Improvement method for selective catalytic reduction flue gas denitrification and ammonia injection control system

A technology of control system and reduction method, which is applied in the field of flue gas denitrification, can solve the problems of inconsistent ammonia injection amount and theoretical ammonia injection amount, strong nonlinearity, and large hysteresis, and achieve improved stability, timeliness, and good nonlinearity The effect of mapping ability and good parallel computing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

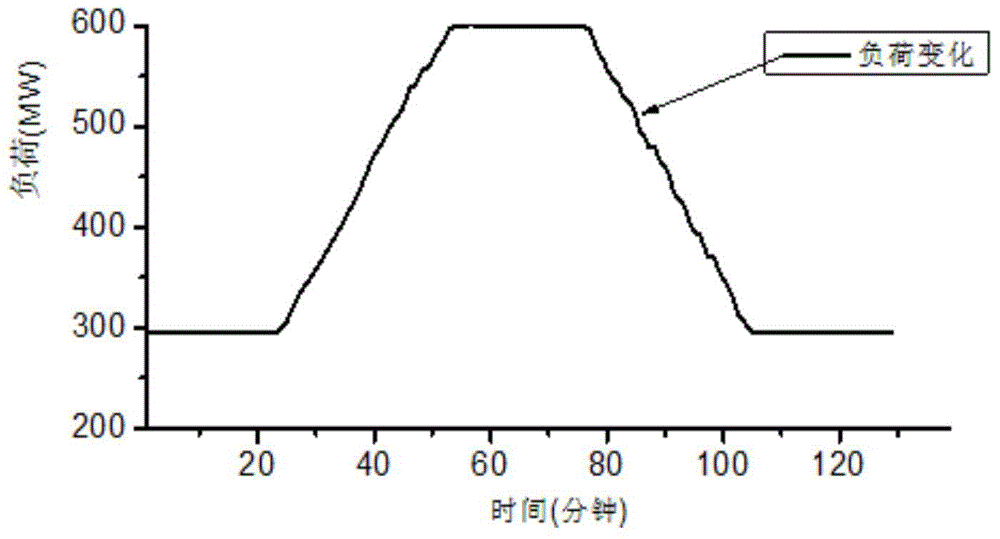

[0060] The simulation experiment results of a 600MW coal-fired boiler denitrification system in variable load operation, in which Figure 2a is the change curve of boiler load with time, Figure 2b is the NOx emission concentration at the outlet of the denitrification system. The denitrification control system operates in the outlet NOx fixed value control mode, and the set outlet NOx concentration is 50ppm. It operates in two control modes: the traditional PID control mode and the optimal control mode of the present invention. from Figure 2b It can be seen from the figure that when the unit is operating with varying loads, the NOx emission concentration at the outlet of the denitrification system increases when the traditional PID control method is adopted, and will exceed the set value; however, when the control method of the present invention is adopted, the NOx concentration at the outlet of the denitrification system exceeds The probability of the set value is relative...

Embodiment 2

[0062] The simulation experiment results of a 600MW coal-fired boiler denitrification system in variable load operation, in which Figure 3a is the change curve of boiler load with time, Figure 3b is the escape amount of ammonia at the outlet of the denitrification system. The denitrification control system operates in the outlet NOx fixed value control mode, and the set outlet NOx concentration is 50ppm. It operates in two control modes: the traditional PID control mode and the optimal control mode of the present invention. from Figure 3b It can be seen that the denitrification operation control provided by the present invention can reduce the amount of ammonia escape from the denitrification system. The reason is that the control system provided by the present invention comprehensively considers various parameters affecting the denitrification efficiency, and can accurately control the amount of ammonia injection in real time, which can reduce the escape amount of ammoni...

Embodiment 3

[0064] Figure 4 A comparison of the amount of ammonia sprayed by the denitrification system of a 600MW coal-fired boiler denitrification system when the traditional PID control method and the control method provided by the present invention are used respectively during variable load operation. from Figure 4 It can be seen from the figure that when the SCR denitrification system is operated in the optimal control station control mode, the ammonia injection volume can be saved when the outlet NOx concentration standard is met.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com