Method and apparatus for collecting carbonic anhydride in coal-fired plant flue gas

A technology for carbon dioxide and coal-fired power plants, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve problems such as the inability to apply carbon dioxide capture, achieve the effects of reducing solution consumption, flexible operation, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

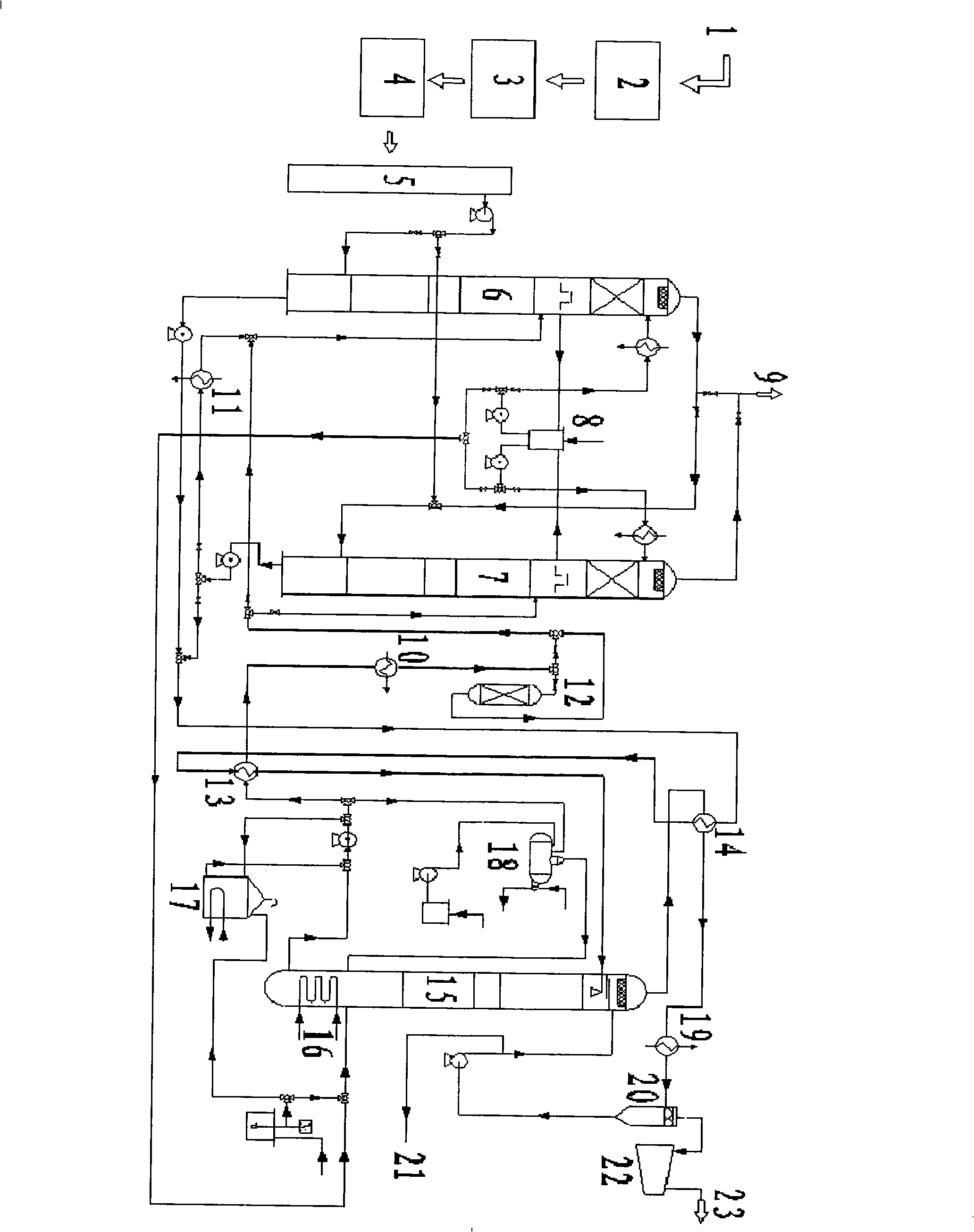

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] see figure 1 , the device of the present invention comprises a denitrification device 2, a dedusting device 3, a desulfurization device 4 and a cyclone 5 which are sequentially connected with the incoming flue gas 1 of a coal-fired boiler, and the outlet of the cyclone 5 is pressurized by a fan and connected in series with two Or the bottoms of the parallel absorption towers 6 and 7 are connected, the flue gas flows from bottom to top, and forms countercurrent contact with the absorption solution that can absorb carbon dioxide that enters the tower from the upper part of the absorption towers 6 and 7, and the flue gas that removes carbon dioxide is emptied through the tail gas The rich liquid that has absorbed carbon dioxide is pressurized by the rich liquid pump and enters from the upper part of the regeneration tower 15. The pipelines connecting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com