Low overpotential electrocatalyst for producing hydrogen by efficient water splitting and preparation method of electrocatalyst

An electrocatalyst and overpotential technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, electrolysis process, etc., can solve the problems of energy waste and high overpotential, achieve efficiency improvement, low energy consumption, and good industrial application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Get 0.249 grams of cobalt nitrate hexahydrate solid particles, add 20 milliliters of deionized water to the reaction vessel and stir for 40 minutes to dissolve completely;

[0025] (2) Get 0.173 grams of sodium selenite pentahydrate solid particles in another reaction vessel, then add 20 milliliters of diethylenetriamine liquid and stir until sodium selenite pentahydrate is completely dissolved;

[0026] (3) Mix the solutions in step (1) and step (2), then stir for 2 hours to make the mixture uniform;

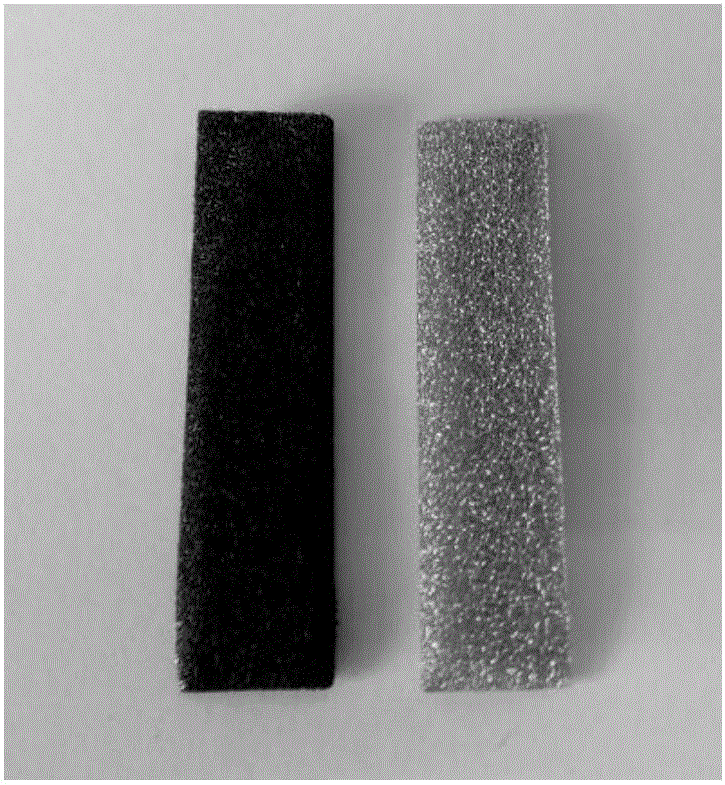

[0027] (4) Cut the cut area to 4cm 2 Foam nickel (Ni) soaks 15 minutes with hydrochloric acid (volume fraction 37%), takes out foam nickel and then cleans 5 times with deionized water, then the foam nickel after deionized water cleaning is soaked in acetone liquid for 5 hours, The nickel foam is taken out and cleaned 12 times with absolute ethanol, and then the nickel foam is dried at room temperature;

[0028] (5) the cleaned foamed nickel of step (4) is put into ...

Embodiment 2

[0031] (1) Get 0.249 grams of cobalt nitrate hexahydrate solid particles, add 10 milliliters of deionized water in the reaction vessel and stir for 40 minutes to make it dissolve completely;

[0032] (2) Get 0.173 grams of sodium selenite pentahydrate solid particles in another reaction vessel, then add 30 milliliters of diethylenetriamine liquid and stir until sodium selenite pentahydrate is completely dissolved;

[0033] Step (3)~(5) is the same as embodiment 1,

[0034] (6) Put the reaction kettle in the step (5) into an electric blast oven that has been warmed up to 180 degrees in advance and keep it for 24 hours, and then take out the loaded product from the reaction kettle when the temperature of the reaction kettle drops to room temperature. Foam nickel, then wash 6 times with deionized water, 8 times with acetone, and 10 times with absolute ethanol, then put the cleaned foamed nickel that has grown on the product into an electric blast drying oven at 80 degrees Celsius a...

Embodiment 3

[0036] (1) Get 0.249 grams of cobalt nitrate hexahydrate solid particles, add 20 milliliters of deionized water to the reaction vessel and stir for 40 minutes to dissolve completely;

[0037] (2) Get 0.173 grams of sodium selenite pentahydrate solid particles in another reaction vessel, then add 20 milliliters of deionized water and stir until sodium selenite pentahydrate is completely dissolved;

[0038] (3) Mix the solutions in step (1) and step (2), and then stir for 2 hours;

[0039] (4) transfer the reaction solution to the reaction kettle of 150 milliliters that has been put into the band stainless steel substrate after mixing uniformly in the step (3) again;

[0040] (5) Put the reaction kettle in step (4) into an electric blast oven that has been warmed up to 180 degrees in advance and keep it for 24 hours, and then pour out the supernatant in the reaction kettle when the temperature of the reaction kettle drops to room temperature , the substrate was washed 5 times w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com