Upward-flowing fluidization biofilter coupled with negative pressure membrane

A biological filter, negative pressure membrane technology, applied in biological water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. The effect of biomass, power consumption reduction, and biological loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

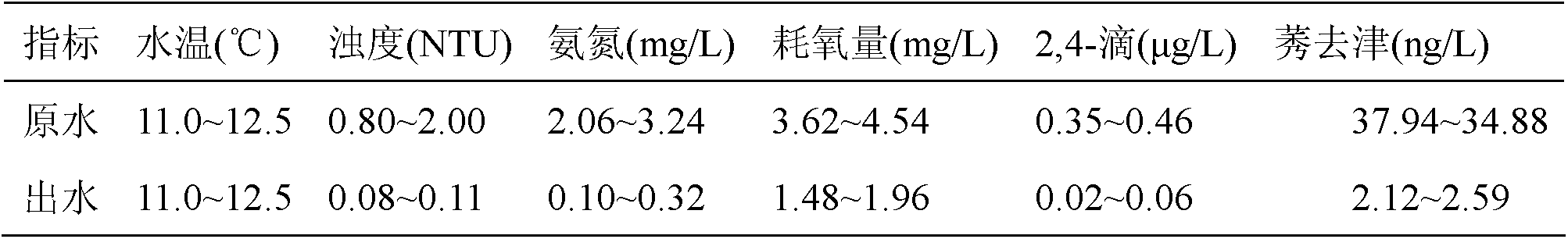

Examples

specific Embodiment approach 1

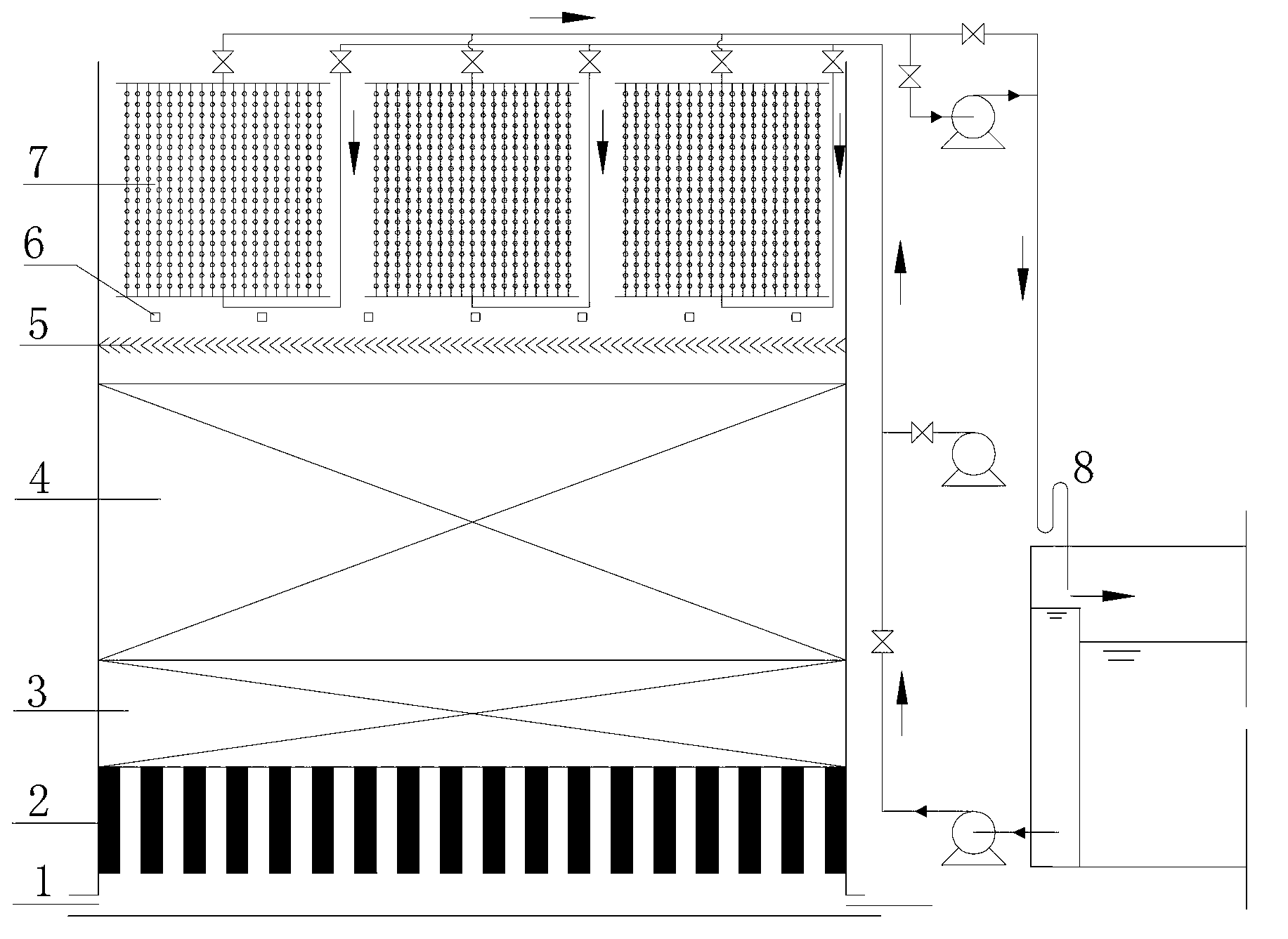

[0026] Specific embodiment 1: In this embodiment, an upflow fluidized biological filter coupled with a negative pressure membrane includes a water inlet 1, a water distribution layer 2, a supporting layer 3, a packing layer 4, and an anti-disturbance inclined plate 5 , air flotation release device 6 and negative pressure membrane assembly 7, it is characterized in that:

[0027] The negative pressure membrane assembly 7 is completely submerged in the clear water area on the upper part of the filling layer 4 in the upward flow fluidized biological filter coupled with the negative pressure membrane;

[0028] The anti-disturbance sloping plate 5 is located between the biofilter packing layer 4 and the negative pressure membrane assembly 7;

[0029] The air flotation releaser 6 is located at the bottom of the negative pressure membrane assembly 7;

[0030] The top wall of the upward flow fluidized biological filter coupled with the negative pressure membrane is provided with a fl...

specific Embodiment approach 2

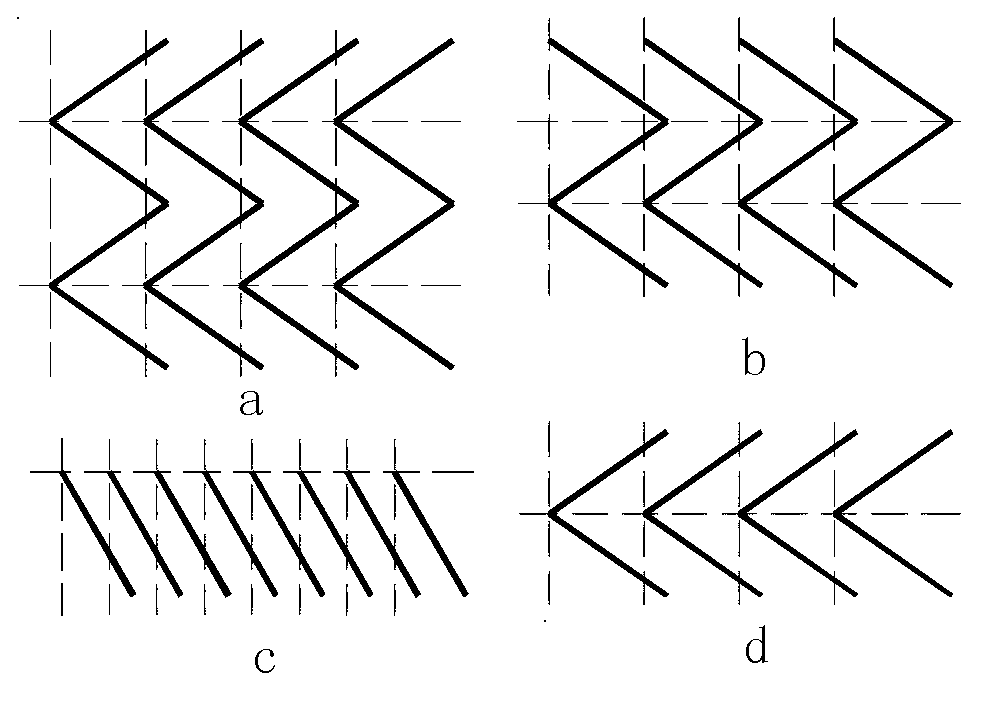

[0031] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the anti-disturbance swash plate 5 is composed of a series of "V" or "W" components rotated by 90 degrees. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the single component of the anti-disturbance swash plate 5 is composed of two or several long-strip plates connected in sequence by the long sides, and the clamping The angle is between 30 degrees and 90 degrees. Others are different from the first or second specific embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com