A method of preparing a polyaniline/silver nanometer material by a cladding manner

A technology of polyaniline and silver nanometers, which is applied in the field of preparation of polyaniline/silver nanomaterials by coating method, can solve the problems of reducing the conductivity of composite materials, and achieve the effect of improving conductivity, good water solubility and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

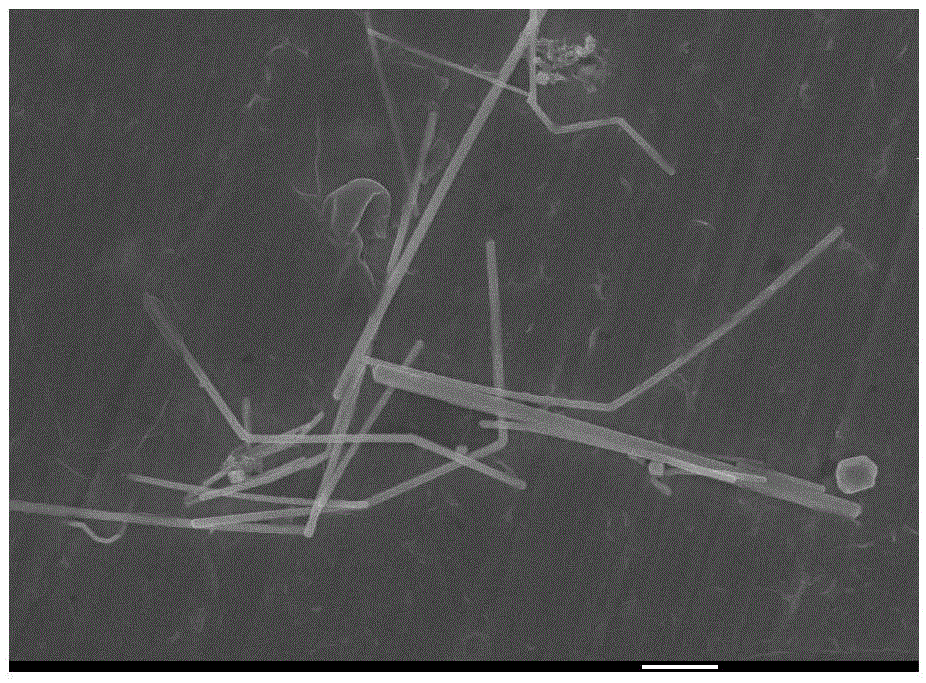

Image

Examples

Embodiment 1

[0022] Add 5mL of ethylene glycol into a three-necked round-bottomed flask, and add a magnetic stirrer to pass nitrogen to maintain airtightness; reflux at 150°C for 20min; then add 4mL of 0.2mol / L AgNO 3 Ethylene glycol solution and 80μL 20mmol / L NiCl 2 After the ethylene glycol solution is mixed, add it to the above ethylene glycol; then add 10ml10g / L polyvinyl alcohol (PVP) ethylene glycol solution within 10min, and react for 40min; after the reaction, the product is washed twice with acetone and absolute ethanol , and centrifuged, the resulting 100mg silver nanowires were dispersed in 10mL absolute ethanol for later use.

Embodiment 2

[0024] Add 10mL of ethylene glycol into a three-necked round-bottomed flask, and add a magnetic stirrer to pass through nitrogen to maintain airtightness; reflux at 160°C for 25min; then add 4mL of 0.3mol / L AgNO 3 Ethylene glycol solution and 80μL 30mmol / L NiCl 2 After the ethylene glycol solution is mixed, add it to the above ethylene glycol; then add 15ml of 10g / L polyvinyl alcohol (PVP) ethylene glycol solution within 15min, and react for 50min; after the reaction, the product is washed twice with acetone and absolute ethanol , and centrifuged, the resulting 120mg silver nanowires were dispersed in 10mL absolute ethanol for later use.

Embodiment 3

[0026] Add 20mL of ethylene glycol into a three-necked round-bottomed flask, and add a magnetic stirrer to pass nitrogen to maintain airtightness; reflux at 170°C for 30min; then add 4mL of 0.3mol / L AgNO 3 Ethylene glycol solution and 80μL 40mmol / L NiCl 2 After the ethylene glycol solution is mixed, add it to the above ethylene glycol; then add 20ml of 10g / L polyvinyl alcohol (PVP) ethylene glycol solution within 20min, and react for 60min; after the reaction, the product is washed twice with acetone and absolute ethanol , and centrifuged, the resulting 150mg silver nanowires were dispersed in 10mL absolute ethanol for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com