Nano biological filler for purifying aquaculture wastewater in biological filter tank and preparation method of nano biological filler

A technology for biological fillers and aquaculture wastewater, applied in chemical instruments and methods, biological water/sewage treatment, sustainable biological treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

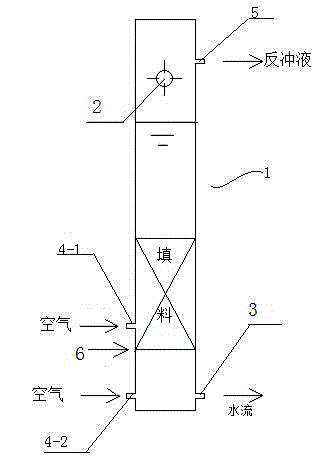

Image

Examples

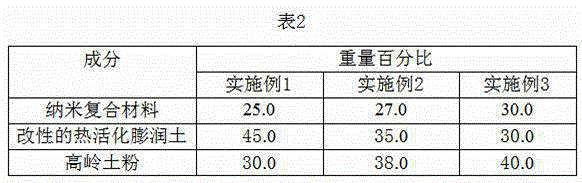

Embodiment 1-3

[0032] Embodiment 1-3 preparation method is as follows:

[0033] (1) Mix nano-alumina, nano-titanium dioxide and nano-silicon dioxide at a mass ratio of 1-5g: 10-20g: 0.5-1g, place them in a temperature-controlled furnace, start heating from 100°C, and increase the temperature at a rate of 10 per minute The heating rate of °C is to raise the temperature to 500-600 °C, and keep it in a constant temperature state for 12-24 hours, so that it can be fully mixed and decomposed to obtain a composite nano-powder.

[0034](2) Weigh 50g of bentonite raw soil, dilute it with deionized water to form a bentonite suspension with a mass fraction of 0.1%, and then mix the diethylaminodithioformate sodium and bentonite suspension at a ratio of 0.07:1 , stirred in a water bath at 80°C for 5 hours, allowed to stand, centrifuged, washed three times with water, air-dried at room temperature, passed through a 100-mesh sieve, and kept at a constant temperature of 110°C for 1 hour to obtain a modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com