Well drilling method sinking ultrasonic measurement instrument

A technology of ultrasonic wave and surveying instrument, which is applied in the direction of surveying, wellbore/well components, earthwork drilling and production, etc. It can solve the problems that the downhole instrument is not suitable for pile foundation drilling, the actual measurement work is not particularly stable and reliable, and the service life is short, so as to achieve sealing Reliability, overcoming leakage and wear, effects of improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

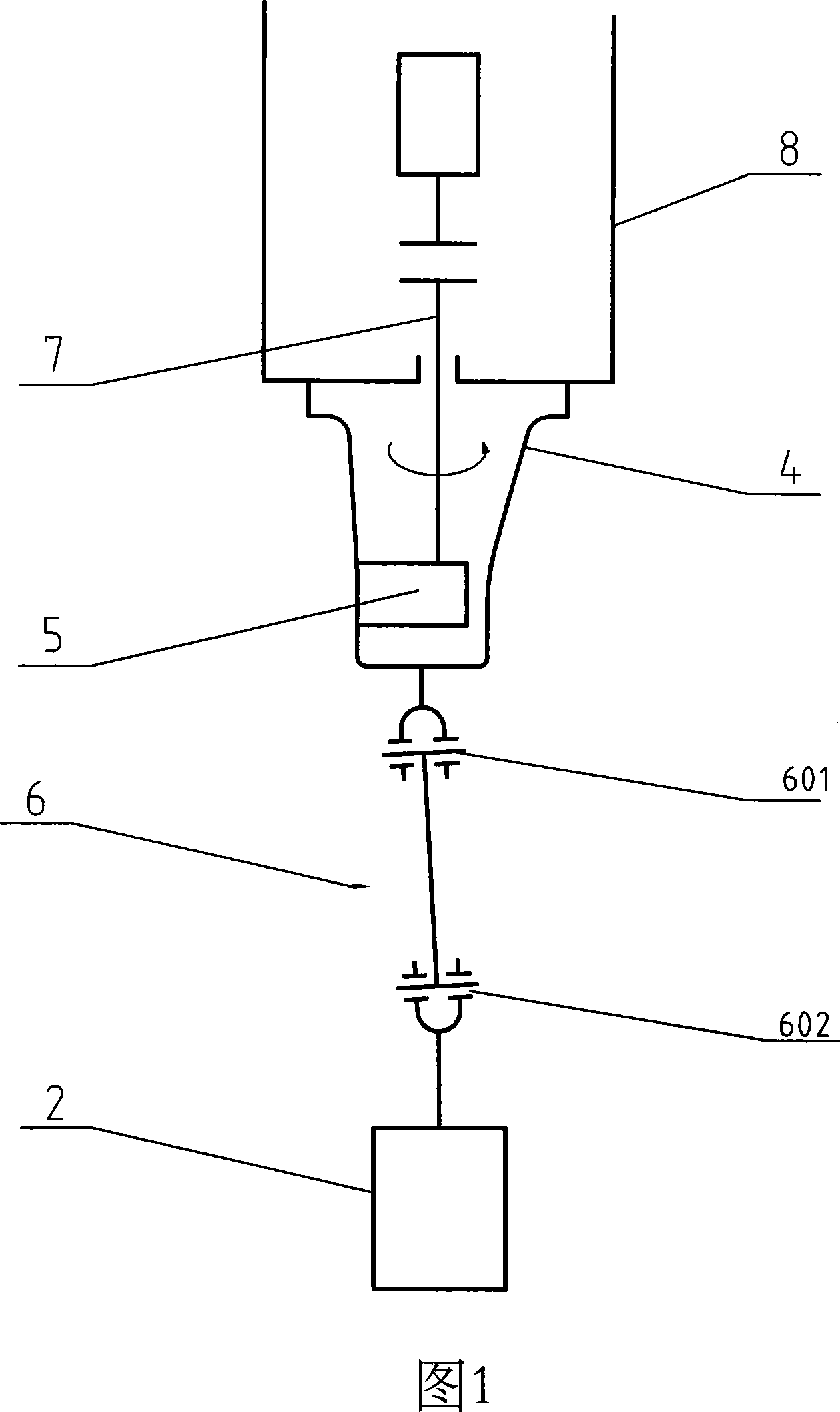

[0031] In conjunction with accompanying drawing 1, the above-mentioned transducer (ultrasonic detection sensor) is equipped with a constant pressure sleeve 2, which is made of nylon polyester material, and a liquid medium is stored in the constant pressure sleeve 2, and the liquid medium can be low-density glycerin etc., the transducer is placed in a liquid medium. The constant pressure sleeve 2 and its inner transducer form a rotating whole. The wall thickness of the above-mentioned constant pressure sleeve 2 should be selected so that it can bear the mud pressure outside the sleeve at the maximum measurement depth, and at the same time enable the transducer inside the sleeve to work in a liquid medium environment under constant pressure. The above-mentioned liquid characteristics can also be coupled with the material and structure of the constant pressure sleeve, so as to ensure that the ultrasonic detection signal sent by the transducer will not be disturbed, and the reliab...

Embodiment 2

[0034] In conjunction with accompanying drawing 2, the above-mentioned transducer 1 is equipped with a constant pressure sleeve 2, the main part of the constant pressure sleeve 2 is made of nylon polyester material, the constant pressure sleeve 2 stores a liquid medium 3, and the transducer 1 is placed in a liquid Medium 3. The constant pressure sleeve 2 is equipped with a metal flange 9 on the upper end of its main body. The flange 9 and the main body of the constant pressure sleeve 2 are connected by thread interference fit and sealed. For sealing connection, for example, multi-stage annular sealing rings 10 can be arranged sequentially from the inside to the outside in the horizontal direction of the sealing surface, the constant pressure sleeve 2 and the instrument cabin 8 are kept in a static state, and the transducer 1 can be opposite to each other in the constant pressure sleeve 2 turn. The wall thickness of the above-mentioned constant pressure sleeve 2 should be sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com