Cellophane direct flotation collecting agent and method for preparing same

A positive flotation, collector technology, applied in flotation, solid separation and other directions, can solve the problems of environmental pollution and human health impact, environmental water quality and human harm, chemical toxicity, etc., to achieve excellent flotation indicators, environmental protection Significant benefits and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] First add 0.2kg of cotton oil residue, 0.06kg of stearic acid and 0.54kg of industrial oleic acid into the reaction kettle, then slowly add 0.2kg of sodium hydroxide into a 20% aqueous solution, heat to 85°C, Stir the mixture for 3 hours at a speed of 1 min until it is evenly mixed. After cooling, the positive flotation collector is obtained. After weighing and calculating its solid content (solid content = mass of raw materials except water / total mass of collector) Add water to prepare 2wt% aqueous solution for positive flotation.

Embodiment 2

[0026] First add 0.2kg of cotton oil residue, 0.22kg of lauric acid and 0.33kg of industrial oleic acid into the reaction kettle, then slowly add 0.05kg of sodium hydroxide into a 15% aqueous solution, heat to 65°C, and set the temperature at 1700r / min Stir the mixture for 2.5 hours at a constant speed, cool to 60°C, add 0.2 kg of chlorinated fatty acid citrate, and stir until evenly mixed to obtain the positive flotation collector. After weighing and calculating its solid content, add water to prepare 2 wt % solution for positive flotation.

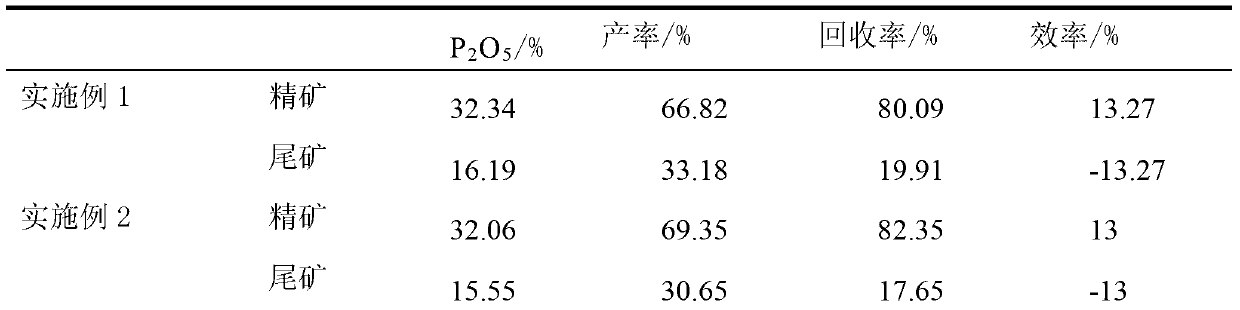

[0027] The positive flotation collectors prepared in Example 1 and Example 2 were used to carry out positive flotation to the refractory collophanite. The method of positive flotation adds Na 2 CO 3 Regulates pH and inhibits Ca 2+ , Mg 2+ , Na 2 SiO 3 Inhibit SiO 2 , (NaPO 4 ) 6 Various metals are suppressed, and then the positive flotation collector involved in the present invention is added to float the useful collophanite.

...

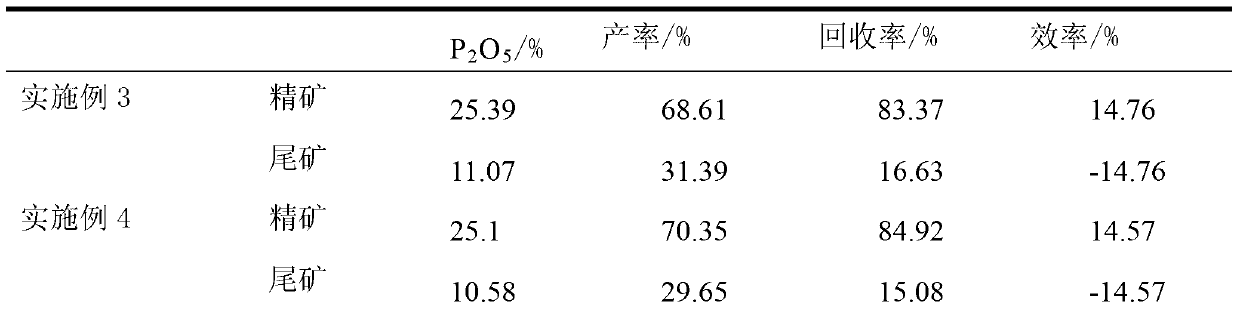

Embodiment 3

[0033] First add 0.8kg of cotton oil residue, 0.04kg of lauric acid and 0.06kg of industrial oleic acid into the reaction kettle, then slowly add 0.05kg of sodium hydroxide into a 35% aqueous solution, heat to 115°C, and heat at 1800r / min Stir the mixture for 2 hours at a constant speed, cool to 60°C and add 0.05kg of chlorinated fatty acid citrate, stir until evenly mixed to obtain the positive flotation collector, weigh and calculate its solid content, add water to prepare 2wt% The solution was subjected to positive flotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com