Process for preparing polymer microporous membrane and usage of same

A polymer membrane, microporous membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of high equipment investment cost and difficult pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The invention provides a method for preparing a microporous membrane that can be used in a secondary battery, which includes the step of preparing a polymer membrane material containing one or more small molecule additives.

[0015] In the method of the present invention, a polymer film material containing one or more small molecule additives is first prepared. The method for preparing the polymer film containing the small molecule additive is not particularly limited, and may be any method known in the art. In a preferred example of the present invention, the preparation method of the polymer film includes: mixing the polymer and the small molecule additive in a certain proportion, and casting to form a film.

[0016] Applicable polymers and small molecule additives can be selected according to the needs of specific applications. For example, the polymerized monomers used to form the polymers of the present invention may be selected from C 1-10 Olefins such as ethyle...

Embodiment 1

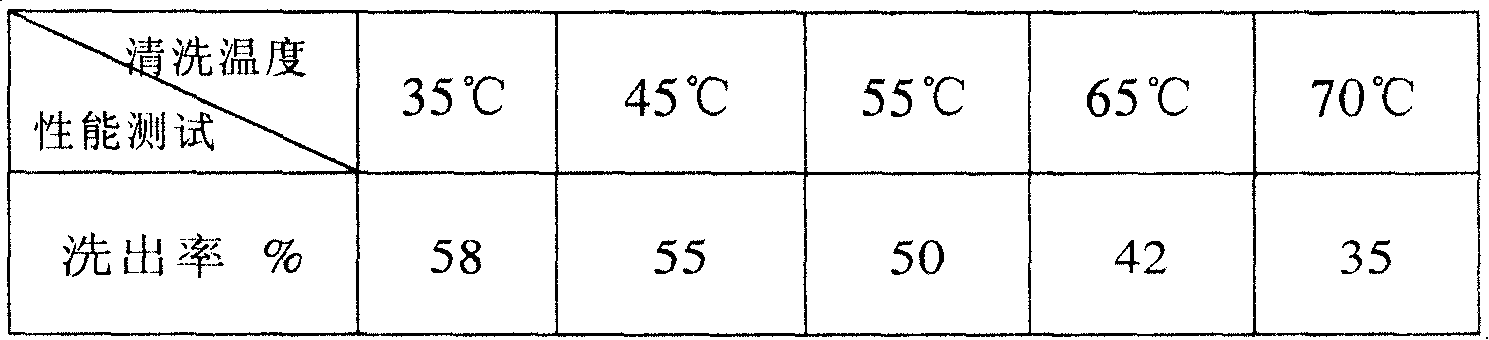

[0040] This example illustrates the effect of the temperature of the supercritical fluid on the final elution rate of small molecules.

[0041] Mix polyethylene polymer and N, N-diethyl-m-toluamide small molecule additive in a weight ratio of 4:6, and cast to form a film

[0042]The polymer membrane material containing 60% small molecule additive is put into the chamber of supercritical fluid equipment (purchased from Hangzhou Huali Pump Industry Co., Ltd.), and the polymer membrane material prepared is treated with supercritical carbon dioxide fluid. For elution, the operating pressure was controlled at 25MPa, and the cleaning time was 30 minutes. After the membrane was taken out, it was dried, and the quality difference before and after cleaning was compared. The results are listed in Table 1 below.

[0043] Table 1

[0044]

[0045] The test results show that the suitable temperature of supercritical fluid is between 35 and 45°C.

Embodiment 2

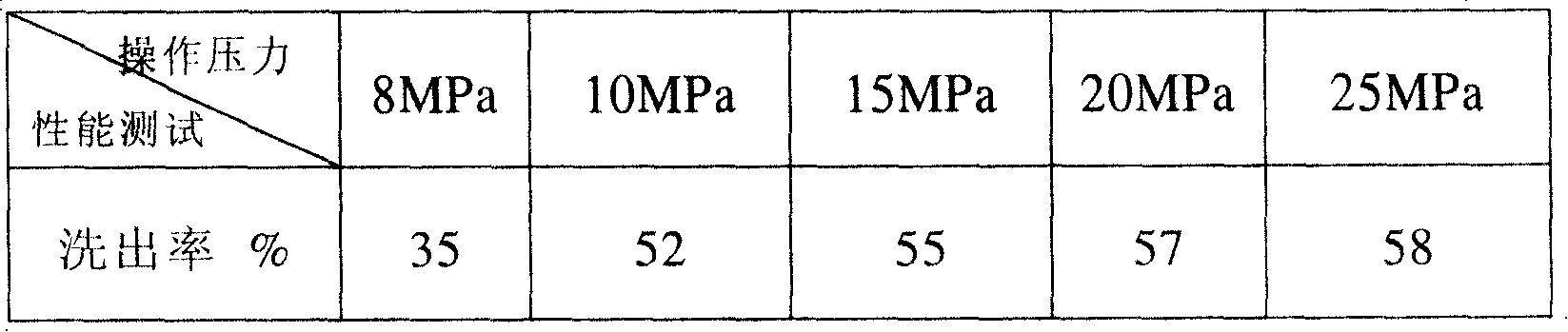

[0047] This example illustrates the effect of supercritical fluid operating pressure on the final small molecule elution rate.

[0048] Mix the polypropylene polymer and the butanol small molecule additive in a weight ratio of 4:6, and cast it into a film

[0049] Put the polymer membrane material containing 60% small molecule additive into the chamber of supercritical fluid equipment (purchased from Hangzhou Huali Pump Industry Co., Ltd.), and use supercritical carbon dioxide fluid to elute the prepared polymer membrane material , the cleaning temperature was controlled at 40°C, and the cleaning time was 30 minutes. After the membrane was taken out, it was dried, and the quality difference before and after cleaning was compared. The results are listed in Table 2 below.

[0050] Table 2

[0051]

[0052] The test results show that the operating pressure is suitable between 15 and 25 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com