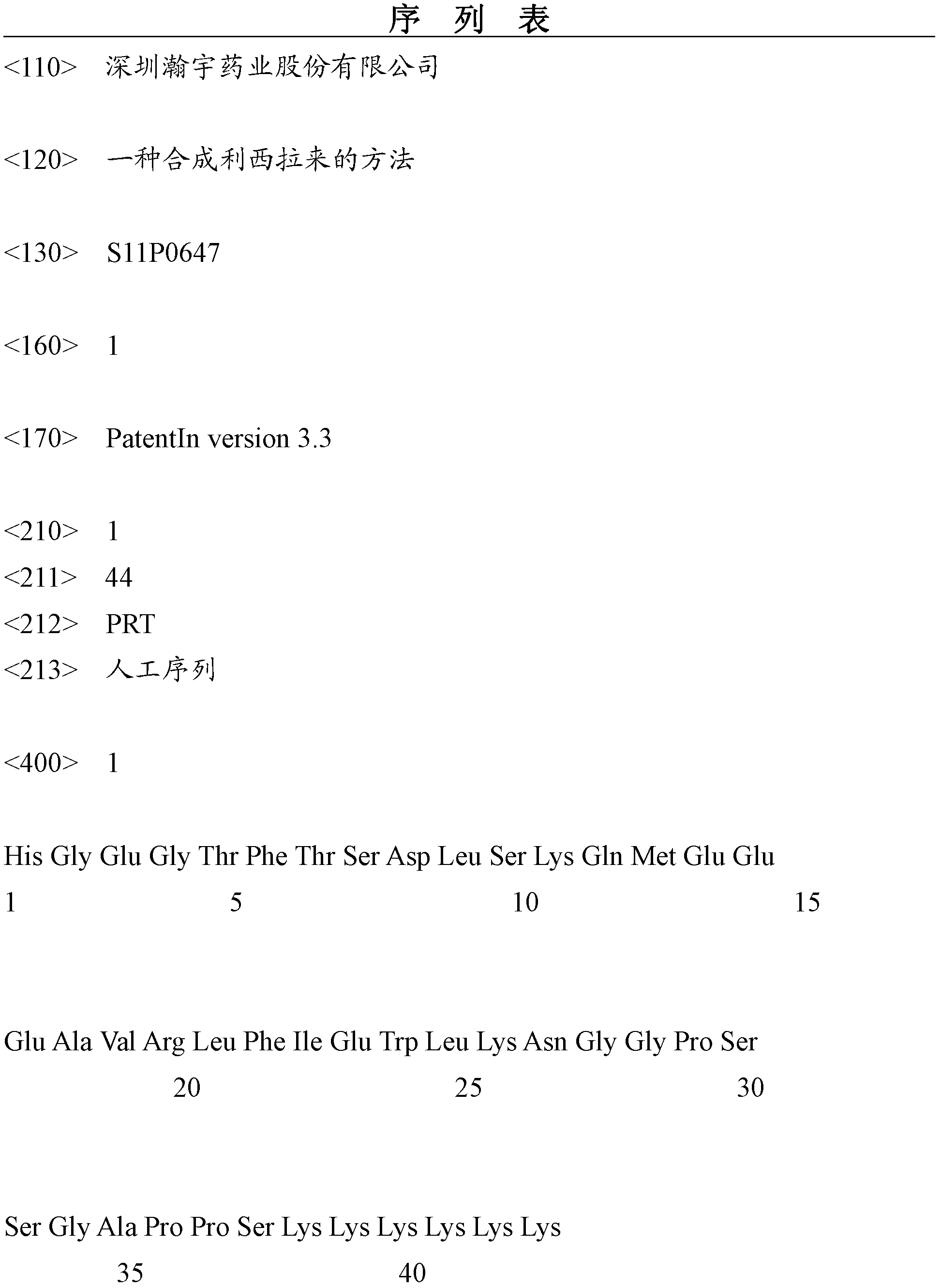

Method for synthesizing lixisenatide

A technology of lixisenatide and side chain protecting groups, which is applied in the field of solid-phase synthesis of polypeptides, can solve the problems of difficult acquisition of specific strains, consumption of manpower and material resources, and inapplicability to large-scale industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Preparation of Fmoc-Lys(Boc)-Rink Amide Resin:

[0054] Weigh 10g of Fmoc-Rink Amide Resin with a substitution degree of 0.25mmol / g, put it into a solid-phase reaction column, wash the resin twice with DMF (100ml+50ml), soak the resin in 50ml of DMF for 45 minutes to fully swell the resin, add 20% 40ml of piperidine / DMF solution, reacted for 10 minutes, drained the reaction liquid, and washed the resin 6 times with DMF (50ml×6). Weigh 3.52g of Fmoc-Lys(Boc)-OH, 1.01g of HOBt, and 1.39ml of DIC, dissolve them in 40ml of DMF, stir slowly in an ice bath for 3 minutes, pour into a solid-phase reaction column and mix with the resin, and react at room temperature for 2 hours. The Ninhydrin method was used to detect the completion of the reaction, the reaction solution was removed, and the resin was washed with DMF three times (50m×6) to obtain Fmoc-Lys(Boc)-Rink Amide Resin. The molar ratio of Fmoc-Lys(Boc)-OH:HOBt:DIC used in the above operations is 1:1:1.2, wherein the mol...

Embodiment 2

[0071] Preparation of Fmoc-Lys(Boc)-Rink Amide-BHA Resin:

[0072]Weigh 20g of Fmoc-Rink Amide-BHA Resin with a substitution degree of 0.15mmol / g, put it into a solid-phase reaction column, wash the resin twice with DMF (180ml+100ml), then soak it in DMF for 60 minutes to fully swell the resin, add 80ml of 20% piperidine / DMF solution was reacted for 10 minutes, the reaction solution was drained, and the resin was washed 6 times with DMF (100ml×6). Weigh 7.03g of Fmoc-Lys(Boc)-OH, 2.78ml of DIC, dissolve in 80ml of DMF, pour the Fmoc-Lys(Boc)-OH and DIC solution into the solid phase reaction column and mix with the resin, react at room temperature for 2 hours, Ninhydrin method After detecting the completion of the reaction, the reaction solution was removed, and the resin was washed three times with DMF (100m×6) to obtain Fmoc-Lys(Boc)-Rink Amide-BHAResin. The molar ratio of Fmoc-Lys(Boc)-OH:DIC used in the above operations is 1:1.2, wherein the molar number of Fmoc-Lys(Boc)-O...

Embodiment 3

[0089] Preparation of Fmoc-Lys(Boc)-Rink Amide-MBHA Resin:

[0090] Weigh 10g of Fmoc-Rink Amide-MBHA Resin with a substitution degree of 0.25mmol / g, put it into a solid-phase reaction column, wash the resin twice with DMF (100ml+50ml), soak the resin in 50ml of DMF for 45 minutes to fully swell the resin, add 20% piperidine / DMF solution 40ml, reacted for 10 minutes, drained the reaction solution, and washed the resin 6 times with DMF (50ml×6). Weigh 3.52g of Fmoc-Lys(Boc)-OH, 1.01g of HOBt, and 1.39ml of DIC, dissolve in 40ml of DMF, stir slowly in ice bath for 3 minutes, pour into solid phase reaction column and mix with resin, and react at room temperature for 2 hours. The Ninhydrin method was used to detect the completion of the reaction, the reaction solution was removed, and the resin was washed with DMF three times (50m×6) to obtain Fmoc-Lys(Boc)-RinkAmide-MBHA Resin. The molar ratio of Fmoc-Lys(Boc)-OH used in the above operation:HOBt:DIC is 1:1:1.2, wherein the molar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com