Rhamnolipid crude extract prepared by fermenting food and rink waste oil and application thereof

A technology for rhamnolipid and catering waste oil, which is applied in the fields of fermentation, biological water/sewage treatment, water/sludge/sewage treatment, etc. The problem of high production cost, to achieve the effect of shortening the processing time, shortening the processing time, and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

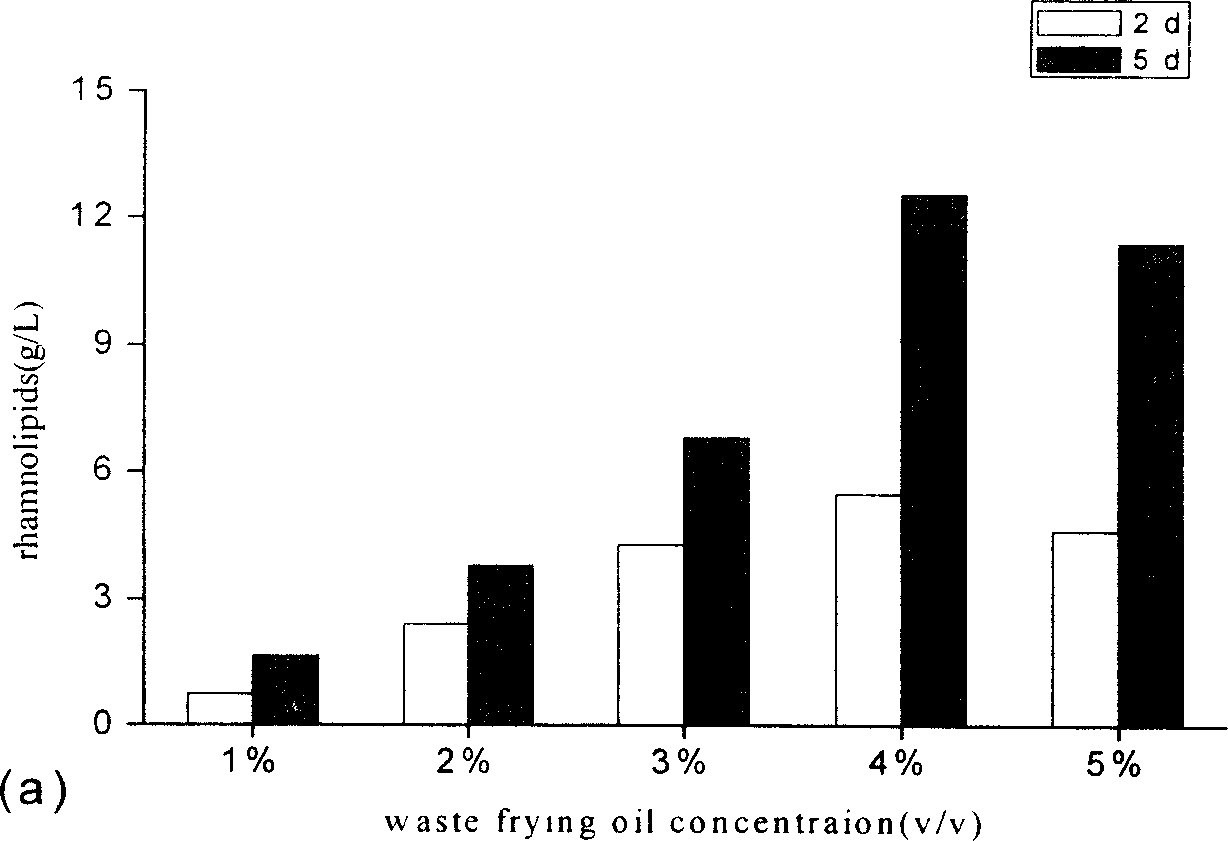

[0032] Embodiment 1: the shake flask culture of natural bacterial strain and mutagenized bacterial strain:

[0033] Divide the 50ml shake flasks into two batches of ten groups, add activated 3% ultraviolet mutagenized Pseudomonas aeruginosa ZJU. Bacteria; the non-mutated strain used was naturally screened from the soil of the refinery sewage outlet, and was confirmed to be Pseudomonas aeruginosa after testing its 16sRNA, and the ultraviolet mutagenic strain was based on this strain as the starting bacteria after 15W ultraviolet light The high-yield strain screened after 30 seconds of lamp irradiation was named Pseudomonas aeruginosaZJU.u1.

[0034] a. Medium composition (g / L): NaNO 3 , 4.0; NaCl, 1.0; KCl, 1.0; CaCl 2 2H 2 O, 0.1; KH 2 PO 4 , 3.0; Na 2 HPO 4 12H 2 O, 3.0; MgSO4, 0.2; FeSO 4 ·7H 2 O, 0.001; trace elements, 2mL / L, composition (g / L): FeCl 3 ·6H 2 O 0.08, ZnSO 4 ·7H 2 O 0.75, CuSO 4 ·5H 2 O 0.075, MnSO 4 ·H 2 O 0.75, H 3 BO 3 , 0.15;

[0035] ...

Embodiment 2

[0040] Embodiment 2: Preparation of rhamnolipid powdery crude product (1)

[0041] 1. Strain: the fermentation strain is Pseudomonas aeruginosa ZJU.U1 (Pseudomonas aeruginosa ZJU.u1)

[0042] 2. Place the strain in glycerin medium and activate it in a shaker for 48-72 hours to obtain a sufficient inoculum size for fermentation. The activation temperature is 36-37°C. The pH is controlled between 6.5-7.0, and the shaking time is 300rpm.

[0043] 3. The composition of the activation medium is as follows (g / L):

[0044] Glycerol, 30; NaNO 3 , 4.0; NaCl, 1.0; KCl, 1.0; CaCl 2 2H 2 O, 0.1; KH 2 PO 4 , 3.0; Na 2 HPO 4 12H 2 O, 3.0; MgSO 4 , 0.2; FeSO 4 ·7H 2 O, 0.001; trace elements, 2mL / L, composition (g / L): FeCl 3 ·6H 2 O 0.08, ZnSO 4 ·7H 2 O 0.75, CuSO 4 ·5H 2 O 0.075, MnSO 4 ·H 2 O 0.75, H 3 BO 3 , 0.15

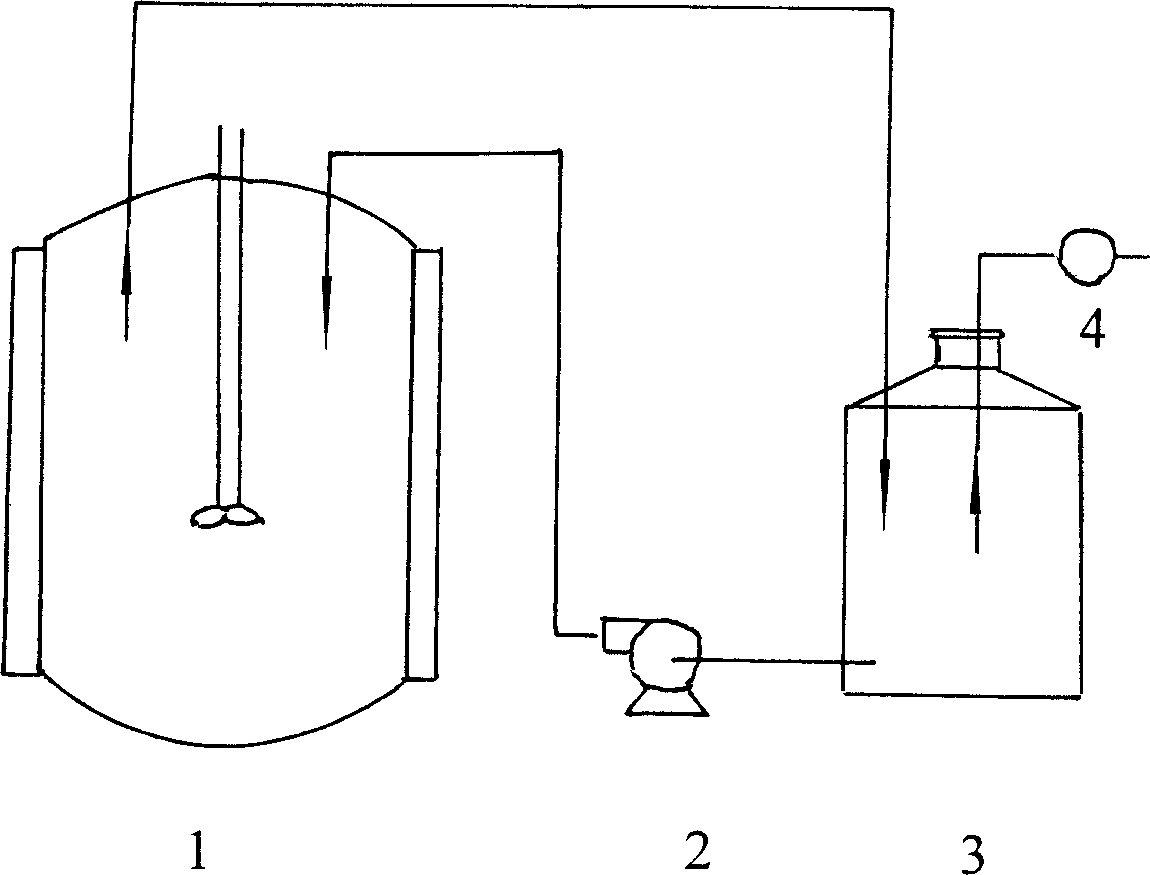

[0045] 4. Production of rhamnolipids in fermentation tanks

[0046] a. Medium composition (g / l): NaNO 3 , 5.0; NaCl, 1.0; KCl, 1.0; CaCl 2 2H 2 O, 0.0...

Embodiment 3

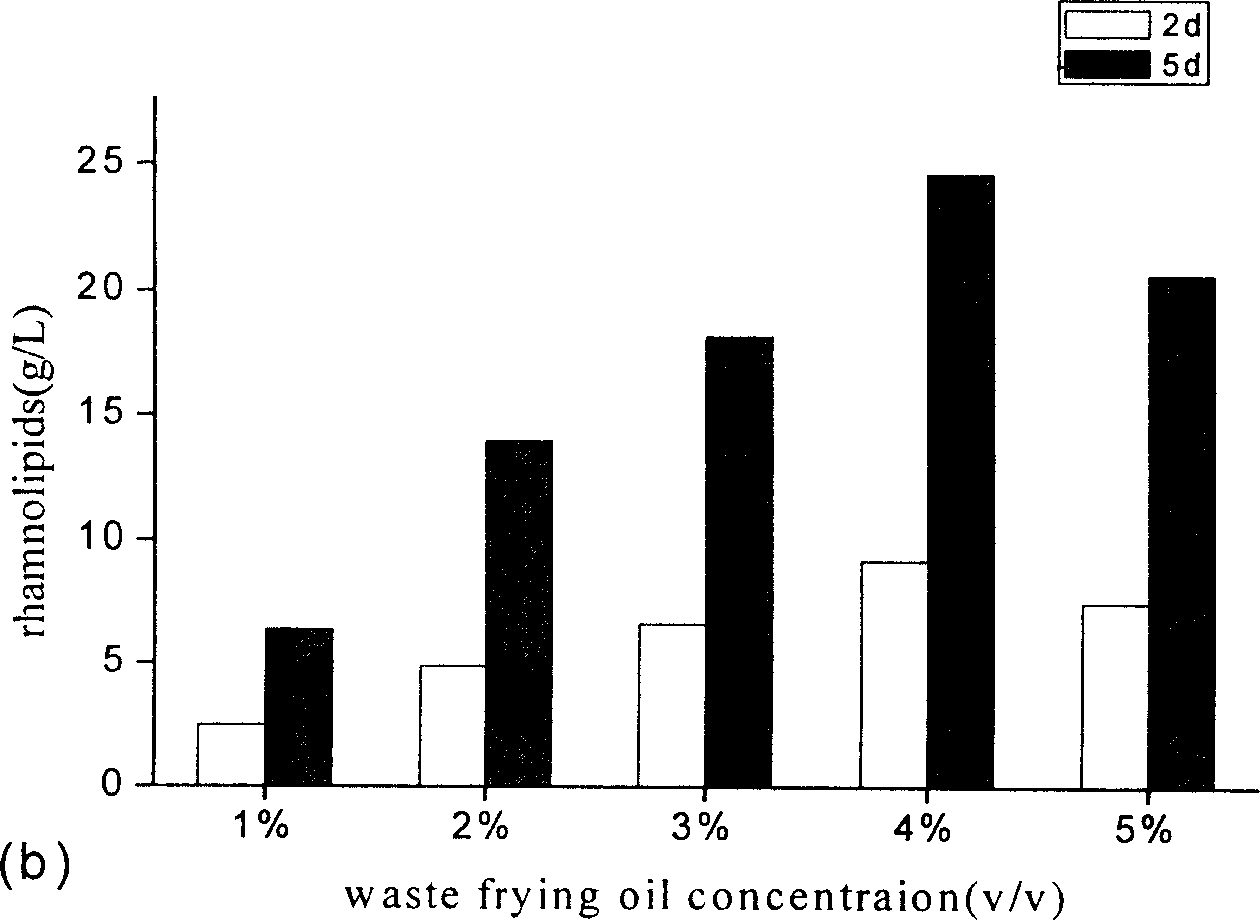

[0050] Embodiment 3: the preparation of rhamnolipid fermentation broth (two)

[0051] 1, bacterial classification: with embodiment 1

[0052] 2, activation: with embodiment 1

[0053] 3. Production of rhamnolipids in fermentation tanks

[0054] a. Medium composition (g / l): NaNO 3 , 2.0; NaCl, 5.0; KCl, 0.5; CaCl 2 2H 2 O, 0.03; KH 2 PO 4 , 2.0; Na 2 HPO 4 12H 2 O, 6.0; MgSO 4 , 0.05; FeSO 4 ·7H 2 O, 0.005; trace elements, 2mL / L, composition (g / L): FeCl 3 ·6H 2 O 0.08, ZnSO 4 ·7H 2 O 0.75, CuSO 4 ·5H 2 O 0.075, MnSO 4 ·H 2 O 0.75, H 3 BO 3 , 0.15.

[0055] b. Waste oil content 30g / L

[0056] c. Fermentation conditions: 72 hours later, the amount of waste catering oil added was 0.125Kg, and the rest of the conditions were the same as in Example 1; the filtrate was directly used as the crude product of the rhamnolipid solution.

[0057] d. Sterilization of fermentation broth and preparation of crude extract: remove bacteria by microfiltration of 0.22 micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com