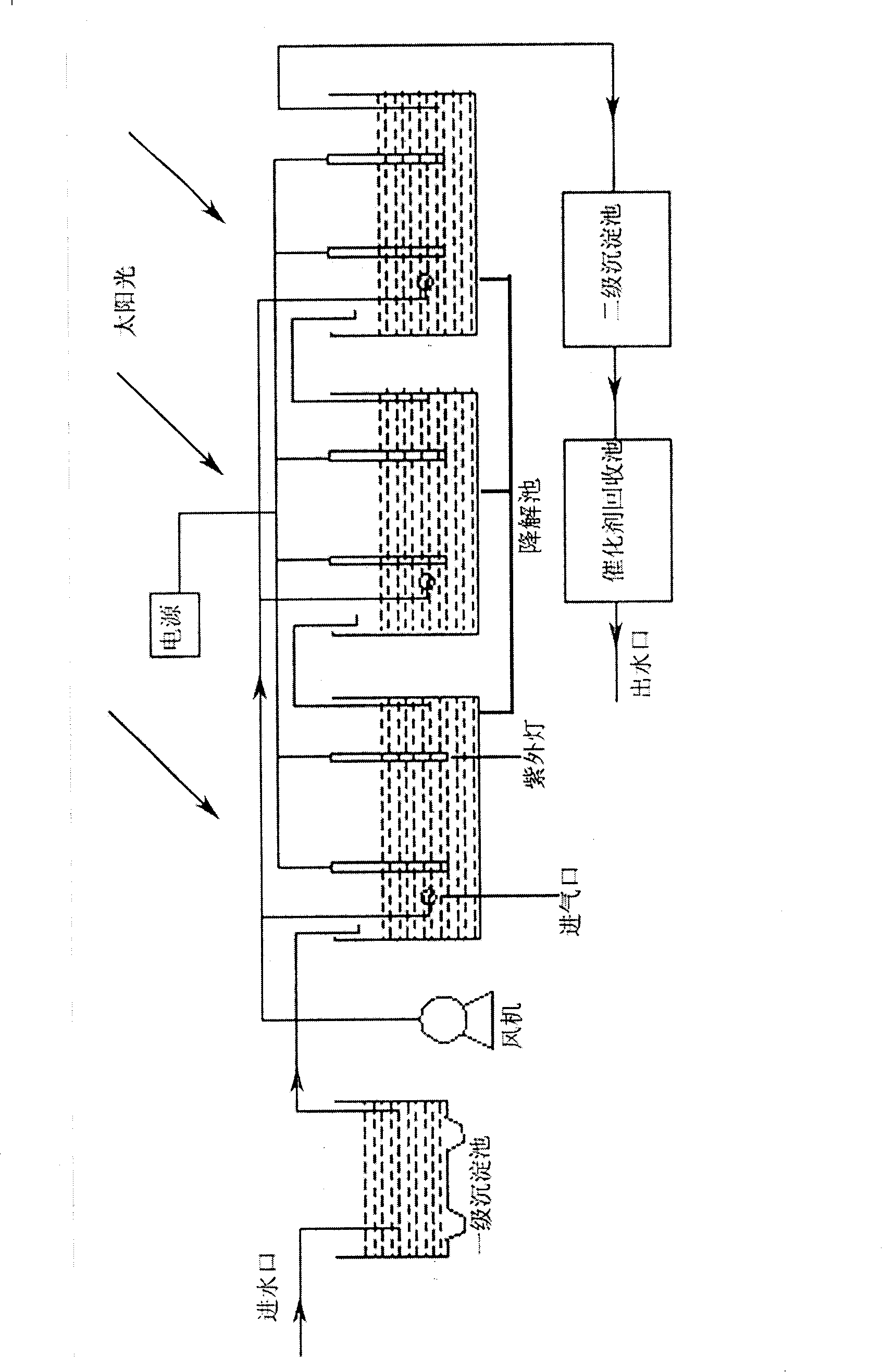

Photocatalysis oxidation treated high concentration organic trade waste

InactiveCN101219371AHigh activityImprove stabilityCatalyst carriersEnergy based wastewater treatmentHigh concentrationEmission standard

The invention relates to a modified loading nano composite photocatalyst which takes titanium dioxide as main part and adopts new reaction technique to degraded the organic industrial wastewater in a water processing system (see attached drawing 1 in Instruction). The main point on preparing the catalyst lies in that titanium dioxide active compounds loaded on different carriers are employed to prepare a loading photocatalyst with grain diameter of 5-40nm; meanwhile, different elements are mixed into the loading photocatalyst to reduce the composition between photoproduciton electron and cavity, which enables the catalyst to move the light absorbing wavelength thereof towards the visible regions, thus effectively improving the degradation rate of organic pollutants as a new environmental-friendly catalyst. As to the new technique of processing the organic industrial wastewater, the invention overcomes the defects that the present photocatalysts are only used for degrading the organic industrial wastewater with low concentration. The catalyst being irradiated respectively or simultaneously under sunbeam and ultraviolet light can decrease COD values of high-concentration organic industrial wastewater from 10000-40000mg / L to less than 100mg / L in short time, thus meeting the national emission standard.

Owner:BEIJING UNIV OF CHEM TECH

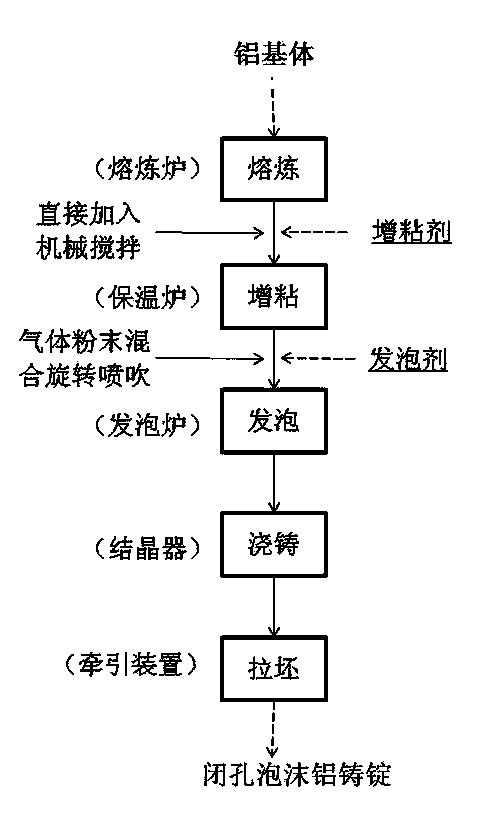

High-efficiency continuous casting method of structure-controllable closed cell foam aluminum ingot

The invention discloses a high-efficiency continuous casting method of controllable structure-controllable closed cell foam aluminum ingot, belonging to the technical field of continuous porous metal preparation. According to the method, the decomposition control on a foaming agent in a melting body is realized by changing the treatment means of the foaming agent, the continuous production not only greatly improves the production efficiency but also solves the problem of bubble-free layers during static casting, and the continuous production of the closed cell foam aluminum ingot is achieved by controlling the casting temperature, the casting speed and the cooling intensity in a continuous casting process; the sizes and the shapes of bubbles in an aluminum substrate are controlled by adding foaming agents which have different types, different additive amounts and different particle sizes and are subjected to different pretreatments, and a control method of the porous structure is relatively high in realizability and relatively meets the requirements on the product diversity in actual application. The method is simple in process and low in cost, achieves the continuous casting, greatly improves the production efficiency, relatively meets the industrialized requirements and can be used for efficiently and continuously preparing large-sized closed cell foam aluminum ingot.

Owner:DALIAN UNIV OF TECH

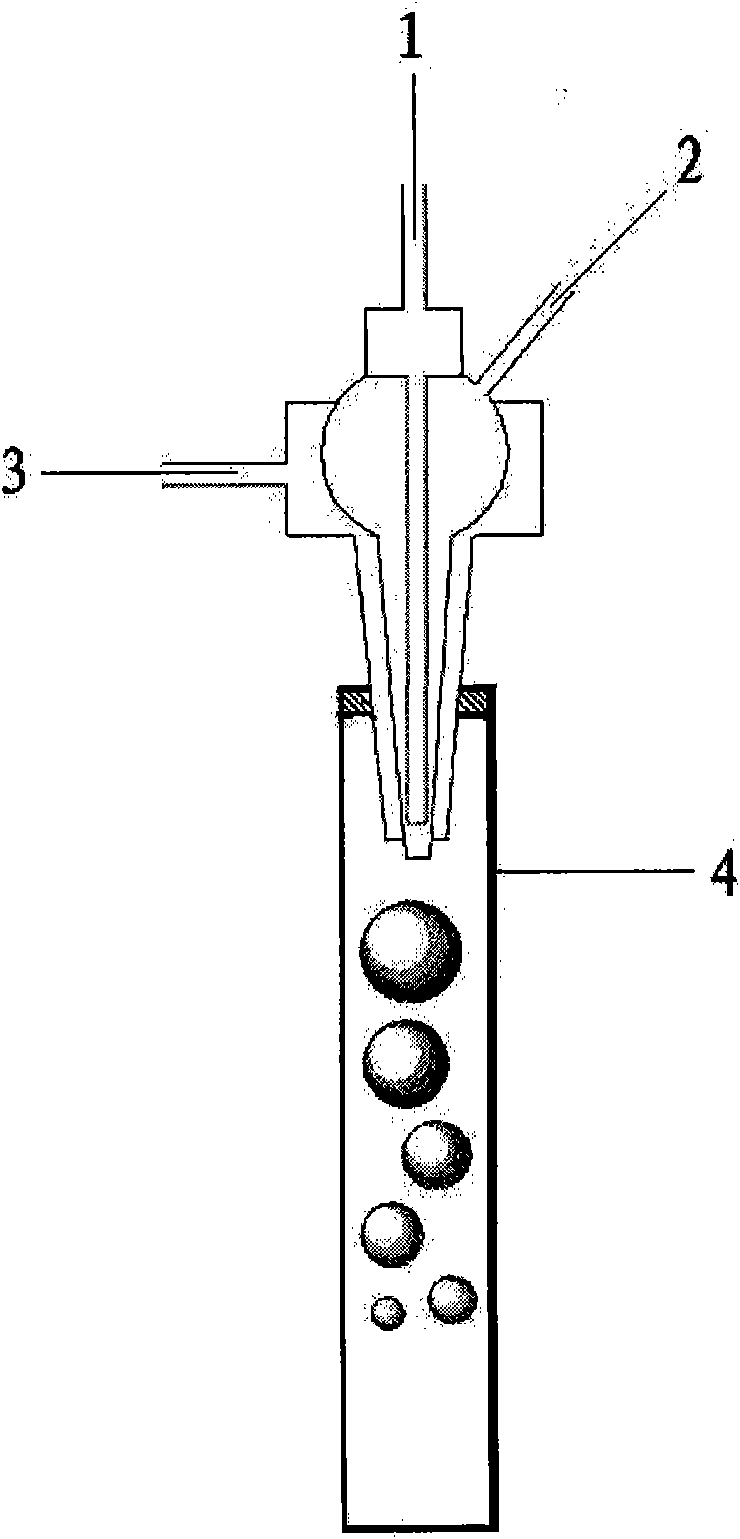

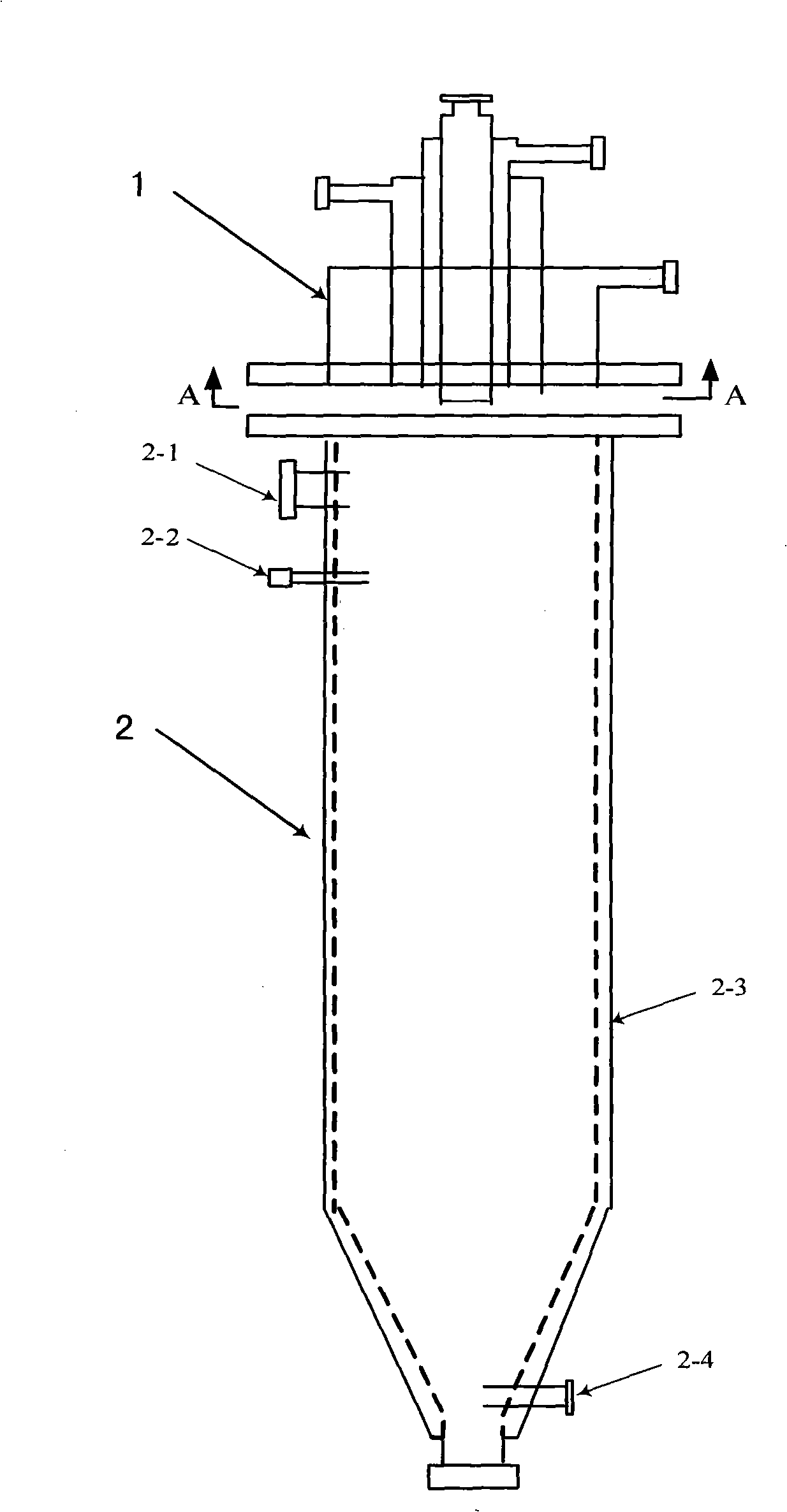

Gas-phase combustion reactor for preparing nano granule and its industrial application

ActiveCN101264433AAvoid scaringOvercome temperatureCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelTin dioxideGas phase

The invention discloses a gas phase combustion reactor for preparing nanometer particles and the industrial application method. By changing the nozzle structure of the reactor in the prior art, the reactor enables the reaction material and the combustion gas to be evenly mixed to form ultrahigh speed jet flame, overcomes the defects of uneven temperature field and concentration field and liability to scab of nozzle, and enables continuous production for long period. The gas phase combustion reactor can be used for industrial and continuous preparation of various oxide nanometer particles such as nanometer titanium dioxide, silicon dioxide, aluminum oxide, and antimony doped tin dioxide.

Owner:EAST CHINA UNIV OF SCI & TECH

Whitening method for washing iron-dyed kaolin

InactiveCN101602898ALow costEasy to operatePigment physical treatmentPigment treatment with non-polymer organic compoundsChloride saltWhitening Agents

The invention discloses a whitening method for washing iron-dyed kaolin, and relates to kaolin. The invention provides the whitening method for washing the iron-dyed kaolin, which can remove iron in the iron-dyed kaolin with higher whiteness, has lower cost and can be industrialized. The method comprises the following steps: washing crude kaolin ore to remove detrital minerals such as fine sand, feldspar and the like and coarse impurities such as rock debris and the like, then adding a bleaching agent into the kaolin ore to reduce ferric iron in the kaolin ore into ferrous iron, washing the ferric iron, filtering and removing the iron, finally making iron impurities in the clay and chlorine react to generate gaseous ferric chloride salt by adding a whitening agent into the solution and calcining the kaolin ore, and eliminating the ferric chloride salt in a mode of volatilization so as to achieve the aims of removing the impurities and improving the whiteness of the kaolin.

Owner:XIAMEN UNIV

Method for synthesizing lixisenatide

InactiveCN102558338AHigh purityEasy to operateHormone peptidesPeptide preparation methodsLixisenatideEther

The invention relates to a polypeptide synthesis field in solid phase, and particularly relates to a method for synthesizing lixisenatide. The method uses amino resin as a solid phase carrier, comprising: subsequently gradually amino acids by solid phase peptide connecting method of Fmoc protection strategy after coupling Fmoc-Lys(Boc)-OH on the resin, to obtain complete protection peptide resin, and then cutting the peptide resin by a lysate, settling the peptide resin in ether, centrifugating the peptide resin and drying the peptide resin to obtain the crude product of lixisenatide, purifying the crude product by a reversed phase HPLC, and then salinizing the purified crude product to obtain lixisenatide. The method has advantages of simple operation and good yield, and satisfies the industrialization requirement.

Owner:HYBIO PHARMA

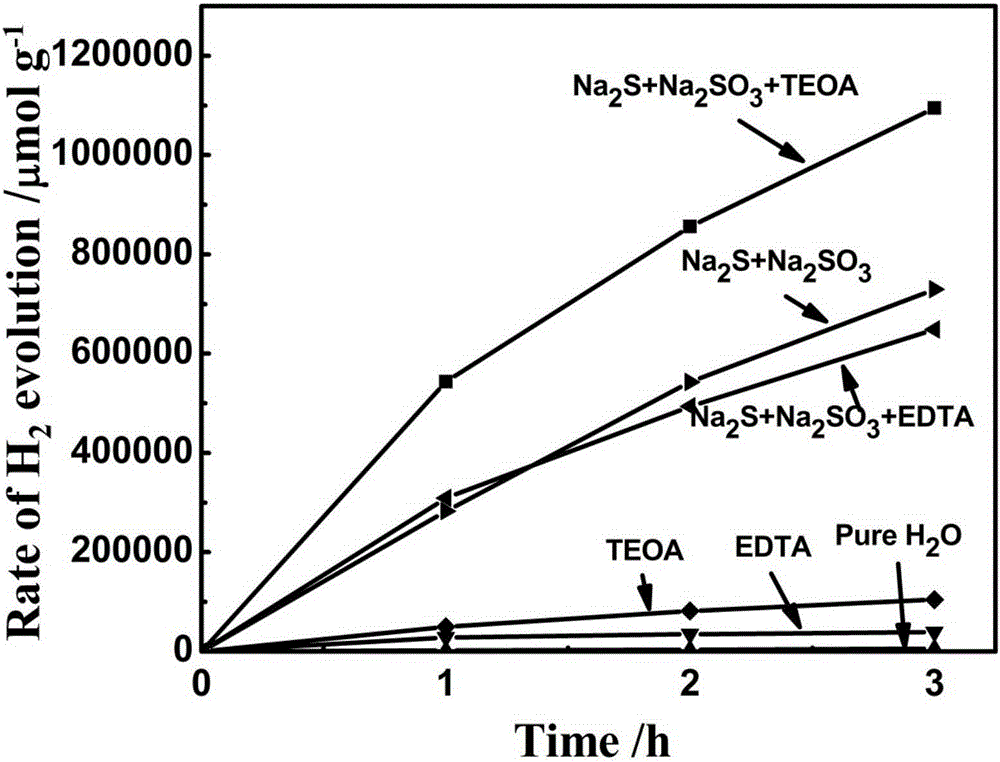

Solid solution catalyst for photocatalytic decomposition of water to produce hydrogen, and preparation method thereof

ActiveCN105289656AImprove performanceAddress industrial applicabilityPhysical/chemical process catalystsHydrogen productionReaction rateZinc Acetate Dihydrate

The invention relates to a solid solution catalyst with simple substances nickel and cobalt loaded surface and for photocatalytic decomposition of water to produce hydrogen, and a preparation method thereof, and belongs to the technical field of photocatalysts. The preparation method of the catalyst for high-efficiency photocatalytic decomposition of water to produce hydrogen comprises the following steps: dissolving copper acetate and zinc acetate in deionized water, adding sodium sulfide to form a solid solution precursor, adding the obtained precursor to a reaction kettle, reacting at a certain temperature for a period of time, washing the obtained product, and drying to obtain a product zinc cadmium sulfide; and loading metals nickel and cobalt on the surface of the zinc cadmium sulfide. The catalyst improves the reaction rate of hydrogen production through photocatalytic decomposition of water to 211417[mu]mol h<-1>g<-1> from 78130[mu]mol h<-1>g<-1> of pure zinc cadmium sulfide, and improves the performances above 2 times. The catalyst has industrial application in energy crisis solution, and is a new technical means for producing environmentally-friendly novel energy.

Owner:JILIN UNIV

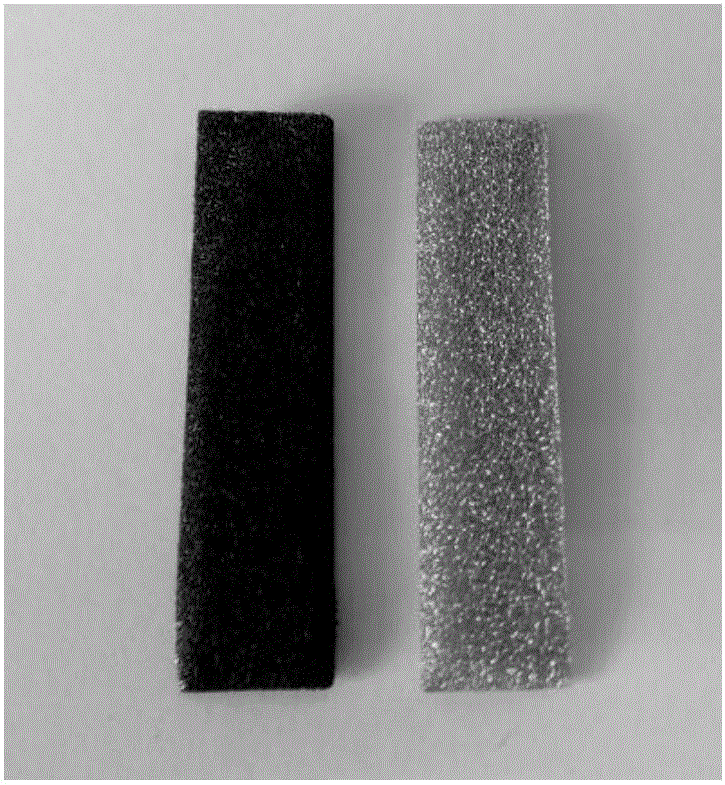

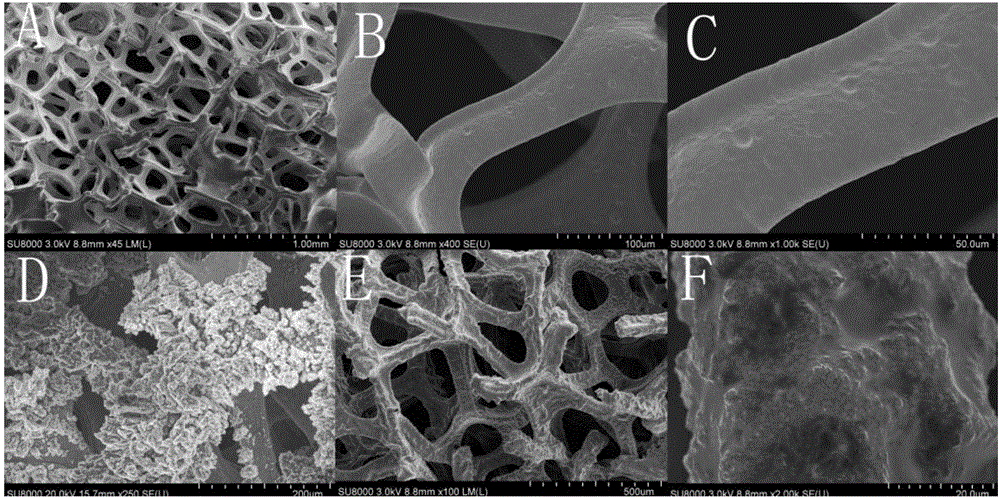

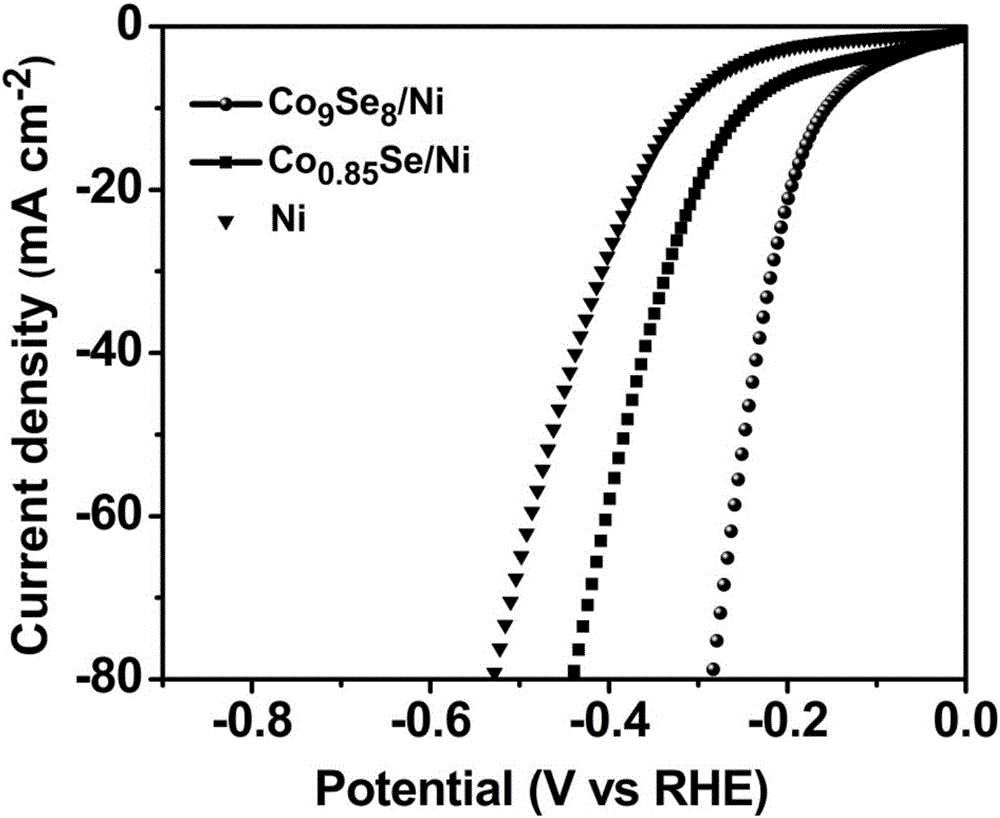

Low overpotential electrocatalyst for producing hydrogen by efficient water splitting and preparation method of electrocatalyst

ActiveCN106492846AImprove hydrogen production efficiencyReduce consumptionPhysical/chemical process catalystsHydrogen productionSodium Selenite PentahydratePotassium

The invention provides a low overpotential electrocatalyst for producing hydrogen by efficient water splitting and a preparation method of the electrocatalyst, and belongs to the technical field of catalyst preparation. The low overpotential electrocatalyst is prepared by in-situ growth of Co9Se8 on foamed nickel. The low overpotential electrocatalyst is prepared by one of cobalt nitrate hexahydrate, cobalt chloride, cobalt acetate or cobalt sulfate and one of sodium selenite pentahydrate, potassium selenite or seleninic acid in an organic amine environment in which the foamed nickel serves as a catalyst. The foamed nickel can serve as both a carrier and the catalyst of a synthetic reaction. The overpotential of the electrocatalyst is only -284mV when the electric current density is 80 mA / cm<-2> and is increased by more than 46.5% relative to that of pure foamed nickel with the overpotential of -530 mV when the electric current density is 80 mA / cm<-2>, and the electrocatalyst is a relatively low overpotential electrocatalyst in non noble metal electrocatalysts. The electrocatalyst is one of advanced technical means for the sustainable production of hydrogen energy, has good industrial application prospects and can be used to relieve an increasingly intense global energy supply pattern at present.

Owner:JILIN UNIV

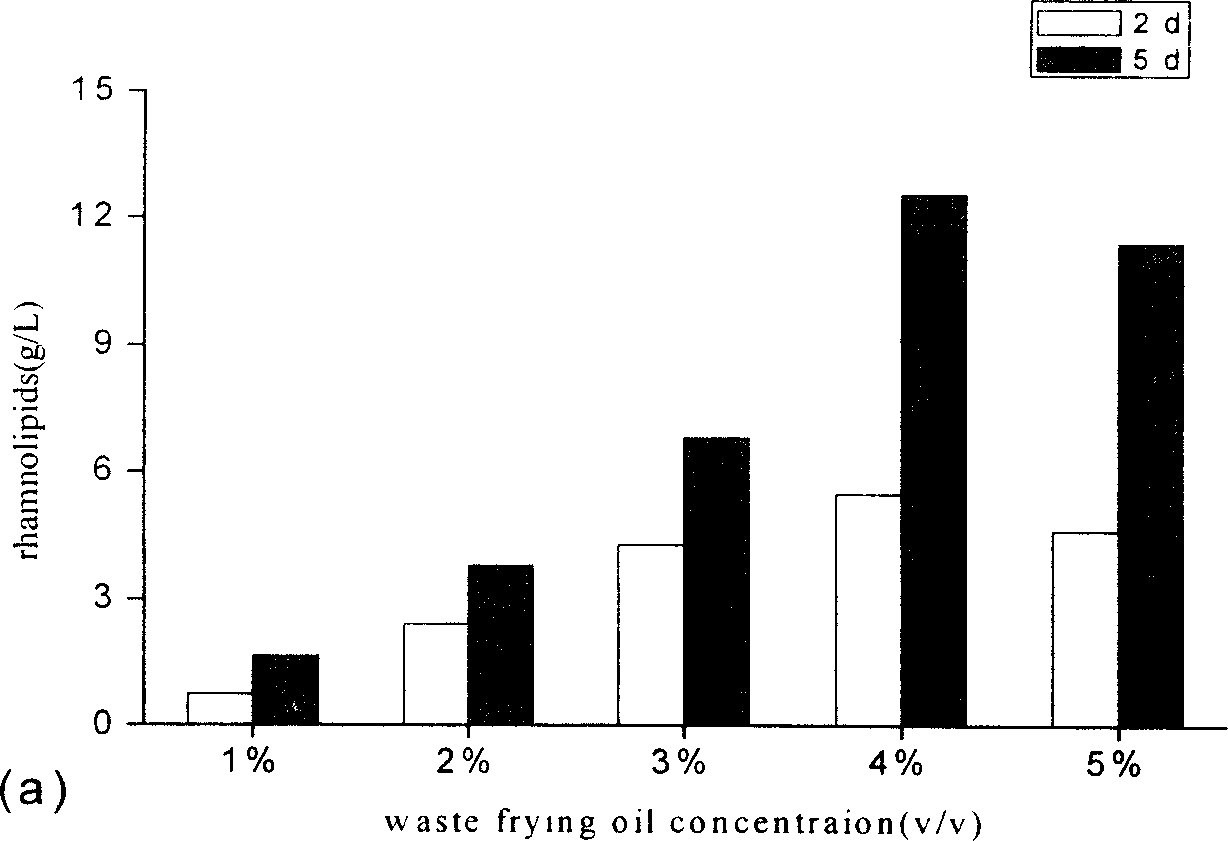

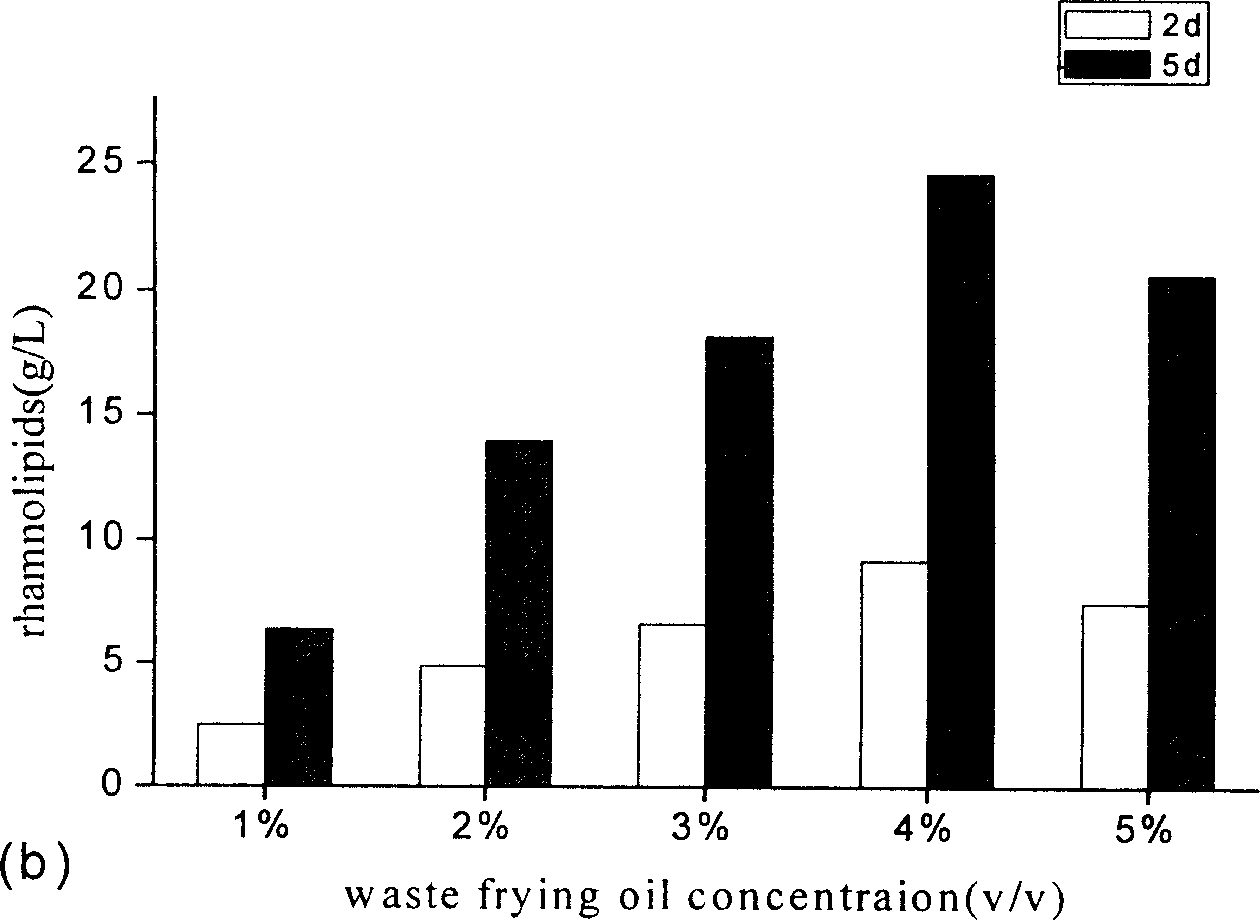

Rhamnolipid crude extract prepared by fermenting food and rink waste oil and application thereof

InactiveCN1908180AImprove processing efficiencyReduce processing timeOther chemical processesFermentationVegetable oilUltrafiltration

the invention discloses a manufacturing method of rough rhamnolipid extract and application fermented by waste food and drink oil, which is characterized by the following: proceeding ultraviolet mutagenesis for natural sieved pseudomonas; picking fitful bacteria; adopting waste food and drink oil as ferment carbon source; making the density of rhamnolipid reach 35-45g / L; ultrafiltrating the ferment liquid to remove bacteria to obtain the powder-shaped rough extract through spraying and drying method; adding 0.01-3% rough extract in the biochemical dirty water to improve disposing efficiency.

Owner:ZHEJIANG UNIV

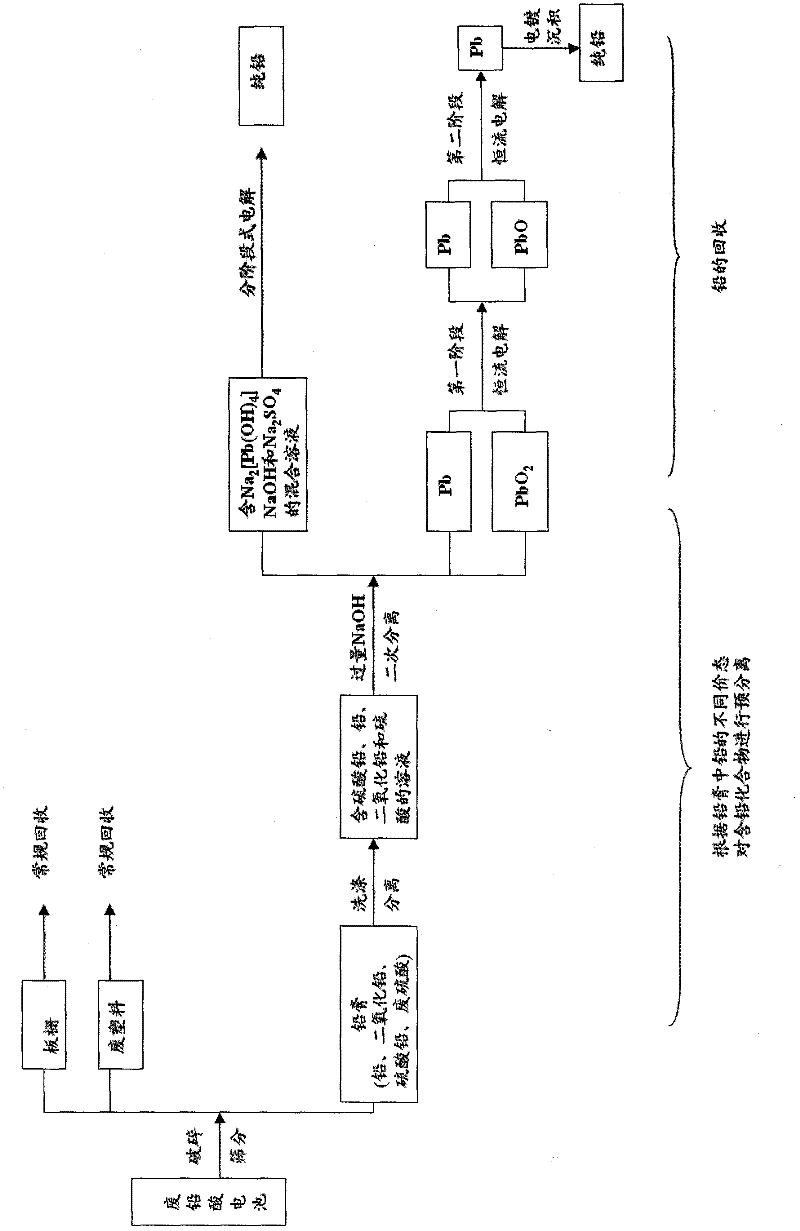

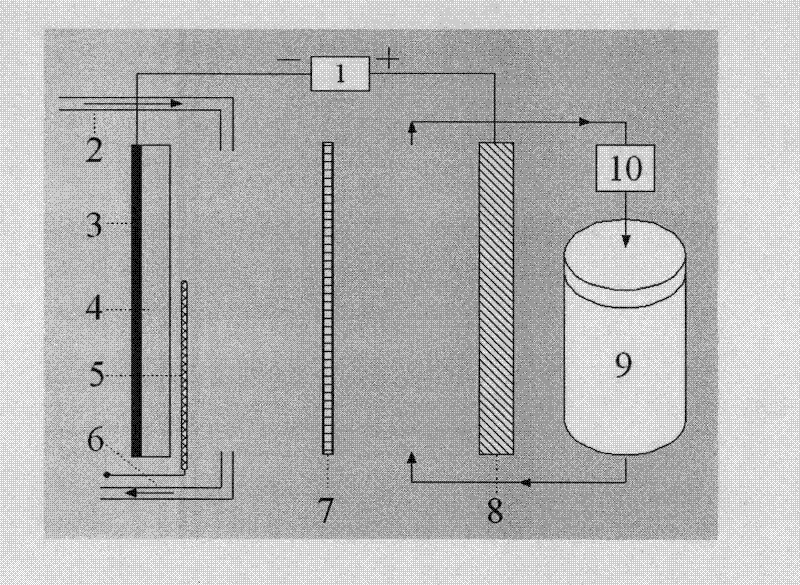

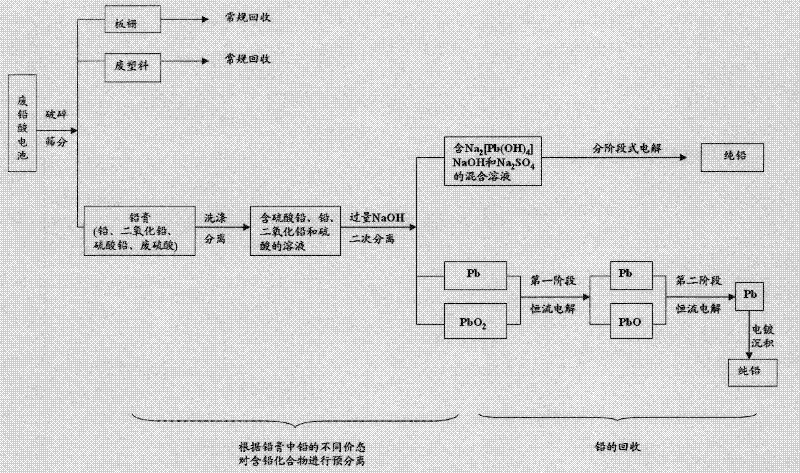

Combined method for electrolyzing and recovering lead

ActiveCN102367578AReduce consumptionMeet the requirements of industrializationPhotography auxillary processesProcess efficiency improvementElectricityElectrolysis

The invention provides a method for electrolyzing and recovering lead from lead plaster, which comprises the following steps: 1) washing the lead plaster by deionized water and performing solid-liquid separation to obtain a mixture of lead sulphate, lead and lead dioxide as well as a dilute sulphuric acid solution; 2) reacting the solution and excessive NaOH solution, and performing a second solid-liquid separation to obtain a mixed solution containing Na2[Pb(OH)4] and sodium hydroxide, and a solid mixture containing Pb and PbO2; 3) performing phase-divided electrolysis containing a constant current electrolytic phase and a constant voltage electrolytic phase to the mixed solution composed of Na2[Pb(OH)4] and sodium hydroxide in an ion-exchange membrane electrolyzer for recovering pure lead; and 4) electrolyzing a mixture of lead and lead dioxide by constant current controlled by using two-phase voltage, and combining electrolytic deposition to recover pure lead. The combined method for electrolyzing and recovering lead is capable of substantially minimizing the recovery of reducing agent, alkaline matter and lead consumed by electric energy, and raising purity of the recovered lead.

Owner:BEIJING UNIV OF CHEM TECH

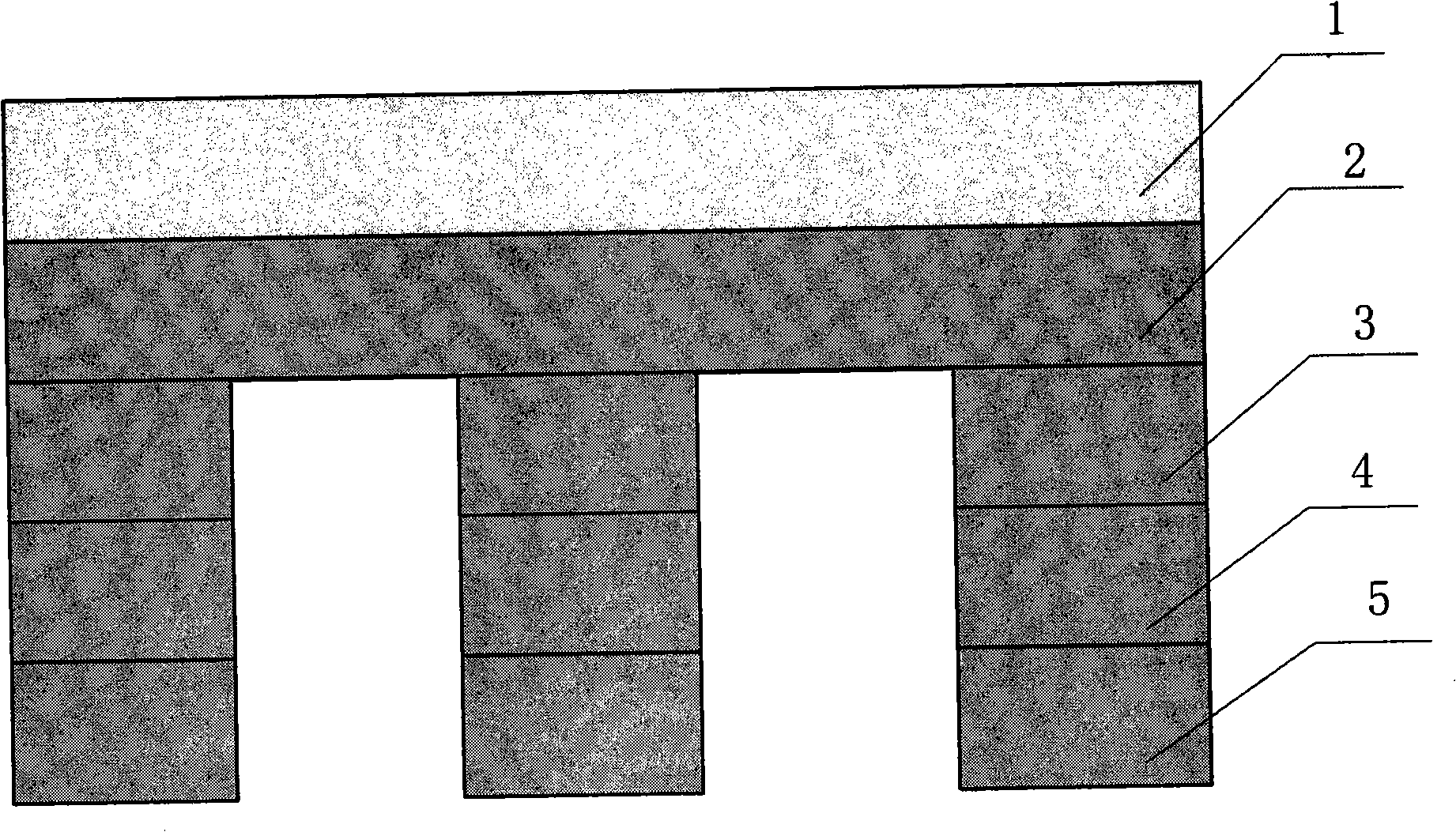

Multi-storey and high-rise steel structure house integrated system with pillars and walls in equal thickness

InactiveCN104481170AReduce labor intensityReduce transport volumeHeat proofingSound proofingThermal insulationEngineering

The invention relates to a multi-storey and high-rise steel structure house integrated system with pillars and walls in equal thickness. According to a structural scheme of rectangular steel tube concrete pillars, a steel framework beam and a steel support adopted by the invention, an outer wall, a separating wall, a core tube wall and a firewall are arranged in the steel structure framework, and indoor partitioning walls are arranged in rooms; floors and stairs are arranged between each layer of the steel framework beams. The multi-storey and high-rise steel structure house integrated system with equal-thickness pillars and walls is characterized in that the width of the pillars is 180mm-200mm, an inner partition plate and a transverse partition plate are not arranged inside each pillar, and the width of an outer ring beam combined with each pillar is limited to be within 200mm; inner beams of the steel structure house adopt small steel beams; after fireproof paint and a screeding layer are sprayed, the beam width is controlled to be within the width of the partition walls, the wall plates adopt composite wall plates with good thermal insulation performance and good fireproof soundproof performance, and using area of a house is increased according to the thicknesses of the walls. The multi-storey and high-rise steel structure house integrated system with pillars and walls in equal thickness has the advantages of reasonable layout, low cost, high prefabricating efficiency, good anti-seismic performance and capacity of increasing the using area of the house.

Owner:HANG XIAO STEEL STRUCTURE (INNER MONGOLIA) CO LTD

Five-layer co-extruded fiber felt reinforced plastic composite board and manufacturing method thereof

InactiveCN103448337AChange in mechanical strengthMeet different functional needsLamination ancillary operationsSynthetic resin layered productsFiberWeather resistance

The invention relates to the field of film or sheet products produced by plastic or plastic state substance, in particular to a five-layer co-extruded fiber felt reinforced plastic composite board. The five-layer co-extruded fiber felt reinforced plastic composite board is composed of plastic layers and fiber felts and is characterized in that there are three plastic layers and two fiber felts, the three plastic layers are respectively arranged in parallel, the three plastic layers are respectively a top layer, an intermediate layer and a bottom layer, a layer of fiber felts is respectively lined between the top plastic layer and the intermediate plastic layer and between the intermediate plastic layer and the bottom plastic layer, and the plastic layer is prepared from any one of polypropylene, polyethylene and rigid polyvinyl chloride. The five-layer co-extruded fiber felt reinforced plastic composite board provided by the invention is high in strength, low in density, good in weather resistance and wide in range of application.

Owner:林世平

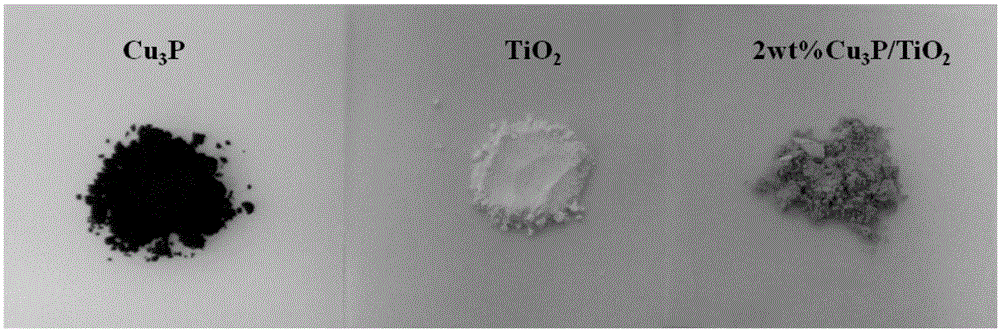

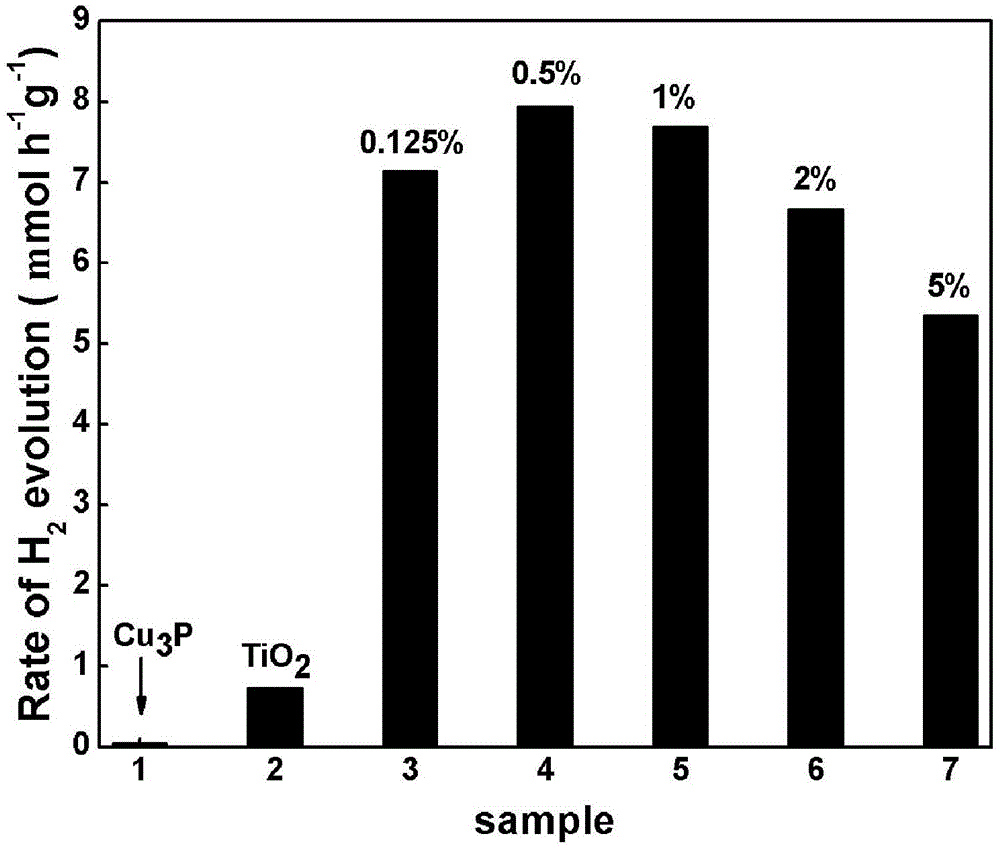

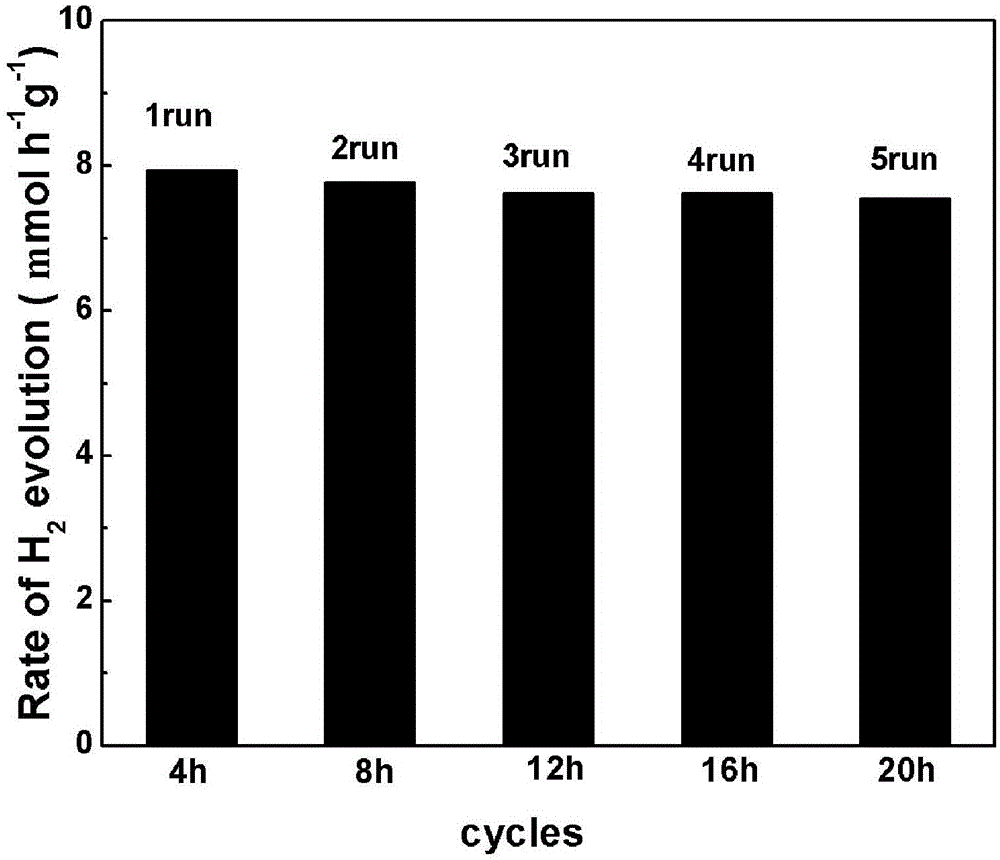

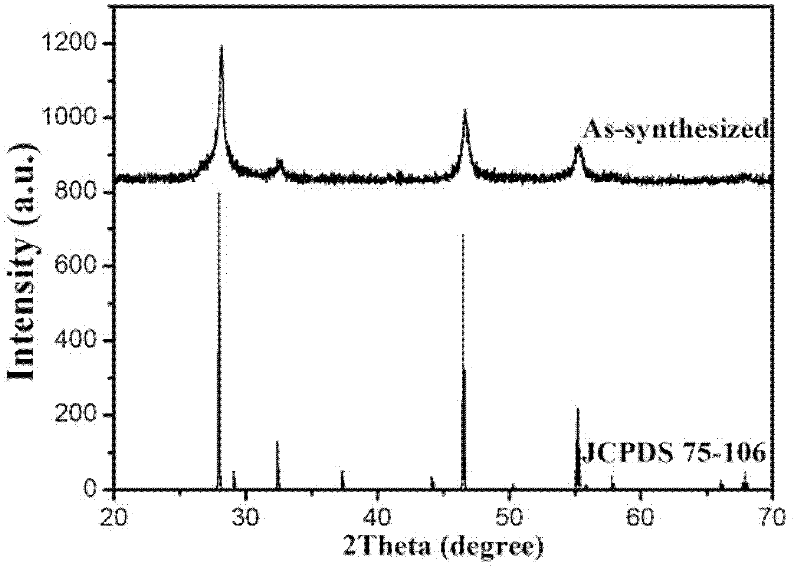

Efficient photocatalytic-water-splitting hydrogen production catalyst and preparation method thereof

ActiveCN105148956AAddress potential industrial applicabilityImprove performancePhysical/chemical process catalystsHydrogen productionNano catalystPhotocatalytic water splitting

The invention discloses a copper phosphide and titanium dioxide nanocrystalline compound-type photocatalytic-water-splitting hydrogen production catalyst and a preparation method thereof, and belongs to the technical field of nano-catalysts. The preparation method includes the steps that copper nitrate is prepared into copper hydroxide, copper hydroxide and sodium hypophosphite are calcined at certain temperature and under nitrogen protection, and then a product is rinsed, centrifuged and dried to obtain product copper phosphide; then, copper phosphide and anatase titanium dioxide nanocrystals are mixed and ground evenly to obtain the catalyst through preparation. The reaction rate of photocatalytic-water-splitting hydrogen production can be increased to 7.94 mmol h<-1>g<-1> from 0.74 mmol h<-1>g<-1> of pure titanium dioxide, and is increased by over 10 times. In this way, the catalyst is used as a new technological means for solving energy crisis, having potential industry applicability and producing environmentally-friendly novel energy.

Owner:JILIN UNIV

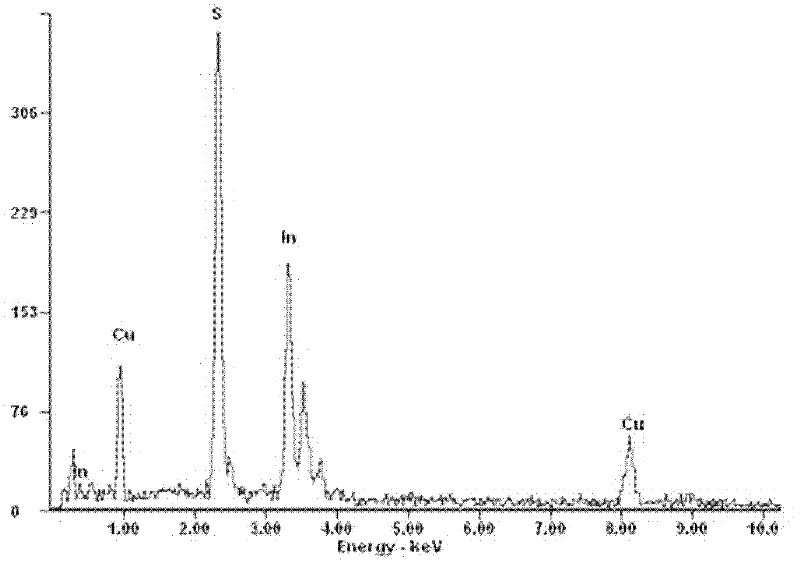

Method for preparing CuInS2 hollow solar absorbing material

The invention relates to a method for preparing a CuInS2 hollow solar absorbing material. According to the method, an indium source, a sulfur source and the like are taken as precursors, cuprous oxide with a specific morphology is taken as a self-sacrifice template and a copper source, and a CuInS2 hollow nanomaterial can be prepared through selecting appropriate solvents and surfactants and controlling a certain reacting temperature and reacting time. Compared with the prior art, the invention has the advantages that: the method is simple in operating steps, rapid in reaction, and low in cost and can meet the industrial requirements, and the prepared CuInS2 hollow nanomaterial can have good application on photocatalytic and solar photovoltaic cells.

Owner:SHANGHAI JIAO TONG UNIV

Construction method for non-prestressed centrifugal high-strength concrete pile planted pile

InactiveCN105421445AIncrease resistanceImprove pullout resistanceBulkheads/pilesHigh strength concreteSocial benefits

The invention provides a non-prestressed centrifugal high-strength concrete pile planted pile structure and a construction method thereof. The method comprises the construction steps that a pile planting machine is in place, the hole guiding operation is conducted, a bearing stratum is determined, base expansion is carried out, pile end cement paste is injected, pile periphery cement paste is injected and drill stems are pulled out, pile connection of pre-drilled holes is conducted, and non-prestressed centrifugal high-strength concrete piles are planted into pile holes. The pile planting construction method has the effects that damage to pile bodies is effectively reduced; the ductility of the pile bodies is improved more than 30%; the pile body cracking phenomenon is avoided; the whole performances of the pipe piles are improved more than 20%; the technique is simple, the cost is low and the cost performance is high; the centrifugal concrete piles which are high in vertical bearing capacity and horizontal pile foundation bearing capacity and capable of meeting the anti-seismic requirement can penetrate through a hard middle layer and a thick solidified layer and can be widely applied to foundation construction of various soil textures; it is ensured that the requirement of housing industrialization for quality is met; the pile planting construction method has good social benefits and popularization value.

Owner:TIANJIN JIANCHENGJIYE GRP

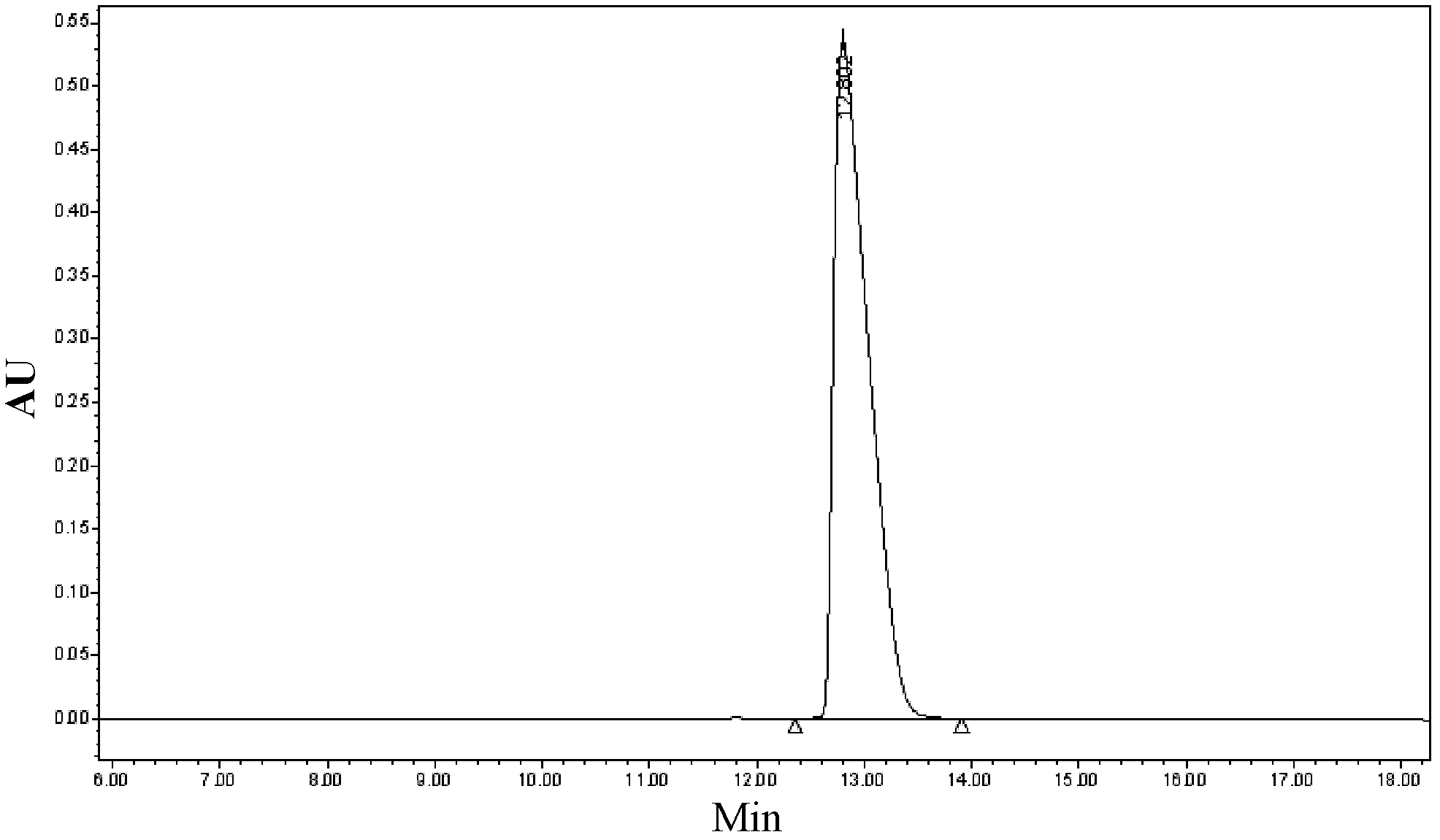

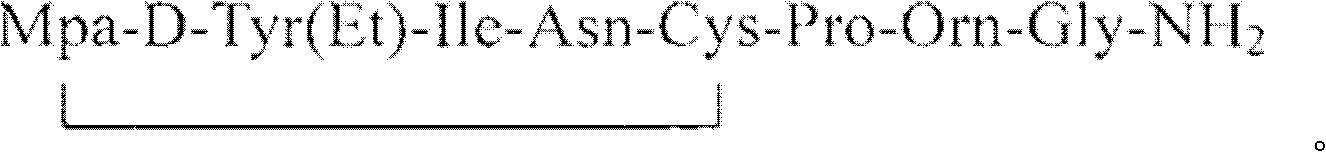

Cetrorelix purification and separation method

InactiveCN107312073AEfficient separationHigh yieldLuteinising hormone-releasing hormonePeptide preparation methodsFreeze-dryingEvaporation

The invention discloses a cetrorelix purification and separation method. The method includes steps: dissolving a crude product of cetrorelix in acetonitrile water solution, and filtering through a filter membrane to obtain crude solution for standby application; adopting a mobile phase A for balancing a reversed phase column, loading the crude solution into the reversed phase column, performing gradient eluting for separation and purification, wherein the mobile phase A refers to sodium dihydrogen phosphate aqueous solution, and a mobile phase B refers to acetonitrile; subjecting target peptide solution with purity higher than 99.5% to vacuum rotary evaporation and concentration at a water temperature not higher than 38 DEG C; adopting acetic acid aqueous solution for balancing the reversed phase column, loading a sample of concentrated liquid into the reversed phase column, and adopting an acetic acid aqueous solution / acetonitrile system for salt conversion; subjecting the converted acetate and the target peptide solution with purity higher than 99.5% to vacuum rotary evaporation and concentration at a water temperature not higher than 38 DEG C, and performing freeze drying to obtain powdery cetrorelix. The obtained cetrorelix is high in purity and yield, meets industrial production requirements and has a high economic value and a promising application prospect.

Owner:ZHEJIANG PEPTITES BIOTECH CO LTD

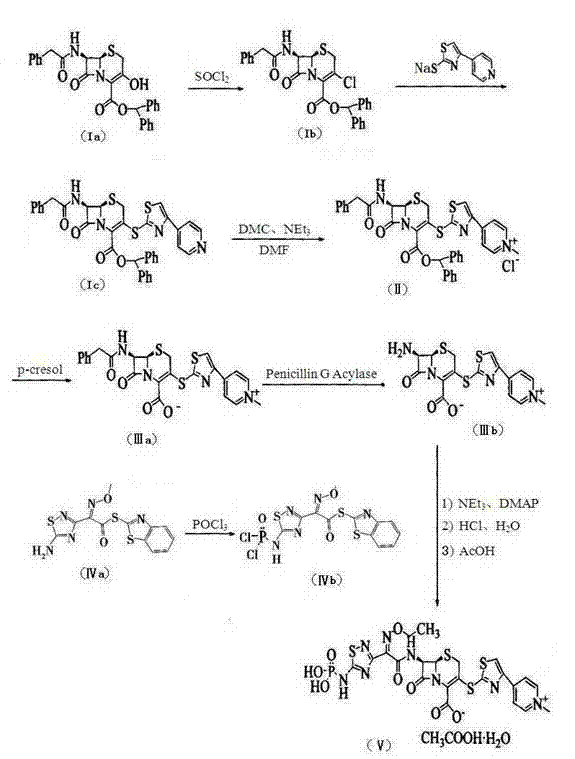

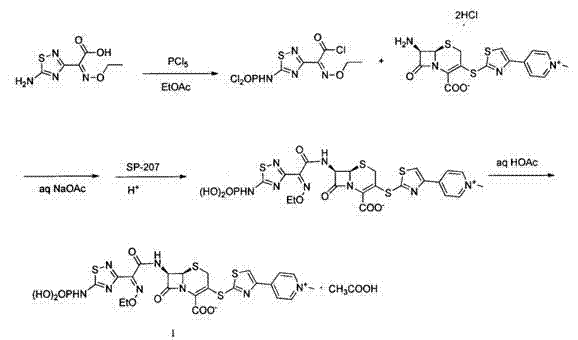

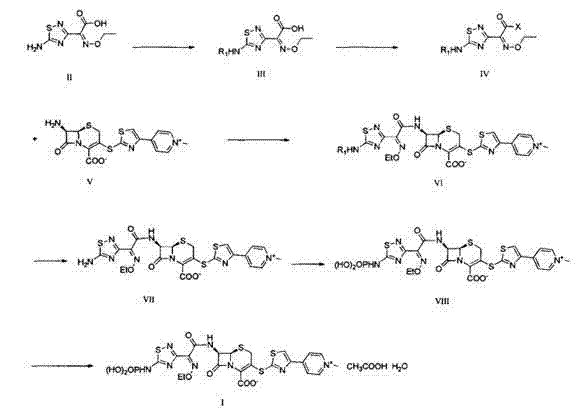

Preparation method for ceftaroline fosamil

ActiveCN104725425AMild reaction conditionsLess side effectsGroup 5/15 element organic compoundsBulk chemical productionCarboxylic groupG penicillin

The invention relates to a synthetic method for ceftaroline fosamil. According to the synthetic method, 7-phenylacetamide-3-hydroxy-3-cephalosporin-4-carboxylate-diphenylmethyl is selected as a raw material to be chloridized and reacts with 4-(4-pyridyl)-1,3-thiazole-2-thiol sodium salt at a C-3 site to obtain a thioether compound, p-cresol and immobilized penicillinase are adopted for removing carboxyl and amino protecting groups respectively, the thioether compound and the acylated AE-active ester are subjected to C-7 site condensation reaction, and crystallization in acetic acid is performed after hydrolyzation to prepare the ceftaroline fosamil successfully. The preparation method has the advantages that use of toxic and harmful substances such as trifluoroacetic acid and phosphorus pentachloride is avoided, reaction conditions are moderate, side reactions are few, technology is simple, yield and product purity are high, cost is low, raw materials are cheap and easy to obtain, and the preparation method is applicable to industrial production.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD

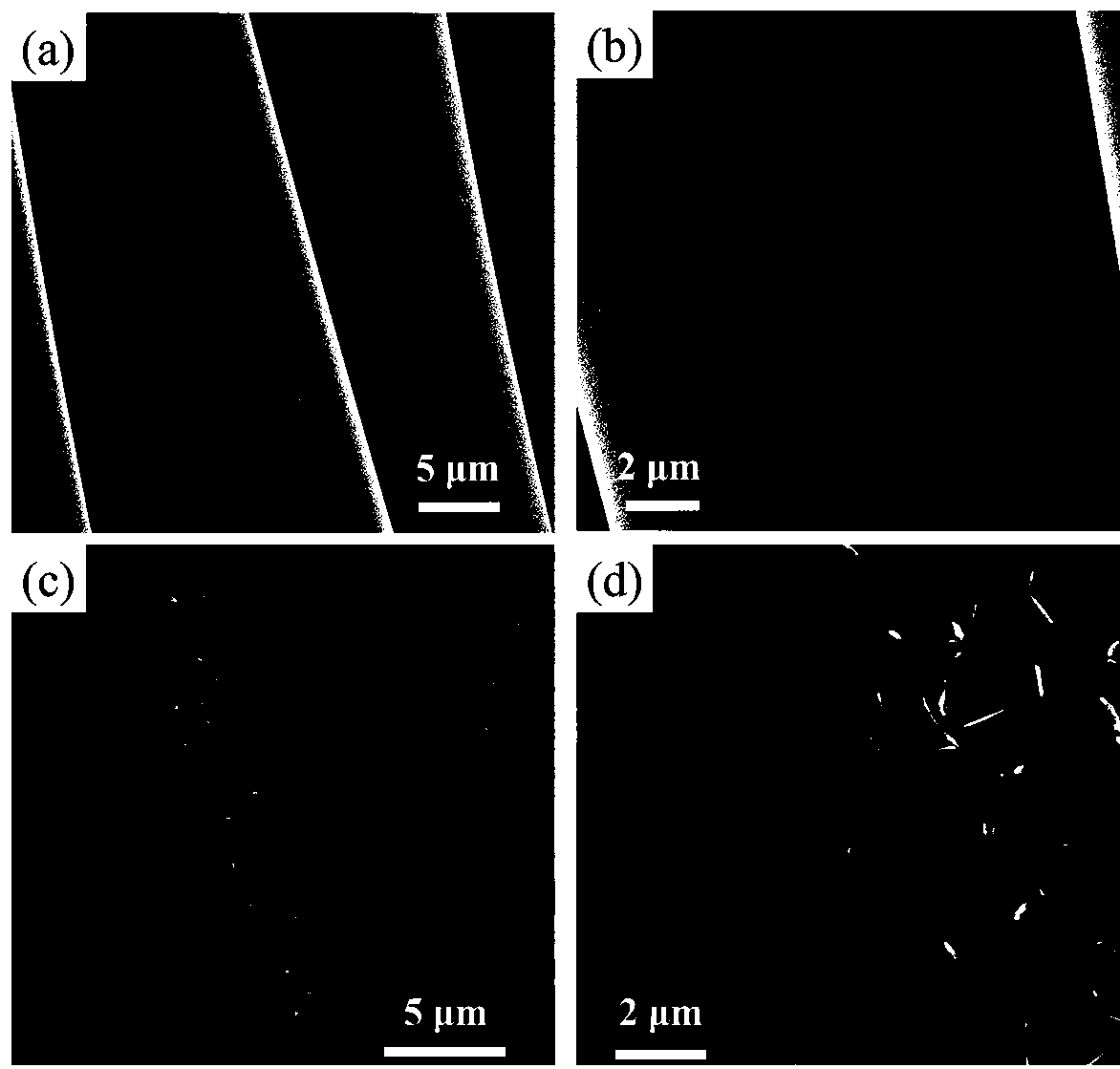

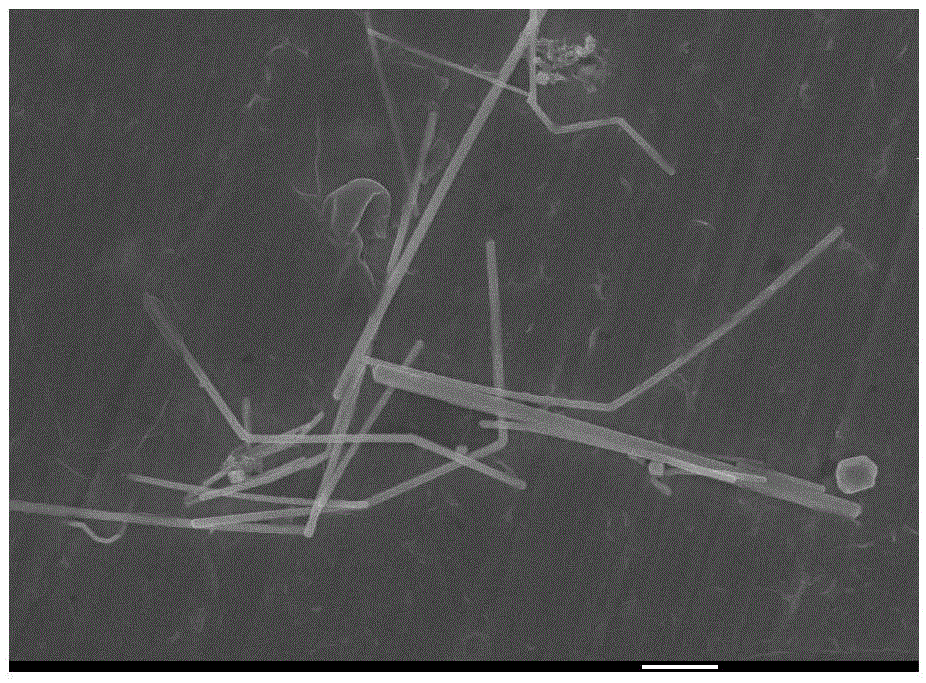

A method of preparing a polyaniline/silver nanometer material by a cladding manner

The invention relates to a method of preparing a polyaniline / silver nanometer material by a cladding manner. The method includes (1) a step of preparing silver nanowires by adopting a polyol manner, and (2) a step of preparing the polyaniline / silver nano-material by an in-situ cladding manner, namely a step of mixing the silver nanowires with absolute alcohol, stirring, adding the mixture into a reactor, adding aniline, sodium dodecylbenzenesulfonate and hydrochloric acid, stirring at room temperature for 30-60 min, adding ammonium persulfate, stirring for 60-240 min, and subjecting a product to separation and purification to obtain the polyaniline / silver nanometer composite material. The doped polyaniline / silver nanometer composite material is prepared through the cladding manner by adopting a step-by-step reaction manner, thus improving electrical conductivity of the material and facilitating control of the cladding amount of the silver nanowires and morphology of the composite material. In addition, doped inorganic and organic acids facilitate improvement of water solubility and electrical conductivity of the composite material. The method allows the product to be good in electrical conductivity and water solubility and to meet industrialization requirements of the material and is beneficial to industrialization and application of the material.

Owner:WENZHOU UNIVERSITY

Polyurethane paint applied to woodworking and application thereof

InactiveCN102504682ANot easy to yellowSolve yellowingPolyurea/polyurethane coatingsOrganic solventKetone solvents

The invention discloses polyurethane paint applied to woodworking and application thereof. The polyurethane paint is used for preventing a paint film of conventional polyurethane paint sprayed on a bleached wooden ware from being yellowed. The polyurethane paint consists of components A, B and C. When the polyurethane paint is in use, the components A, B and C are mixed according to a certain ratio. The component A consists of 30 to 70 percent of hydroxy-containing alkyd resin or acrylic resin, 29 to 45 percent of organic solvent, 1 to 7 percent of zinc stearate and 0 to 18 percent of talcum powder; the component B consists of 20 to 80 percent of isocyanate curing agent and 20 to 80 percent of esters solvent; and the component C is diluent and mainly consists of one or more of an esters solvent, an arene solvent or a ketones solvent. The polyurethane primer is used on a high-end bleached furniture, is used as a primer of the bleached wooden ware and can be used for ensuring the paint film of the conventional polyurethane paint sprayed on a bleached wooden ware not to be yellowed.

Owner:GUANGDONG LANYANG SCI & TECH

Purification method for atosiban

ActiveCN102584953AHigh purityEasy to operateOxytocins/vasopressinsPeptide preparation methodsPurification methodsAtosiban

The invention belongs to the technical field of pharmaceutical chemistry, and discloses a purification method for atosiban. The purification method comprises the following steps of: treating atosiban coarse peptide solution by taking trivalent iron ion salt as a reducing agent; removing impurities which are not fully oxidized in the atosiban coarse peptide solution; purifying the atosiban coarse peptide solution by using high performance liquid chromatography; and converting atosiban perchlorate prepared through purification to prepare an atosiban pure product by using the high performance liquid chromatography. The purification method provided by the invention is easy and feasible to operate; the prepared atosiban pure peptide product has high purity; meanwhile, the yield of the atosiban pure peptide product prepared by the method is high; and over 1,000 g of the atosiban pure peptide product can be obtained in one batch and is sufficient to meet the industrial requirements.

Owner:HYBIO PHARMA

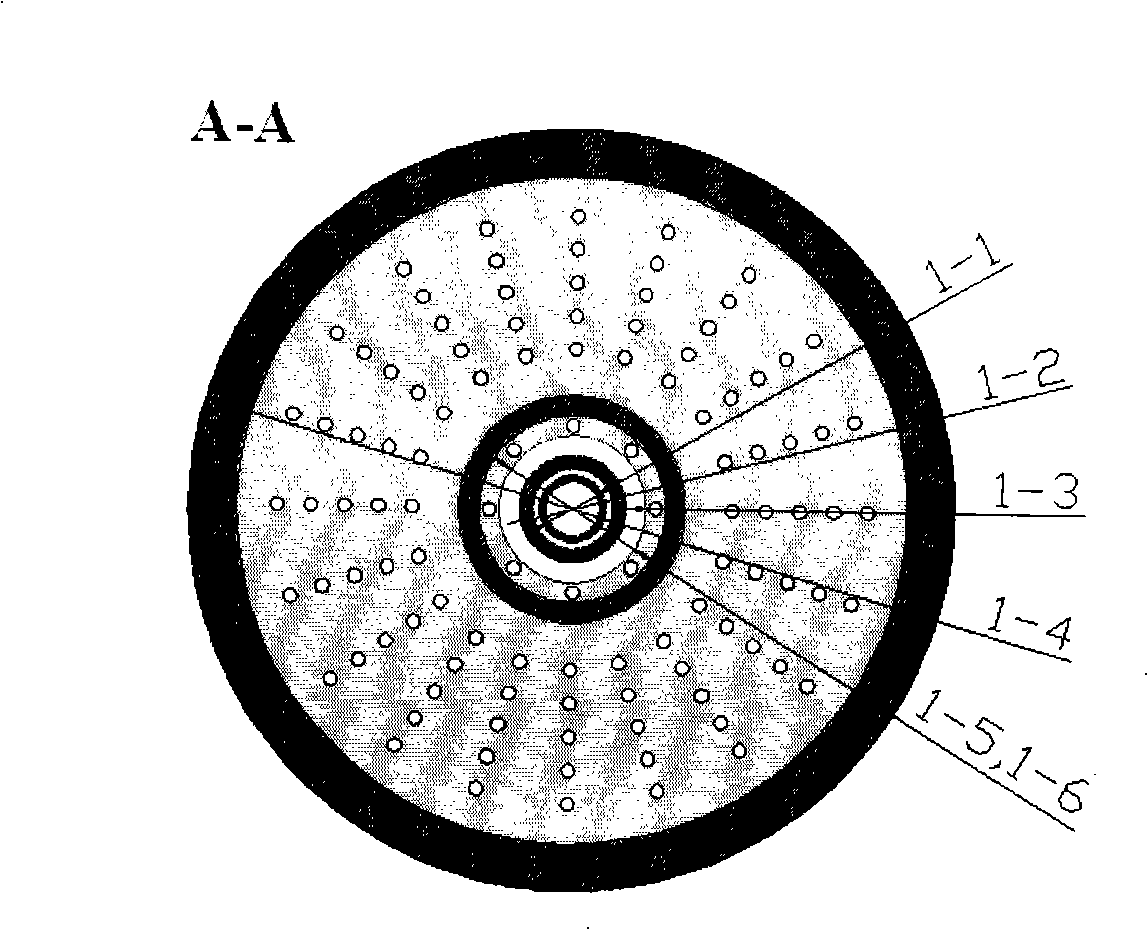

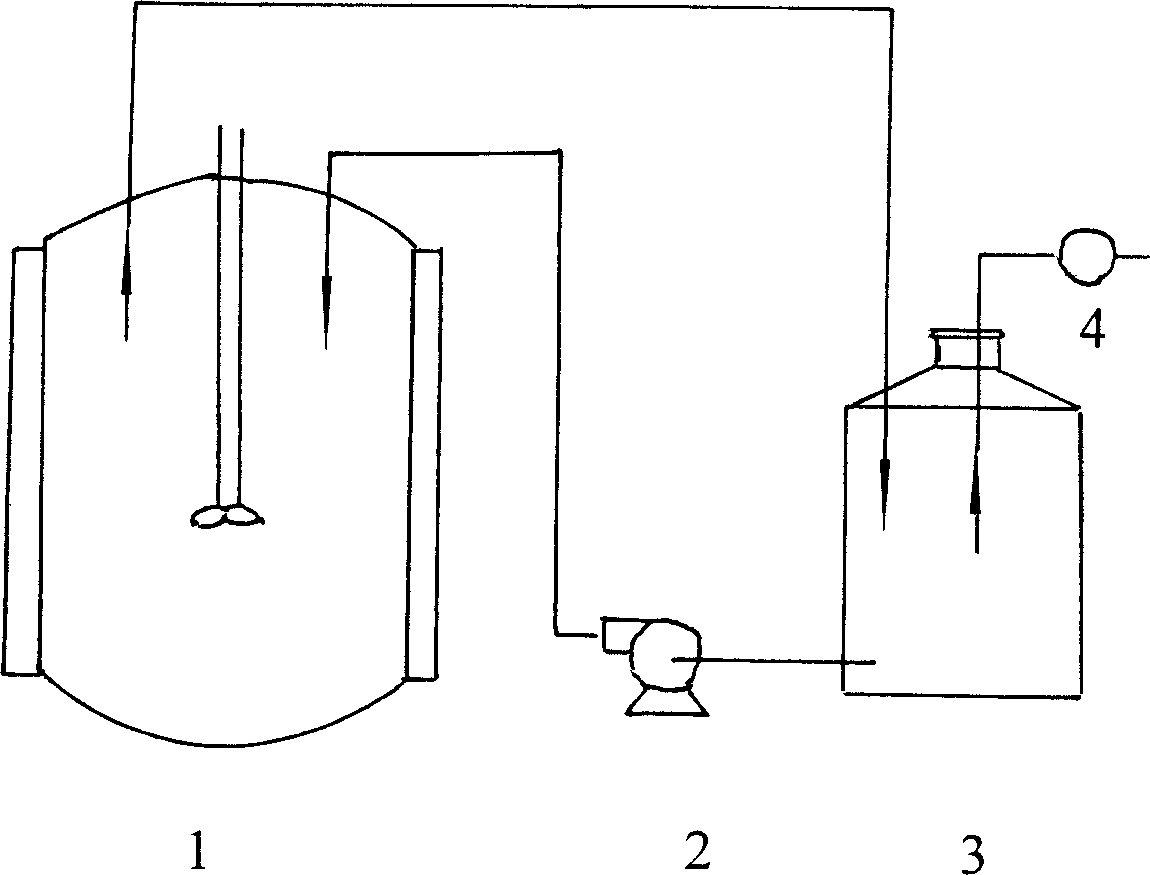

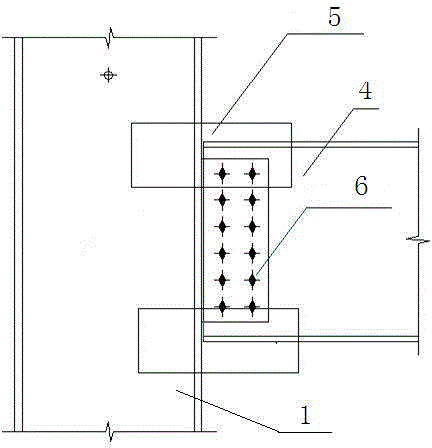

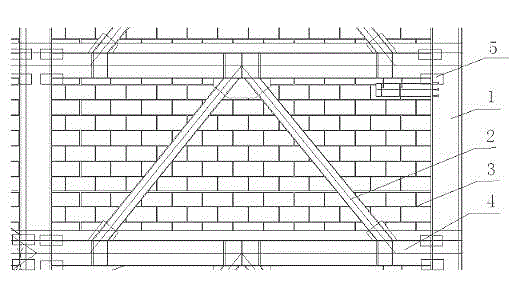

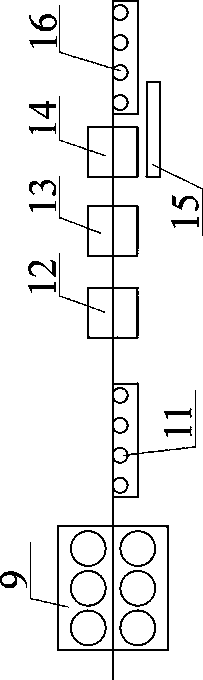

Method for preparing Na2[Pb(OH)4] solution and method for recycling lead from lead-containing waste

ActiveCN102367577AHigh lead recovery rateHigh purityPhotography auxillary processesProcess efficiency improvementScrapVoltage

A method for recycling lead from the lead-containing waste comprises the following steps of: converting the lead of the lead-containing waste to a Na2[Pb(OH)4] solution; injecting the Na2[Pb(OH)4] solution in the cathode chamber of an electrolytic cell, and introducing hydrogen gas and a NaOH solution in the anode chamber of the electrolytic cell; adjusting the voltage between the cathode and the anode to ensure that the electrolytic cell is always in a working state of continuous generation; and recycling lead at the cathode of the cathode chamber. A method for preparing the Na2[Pb(OH)4] solution comprises the following steps of: converting the lead and lead oxides of the lead-containing waste to lead sulfate; using the lead sulfate and an excess NaOH solution to react, generate Na2[Pb(OH)4] and obtain a mixed solution with Na2[Pb(OH)4] and NaOH; filtering the mixed solution at 40-115 DEG C; adding a little high purity PbO in the filtrate to ensure that the Na2[Pb(OH)4] of the solution is converted to PbO crystals; and separating out the PbO crystals, and dissolving the crystals in NaOH again to prepare the Na2[Pb(OH)4] solution. By adopting the methods, the power consumption can be obviously reduced and high purity lead can be recycled.

Owner:BEIJING UNIV OF CHEM TECH

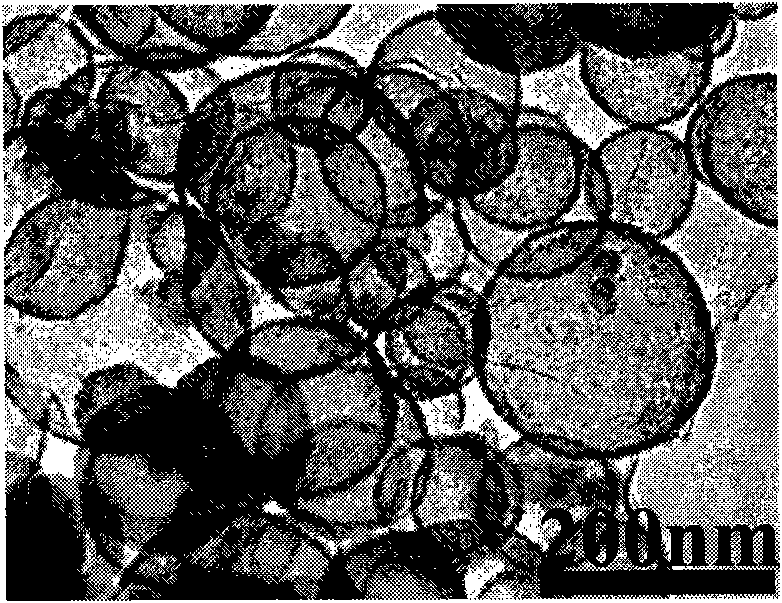

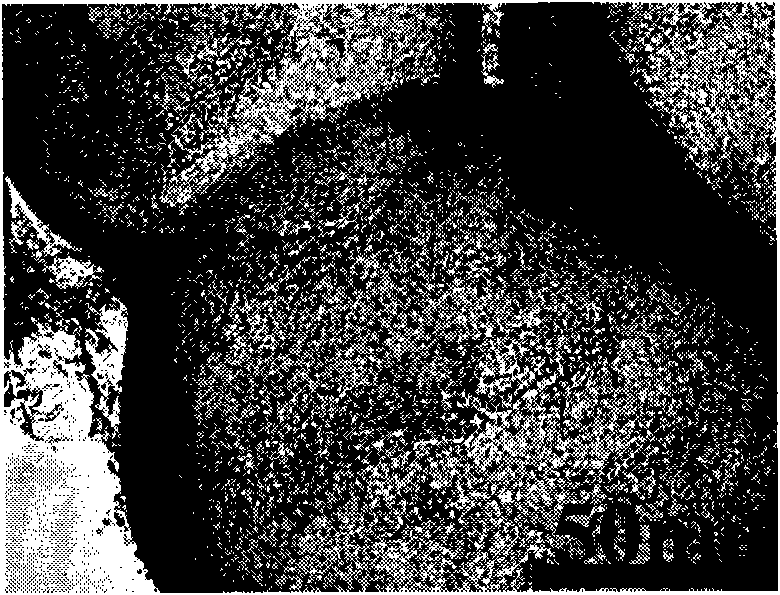

Method for preparing mesoscopic material with controllable appearance

InactiveCN101580244ANo pollution in the processSimple processSemi-permeable membranesSilicaNanoparticleEngineering

The invention discloses a method and a special device for preparing a mesoscopic material with a controllable appearance. The device comprises three sleeved pipes, i.e. an inter gas pipe, an outer gas pipe and a liquid inlet pipe and further comprises a solidified channel, wherein the inner gas pipe is positioned in the cavity of the liquid inlet pipe; and the liquid inlet pipe is positioned in the cavity of the outer gas. The method for preparing a mesoscopic material with a controllable appearance comprises the following steps: (1) adding foaming surface active agent into water, uniformly stirring, adding shell preformed polymer, uniformly stirring and reacting to obtain a precursor solution; and (2) injecting the precursor solution into the liquid inlet pipe of the special device to generate air bubbles at the air outlet of the inner gas pipe, frothing by the outer gas pipe, and solidifying the bubbles. Continuous preparation of hollow microballoon spheres, nano-plates and nano-granules can be realized through adjusting the airflow speed of frothing. The method can continuously prepare the mesoscopic material in large scale in one step, has strong controllability for the shape and the function of the material, simple and convenient process, no environment pollution, low production cost and wide application range and can fully satisfy the industrial requirement.

Owner:INST OF CHEM CHINESE ACAD OF SCI

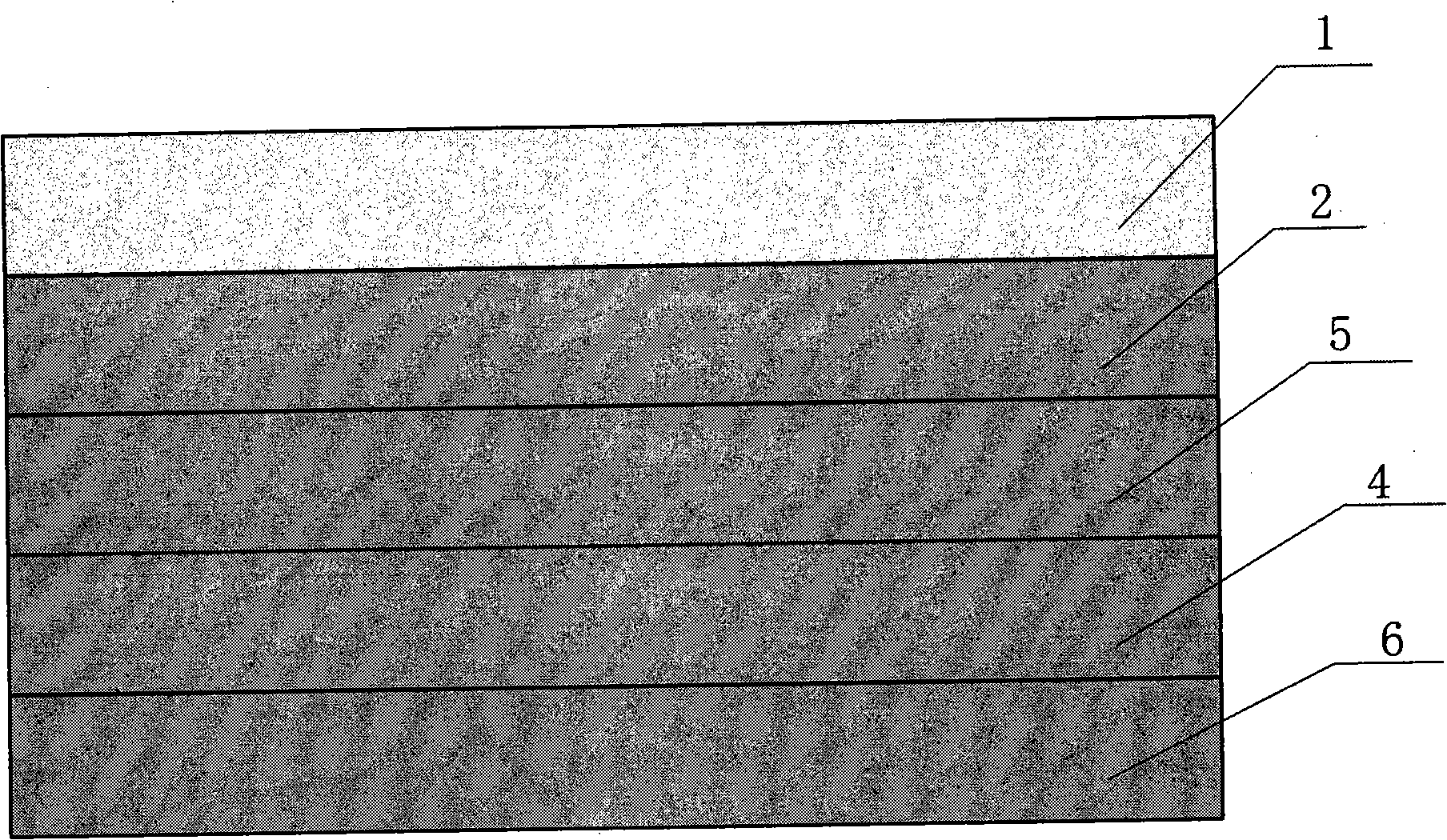

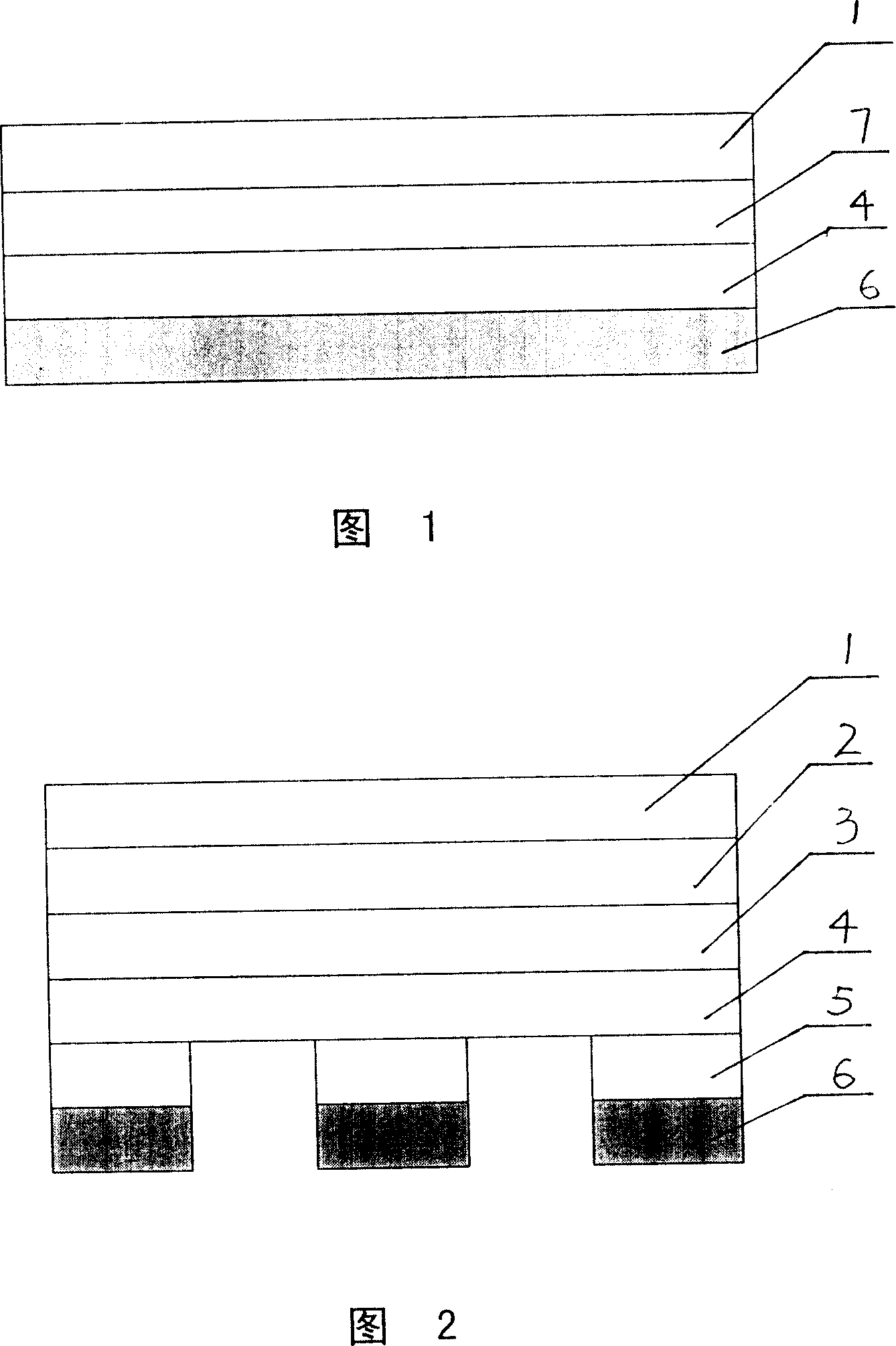

Transfer printing film capable of printing

InactiveCN101327699AIncrease elasticityImprove adhesion fastnessLayered productsDecorative surface effectsEngineeringHot melt

The invention discloses a printable transfer film which comprises a transfer carrier film (1), a release layer (2) and a thermal welding layer (5). The printable transfer film also comprises a printable layer (6). The transfer carrier film (1) is totally covered with the release layer (2) which is totally covered with the thermal welding layer (5). The thermal welding layer (5) is totally covered with the printable layer (6). A background layer (4) is clipped between the printable layer (6) and the thermal welding layer (5) and is characterized in that the printable layer (6) and the background layer (4) can be integrated into one through changing the resin polarity of the background layer (4) and adding printable auxiliary agent.

Owner:王兆进

Preparation method for cephalosporin anti-infective drug

ActiveCN105017286ASimple preparation processReduce generationOrganic chemistry7-ACACefazedone sodium

The invention relates to a preparation method for a cephalosporin anti-infective drug-cefazedone sodium, belonging to the field of pharmaceutical synthesis. According to the invention, the method uses GCLE as a raw material to substitute 7-ACA and overcomes the defects of low yield, high pollution and the like in prior art; the preparation method with mild reaction conditions, little side reaction and simple process is provided; meanwhile, the method has the advantages of cheap and easily-available raw materials, low cost, high product yield, high product purity and applicability to industrial production.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD

Method for producing 2-butenoic acid

ActiveCN101979371AWell mixedIncrease reaction pressureOrganic compound preparationChemical/physical/physico-chemical nozzle-type rreactors2 Butenoic AcidsOxygen

The invention provides a method for producing 2-butenoic acid, which comprises the following steps: preparing mixed feed liquid from 2-butenoic aldehyde, normal hexane and water in a weight ratio of 1:1:0.05-0.08; mounting an ejector pump on an oxidation reaction kettle for spraying the mixed feed liquid into the oxidation reaction kettle; introducing oxygen into the oxidation reaction kettle to perform a reaction under a condition that the reaction pressure in the oxidation reaction kettle is 0.1 to 0.6MPa and a condition that the temperature is 25 to 35 DEG C to obtain oxidation reaction solution; distilling the oxidation reaction, distilling the remaining 2-butenoic aldehyde under a reduced pressure, recovering the 2-butenoic aldehyde, distilling the remaining normal hexane at normal pressure and obtaining filtrate; and cooling the filtrate to -5 DEG C to 5 DEG C, precipitating, crystallizing and filtering and drying the crystals to obtain the 2-butenoic acid product. The production method has the advantages that: the reaction speed is high; the product yield is high; the energy consumption is small; and the quality of the product obtained is high.

Owner:HENAN ZAITI BIO TECH

Binary nano composite photo-catalyst preparation method

InactiveCN101306357ASmall particle sizeUniform precipitationCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsSpectral responseSurface coating

The invention relates to a method used for preparing a binary-nano composite photo-catalyst which takes titanium dioxide as the main body, and the prepared catalyst is applied to the organic wastewater treatment. The preparation method is characterized in that the supercritical fluid drying technology or the common chemical drying technology is combined with four preparation methods of the coprecipitation method, the successive precipitation method, the surface coating method and the mechanical mixing method to prepare the nano composite photo-catalyst which takes the titanium dioxide as the main body, thereby enlarging the range of the spectral response, enabling the absorption wavelength of the catalyst to be shifted toward the visual light wavelength, and improving the quantum effect.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of wetting selective oil-water separation membrane separated according to requirements

ActiveCN108837707ACause harmLow costMembranesSemi-permeable membranesAluminum IonEnvironmental resistance

The invention belongs to the technical field of chemical separation and relates to a preparation method of a wetting selective oil-water separation membrane separated according to requirements. The preparation method comprises the following steps: firstly, mixing an aluminate precursor and a pH regulator to form a solution, adding 8 to 12 ml of aluminum ion pH regulator mixed solution according toa porous basement membrane per square centimeter, carrying out hydrothermal reaction at the temperature of 150 to 200 DEG C for 12 to 24 hours, taking out a reactant, washing and carrying out vacuumdrying to obtain a precursor separation membrane with a hierarchical structure; carrying out high-temperature calcining to obtain a superhydrophilic / underwater super-oleophobic separation membrane with a hierarchical structure; then adding the superhydrophilic / underwater super-oleophobic separation membrane into a sodium laurate solution and carrying out modification reaction at the temperature of40 to 70 DEG C for 5 to 9 hours, and carrying out high-temperature calcining to obtain the superhydrophilic / underwater super-oleophobic separation membrane with the hierarchical structure; and carrying out repeated calcining and surface modification to obtain the wetting selective membrane according to the requirements. The preparation method disclosed by the invention has the advantages of simple process and low cost, solves the problems of poor selectivity, high possibility of pollution, low separation efficiency and the like of a traditional oil-water separation membrane are solved by utilizing surface superhydrophilic and super-hydrophobic characteristics under different conditions, and has a great application value in the fields of environment friendliness, chemical engineering and the like.

Owner:JIANGSU SAFELY ENVIRONMENT ENG

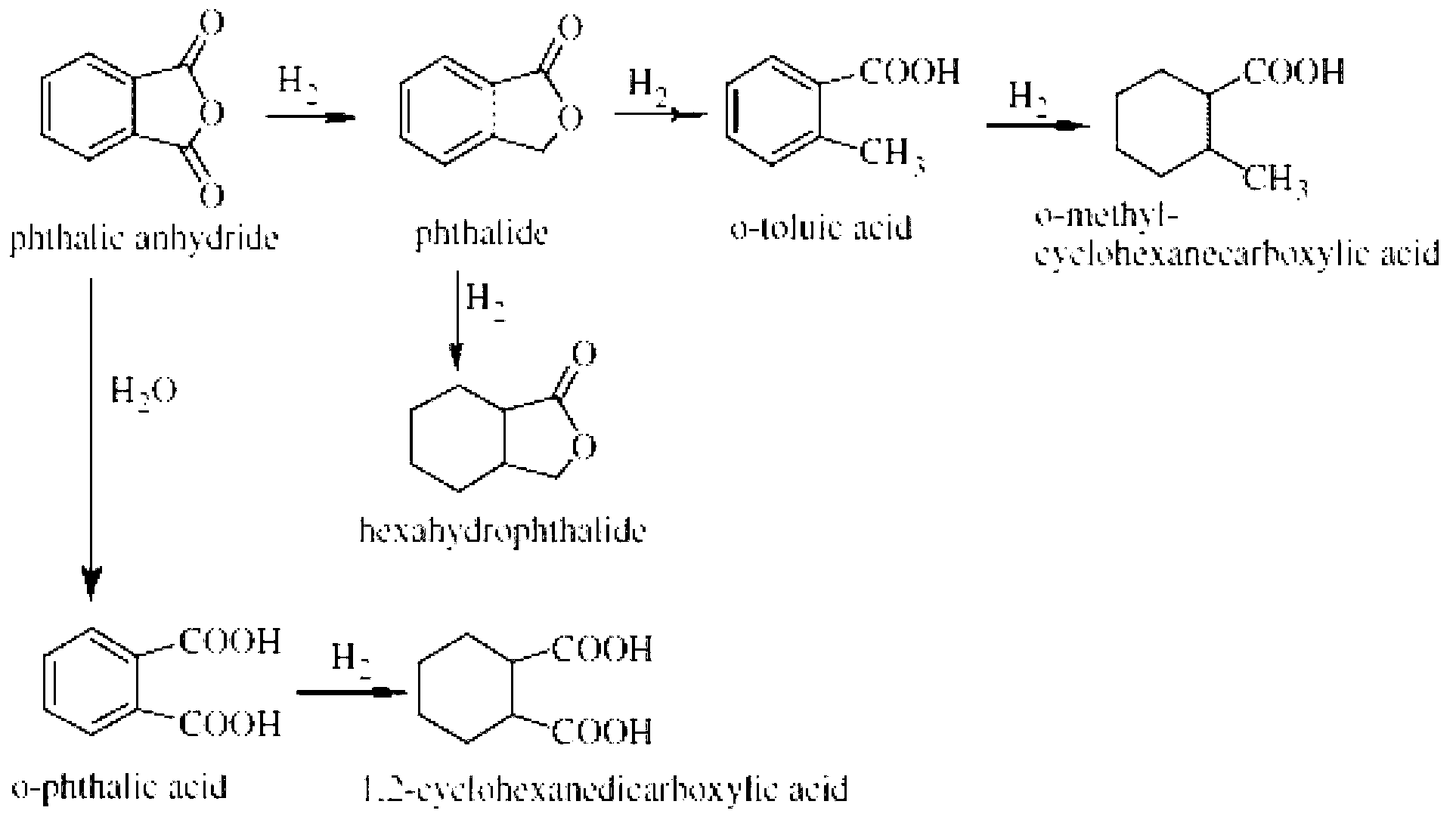

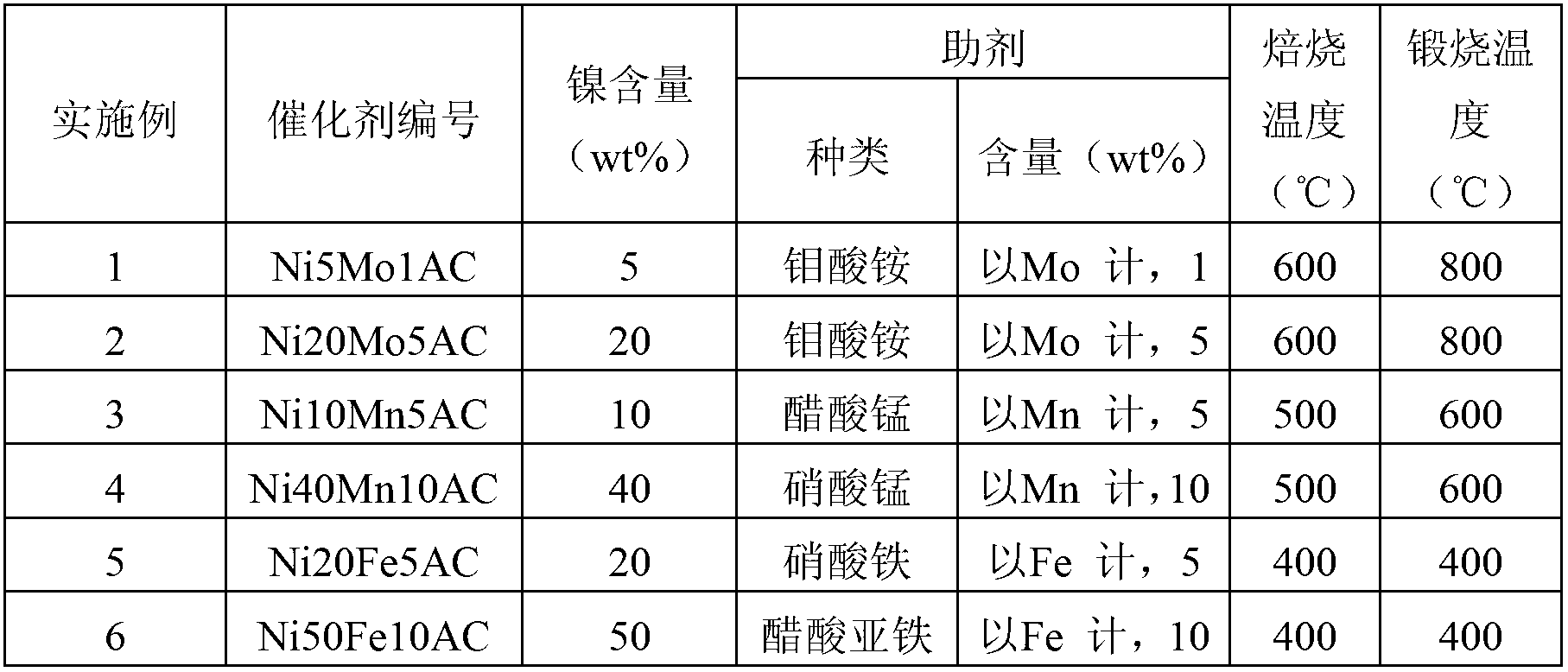

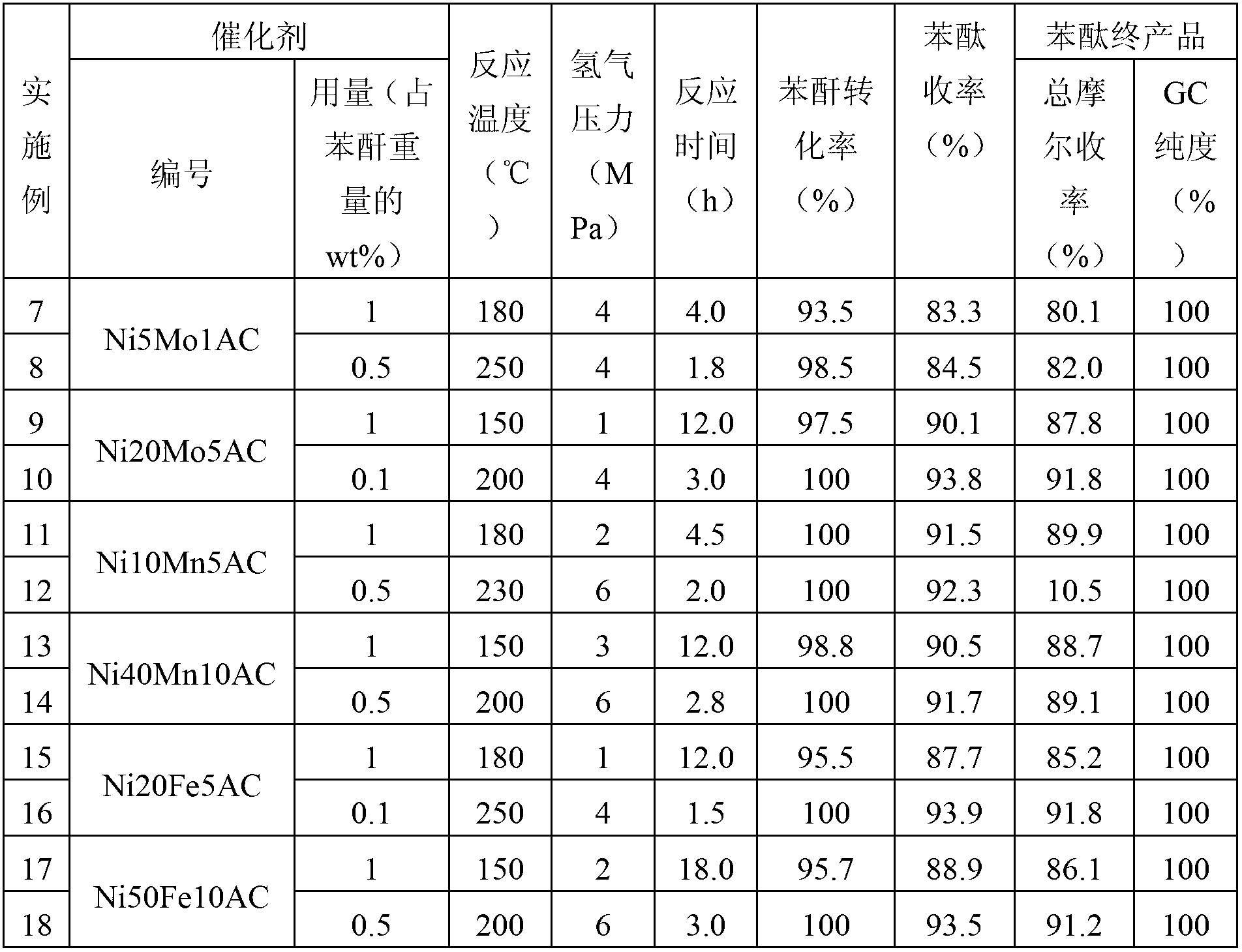

Supported nickel-based catalyst and its preparation method and use

InactiveCN103055883AReduce inactivationImprove conversion rateOrganic chemistryChemical recyclingManganese oxideBrown iron oxide

The invention discloses a supported nickel-based catalyst and its preparation method and use. The supported nickel-based catalyst adopts active carbon as a carrier and the carrier carries one or more assistants and one of nickel and a nickel oxide, wherein the one or more assistants are selected from elemental iron, elemental manganese, elemental molybdenum, iron oxides, manganese oxides, and molybdenum oxides. The supported nickel-based catalyst is prepared by a dipping method, is convenient for operation and has a low cost. In a phthalic anhydride hydrogenation reaction for preparation of phthalide, the supported nickel-based catalyst has an anti-acid activity, can be recycled 5-7 times, and has activity decay less than 7%. In a phthalic anhydride one-step catalytic hydrogenation reaction for preparation of phthalide, the supported nickel-based catalyst has a high catalytic activity and a phthalic anhydride conversion ratio of 93.5 to 100% and a phthalide yield of 83.3 to 93.9%. Therefore, the supported nickel-based catalyst is obviously superior to the prior art and has obvious effects.

Owner:ZHEJIANG UNIV

Method of purifying pramlintide

The invention discloses a method of purifying pramlintide, belonging to the technical field of HPLC and comprising the steps: 1) after a synthesized coarse peptide is dissolved, a fixed phase serving as reverse silica gel column and mobile phases trifluoroacetic acid aqueous solution as phase A and chromatogram pure acetonitrile as phase B, are used to carry out gradient elution and purification to collect peptide solution of target peak; 2) after the target peptide solution purified in the step 1) is concentrated, and the fixed phase as reverse silica gel column and mobile phases phosphate aqueous solution as phase A and chromatogram pure acetonitrile as phase B, are used to carry out gradient elution and purification to collect peptide solution of target peak; and 3) the phosphate is converted into acetate by anion exchange salt conversion method. The invention purifies pramlintide by the reverse phase high-efficiency liquid phase chromatography and anion exchange method, with high purity and good yield, and provides a process suitable for purifying pramlintide in bulk to reach the industrial requirement.

Owner:HYBIO PHARMA

Flocked transfer film and preparing method, and method for forming pattern on printed material thereof

InactiveCN1935536AFacilitate false adhesionStrong adhesionLiquid surface applicatorsDecorative surface effectsHot meltEngineering

The invention discloses a flock transfer membrane for textiles or leathers and the making method and the method of forming pattern on a printing carrier thereof. And it comprises transfer carrier membrane, nondrying glue layer, floss layer and hot melting adhesion layer, where the transfer carrier membrane is completely covered with the nondrying glue layer, the nondrying glue layer is completely covered with the floss layer, and the floss layer is completely covered with the hot melting adhesion layer. And it can simply implement individualized transfer of graphics and texts.

Owner:泰州悦然纸尚装饰材料有限公司

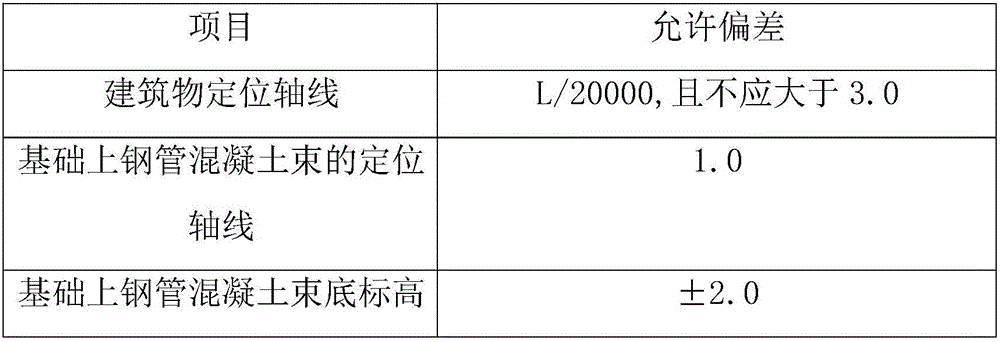

Installation method for multi-cavity steel column shear wall composite structure building system

The invention relates to a shear wall composite structure, in particular to an installation method for a multi-cavity steel column shear wall composite structure building system. The installation method comprises the following steps of 1, base and supporting surface setting, 2, installing and correcting, 3, multi-cavity steel column shear wall internal concrete engineering, and 4, completing and acceptance of parts of construction of a steel structure. According to the shear wall composite structure installation method, the structure is compact, usable areas are increased, and the quality is ensured.

Owner:潮峰钢构集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing Na2[Pb(OH)4] solution and method for recycling lead from lead-containing waste Method for preparing Na2[Pb(OH)4] solution and method for recycling lead from lead-containing waste](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d86af4f7-ef8a-4bf6-a79e-15377d271fd9/HSA00000585441200011.PNG)

![Method for preparing Na2[Pb(OH)4] solution and method for recycling lead from lead-containing waste Method for preparing Na2[Pb(OH)4] solution and method for recycling lead from lead-containing waste](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d86af4f7-ef8a-4bf6-a79e-15377d271fd9/HSA00000585441200021.PNG)

![Method for preparing Na2[Pb(OH)4] solution and method for recycling lead from lead-containing waste Method for preparing Na2[Pb(OH)4] solution and method for recycling lead from lead-containing waste](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d86af4f7-ef8a-4bf6-a79e-15377d271fd9/HSA00000585441200031.PNG)