Catalytic hydrogenation desorption method for oxygenated compound in Fischer-Tropsch synthesized water phase and application thereof

A technology of Fischer-Tropsch synthesis and catalytic hydrogenation, which is applied in the direction of hydrocarbon production from oxygen-containing organic compounds, organic chemistry, chemical instruments and methods, etc., to achieve the effect of improving rationality, simple process flow and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1.0 Ru / C catalyst preparation: prepared by equal volume impregnation method, the loading capacity of metal Ru is 1.0wt%, take 0.81 g of ruthenium chloride trihydrate solid and completely dissolve it in 50 mL of deionized water, and then quickly add 30 g of activated carbon into the solution , stirred gently for a few minutes, let it stand for 12 hours, and dried in a drying oven at 120°C for 12 hours.

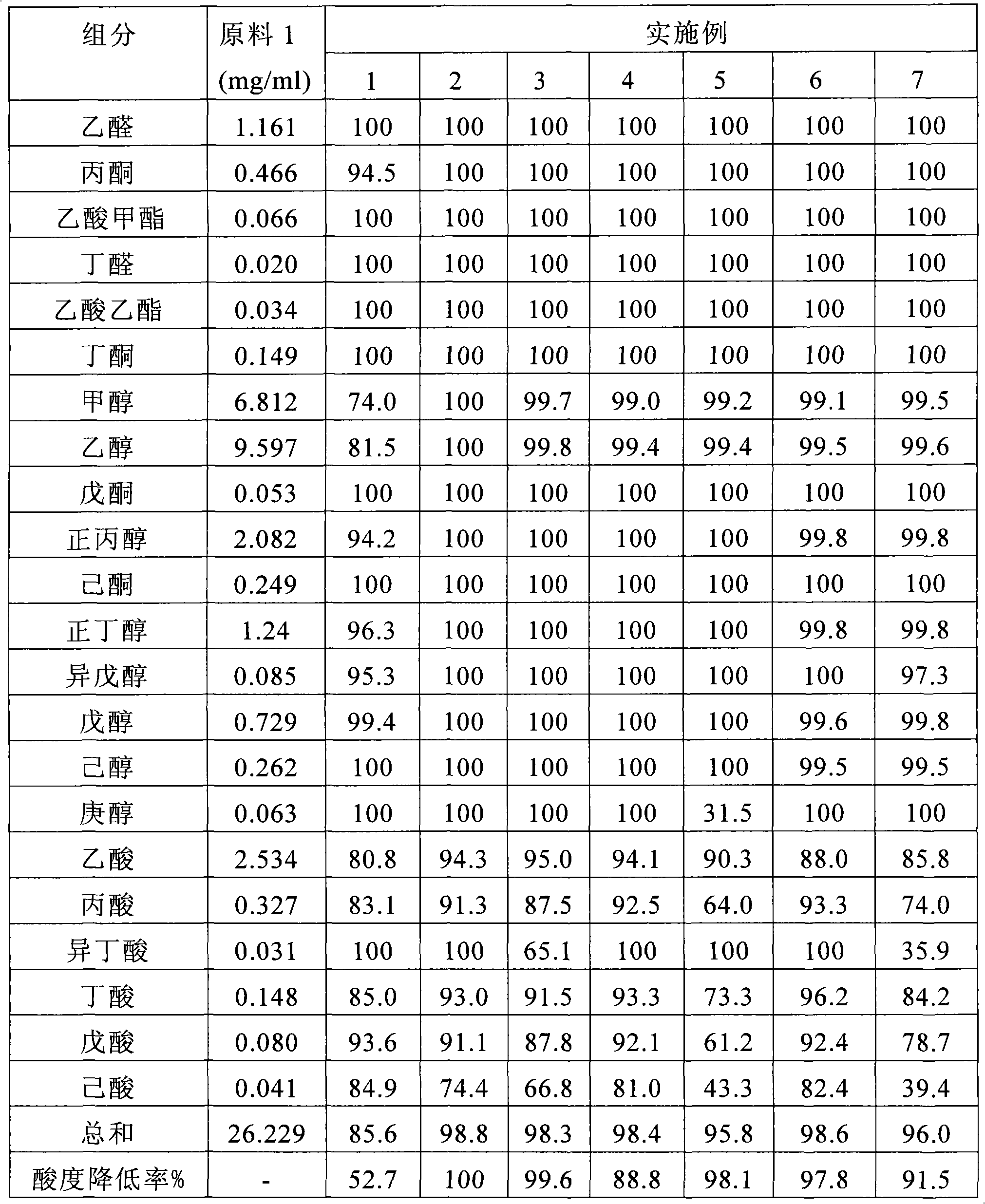

[0039] Add 12 grams of 1.0Ru / C catalyst in the trickle bed reactor, and the Fischer-Tropsch synthesis water phase (raw material 1 with an acidity of 0.423%) of 2.62wt% organic oxygen-containing compound flows through the reactor at a flow rate of 0.2mL / min (airspeed is 1.0h -1 ), adjust the reaction temperature to be 110° C., and the reaction pressure to be 4.0 MPa. The reactor effluent is separated from gas and liquid by a condenser, and then analyzed. After the reaction, the removal rate of each component in the water phase and the acidity reduction rate of the water ...

Embodiment 2

[0041] 12 grams of 1.0 Ru / C catalysts were added to the trickle bed reactor, and the Fischer-Tropsch synthesis aqueous phase (raw material 1 with an acidity of 0.423%) containing 2.62 wt% of organic oxygen-containing compounds was passed through the reaction at a flow rate of 0.1 mL / min. device (space speed 0.5h -1 ), adjust the reaction temperature to be 210°C, and the reaction pressure to be 4.0MPa. The reactor effluent is separated from gas and liquid by a condenser, and then analyzed. After the reaction, the removal rate of each component in the water phase and the acidity reduction rate of the water phase are shown in Table 1.

Embodiment 3

[0043] 12 grams of 1.0 Ru / C catalysts were added to the trickle bed reactor, and the Fischer-Tropsch synthesis aqueous phase (raw material 1 with an acidity of 0.423%) containing 2.62 wt% of organic oxygen-containing compounds was passed through the reaction at a flow rate of 0.2 mL / min. device (airspeed is 1.0h -1 ), adjust the reaction temperature to be 210°C, and the reaction pressure to be 4.0MPa. The reactor effluent is separated from gas and liquid by a condenser, and then analyzed. After the reaction, the removal rate of each component in the water phase and the acidity reduction rate of the water phase are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com