Preparation method of wetting selective oil-water separation membrane separated according to requirements

An oil-water separation membrane and selective technology, applied in semi-permeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problems of complex preparation steps, non-corrosion resistance, high cost, and achieve simple preparation process, low cost and pollution. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

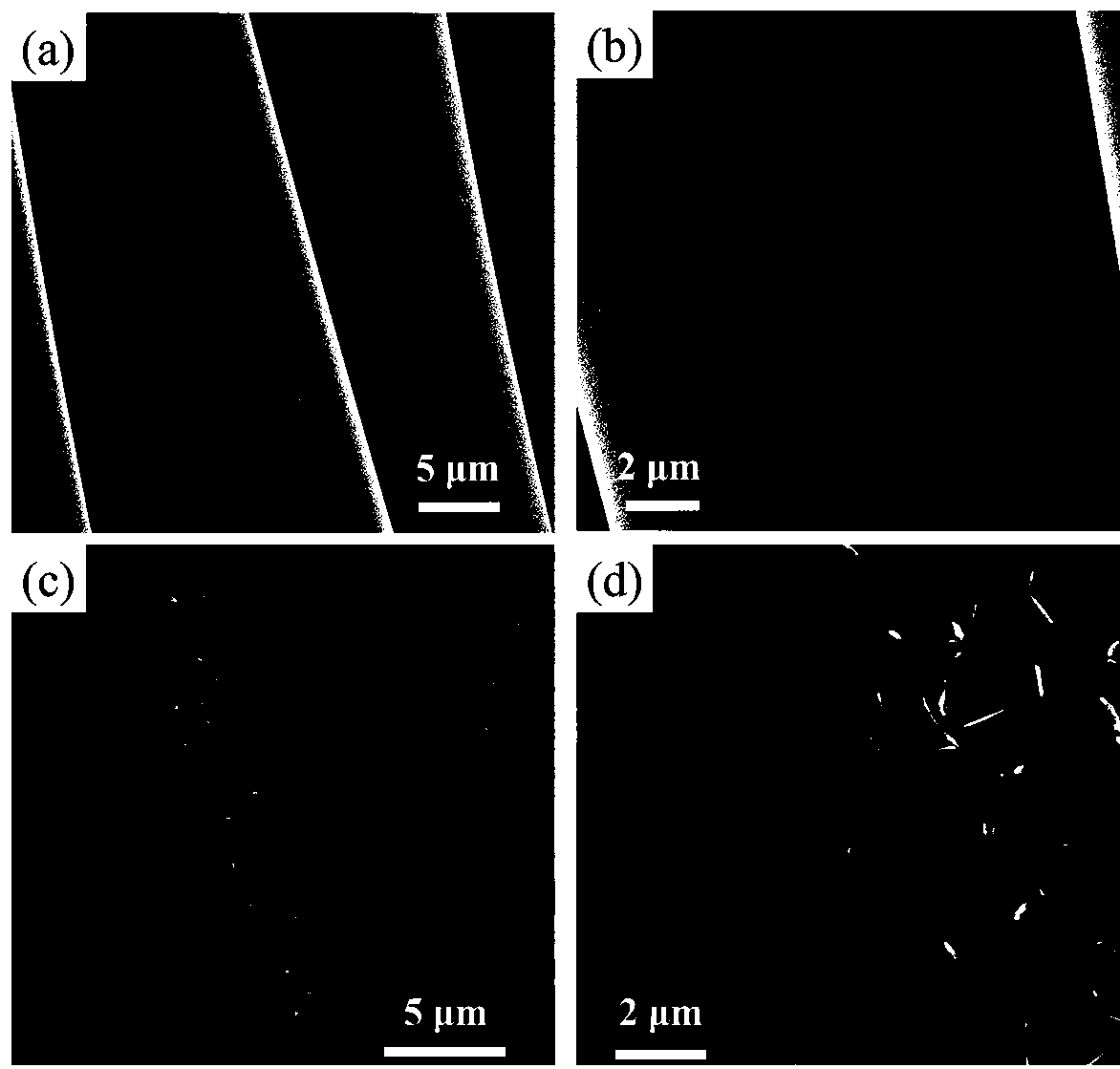

Image

Examples

Embodiment 1

[0026] A method for preparing a wetting selective oil-water separation membrane separated on demand, the specific preparation steps are as follows:

[0027] a) Dissolve the aluminum chloride of 0.001mol and the ammonium chloride of 0.005mol in 100mL deionized water, fully stir it and make it mix uniformly, obtain the aluminum chloride / ammonium chloride mixed solution;

[0028] b) Add 9 square centimeters of glass fiber cloth and 90 mL of aluminum chloride / ammonium chloride mixed solution into the autoclave in turn, react at 200 ° C for 16 hours, take it out and wash it with deionized water 4 times, and put it in Vacuum drying at 40°C for 8 hours to obtain a precursor separation membrane material with a hierarchical structure;

[0029] c) Place the precursor separation membrane with hierarchical structure obtained above in a tube furnace, and calcinate at 500°C for 6 hours under the protection of nitrogen to obtain a superhydrophilic / underwater superoleophobic separation membra...

Embodiment 2

[0035]A method for preparing a wetting selective oil-water separation membrane separated on demand, the specific preparation steps are as follows:

[0036] a) Dissolve 0.005 mol of sodium metaaluminate and 0.02 mol of urea in 100 mL of deionized water, stir well to make it evenly mixed, and obtain a sodium metaaluminate / urea mixed solution;

[0037] b) Add 9 square centimeters of glass fiber cloth and 90 mL of sodium metaaluminate / urea mixed solution into the autoclave in turn, react at 180°C for 16 hours, take it out, wash it twice with deionized water, and put it at 50 Vacuum drying at ℃ for 7 hours to obtain a precursor separation membrane material with a hierarchical structure;

[0038] c) Place the precursor separation membrane with hierarchical structure obtained above in a tube furnace, and calcinate at 500°C for 6 hours under the protection of nitrogen to obtain a superhydrophilic / underwater superoleophobic separation membrane with hierarchical structure;

[0039] d) ...

Embodiment 3

[0044] A method for preparing a wetting selective oil-water separation membrane separated on demand, the specific preparation steps are as follows:

[0045] a) Dissolve 0.01 mol of sodium metaaluminate and 0.04 mol of urea in 100 mL of deionized water, stir well to make it evenly mixed, and obtain a sodium metaaluminate / urea mixed solution;

[0046] b) Add 9 square centimeters of carbon fiber membrane and 90 mL of sodium metaaluminate / urea mixed solution into the autoclave in turn, react at 160 °C for 18 h, take it out, wash it with deionized water 4 times, and heat it at 60 °C Under vacuum drying for 6h, the precursor separation membrane material with hierarchical structure is obtained;

[0047] c) Place the precursor separation membrane with hierarchical structure obtained above in a tube furnace, and calcinate at 600°C for 4 hours under the protection of nitrogen to obtain a superhydrophilic / underwater superoleophobic aluminum oxide nanosheet coating with a hierarchical str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com