Combined method for electrolyzing and recovering lead

A technology of electrolytic recovery and electrolytic method, which is applied in the field of electrolytic recovery of lead, can solve the problems of large power consumption, long time-consuming pre-oxidation and reduction reaction process, and large corrosiveness of equipment to achieve the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

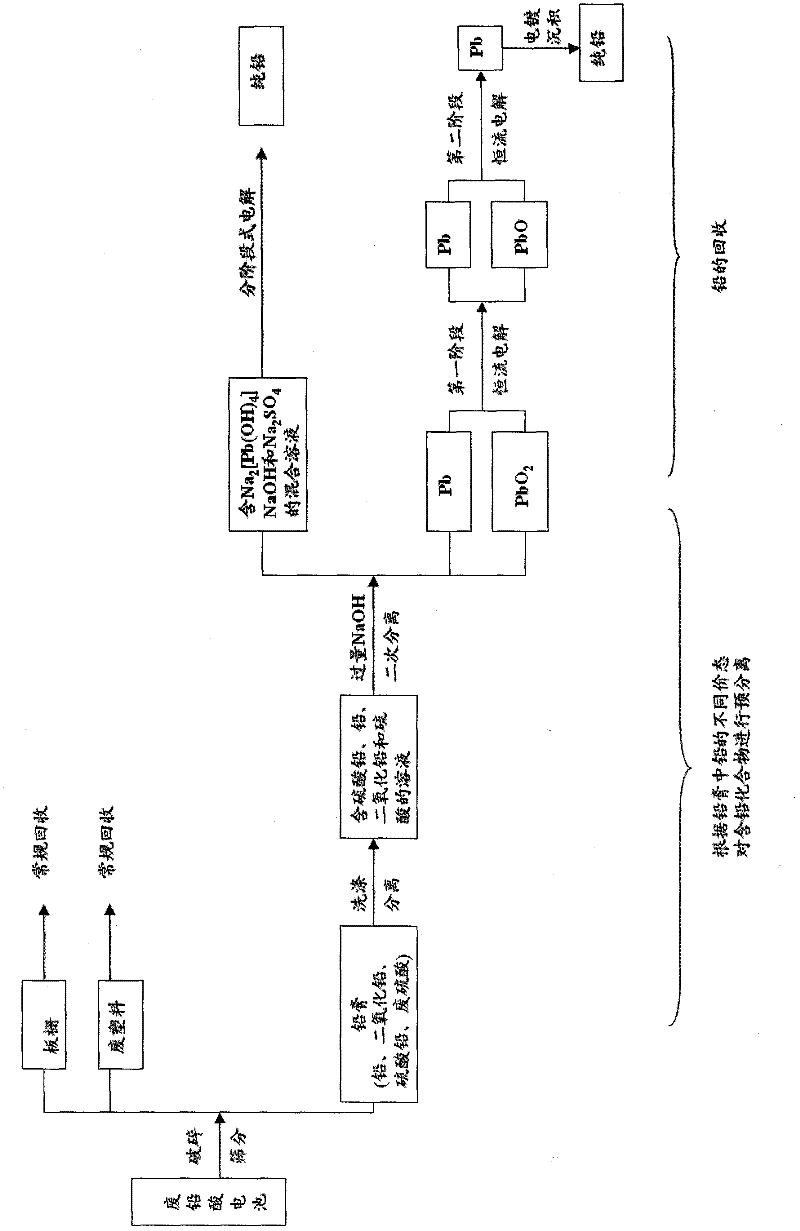

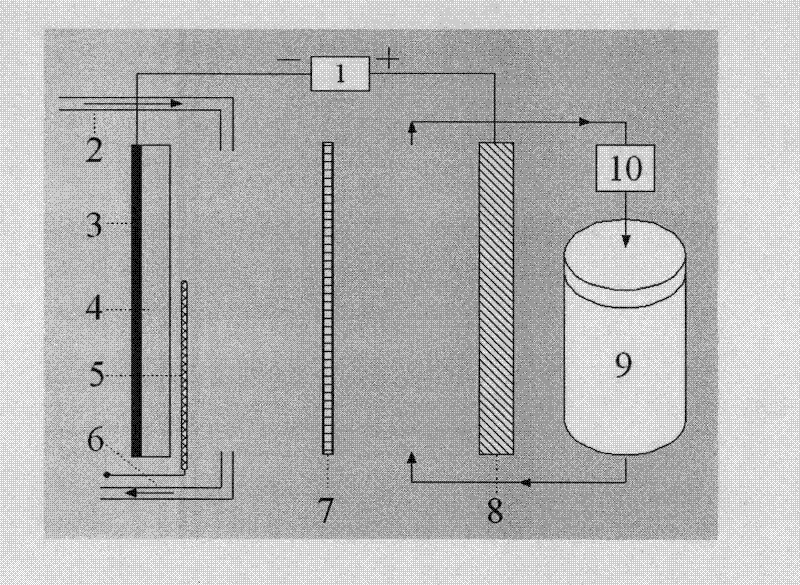

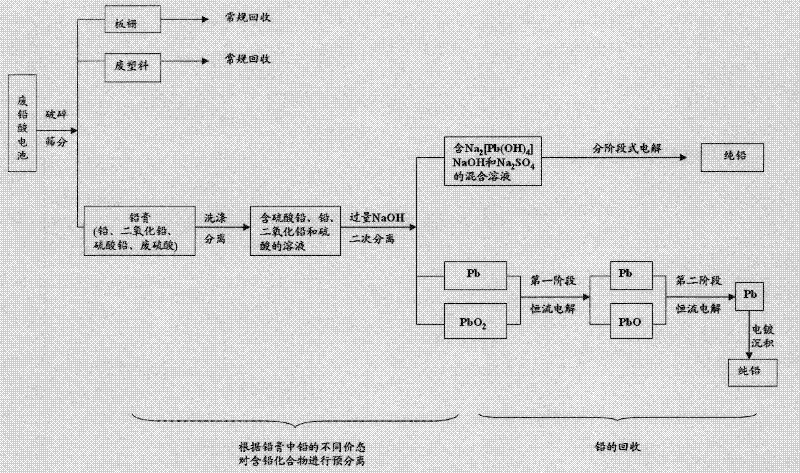

Method used

Image

Examples

Embodiment 1

[0105] The 12V, 10AH waste lead-acid batteries sold on the market were crushed and separated to obtain 2.6kg of lead paste. Get wherein 200 grams of lead plaster and wash with 150ml deionized water and filter to obtain 2% (wt.) dilute sulfuric acid and 196 grams of lead plaster. Then the lead paste and 1 liter of 10M NaOH were subjected to alkaline desulfurization reaction at 95°C. After keeping the reaction time for 1.5h, hot filtration was performed immediately to obtain 1 liter of NaOH solution containing 70g / LPbO and 95 grams of Pb and PbO 2 solid mixture.

[0106] The lead-containing mother liquor enters the electrolytic cell for ionic membrane electrolysis after conventional standing and purification. First, constant current electrolysis is carried out in the electrolytic cell, and the current density of the cathode and anode is controlled to be 700A / m 2 , the electrolysis temperature is 90°C, and the electrolysis voltage is 1.44V. When the electrolysis time reaches 1...

Embodiment 2

[0110] Take a 12V, 45Ah waste lead-acid battery for automobiles, and the total weight of the battery pack is 13.2 kg. Use conventional mechanical methods to crush and separate waste batteries to obtain lead paste, grids, separators and plastics.

[0111] Get about 5.9 kg of lead plaster and 5 liters of 2% dilute sulfuric acid after washing with 6 kg of lead plaster powder obtained in the above process and 5 liters of deionized water.

[0112] The lead plaster obtained by solid-liquid separation and 27 liters of 10.5M NaOH were subjected to alkaline desulfurization reaction at 100°C. After keeping the reaction time for 1.0h, they were immediately filtered while hot to obtain 28 liters of NaOH solution containing 75g / L PbO and 2.8 kg contains Pb and PbO 2 solid mixture.

[0113] The alkaline solution containing 75g / L lead oxide obtained by the above process is injected into the cathode chamber of the ion-exchange membrane (Nafion982) electrolyzer, and the anode chamber is then...

Embodiment 3

[0117] From the 12V, 14Ah lead-acid battery workshop, 13 kg of scrap negative plates mixed with waste lead-acid battery positive plates were obtained. After the waste battery plates were crushed, about 10 kg of lead powder was obtained, and the main components were Pb and PbSO in the electrodes themselves. 4 , PbO and a small amount of PbO 2 .

[0118] Get about 10 kilograms of lead plaster powder and 5 liters of 0.2% dilute sulfuric acid after washing the 10 kilograms of lead plaster powder obtained in the above process and 5 liters of deionized water.

[0119] The lead plaster obtained by solid-liquid separation and 50 liters of 11M NaOH were subjected to alkaline desulfurization reaction at 100°C. After keeping the reaction time for 1.0h, they were immediately filtered while hot to obtain about 50 liters of NaOH solution containing 89g / L PbO and 3.7 kg contains Pb and PbO 2 solid mixture.

[0120] The alkaline solution containing 89g / L lead oxide obtained by the above pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com