Installation method for multi-cavity steel column shear wall composite structure building system

An installation method and technology of combined structure, applied in the processing of building materials, construction, building components, etc., can solve the problems of complex structure and poor performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] Embodiment 1: An installation method of a multi-cavity steel column shear wall composite structure building system is characterized in that it is carried out in the following steps:

[0111] (1) Setting of foundation and supporting surface:

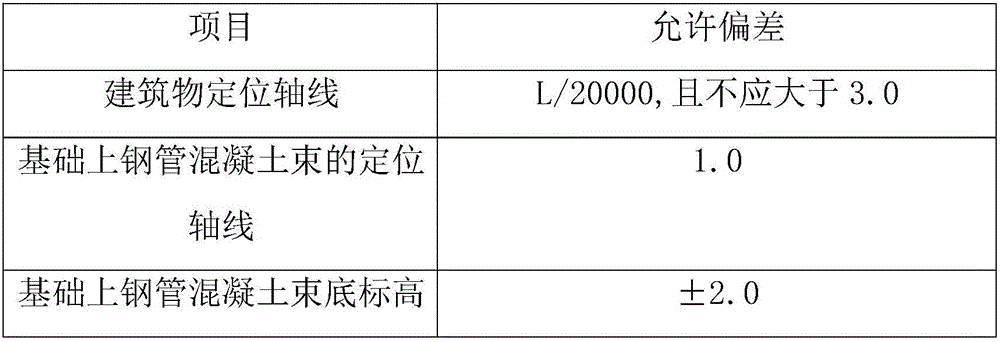

[0112] 1. The positioning axis of the building, the positioning axis and elevation of the multi-cavity steel column shear wall on the foundation shall meet the design requirements;

[0113] When there is no requirement in the design, it shall comply with the provisions in Table 1:

[0114] Inspection quantity: full inspection;

[0115] Inspection method: use theodolite, level, total station and steel ruler to measure;

[0116] Table 1 Allowable deviation of building positioning axis, positioning axis and elevation of the multi-cavity steel column shear wall on the foundation (mm)

[0117]

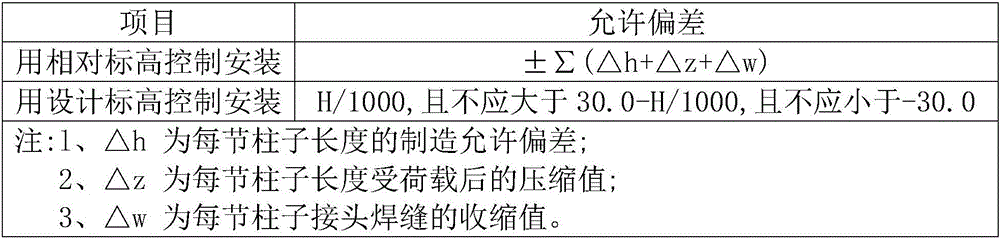

[0118]

[0119] 2. When the pre-embedded steel plate or support on the top surface of the foundation is used as the supporting surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com