Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Shorten ignition delay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

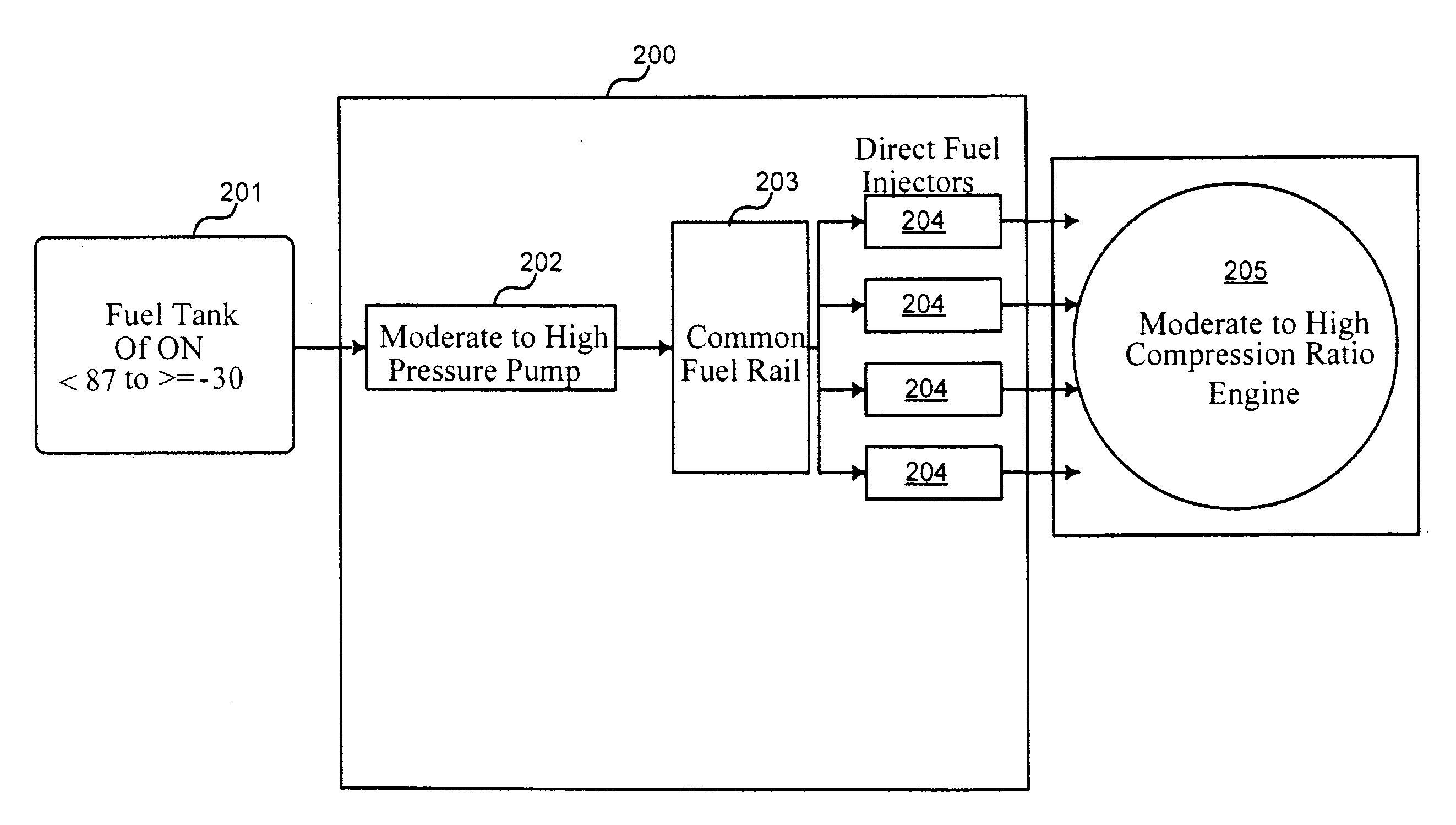

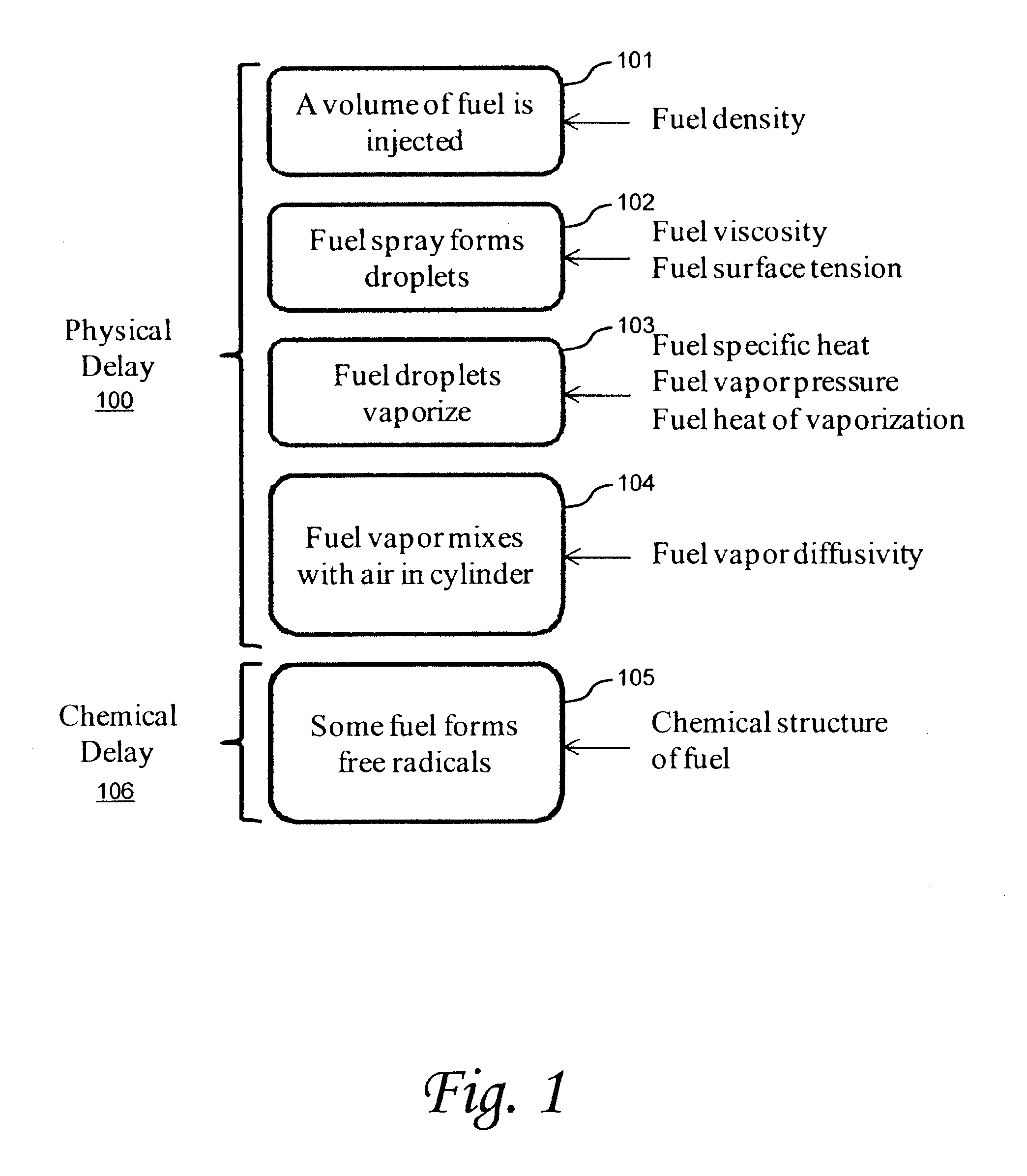

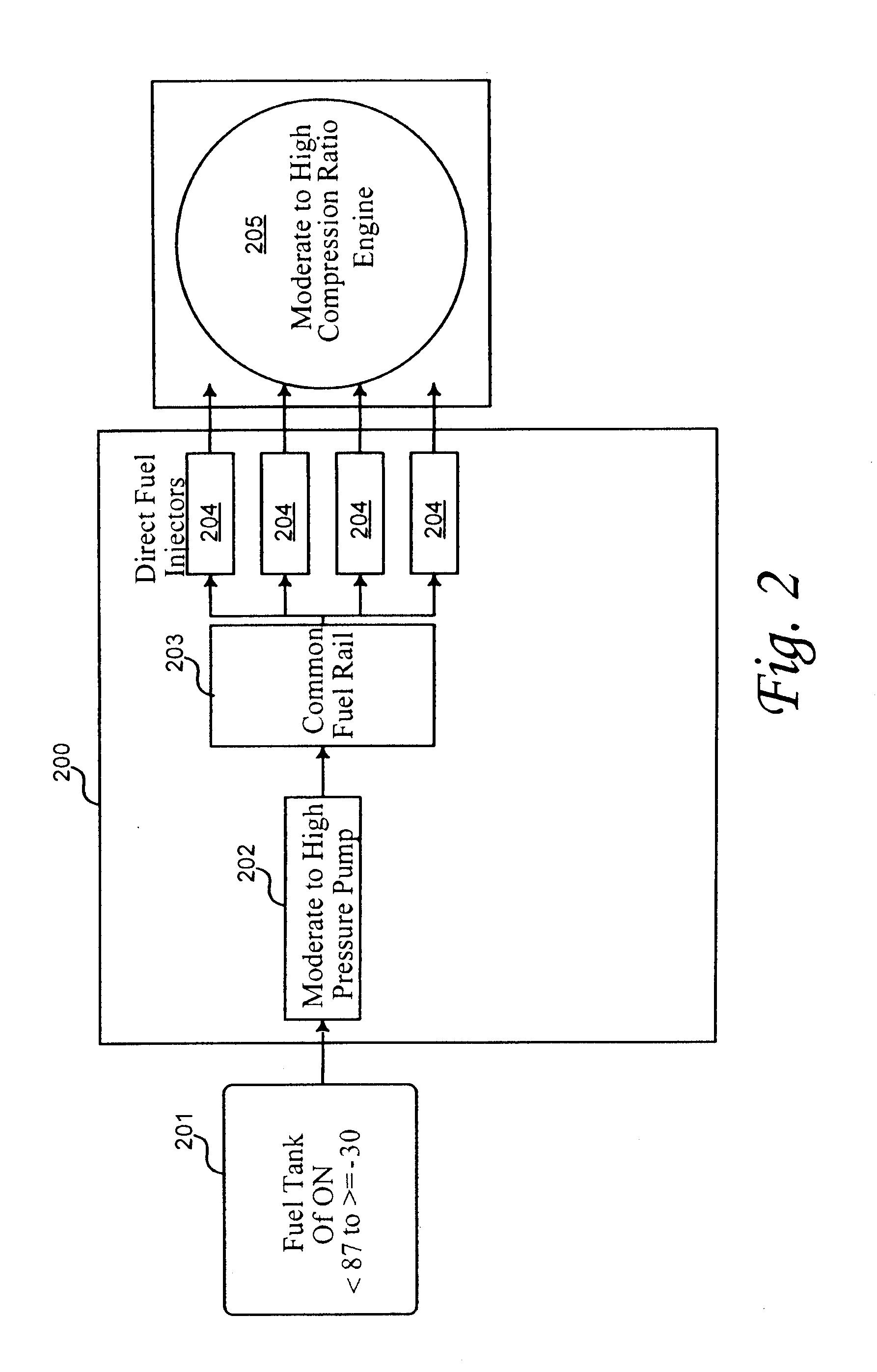

Low octane fuel for gasoline compression ignition

InactiveUS20110209686A1Shorten ignition delayCompression ignition characteristicCombustion enginesSolid fuelsIgnition delayAutomotive fuel

The present invention provides an automotive fuel injection system for a compression ignition engine, comprising a fuel injector configured to receive a fuel having an octane rating between 87 and −30 and configured to meter the fuel into the compression ignition engine, and a heater coupled to the fuel injector and configured to heat the fuel injector such that the fuel is heated to a predetermined minimum temperature, whereby the ignition delay of the fuel is reduced below a predetermined maximum ignition delay.

Owner:TRANSONIC COMBUSTION

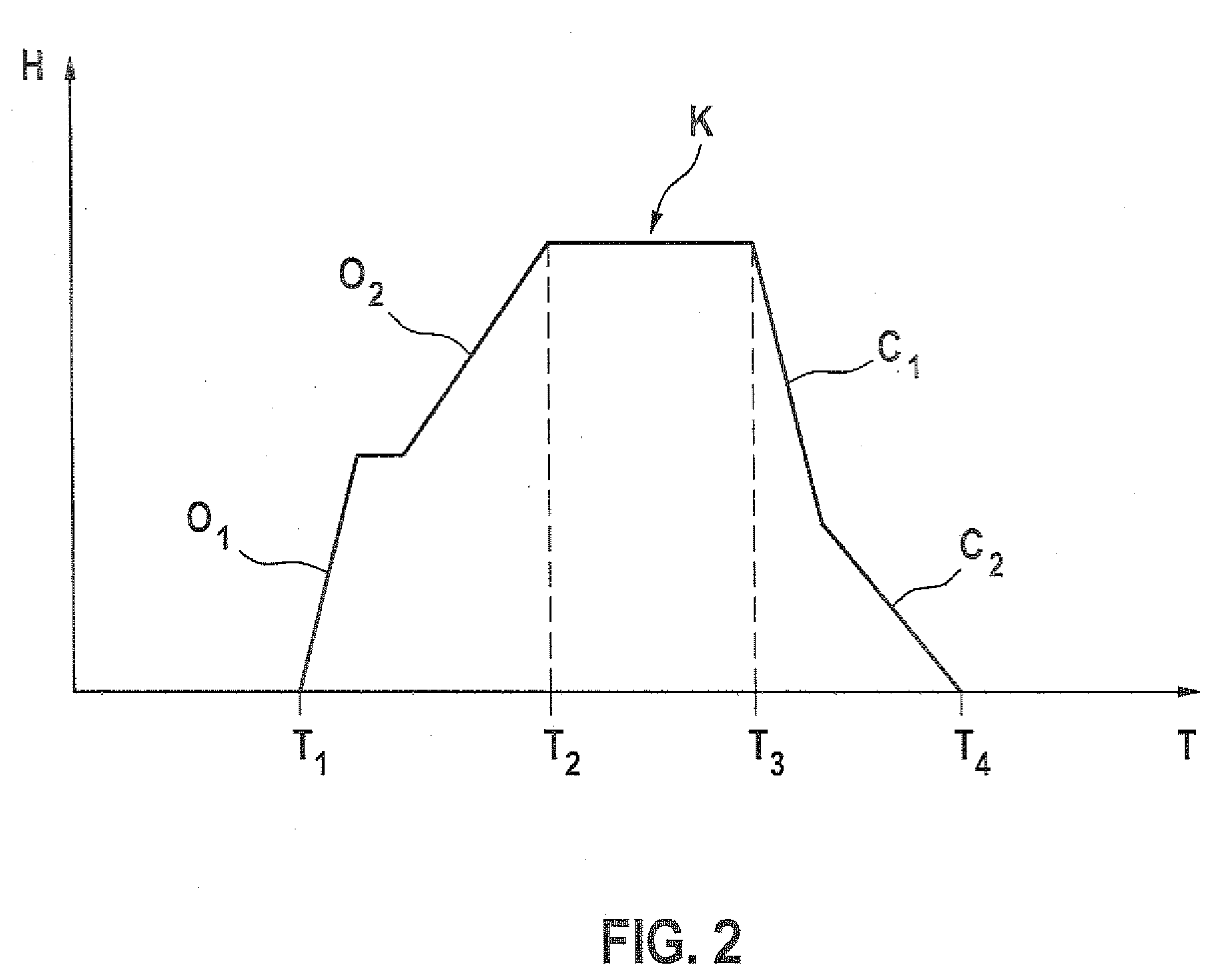

Diesel engine for automobile, control device and control method

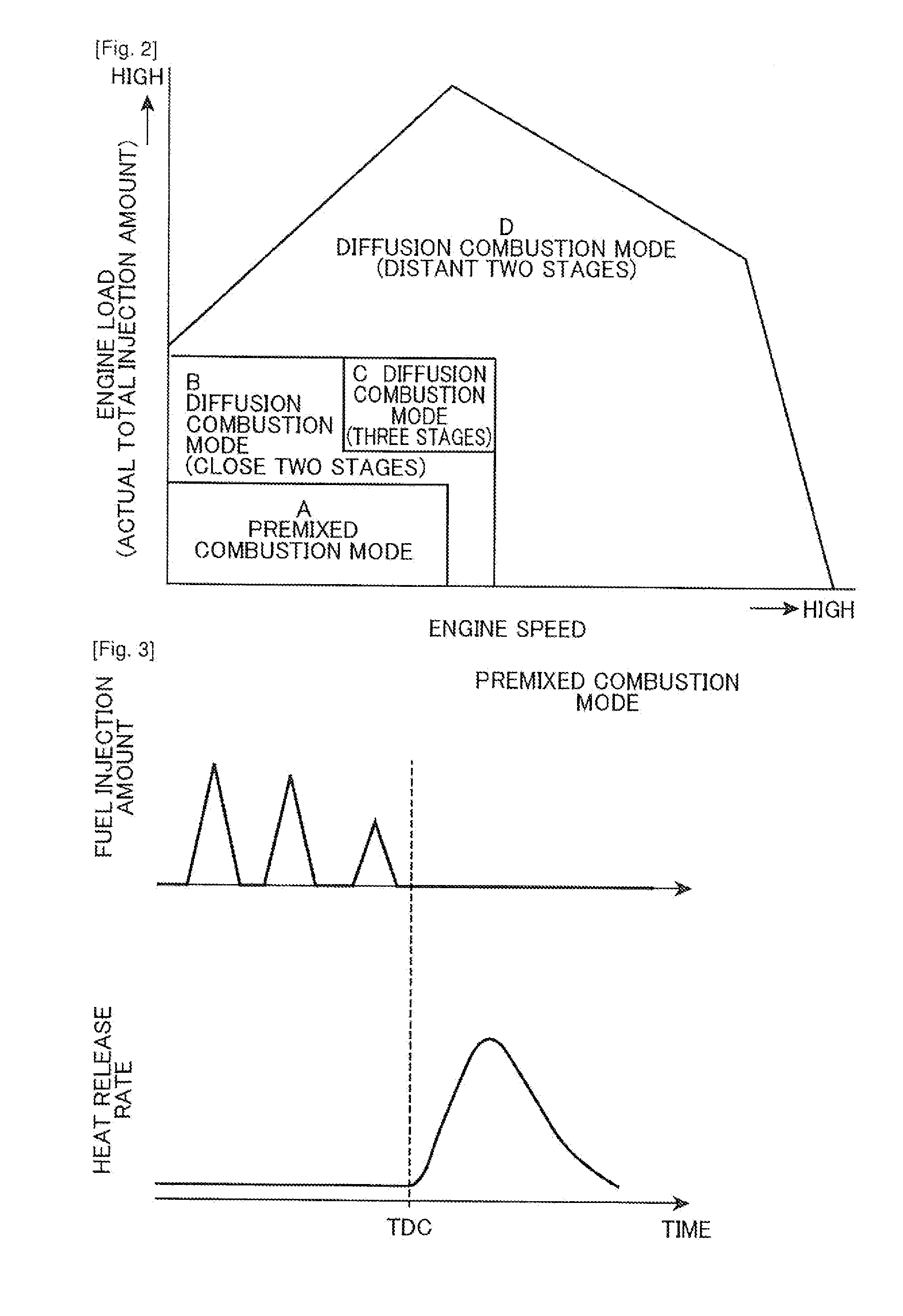

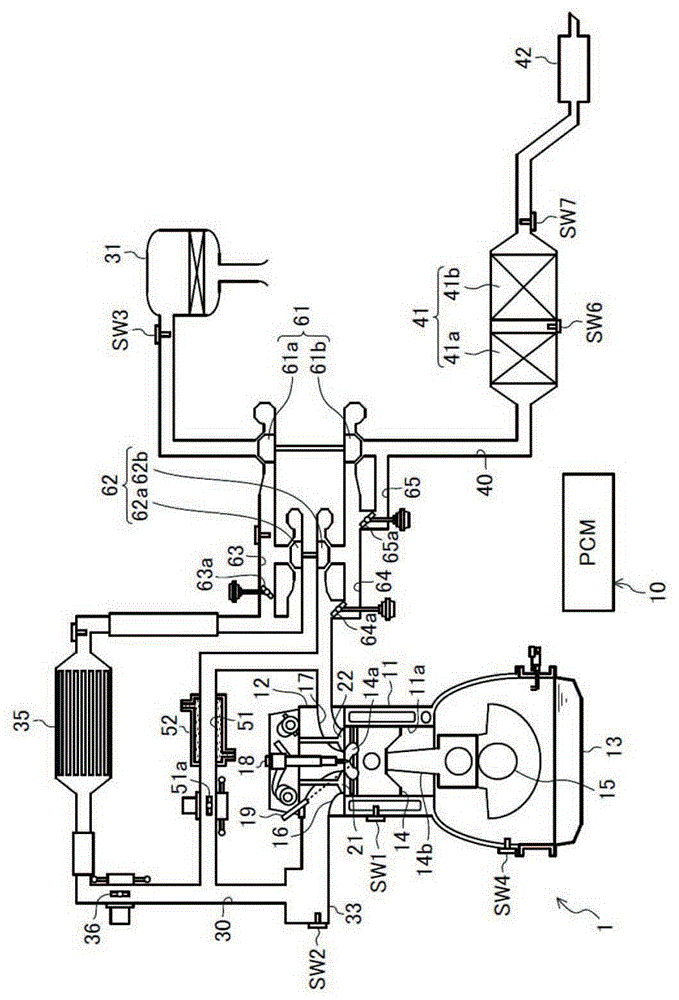

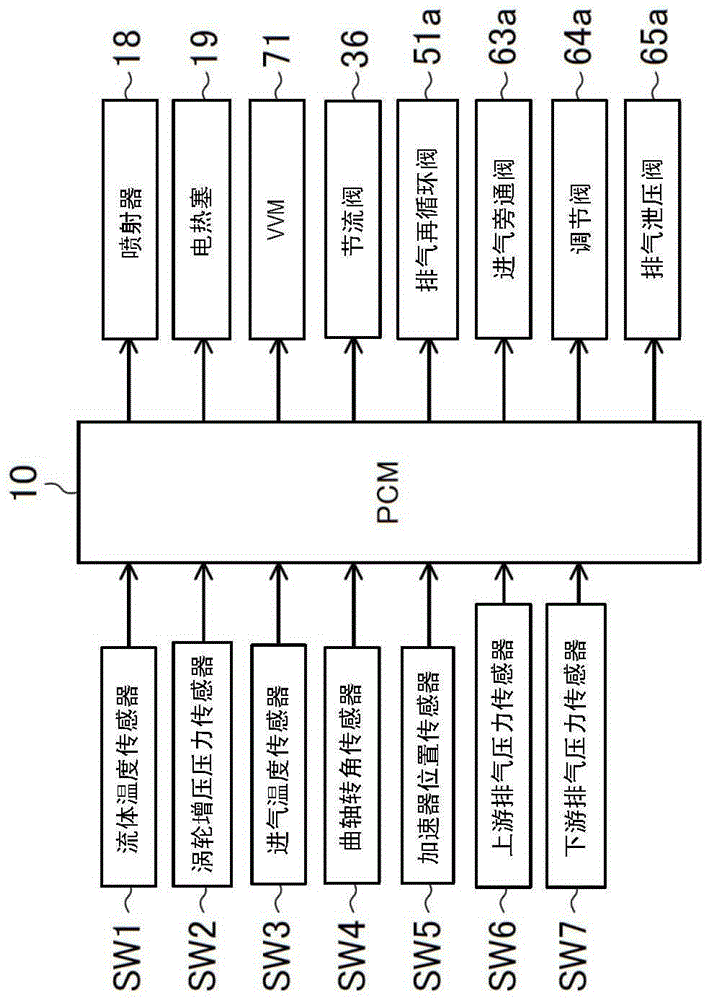

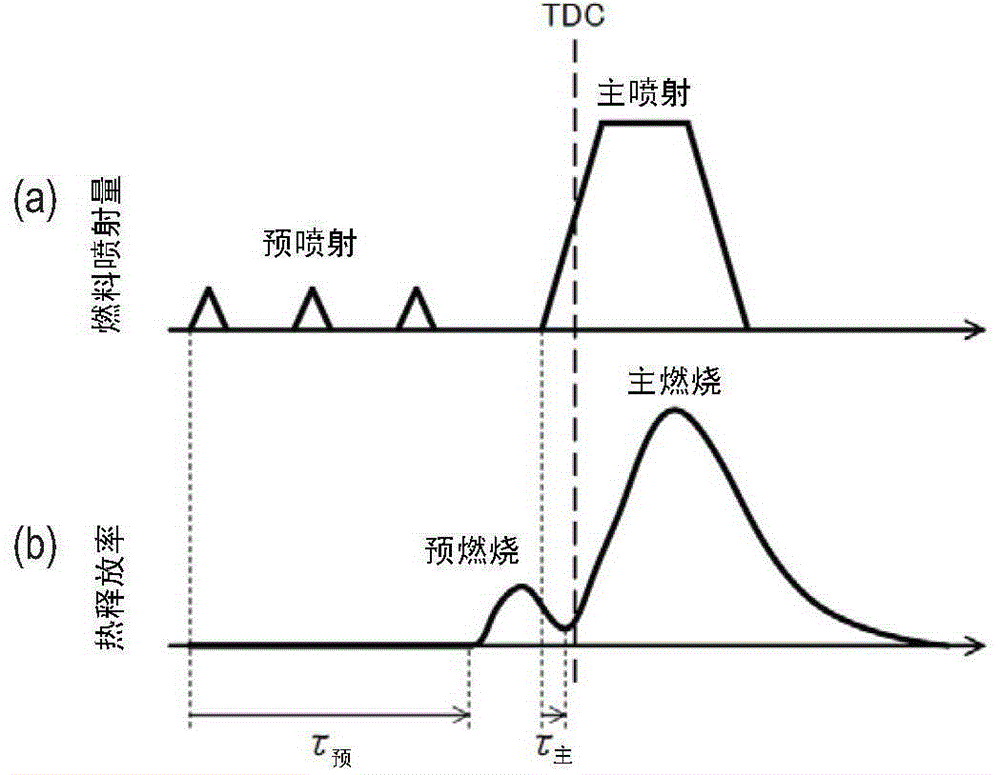

ActiveUS20130073186A1Shorten ignition delaySlow down main combustionElectrical controlInternal combustion piston enginesLow speedTop dead center

A geometric compression ratio in an engine main body 1 is set to 15 or less. Injection control means (ECU 40) performs a main injection of injecting fuel near a compression top dead center, and a preceding injection prior to the main injection at a specific region of predetermined load within an operating region on a relatively low-speed side. The injection control means performs, as the preceding injection, a pilot injection of performing injection at a timing such that at least part of a fuel spray reaches outside a cavity 31 on a top face of a piston, and a pre-injection of injecting fuel at a predetermined timing after the pilot injection, to suppress thereby ignition of the fuel injected by the pilot injection and shorten an ignition delay of the fuel injected by the main injection.

Owner:MAZDA MOTOR CORP

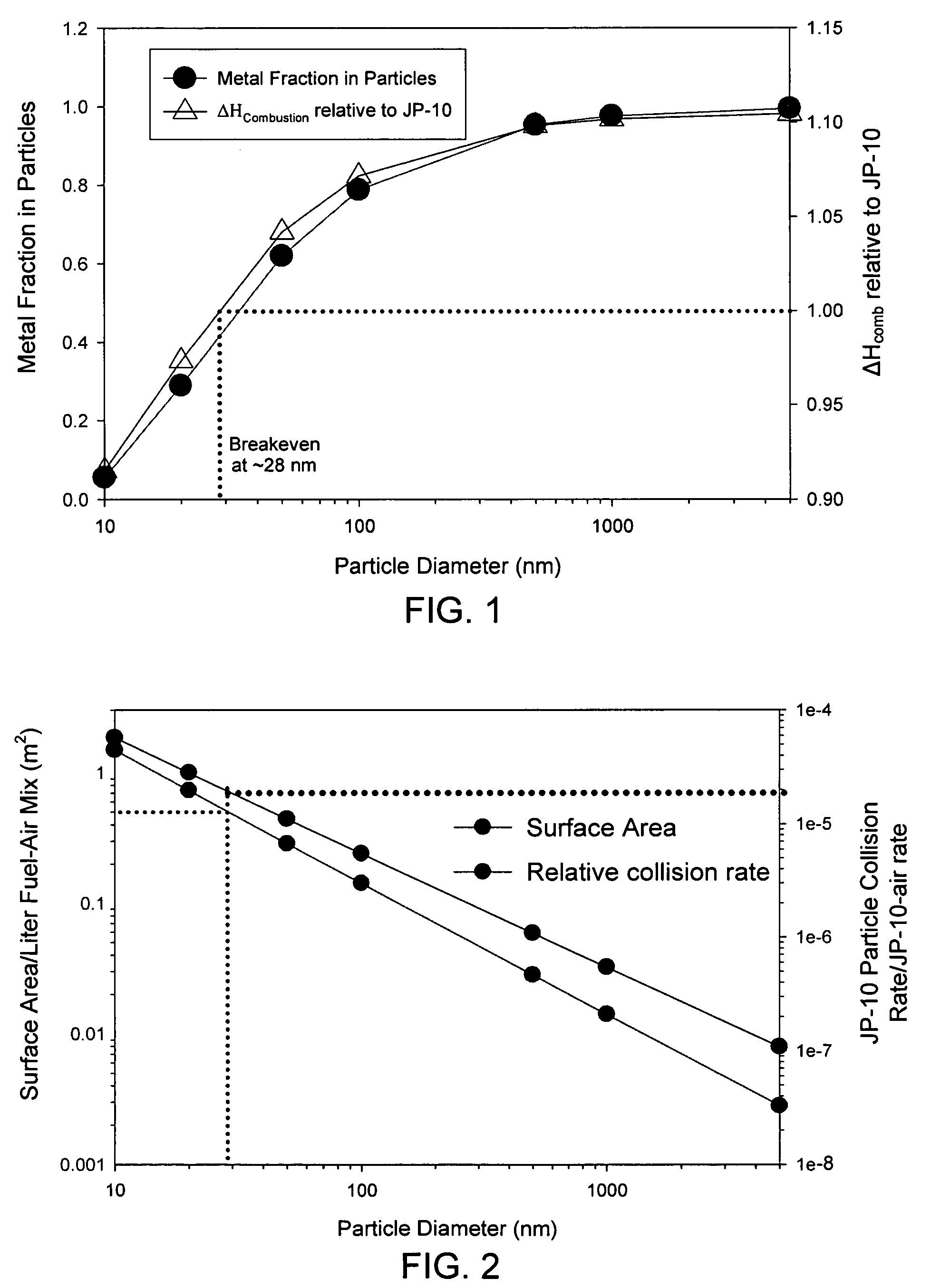

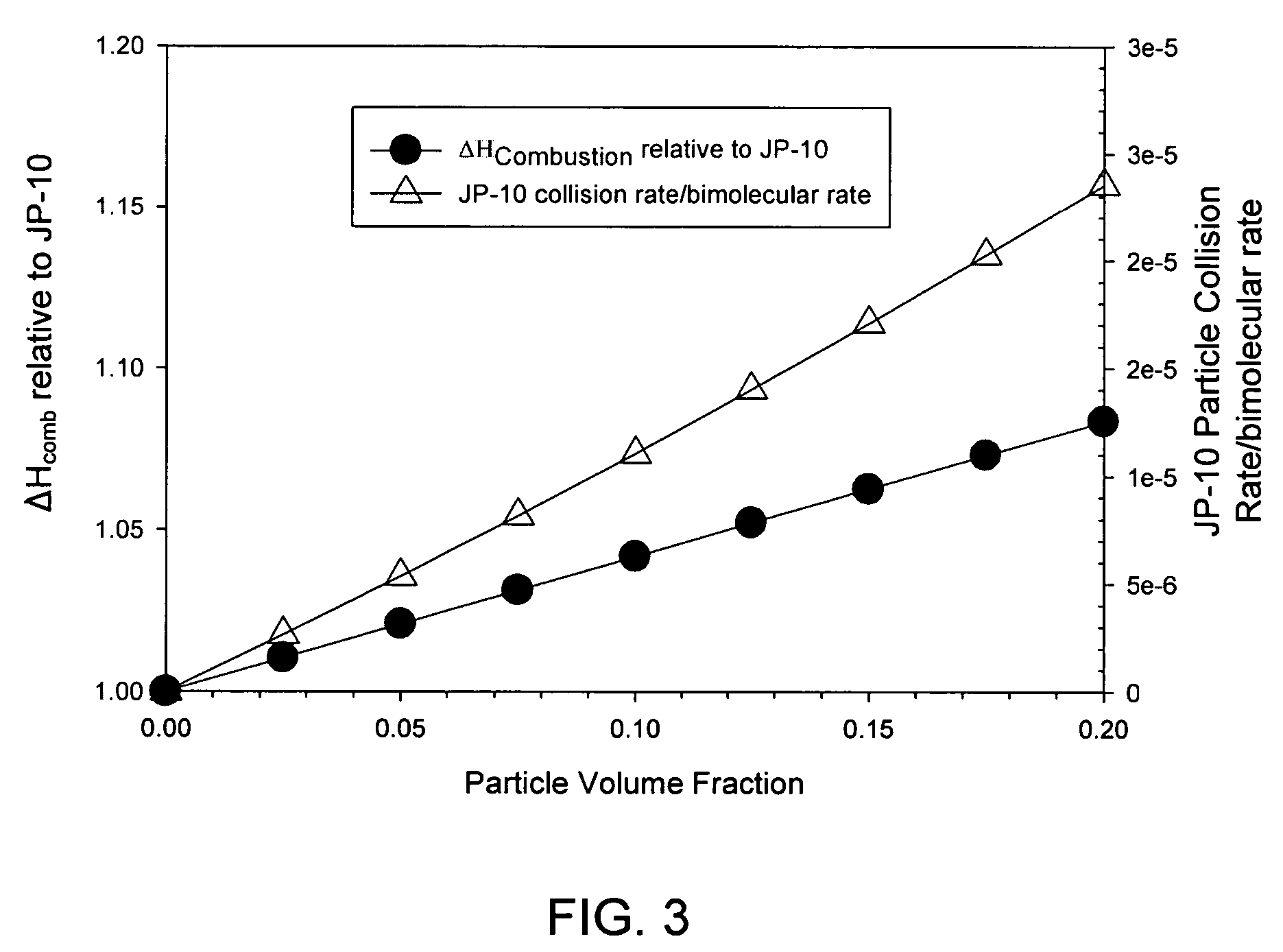

Composite combustion catalyst and associated methods

InactiveUS7635461B2Contribute to energy released during combustionIncrease burn rateMaterial nanotechnologyOxygen/ozone/oxide/hydroxideRamjetJet engine

Composite combustion catalyst particles are described and disclosed. A metal core of a combustible metal can be coated with a metal oxide coating. Additionally, a catalyst coating can at least partially surround the metal oxide coating to form a composite catalyst particle. The composite catalyst particles can be dispersed in a variety of fuels such as propulsion fuels and the like to form an enhanced fuel. During initial stages of combustion, the catalyst coating acts to increase combustion of the fuel. As combustion proceeds, the metal core heats sufficiently to disturb the metal oxide coating. The metal core then combusts in highly exothermic reactions with an oxidizer and the catalyst coating to provide improved energy densities to the enhanced fuel. Enhanced fuels using these composite combustion catalyst particles can exhibit decreased ignition delay times and increased energy densities sufficient for use in high performance propulsion applications such as pulse detonation engines, scramjets, and ramjets.

Owner:THE UNIV OF UTAH +1

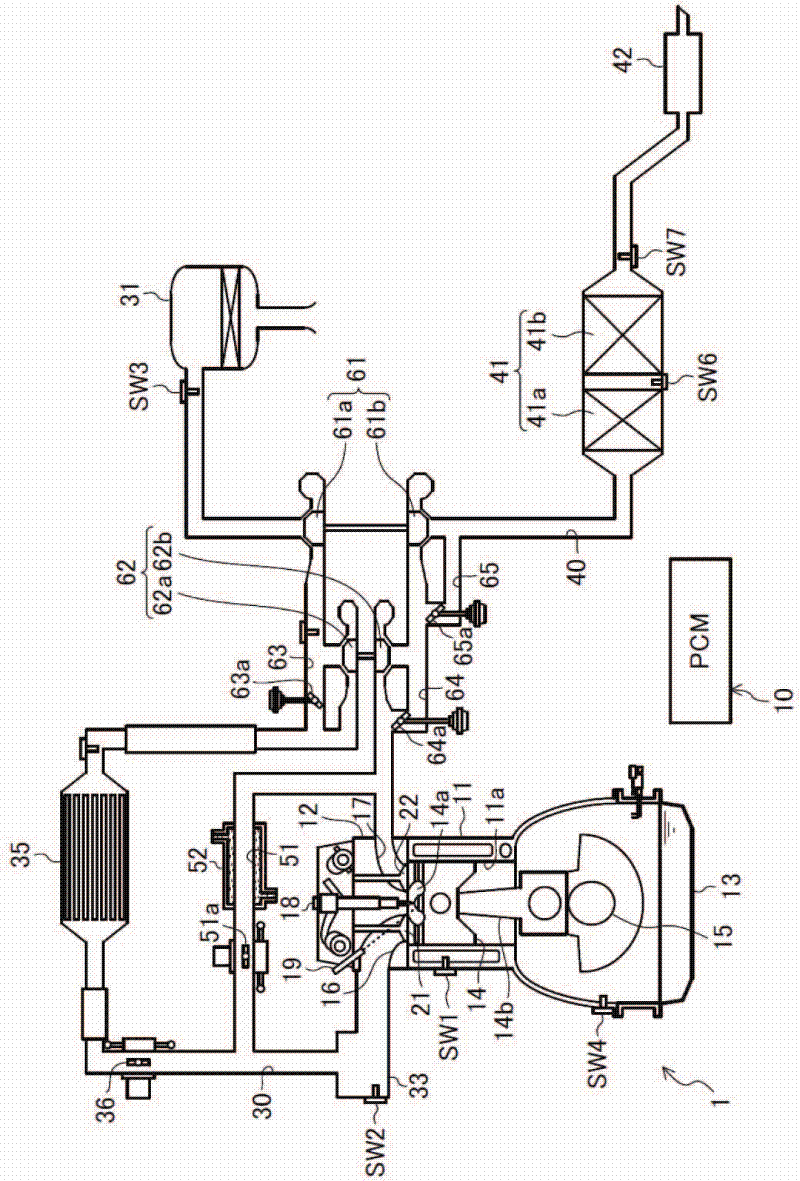

Diesel engine and method of controlling the diesel engine

InactiveCN102312745AEnsure ignitionAvoid NVH Performance Degradation IssuesElectrical controlInternal combustion piston enginesStaged combustionControl theory

The invention relates to a diesel engine and a method of controlling the diesel engine. The diesel engine includes an engine body to be supplied with fuel containing diesel fuel as its main component, a geometric compression ratio being set to 15:1 or below, a fuel injection valve arranged in the engine body so as to be oriented toward a cylinder of the engine body and for directly injecting the fuel into the cylinder, and a control module for controlling a mode of injecting the fuel into the cylinder through the fuel injection valve. The control module performs a main injection where the fuel is injected to cause a main combustion mainly including a diffusion combustion and performs a plurality of pre-stage injections where the fuel is injected prior to the main injection to cause a pre-stage combustion prior to the main combustion. The control module controls the injection mode of the injections to adjust a heat release rate.

Owner:MAZDA MOTOR CORP

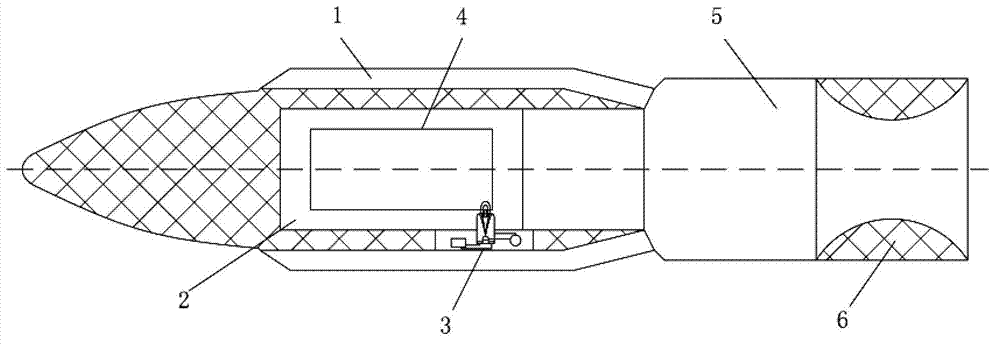

Boron-based solid fuel propeller igniting through plasma generator

InactiveCN102877985ASolve the real problemObvious advantagesRocket engine plantsCombustion chamberPlasma generator

The invention relates to the technology of a propeller, which aims to provide a boron-based solid fuel propeller igniting through a plasma generator. The boron-based solid fuel propeller igniting by using the plasma generator comprises an air inlet, a gas generator, a secondary combustion chamber and a tail sprayer nozzle. The gas generator is internally provided with the boron-based solid fuel, the plasma generator is arranged at the tail end of the gas generator, and the plasma injection opening is aligned with solid fuel. The propeller further comprises an electric control and adjustment system for adjusting the power of the plasma generator and a cooling water system for cooling. The plasma generation process is stable, and high density heat can be provided within a certain time. Compared with conventional igniting powder applied to ignition of the boron-based solid fuel propeller, the ignition is not limited by operation time. Compared with the conventional igniting powder, the temperature is greatly enhanced, and ignition of the boron-based solid fuel can be realized. The ignition power of the plasma can be precisely adjusted through the power adjusting system, so that the invention provides the boron-based solid fuel propeller suitable for different dosages.

Owner:ZHEJIANG UNIV

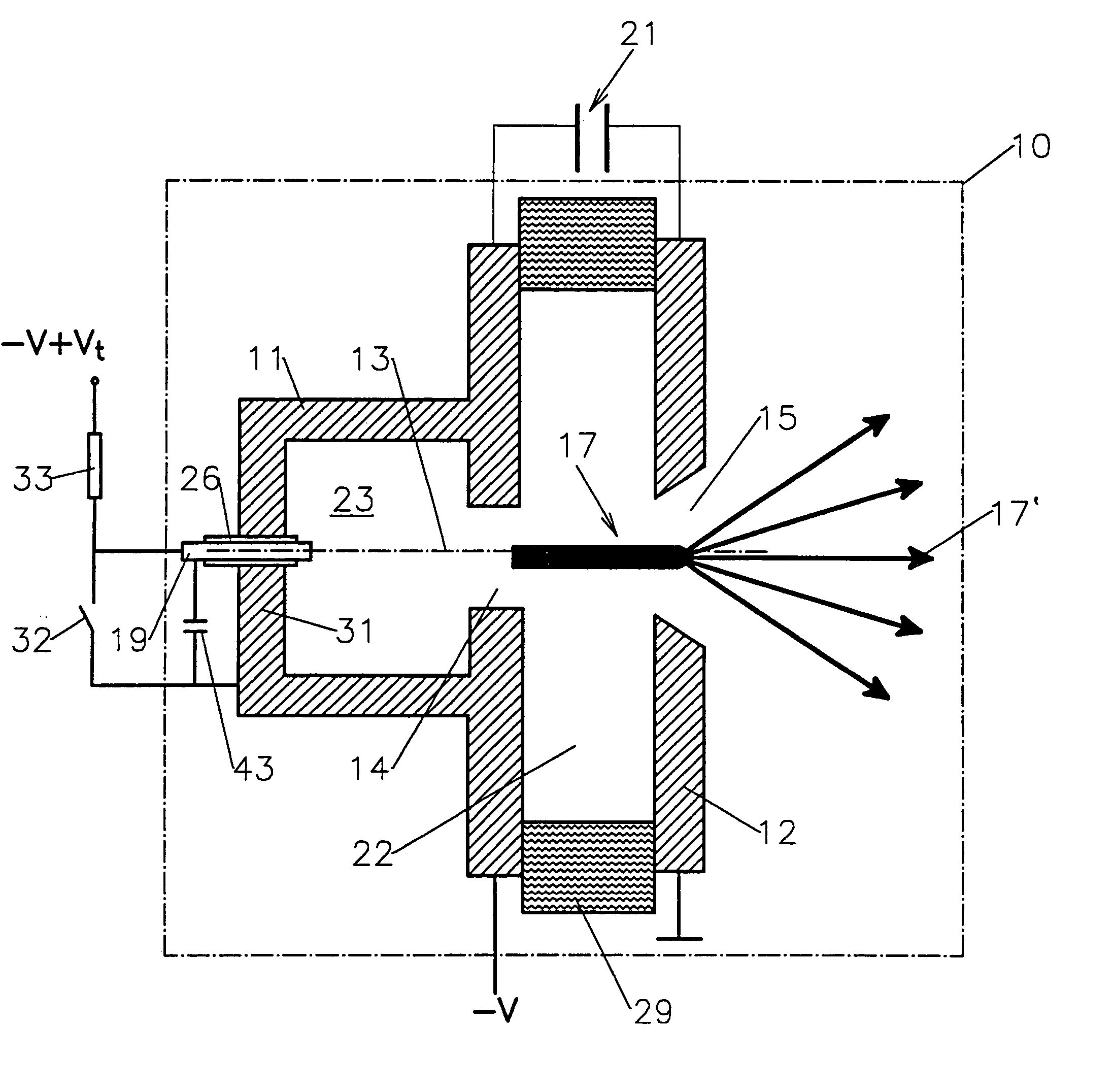

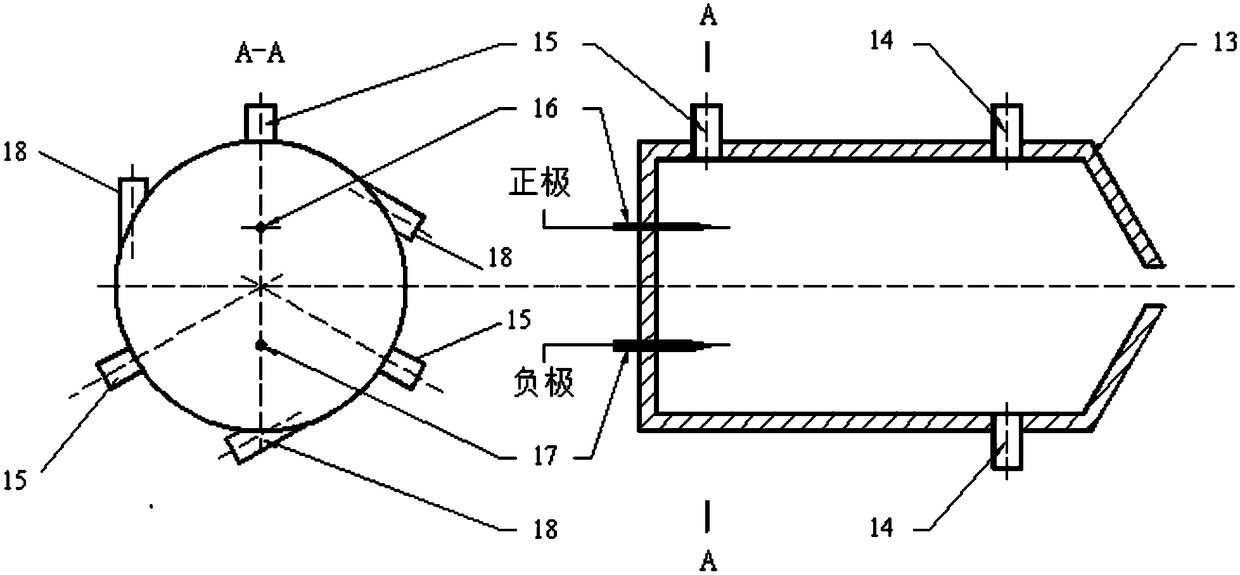

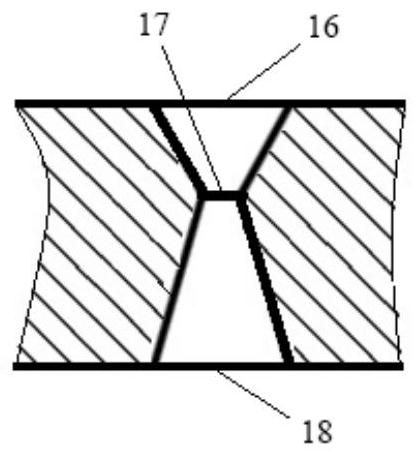

Method and device for producing extreme ultraviolet radiation and soft x-ray radiation

InactiveUS7126143B2Shorten ignition delayIncrease gas pressureRadiation pyrometryRadiation/particle handlingIgnition delayUltraviolet

A method for generating extreme ultraviolet radiation and soft x-ray radiation with a gas discharge operated on the left branch of the Paschen curve, in particular, for EUV lithography,wherein a discharge chamber (10) of a predetermined gas pressure and two electrodes (11, 12) are used, wherein the electrodes have an opening (14, 15), respectively, positioned on the same symmetry axis (13) and, in the course of a voltage increase (16) upon reaching a predetermined ignition voltage (Uz), generate a plasma (17) located in the area between their openings (14, 15), which plasma is a source of the radiation (17′) to be generated,wherein an ignition of the plasma (17) is realized by affecting the gas pressure and / or by triggering,and wherein, with the ignition of the plasma (17), an energy storage device supplies by means of the electrodes (11, 12) stored energy into the plasma (17), characterized in that the ignition of the plasma (17) is realized by using a predetermined ignition delay (18).

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

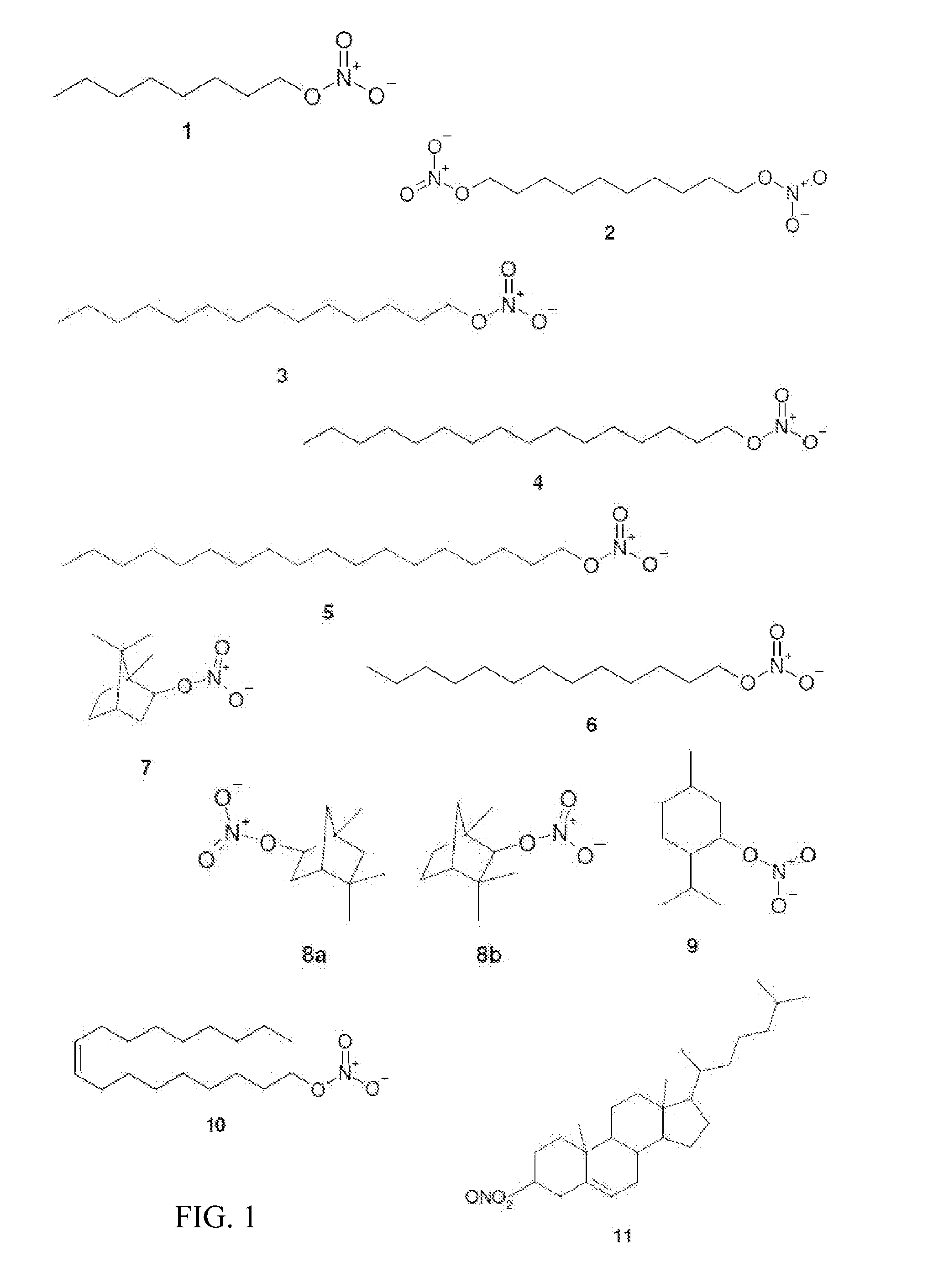

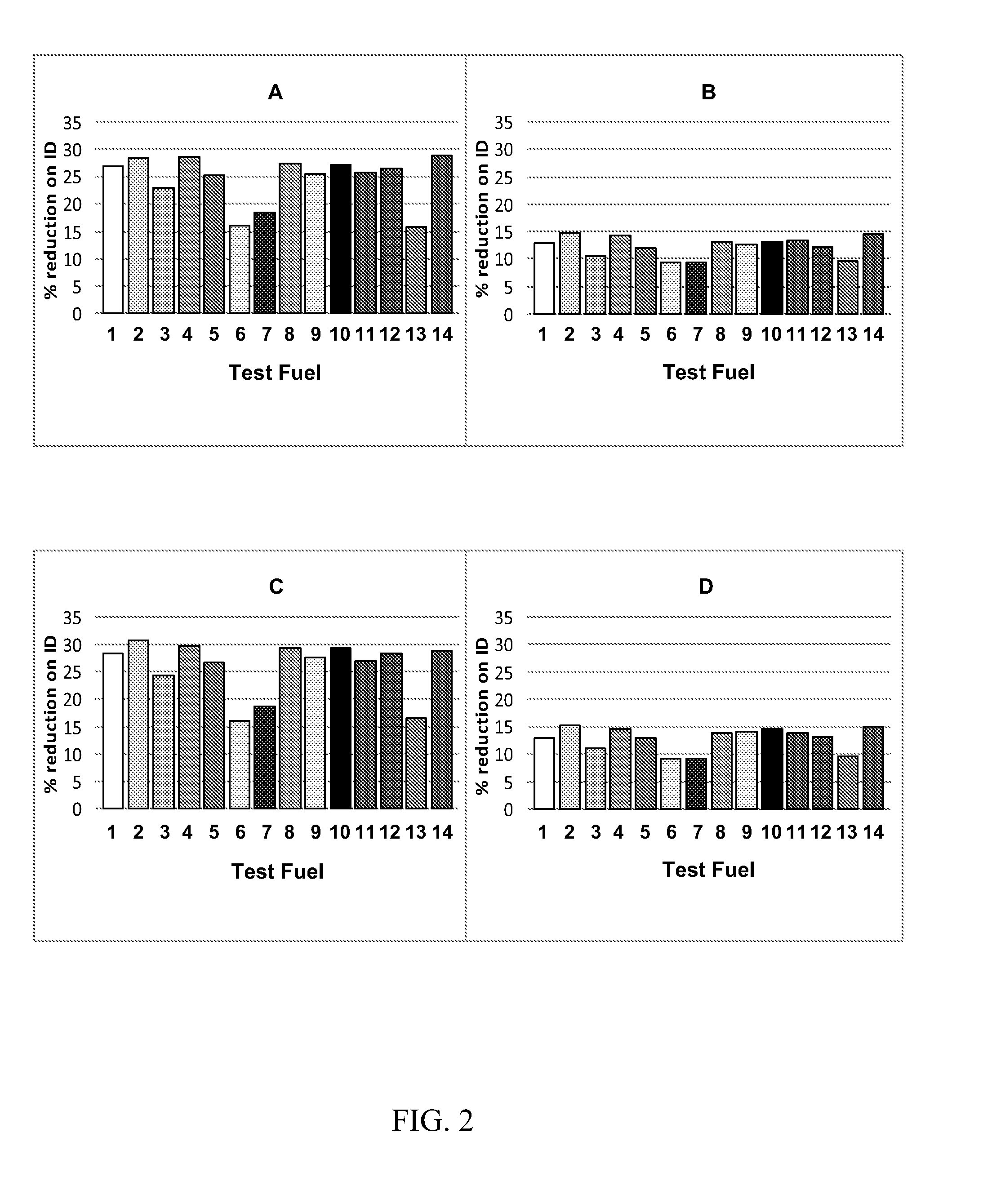

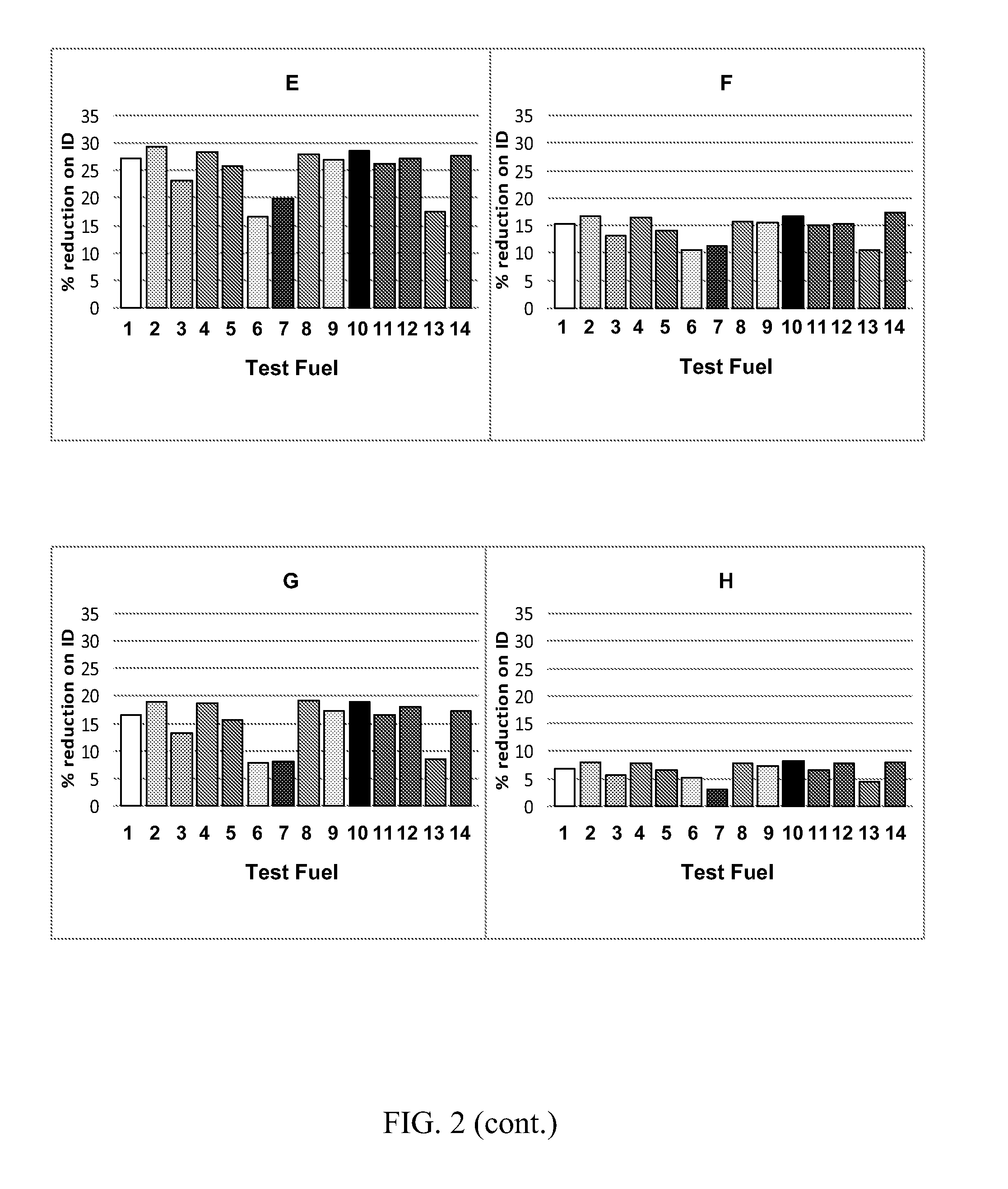

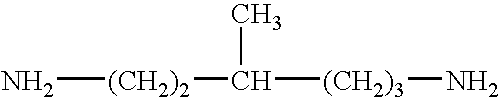

Organic nitrates as ignition enhancers

InactiveUS20130160354A1Similar and low volatilityConvenient and cost-effective for manufacturingLiquid carbonaceous fuelsFuel additivesIgnition delayOrganic nitrates

A diesel fuel composition comprising an organic nitrate is described. The organic nitrate may be a terpene nitrate. Methods of using an organic nitrate for achieving a desired cetane number, and uses of organic nitrates for the purpose of reducing the ignition delay of the fuel and / or for increasing its cetane number to a defined level are also described, as are methods of operating a compression ignition engine.

Owner:SHELL OIL CO

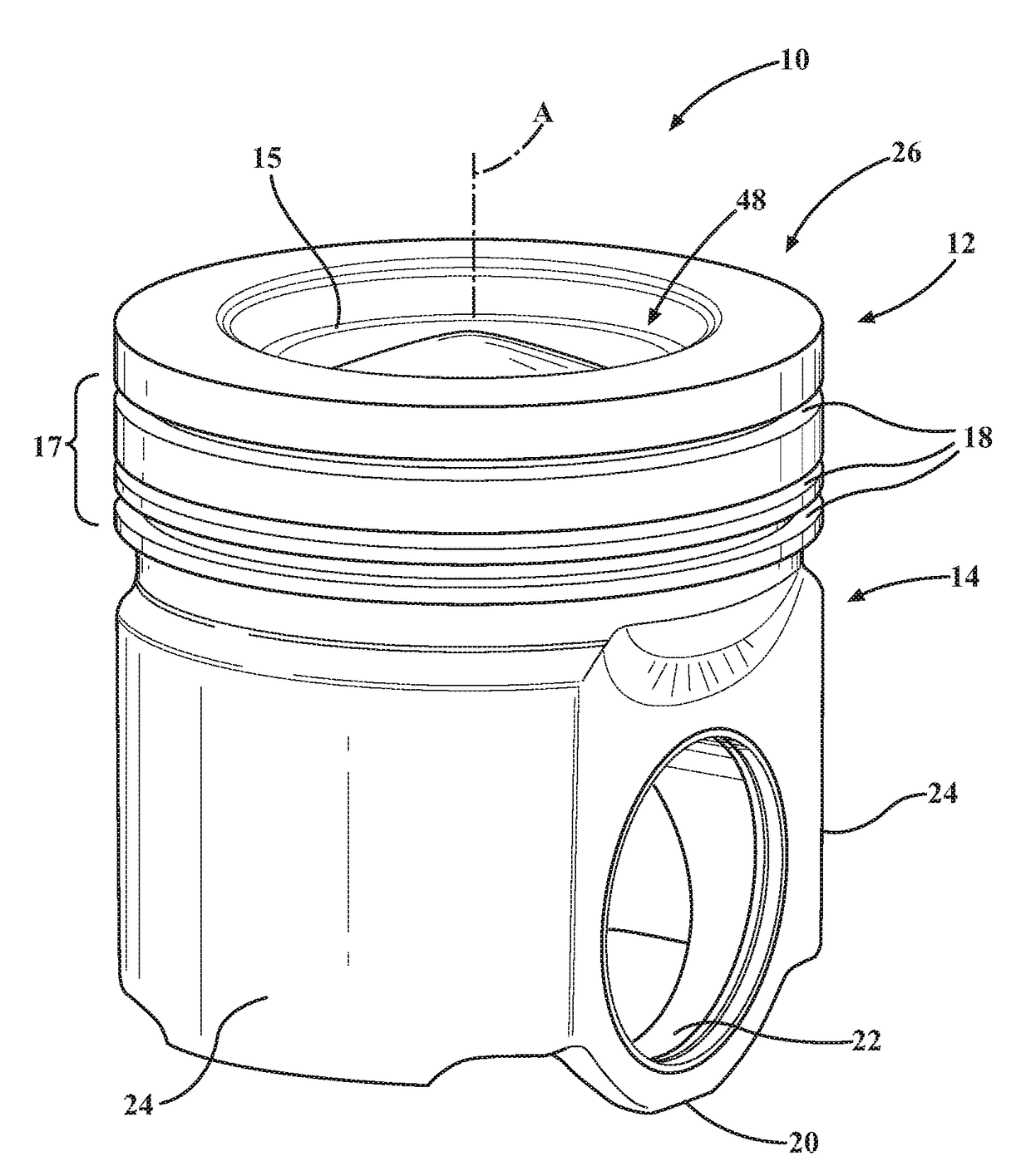

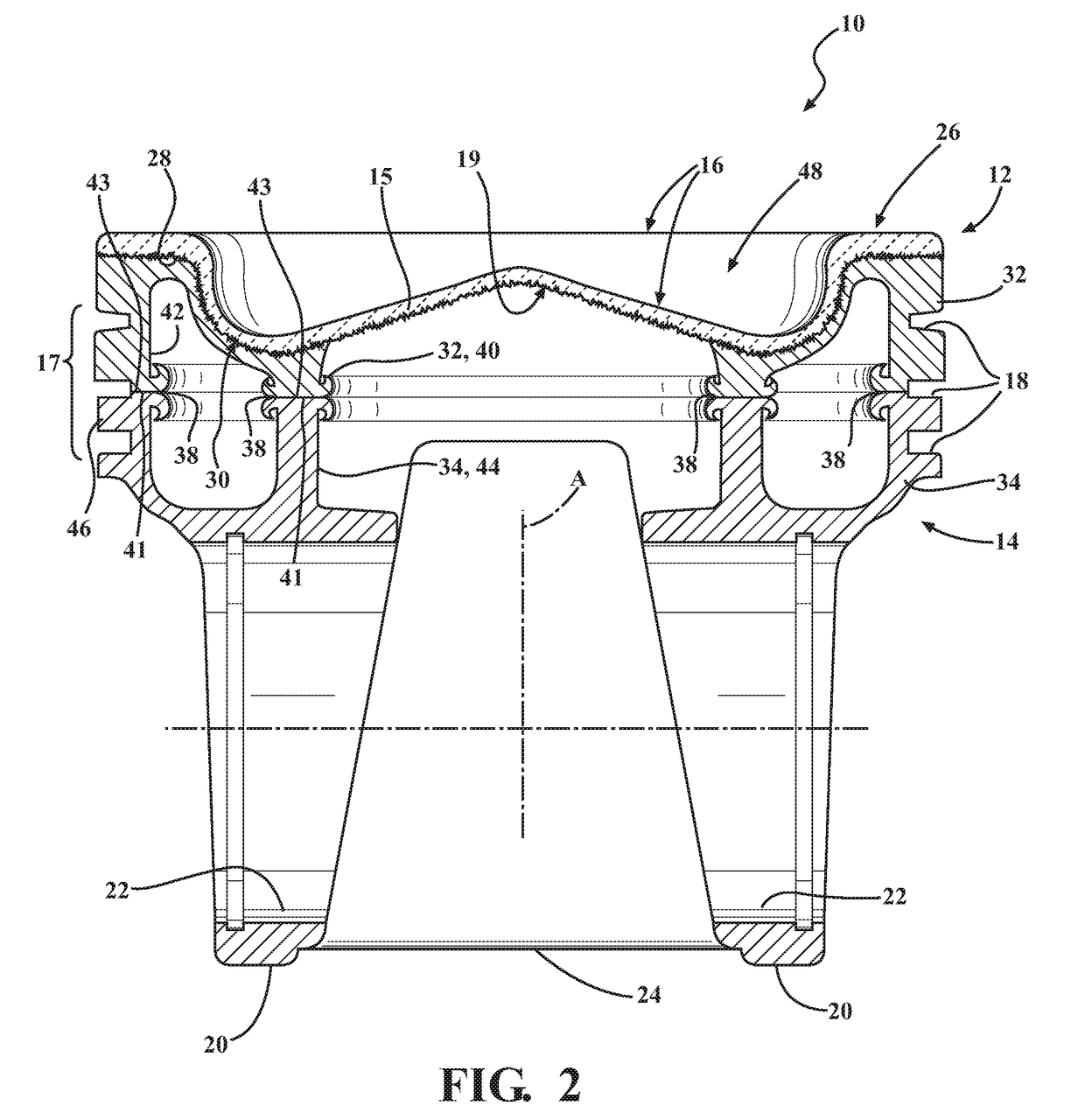

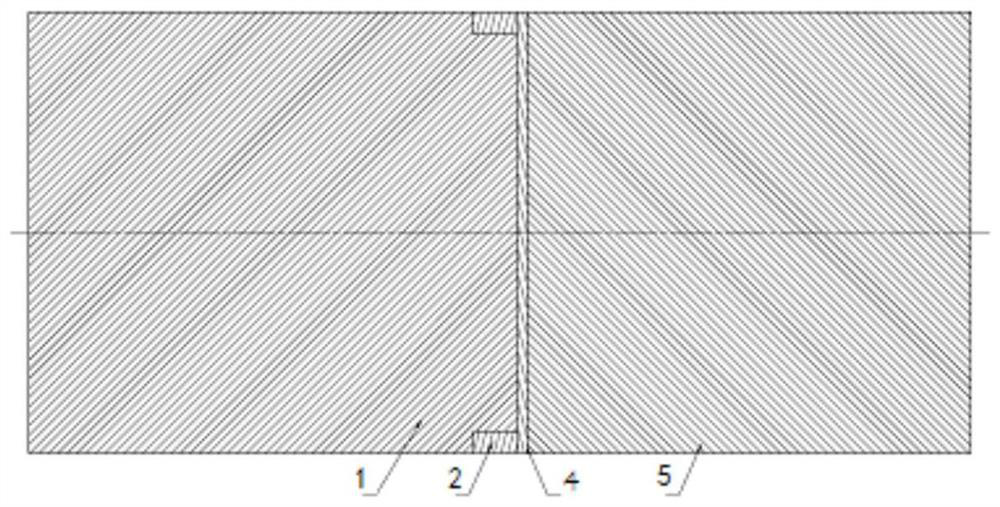

Piston with thermally insulating insert and method of construction thereof

ActiveUS20170284334A1Improve brake thermal efficiencyReduce porositySynthetic resin layered productsCombustion enginesPistonMetallic materials

A piston for an internal combustion engine and method of construction thereof are provided. The piston includes an upper crown formed at least in part by a first metal material and a thermally insulating insert. The upper crown has an upper wall forming an upper combustion surface and a ring belt region. The upper combustion surface is formed at least in part by the thermally insulating insert. The thermally insulating insert has a base surface with pores extending upwardly therein. The first metal material is infused and solidified in the pores, with the first metal material forming a first bonding surface. The piston further includes a body portion formed from a second metal material. The body portion provides pin bosses having coaxially aligned pin bores and diametrically opposite skirt portions. The body portion has a second bonding surface bonded to the first bonding surface of the first metal material.

Owner:TENNECO

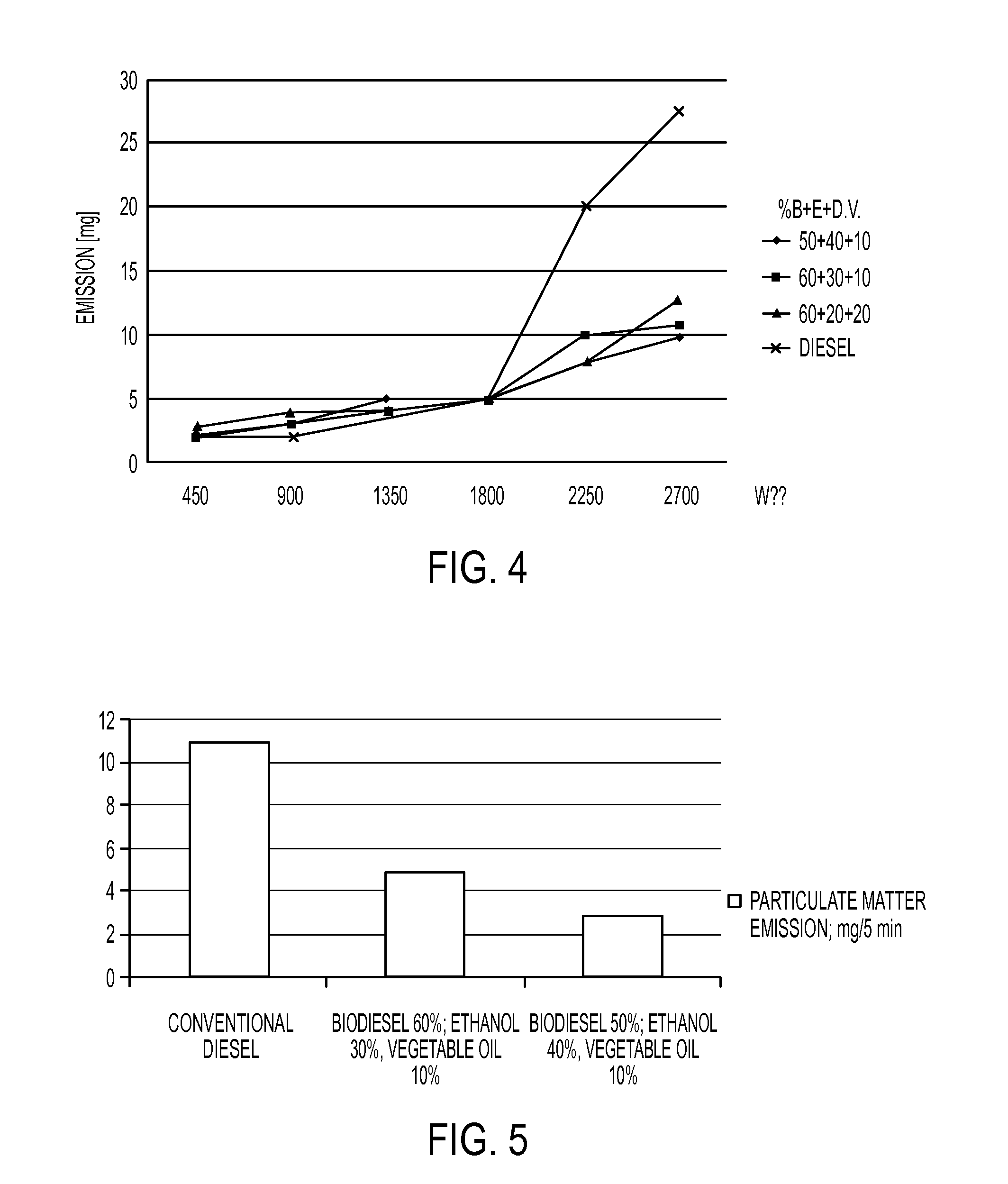

Biodiesel motor fule additive composition

InactiveUS20050268535A1Reduce fuel consumptionShorten ignition delayLiquid carbonaceous fuelsFuel additivesIgnition delayParticulates

Disclosed is a biodiesel fuel additive composition which accelerates combustion phenomenon, reduces ignition delay, and improves Cetane number, thereby lowering particulate emissions, and improving fuel economy in diesel engines.

Owner:POLAR MOLECULAR CORP CORP

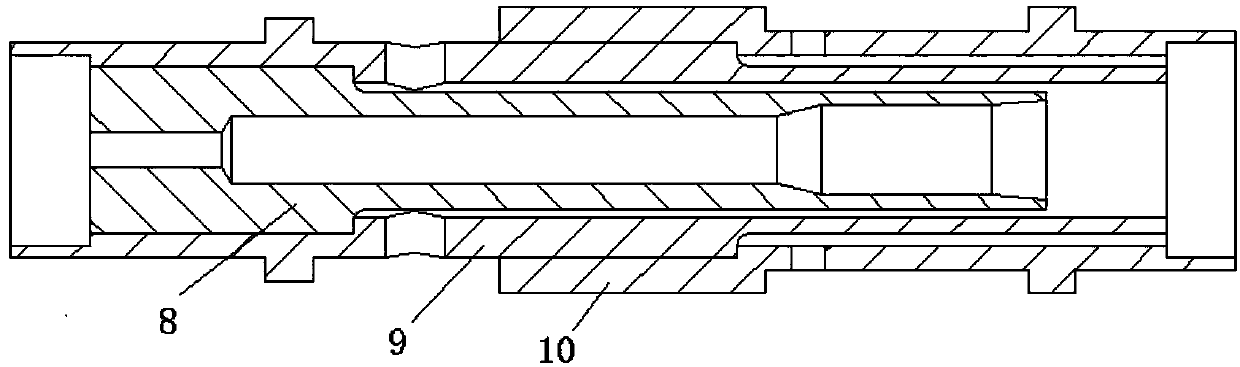

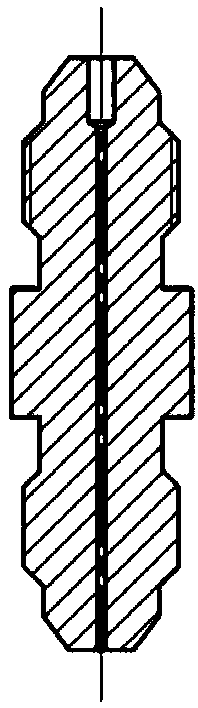

Injection Valve

InactiveUS20080223959A1Rapid onsetReduce dwell timeMachines/enginesFuel injecting pumpsMobile vehicleEngineering

The present invention relates to an injection nozzle for an internal combustion engine in a motor vehicle. A nozzle body has at least one spray hole, a nozzle needle mounted in the nozzle body with adjustable stroke for controlling an injection of fuel through the at least one spray hole. A booster piston is drive-coupled to an actuator and has a booster face which delimits a booster chamber. According to the invention, the nozzle needle has a control face which delimits a control chamber. In order to dampen the movement of the nozzle needle into its needle seat as the nozzle needle closes, a damping piston is arranged in the nozzle body with an adjustable stroke. The damping piston separates the control chamber from the booster chamber. A damping path is provided in the damping piston to hydraulically connect the control chamber to the booster chamber in a throttled manner.

Owner:ROBERT BOSCH GMBH

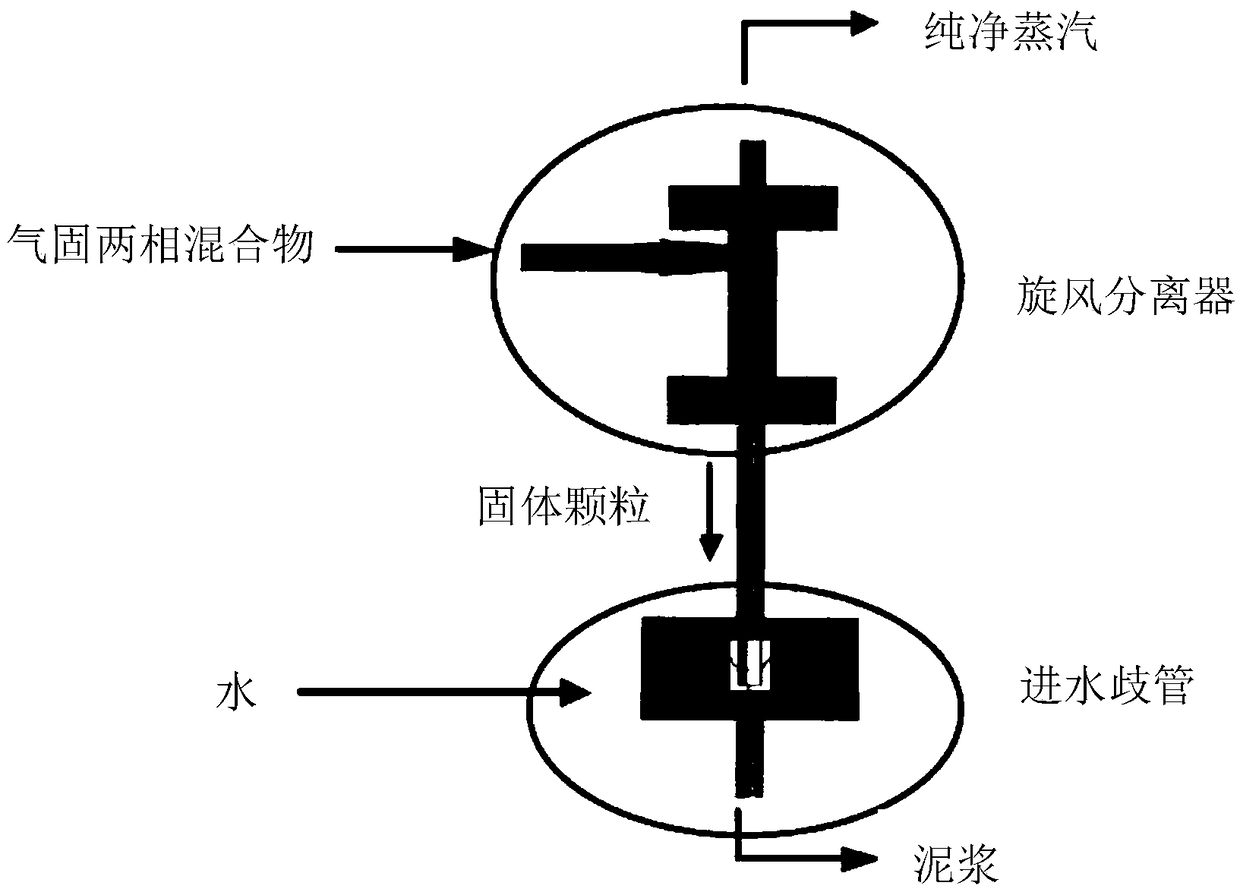

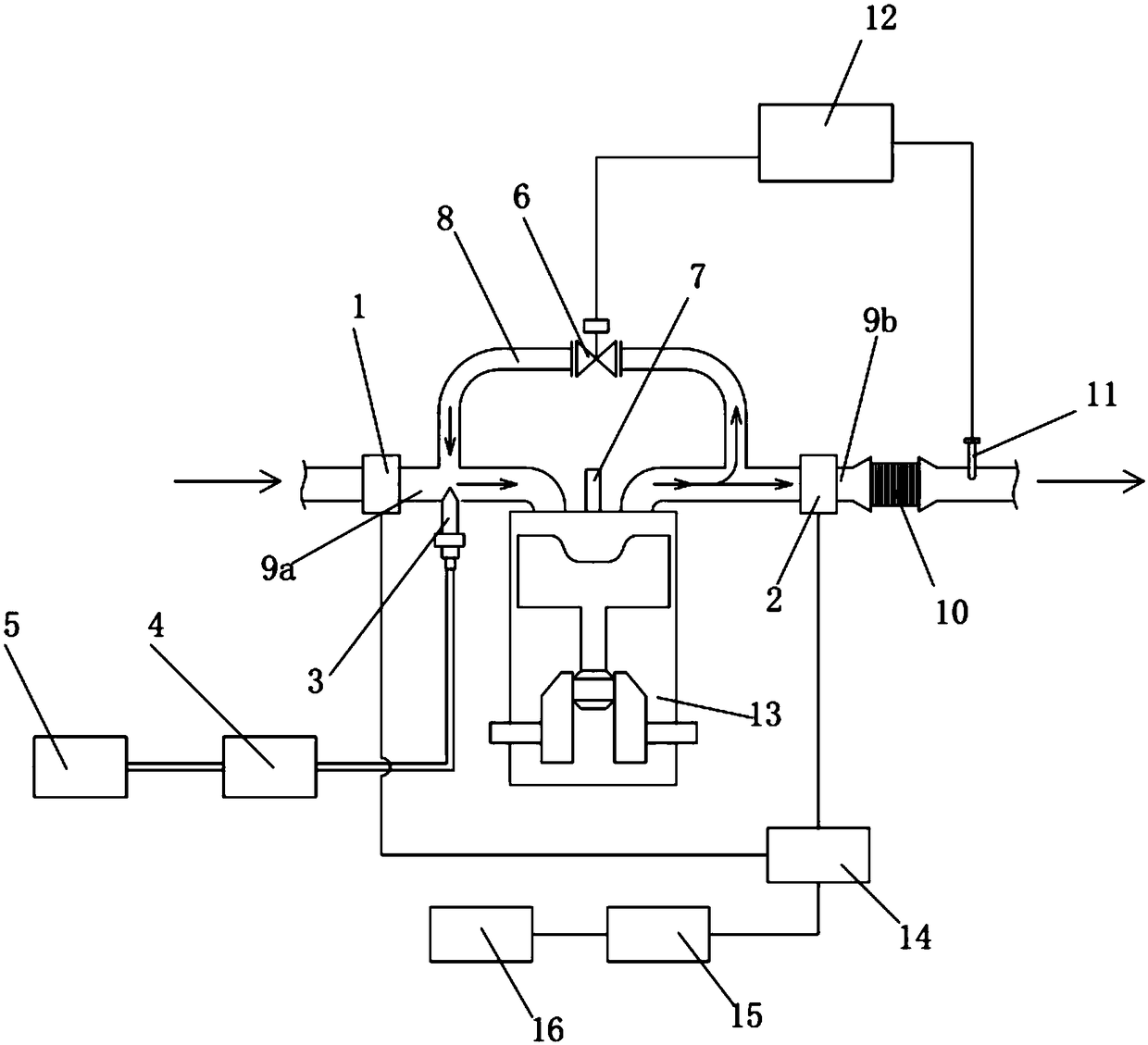

Self-adaptive control supercritical hydrothermal combustion type multi-element thermal fluid generating system

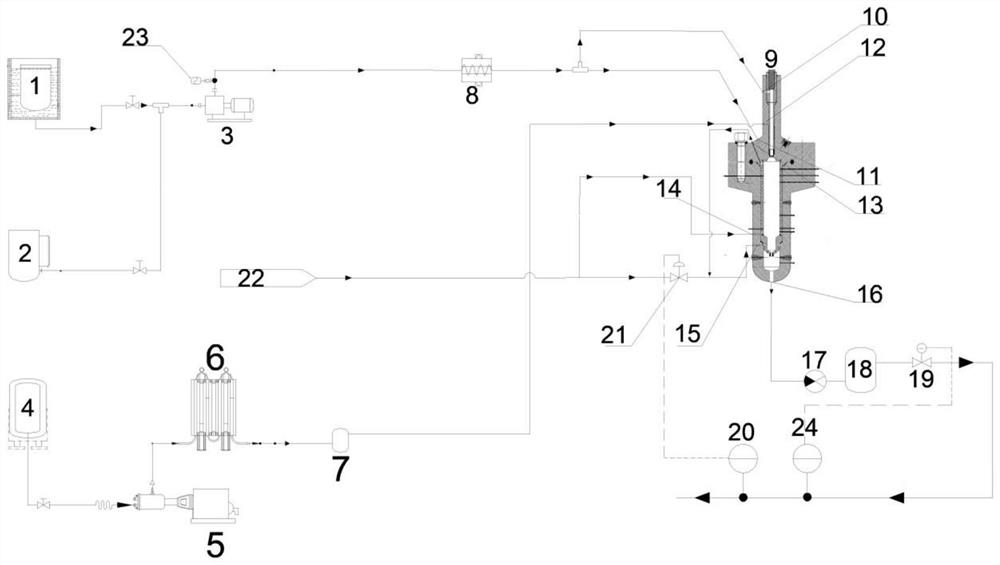

PendingCN113756764AReduce ignition delayImprove mining efficiencyLiquid fuel feeder/distributionFluid removalProcess engineeringCombustion

A self-adaptive regulation and control supercritical hydrothermal combustion type multi-element thermal fluid generation system comprises a reactor, a material pretreatment module, an oxidizing agent supply module, a cooling module, a temperature and pressure regulating module and the like, and the reactor, the material pretreatment module, the oxidizing agent supply module and the supercritical hydrothermal combustion reaction module are used for generating multi-element thermal fluid; the pressure and the temperature of the multi-element thermal fluid are adjusted through the temperature and pressure adjusting module, the wall face of the reactor is protected through the cooling module, the multi-element thermal fluid meeting the exploitation requirement is safely and stably produced, and a feasible scheme is provided for efficient exploitation of thickened oil.

Owner:XI AN JIAOTONG UNIV

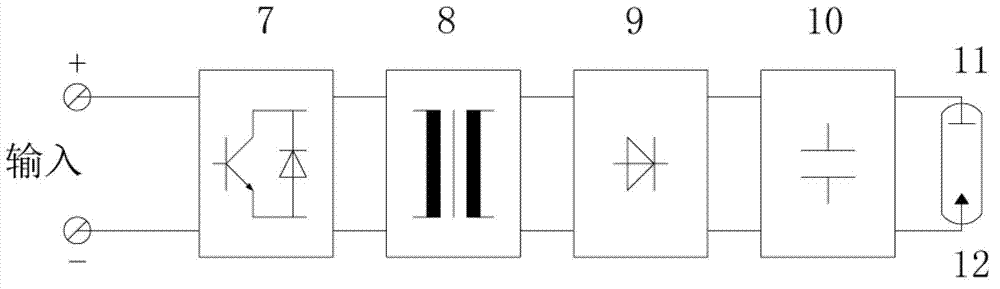

Underwater thermoelectric hybrid power system based on steam plasma

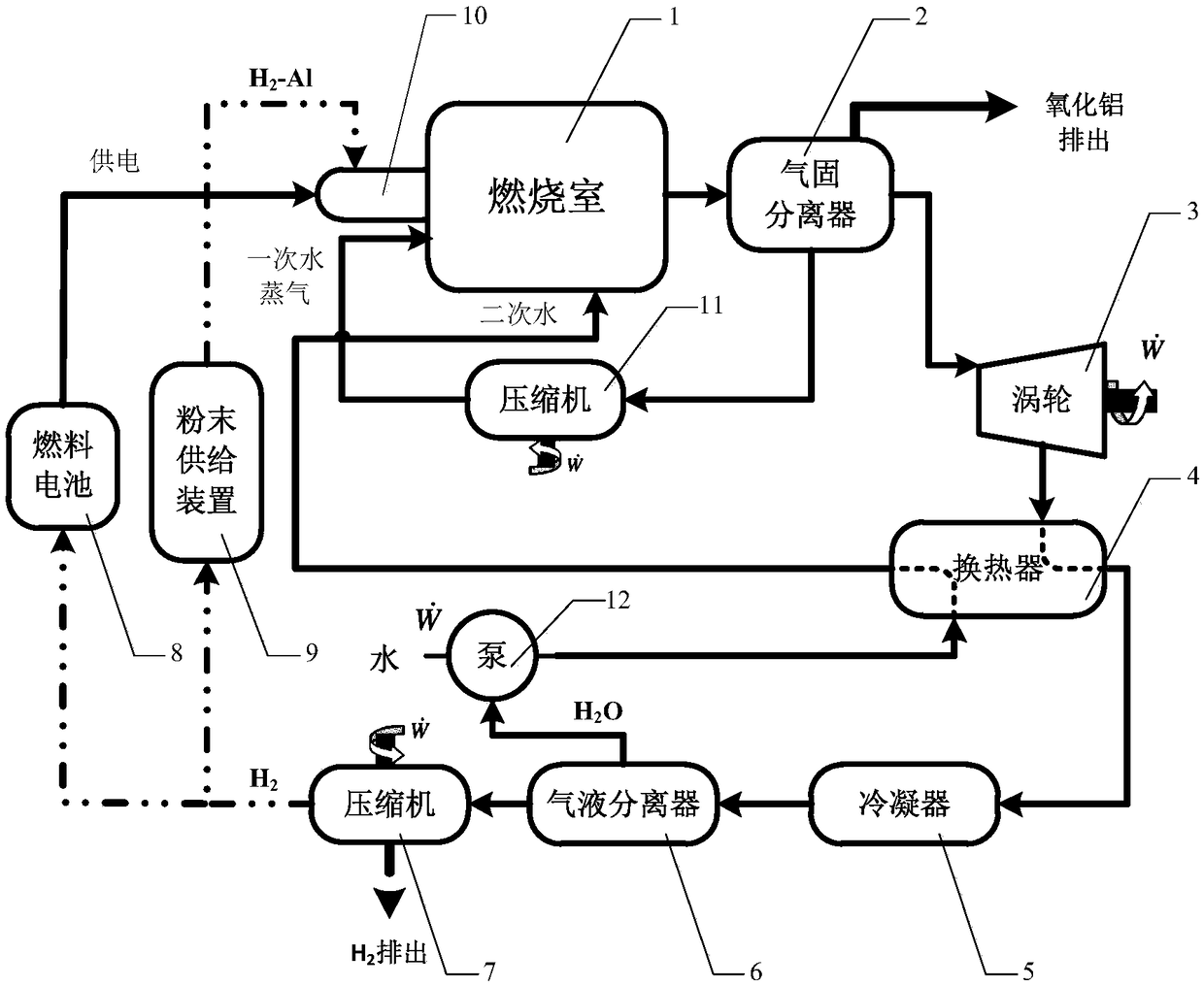

ActiveCN108825378AIncrease energy densityIncrease the energy density per unit volumeGas turbine plantsFuel cell detailsCombustion chamberEngineering

The invention discloses an underwater thermoelectric hybrid power system based on steam plasma. The underwater thermoelectric hybrid power system comprises a combustion chamber, a gas-solid separator,a turbine, a heat exchanger, a condenser, a gas-liquid separator, a second compressor, a fuel cell, a powder supplying device, a plasma igniter / booster, a first compressor and a pump. An aluminum / water combustion reaction is started and enhanced through the plasma igniter / booster by taking aluminum powder as fuel and taking primary superheated steam as an oxidizing agent. On one hand, water is heated through great heat released by the aluminum / water reaction to be changed into steam and drive the turbine to do work to generate thrust; and on the other hand, hydrogen generated through the aluminum / water reaction is converted into electric energy for driving the plasma igniter / booster through the fuel cell, therefore, efficient utilization of energy is achieved, and the disposal problem ofhydrogen in an underwater environment is reasonably solved.

Owner:NAT UNIV OF DEFENSE TECH

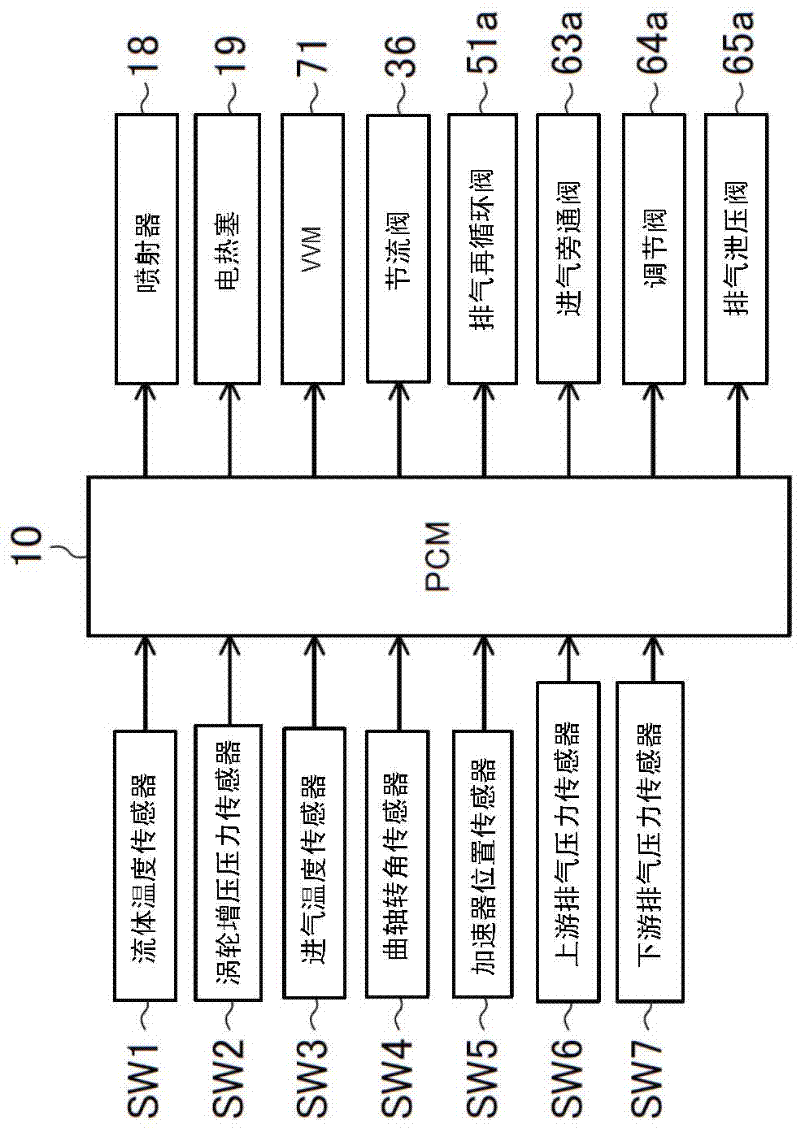

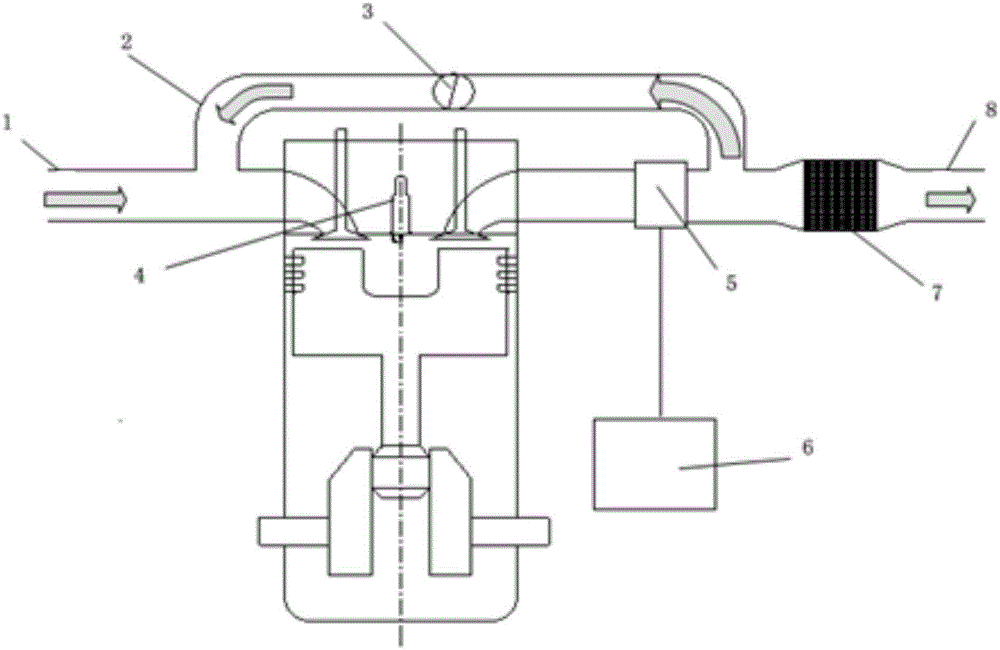

Plasma system of natural gas engine

InactiveCN106050485AShorten ignition delayImprove the problem of decreased combustion stabilityExhaust apparatusExhaust gas recirculationFlame propagationControl manner

The invention discloses a plasma system of a natural gas engine. The plasma system of the natural gas engine comprises a gas inlet pipe, an exhaust pipe, an EGR pipe, a plasma generator and a catalyst. One end of the EGR pipe communicates with the exhaust pipe, and the other end of the EGR pipe communicates with the gas inlet pipe. The EGR pipe is provided with an EGR adjusting valve connected with an ECU in a controlled manner. The plasma generator is arranged on the exhaust pipe and located on the upstream side of the communication position between the EGR pipe and the exhaust pipe. The catalyst is arranged on the exhaust pipe and located on the downstream side of the communication position between the EGR pipe and the exhaust pipe. The plasma system of the natural gas engine can shorten the ignition delay time of the engine, increase the flame propagation velocity in a cylinder and widen the knock border, so that the combustion efficiency is improved, and HC discharge is lowered. Meanwhile, the ignition energy of an ignition system can also be lowered, and the reliability of the ignition system is improved. Besides, the plasma system of the natural gas engine can improve the conversion efficiency of the three pollutants of CH4, NOx and CO.

Owner:GUANGXI YUCHAI MASCH CO LTD

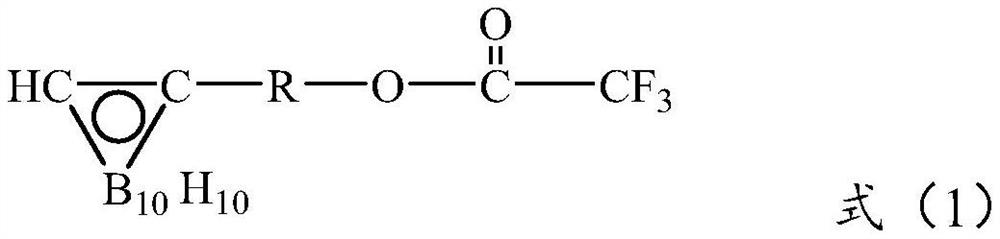

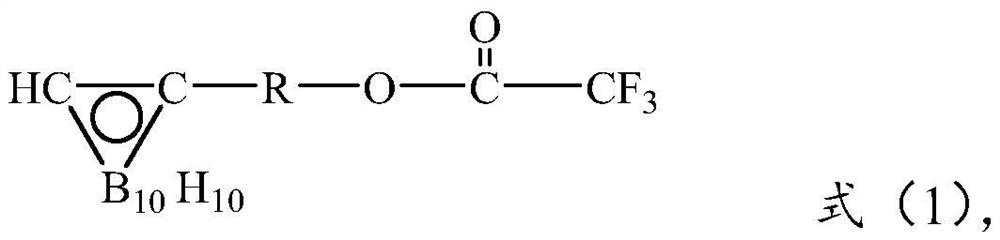

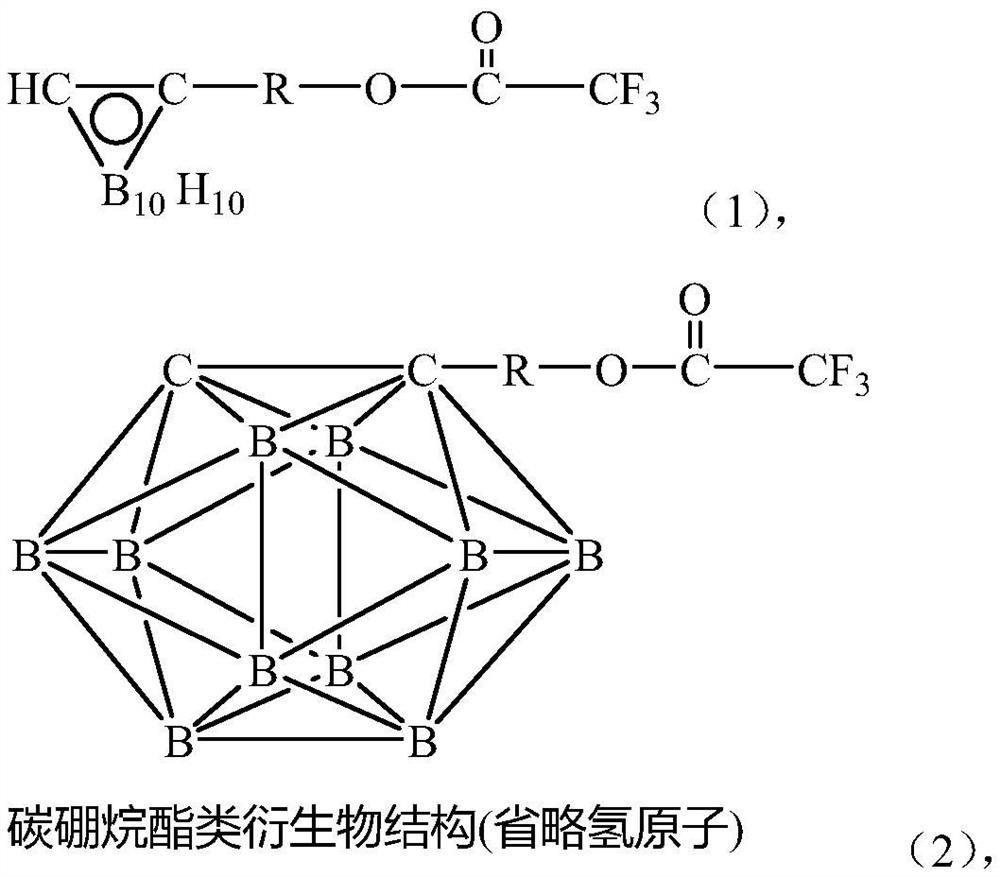

Carborane plasticized boron-containing fuel-rich propellant

ActiveCN114507108AImprove craftsmanshipHigh calorific value characteristicsNon-explosive/non-thermic compositionsPressure gas generationRamjetAlkane

The invention discloses a carborane plasticized boron-containing fuel-rich propellant, the propellant takes a carborane derivative with weak polarity as a plasticizer and boron powder as a fuel, and the carborane plasticizer has a rigid boron cage structure with high calorific value characteristic, a flexible alkane chain structure and a fluoride structure containing boron powder combustion efficiency. The propellant has good compatibility with components of the propellant, does not sublimate or migrate, improves the processing property of the propellant, improves the energy performance and combustion performance of the propellant, reduces the generation of condensed phases, and improves the service life of the propellant. The technical requirements of the solid ramjet engine for high calorific value, excellent ignition performance, high combustion efficiency, low condensed phase, clean fuel gas and low residue of the propellant are met, and a solid foundation is laid for solving the power source requirement problem of the solid ramjet engine.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Gasoline engine ignition mechanism comprising supersonic jet orifice pre-combustion chamber

ActiveCN113685262AShortened lean burn limitImprove combustion effectInternal combustion piston enginesCombustion chamberJet flow

The invention relates to a gasoline engine ignition mechanism comprising a supersonic jet orifice pre-combustion chamber. The ignition mechanism comprises a cylindrical connecting piece, an oil sprayer mounting hole penetrating through the upper end face and the lower end face of the connecting piece, a spark plug mounting hole penetrating through the connecting piece, a pre-combustion chamber connected with the peripheral face of the connecting piece, a pre-combustion chamber oil sprayer matched with the oil sprayer mounting hole and a pre-combustion chamber spark plug matched with the spark plug mounting hole, wherein the pre-combustion chamber is formed by combining three sections, namely a first cylindrical sleeve body, a conical sleeve body and a second cylindrical cavity body from top to bottom in sequence, N uniformly distributed spray holes are formed in the lower part of the second cylindrical cavity body, and N is greater than or equal to 3; at least one of the spray holes is an over-expansion supersonic jet flow spray hole, and jet flow of the supersonic jet holes not only can shorten ignition delay, but also can prolong the lean combustion limit of a mixture in the main combustion chamber.

Owner:TIANJIN UNIV

Diesel engine for automobile, control device and control method

ActiveUS9234478B2Improve NVH performanceImprove controllabilityElectrical controlInternal combustion piston enginesLow speedTop dead center

A geometric compression ratio in an engine main body 1 is set to 15 or less. Injection control means (ECU 40) performs a main injection of injecting fuel near a compression top dead center, and a preceding injection prior to the main injection at a specific region of predetermined load within an operating region on a relatively low-speed side. The injection control means performs, as the preceding injection, a pilot injection of performing injection at a timing such that at least part of a fuel spray reaches outside a cavity 31 on a top face of a piston, and a pre-injection of injecting fuel at a predetermined timing after the pilot injection, to suppress thereby ignition of the fuel injected by the pilot injection and shorten an ignition delay of the fuel injected by the main injection.

Owner:MAZDA MOTOR CORP

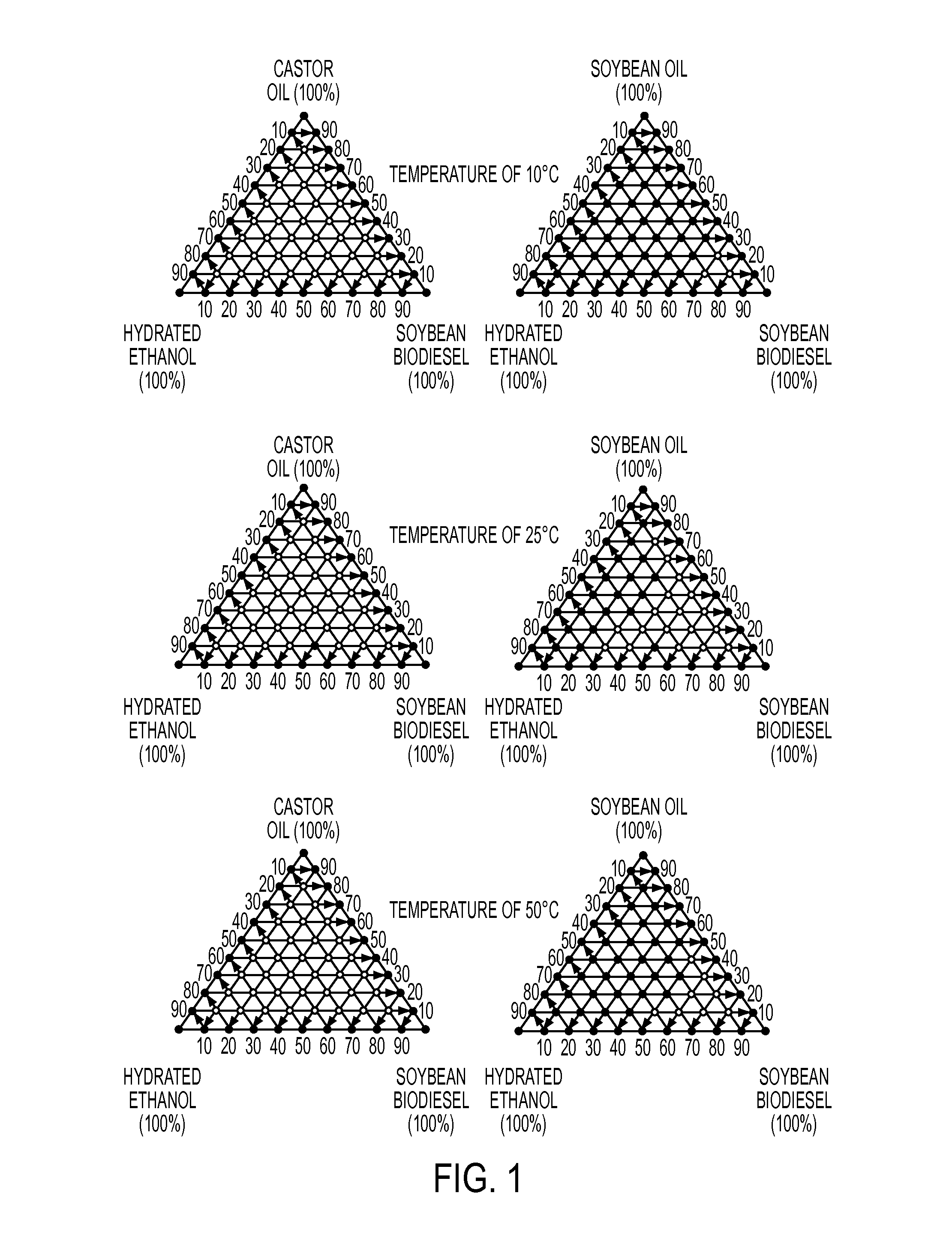

Ternary fuel compositions containing biodiesel, plant oil and lower alcohols for feeding diesel-cycle motors

InactiveUS20130269240A1Shorten ignition delayLow pour pointBiofuelsLiquid carbonaceous fuelsVegetable oilPetroleum

Fuel compositions based on biodiesel, lower alcohols and plant oil for feeding Diesel cycle engines, enabling more perfect burning, less emission of pollutants and less formation of internal deposits of impurities onto the inner surface of engines. Since the blends exhibit density similar to that of diesel oil, as well as chemical affinity for the latter (since it contains biodiesel, which performs the function of co-solvent), the present invention also relates to compositions of quaternary blends, that is, junction of the ternary blends proposed (biodiesel, lower alcohol and vegetable oil) with petroleum diesel in the most varied proportions. The preferred embodiment of this invention provides the replacement of fuel of non-renewable source (diesel oil) by others of renewable source, which are natural, non-toxic, biodegradable and that have excellent technical performance.

Owner:EMPRESA BRASILEIRA DE PESQUISA AGROPECUARIA EMBRAPA

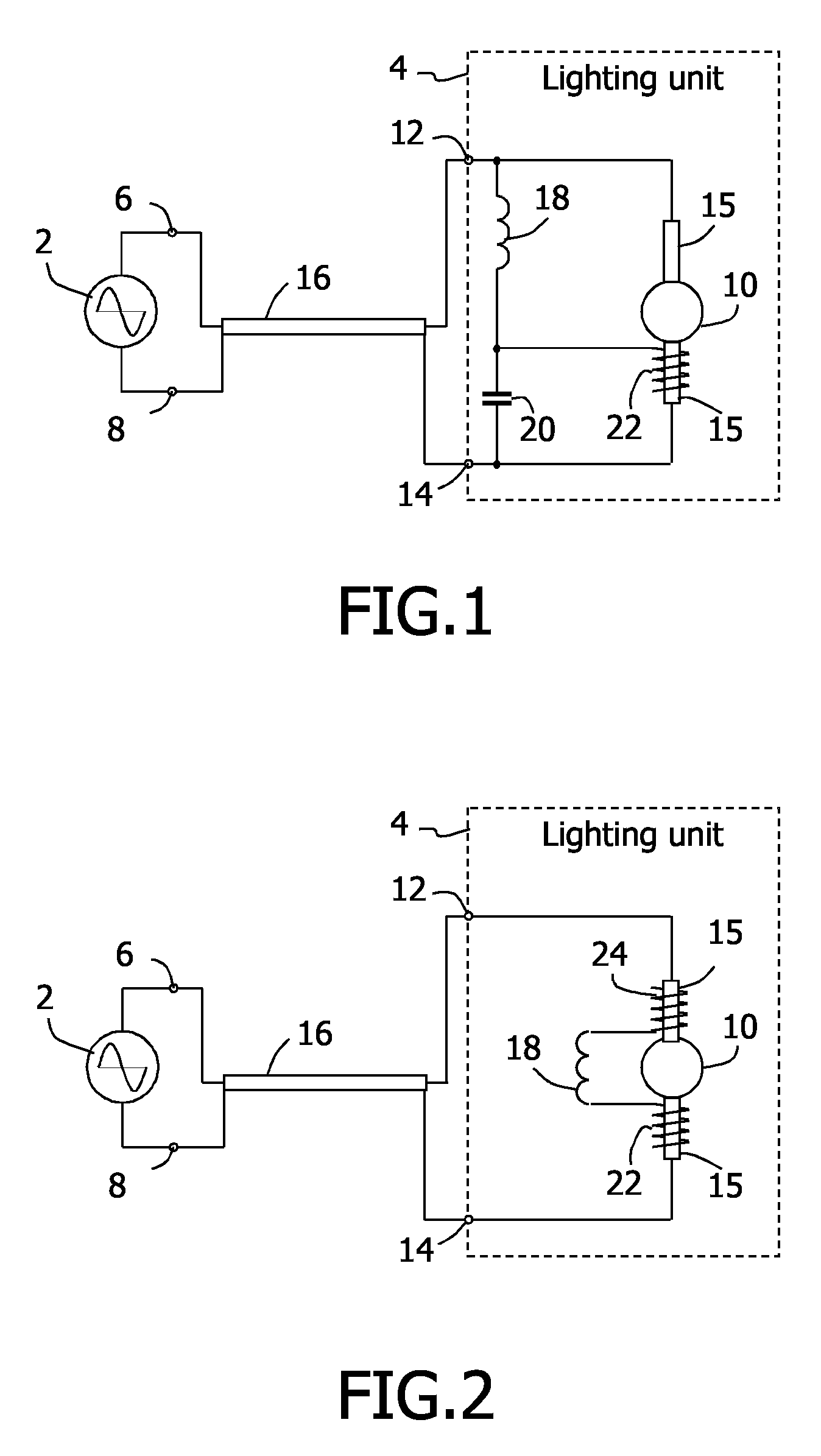

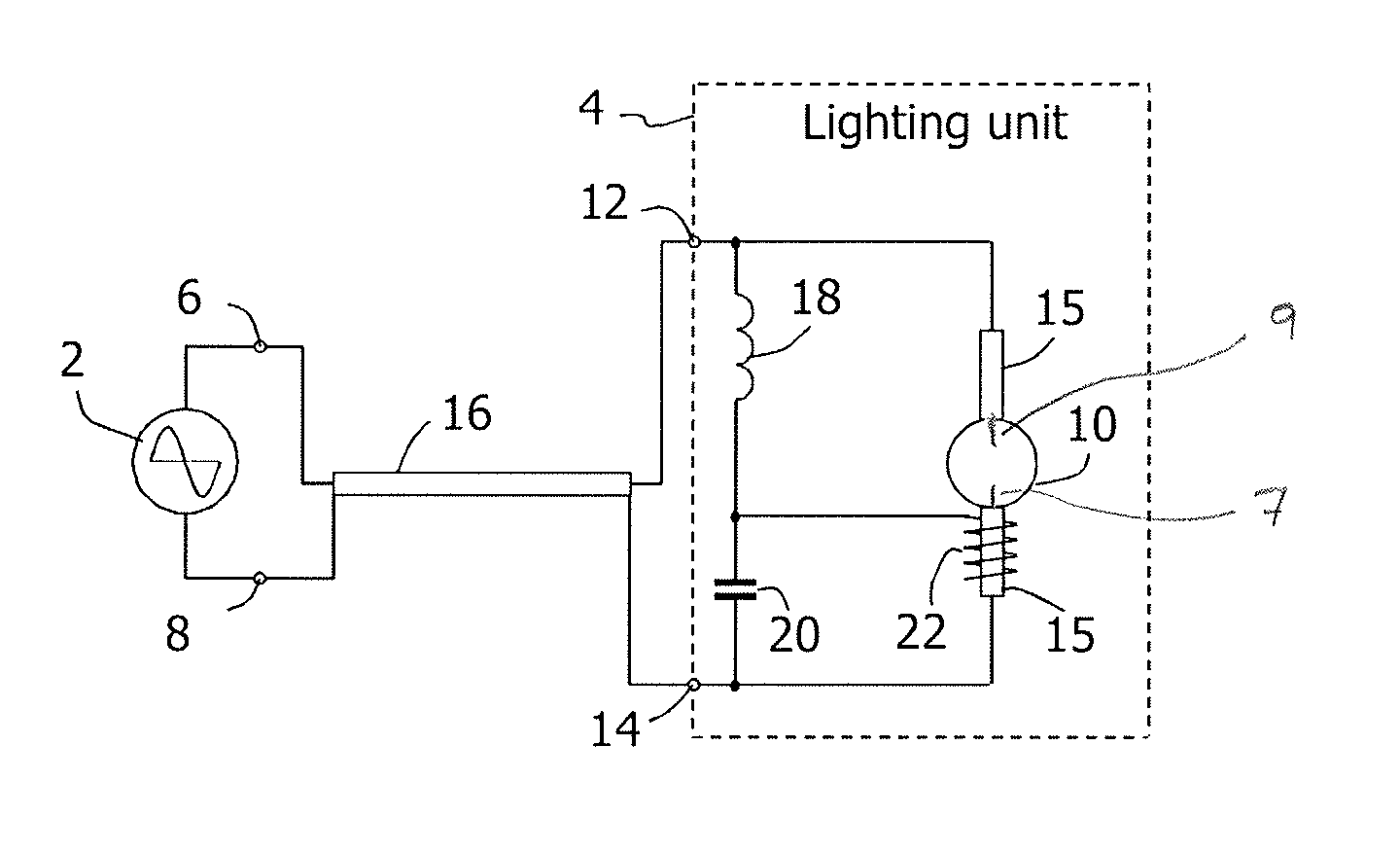

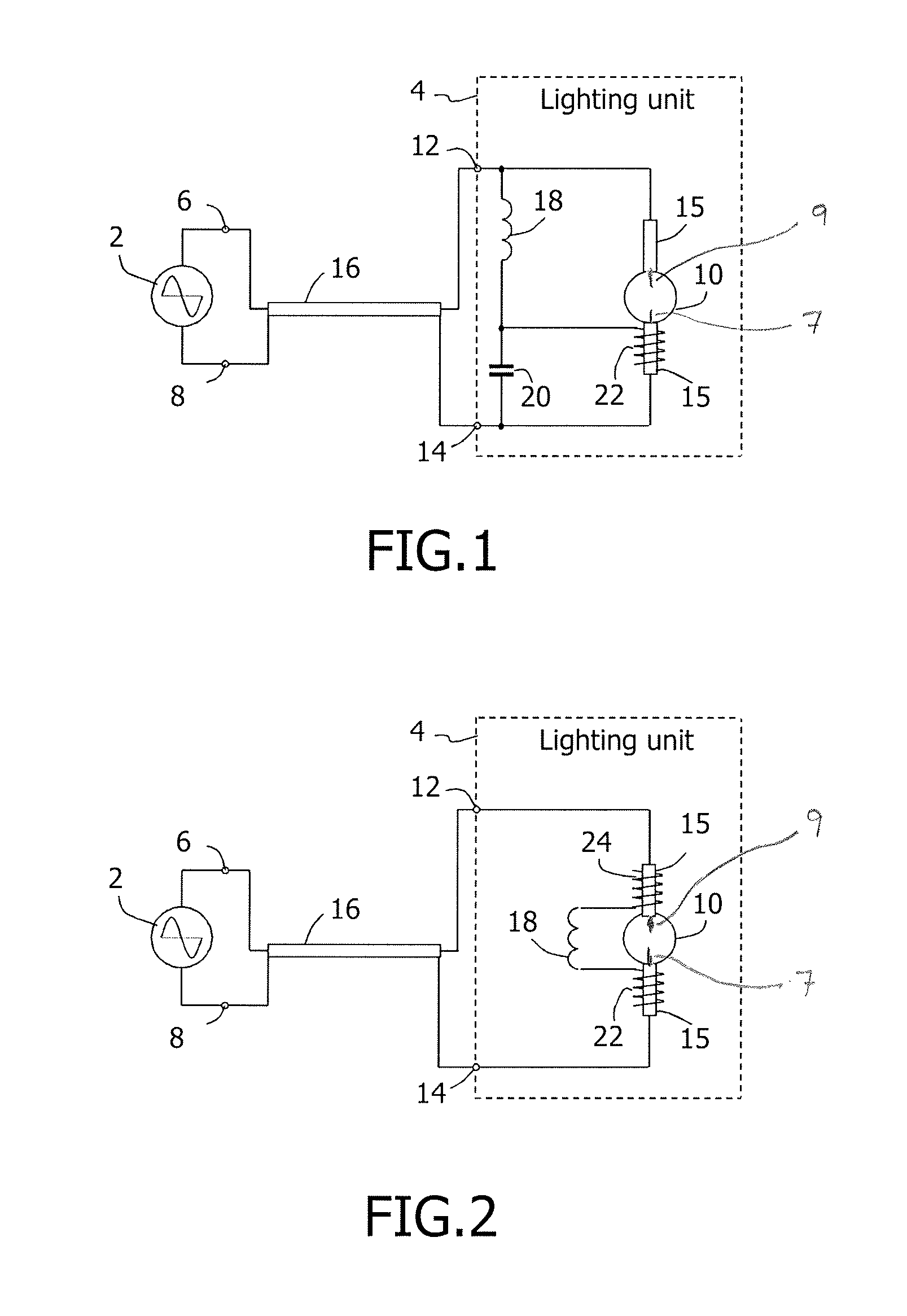

Gas discharge lamp ignition

InactiveUS8022644B2Easy dischargeA large amountAlternating current plasma display panelsElectric light circuit arrangementGas-discharge lampResonance

Ignition of a gas discharge lamp 10, which has a gas containing main space and two inner electrodes, of a lighting unit 4 of a lighting system is achieved by the use of a high frequency resonance circuit. The resonance circuit is connected to the inner electrodes and to a supply device 2, which supplies an alternating supply voltage. An outer electrode 22 is arranged near one the inner electrodes and to a node of the resonance circuit. Upon supplying the supply voltage a high voltage alternating burst will be generated at the outer electrode. This will result into a discharge of the gas in the main space. In turn, this will induce a discharge of the remaining gas. Then the frequency of the supply voltage will increase and a small reactive current only will remain to flow through the resonance circuit.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Ejector matched with high-depth combustion chamber and combustor of ignition structure

PendingCN111853778AOutflow smoothlyFast and smooth mixingElectric spark ignitersGaseous fuel burnerCombustion chamberCombustor

The invention relates to the technical field of commercial kitchen ware and in particular discloses an ejector matched with a high-depth combustion chamber and a combustor of an ignition structure, wherein an air ejection hose is arranged at the bottom of a distributor, an air flow ejected by the air ejection hose can dredge gas in the combustion chamber to flow out of the combustion chamber to reduce the probability of occurrence that the gas vibrates to induce squeal, and air ejected by the air ejection hose supplements air secondarily for combustion reaction of primary fire and mixed gas, so that the air flow of the fixed gas in the main fire can be reduced. A kindling material fire ejecting port is arranged in the inner side surface of an oil-water sundry reserving basin, so that the main fire and the mixed gas can be ignited quickly and stably to reduce the ignition time delay and avoid detonation generated by accumulation of the mixed gas. The ejector has independent tissue air and gas supplying and mixing and combusting functions and an independent kindling material mixed gas distribution chamber. An ignition needle function is not affected by a combustion flame in the distributor fully, so that the ejector has fully independent self-combustion and self-regulation function.

Owner:浙江惠厨节能科技有限公司

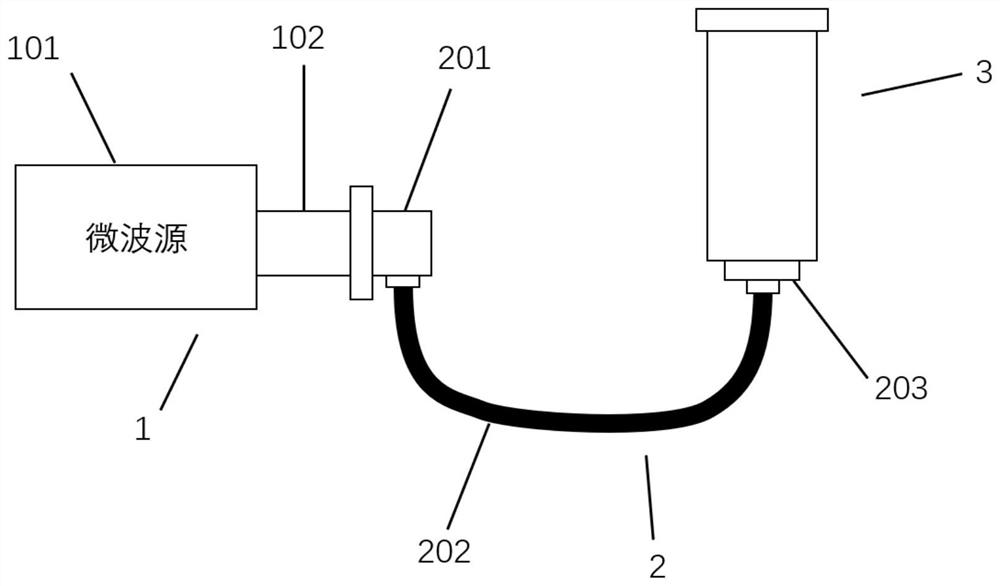

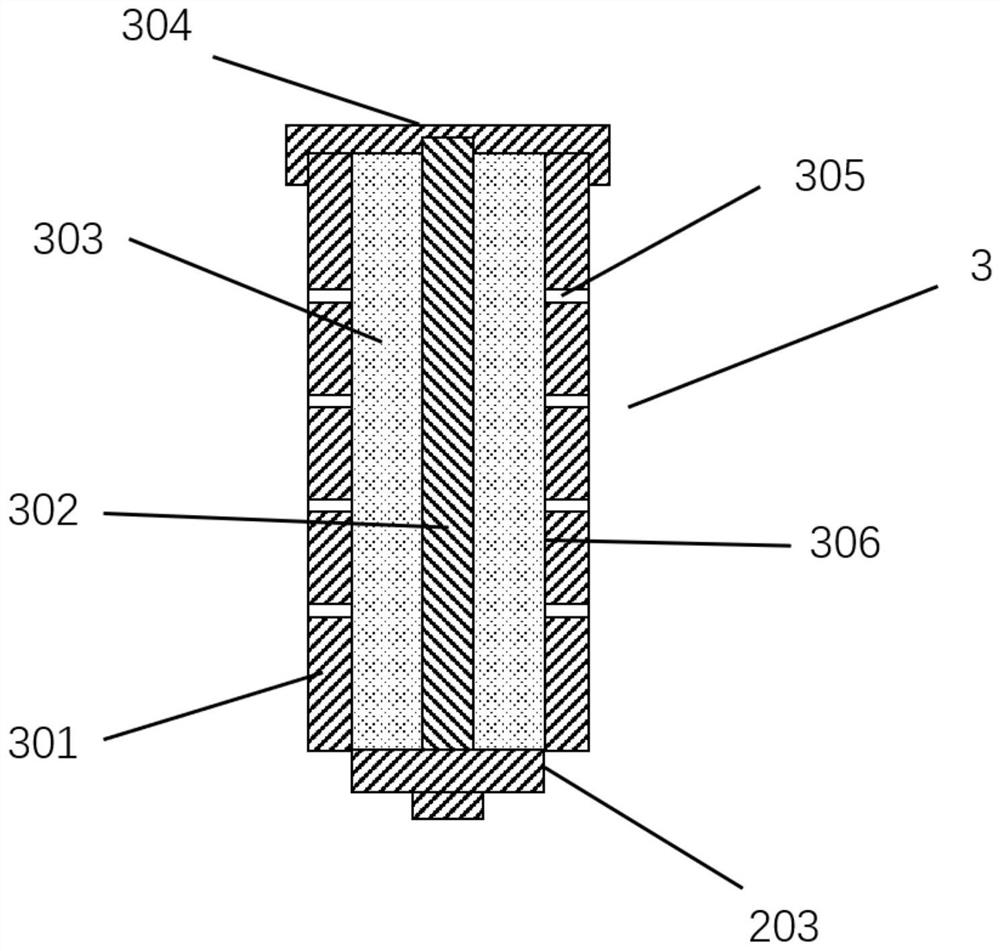

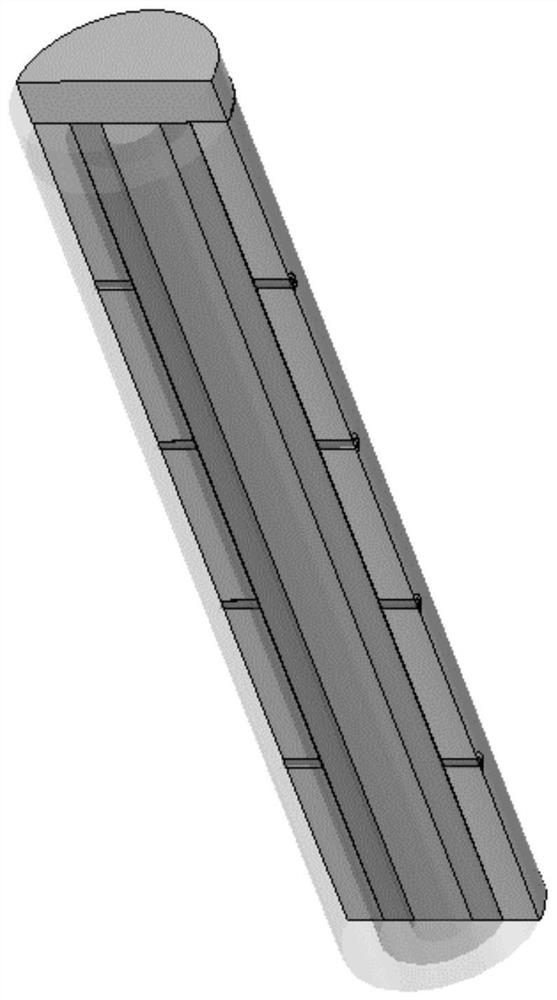

Artillery microwave ignition device

The invention discloses an artillery microwave ignition device, and belongs to the technical field of artillery ignition. According to the artillery microwave ignition device, a coaxial resonant cavity is adopted as a microwave ignition cavity, the coaxial resonant cavity is filled with the gunpowder medium, through holes are evenly distributed in the outer conductor of the coaxial resonant cavity and used for enabling flames after gunpowder ignition to be evenly sprayed out from the through holes, and the purpose that propellant powder is ignited at multiple points at the same time is achieved. The structure is simple, the structure of an ignition emission part of a conventional artillery is slightly changed, and the structure can be conveniently applied to an artillery system. Compared with the prior art, the artillery microwave ignition device can be conveniently and rapidly assembled and debugged, the test efficiency is greatly improved, the trajectory performance of an artillery is effectively improved, and engineering and modularization of artillery microwave ignition are achieved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Methanol engine with dual-plasma generator

PendingCN109505717AShorten ignition delayImprove the problem of decreased combustion stabilityInternal combustion piston enginesExhaust apparatusPlasma generatorIgnition delay

The invention relates to a methanol engine with a dual-plasma generator. According to the technical scheme, the methanol engine comprises an engine air cylinder, an igniter, an ECU, a methanol nozzle,a methanol pressurizing pump and a methanol storage tank, an air inlet manifold and an exhaust pipe communicating with the engine air cylinder are connected to the engine air cylinder, an exhaust gasrecirculation pipeline communicating with the air inlet manifold and the exhaust pipe is arranged between the air inlet manifold and the exhaust pipe, an EGR valve is installed on the exhaust gas recirculation pipeline, the signal input end of the EGR valve is connected with the signal output end of the ECU, a first plasma generator is installed on the air inlet manifold, and a second plasma generator and a three-way catalytic converter are successively installed at a connecting point between the exhaust gas recirculation pipeline and the exhaust pipe along the exhaust pipe at the rear part of the exhaust direction of the exhaust pipe. According to the methanol engine with the dual-plasma generator, the engine ignition delay time is shortened, the flame propagation velocity in the cylinder is increased, thus the combustion efficiency is improved, emission of hydrocarbons is lowered, and the reoxidation temperature of pollutants such as NOx, CO and formaldehyde is lowered, so that theconversion efficiency of the three pollutants is improved.

Owner:李勇

Diesel engine and method of controlling the diesel engine

InactiveCN102312745BEnsure ignitionAvoid NVH Performance Degradation IssuesElectrical controlInternal combustion piston enginesControl theoryMechanical engineering

The invention relates to a diesel engine and a method of controlling the same. The diesel engine of the present invention includes an engine body supplied with fuel containing diesel fuel as its main component, and the geometric compression ratio is set below 15:1; it is arranged in the engine body toward the cylinder of the engine body and directly injected a fuel injection valve for fuel into the cylinder; and a control module for controlling a pattern of injecting the fuel into the cylinder through the fuel injection valve. The control module performs a main injection such that the injected fuel produces a main combustion mainly comprising diffusion combustion, and performs a plurality of pre-stage injections prior to the main injection such that the injected fuel produces a pre-stage prior to the main combustion combustion. The control module controls an injection pattern of the injection to adjust a heat release rate.

Owner:MAZDA MOTOR CORP

Double pulse solid rocket engine ignition device suitable for soft partition plate structure

InactiveCN112628022AStructure miniaturizationSimple structural designRocket engine plantsIgnition delayMechanical engineering

The invention provides a double pulse solid rocket engine ignition device suitable for a soft partition plate structure. An igniter is installed in the center of the end face of a propellant, and grain columns are distributed on the end face of the propellant in a multi-circle surrounding manner with the igniter as the center so that the grain columns can rapidly ignite the propellant, and the ignition delay of a second pulse engine is greatly shortened; that is, by reasonably arranging a dot-matrix structure of the grain columns in a second pulse ignition device and selecting the ignition grain columns working for a long time, the second pulse ignition device can bear the working pressure and vibration of a first pulse engine in the working process, adverse effects brought by instantaneous increase of the initial free volume after a soft partition plate ignition is opened to ignition starting of the second pulse engine can be eliminated, and the problem of ignition delay of the second pulse engine is effectively solved; and besides, the double pulse solid rocket engine ignition device is simple in structural design, the second pulse engine is reliable in ignition and free of ignition delay, part of negative mass is reduced, and the structure of the ignition device is more miniaturized.

Owner:BEIJING POWER MACHINERY INST

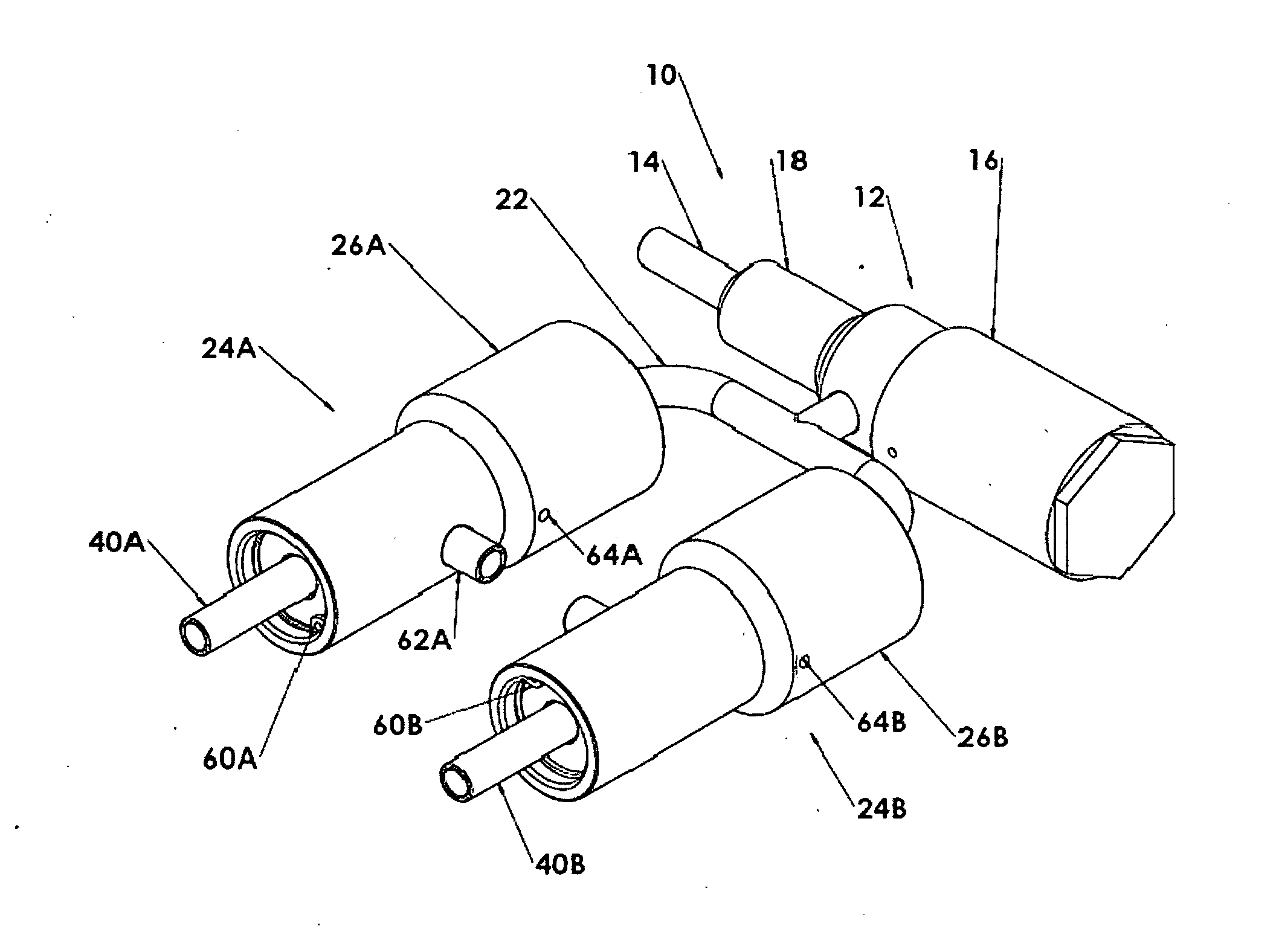

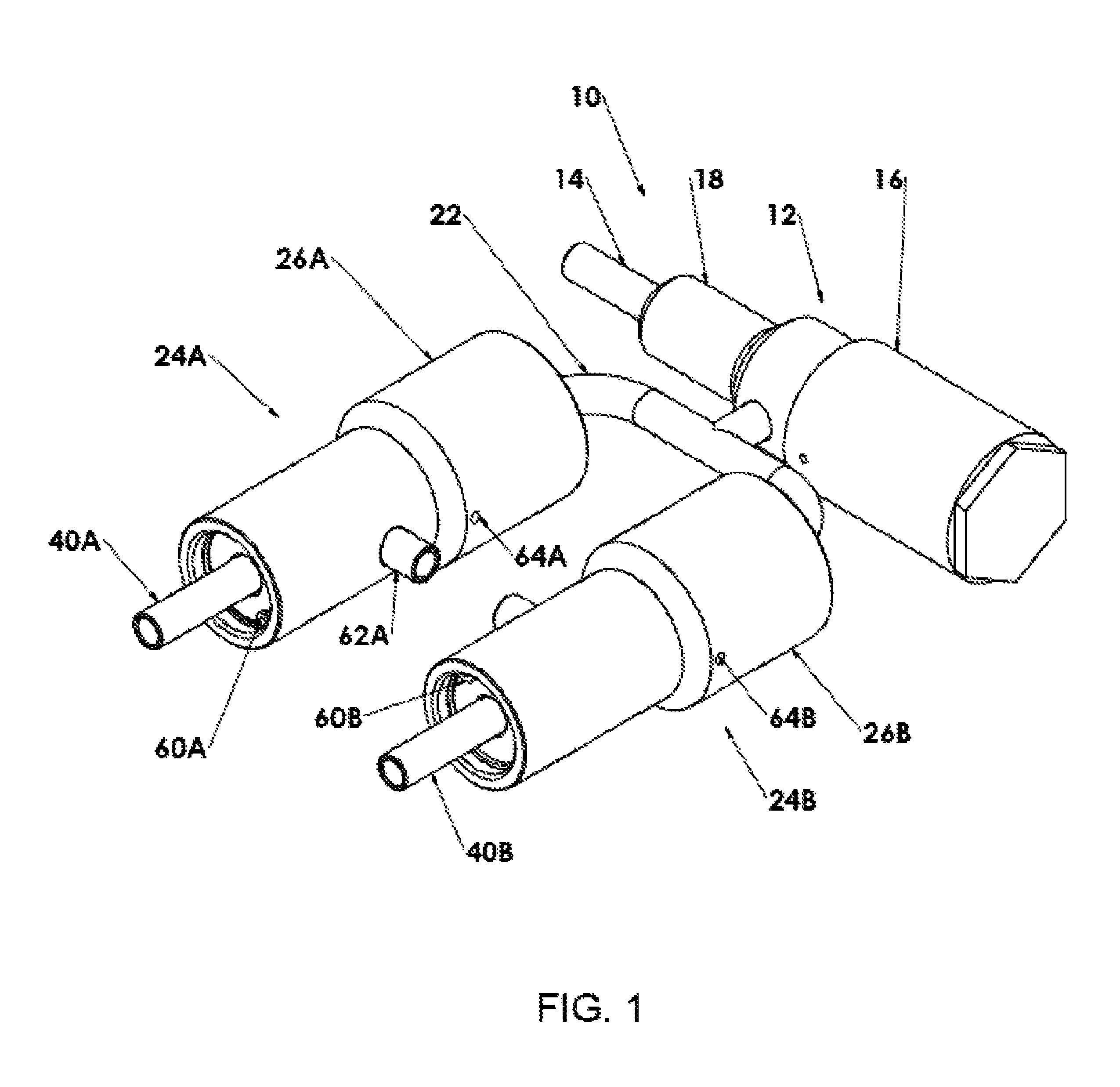

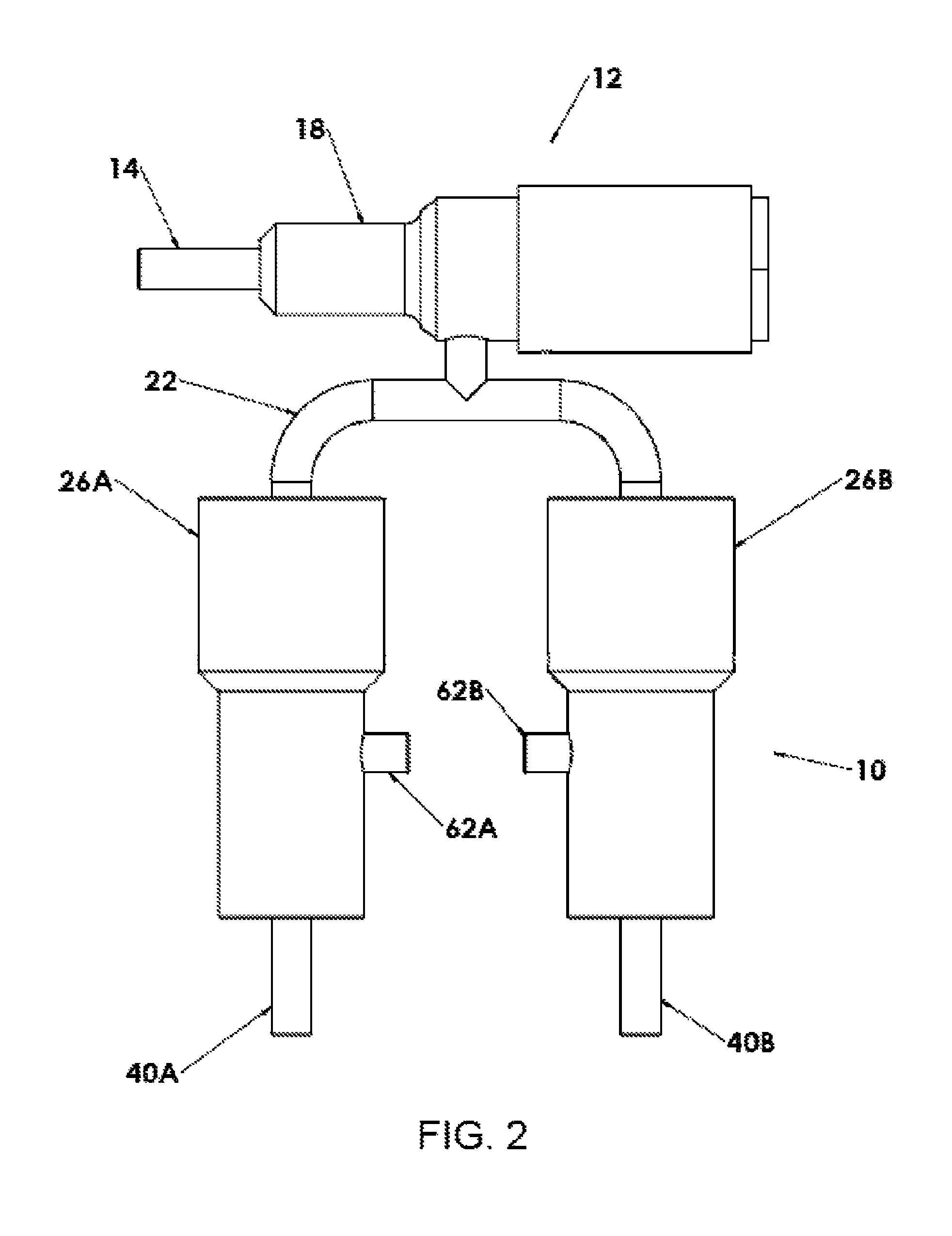

Pnumatically actuated bi-propellant valve (PABV) system for a throttling vortex engine

InactiveUS8505577B2Increase flexibilityLower potentialCircuit elementsMultiple way valvesSolenoid valveGas passing

Regulated pneumatic gas is supplied through a gas supply tube (14) which is welded to a pilot valve housing (18) which accommodates a solenoid valve (16). When the solenoid valve is electrically activated and opened, the pneumatic gas flows through a bifurcated channel (22) which is welded to the pilot valve housing and to a fuel valve mechanism (24A) and to an oxidizer valve mechanism (24B). The force of the pneumatic gas causes pistons (38A, 38B) to actuate respective poppets (36A, 36B). Movement of the poppets results in the dispensing of fuel propellant from a fuel outlet chamber (44A) and the dispensing of oxidizer from an oxidizer outlet chamber (44B). The fuel valve mechanism and oxidizer valve mechanism are positioned and oriented such that the exiting fuel and oxidizer are mixed in a vortex rocket engine.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

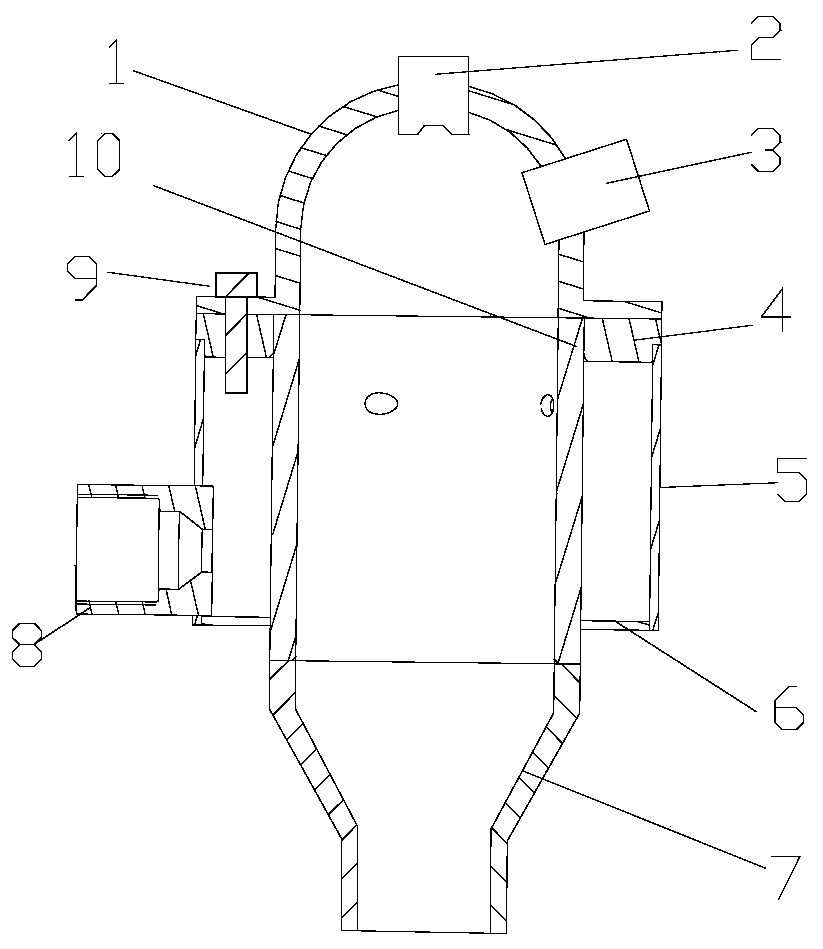

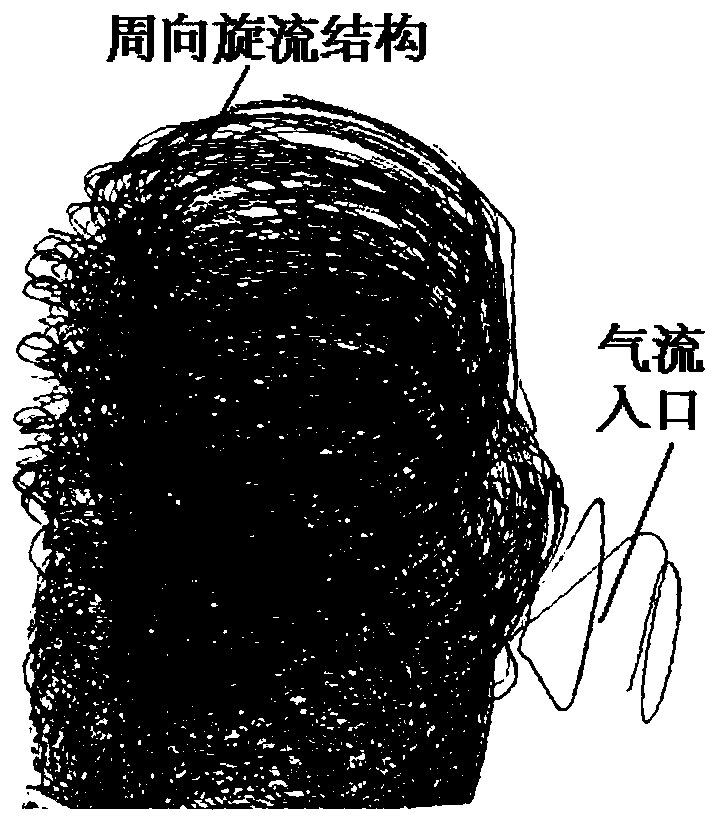

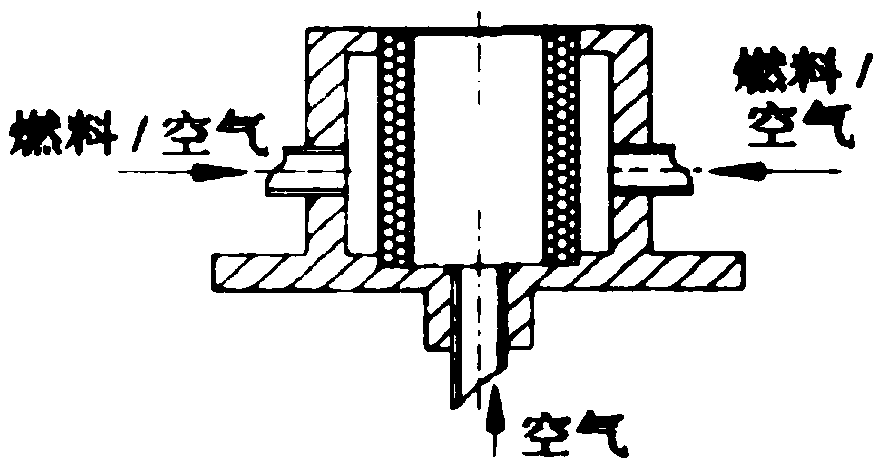

Miniature gas-liquid dual-purpose high-energy igniter

ActiveCN109322750BSmall geometryExtended dwell timeGas turbine plantsJet propulsion plantsStone wallOil retention

The invention relates to a micro gas-liquid dual-purpose high energy igniter, and relates to the technical field of engines. The micro gas-liquid dual-purpose high energy igniter has the advantages that 1) the success rate is increased, and the ignition lag time is shortened under the condition of relatively low ignition energy of a single igniter plug; 2) an efficient circumferential rotational flow structure can be formed in the igniter, the flue gas and flue oil retention time is prolonged, and mixing is enhanced, so that the formation of a stable flame structure is facilitated; 3) a circumferential vortex system structure is formed in a flow field, wherein the vortex system structure comprises a vortex system structure body clinging to the inside wall surface of an inner wall and a circumferential vortex system flow structure formed by entraining inner fluid by the vortex system structure body; 4) the ignition lag is reduced, the ignition success rate is increased, and the flue gasand flue oil retention time is prolonged on the premise of the smallest size of the igniter; and 5) the atomization effect can be ensured, and the fogdrop collision with a stone wall can be avoided.

Owner:BEIJING POWER MACHINERY INST

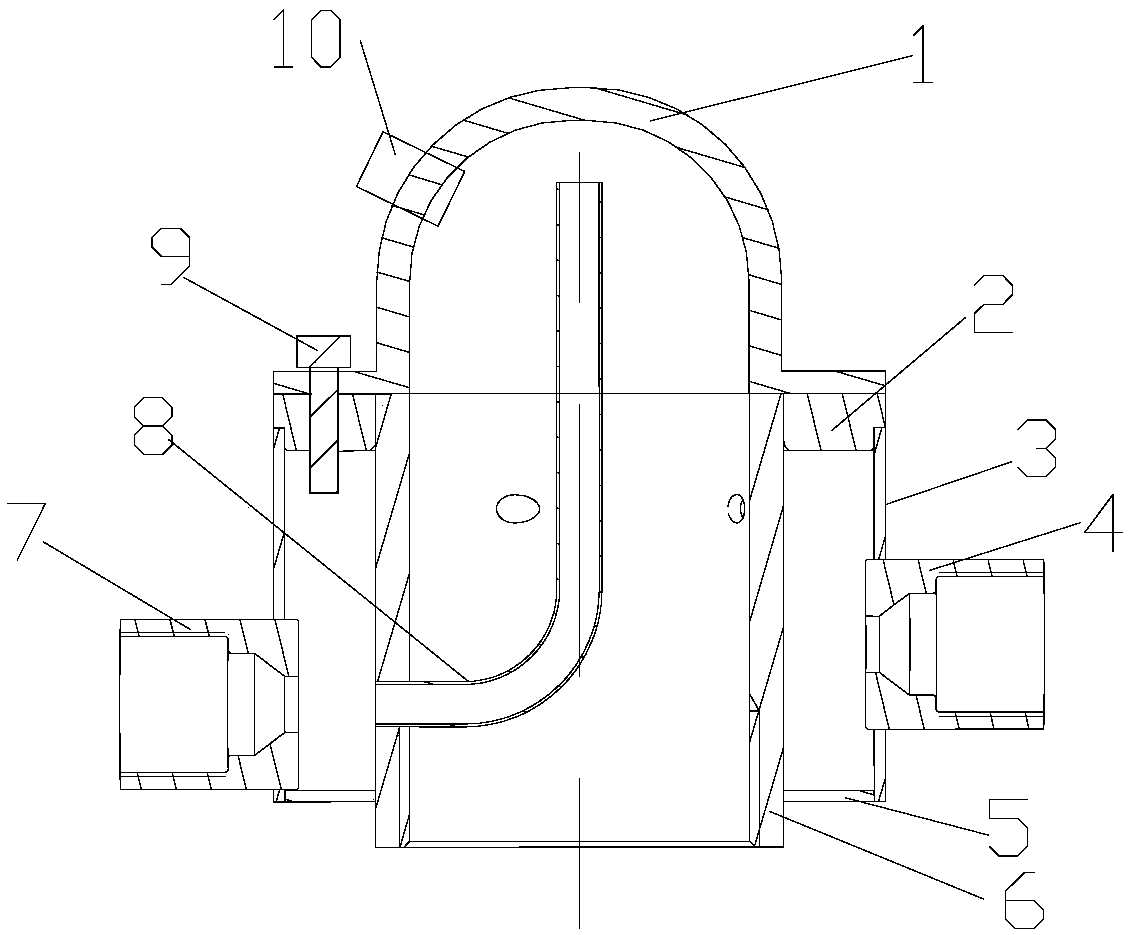

Micro-combustor based on liquid fuel

ActiveCN109307264AEfficient evaporationEvaporation adopts L-type evaporation with high efficiencyBurnersCombustorLiquid state

The invention relates to a micro-combustor based on a liquid fuel, and relates to the technical field of engines. According to the micro-combustor based on the liquid fuel provided by the invention, firstly, the species of fuel oil have no any limitation, so that various liquid-state fuels and even gas-state fuels can be adopted; secondly, the fuel oil is preheated so as to be ensured to be high-efficiently evaporated and combusted; thirdly, the ignition delay is shortened, the success rate of ignition is improved, and the fuel oil and fuel gas residence time can be prolonged with a smaller size, so that the geometric dimension required for an ignitor is reduced; and fourthly, the heat load formed in the inner wall during the combustion process can be effectively absorbed, so that the surface temperature is reduced, and the service life of the combustor is prolonged.

Owner:BEIJING POWER MACHINERY INST

A method for the efficient catalytic decomposition of ammonium perchlorate based on the energetic complex [mn(bto)(h2o)2]n

ActiveCN106083504BExcellent catalytic decomposition performanceLower decomposition temperatureOrganic-compounds/hydrides/coordination-complexes catalystsOrganic chemistry methodsNitrogenIgnition delay

The invention discloses a method for efficiently catalytically decomposing ammonium perchlorate based on energetic complex [Mn(BTO)(H2O)2]n. The method comprises mixing an energetic complex [Mn(BTO)(H2O)2]n and ammonium perchlorate according to a certain ratio and grinding; and putting the ground mixture in a nitrogen environment and reacting at 270-305 DEG C for 5-10 min. The employed catalyst [Mn(BTO)(H2O)2]n has extremely good catalytic decomposition effect on ammonium perchlorate, and is capable of greatly reducing the decomposition temperature, and control on decomposition temperature of ammonium perchlorate is realized by changing the addition amount of the catalyst. The method is simple and reliable, hopefully, the burning rate of spaceflight propellants can be improved, and the firing delay can be shortened.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Pnumatically actuated bi-propellant valve (PABV) system for a throttling vortex engine

InactiveUS20120132297A1Enhance flexibilityReduces excessive heatOperating means/releasing devices for valvesCircuit elementsPistonElectricity

Regulated pneumatic gas is supplied through a gas supply tube (14) which is welded to a pilot valve housing (18) which accommodates a solenoid valve (16). When the solenoid valve is electrically activated and opened, the pneumatic gas flows through a bifurcated channel (22) which is welded to the pilot valve housing and to a fuel valve mechanism (24A) and to an oxidizer valve mechanism (24B). The force of the pneumatic gas causes pistons (38A, 38B) to actuate respective poppets (36A, 36B). Movement of the poppets results in the dispensing of fuel propellant from a fuel outlet chamber (44A) and the dispensing of oxidizer from an oxidizer outlet chamber (44B). The fuel valve mechanism and oxidizer valve mechanism are positioned and oriented such that the exiting fuel and oxidizer are mixed in a vortex rocket engine.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Gas Discharge Lamp Ignition

InactiveUS20080309249A1Shorten ignition delayEasy dischargeAlternating current plasma display panelsElectric light circuit arrangementGas-discharge lampResonance

Ignition of a gas discharge lamp 10, which has a gas containing main space and two inner electrodes, of a lighting unit 4 of a lighting system is achieved by the use of a high frequency resonance circuit. The resonance circuit is connected to the inner electrodes and to a supply device 2, which supplies an alternating supply voltage. An outer electrode 22 is arranged near one the inner electrodes and to a node of the resonance circuit. Upon supplying the supply voltage a high voltage alternating burst will be generated at the outer electrode. This will result into a discharge of the gas in the main space. In turn, this will induce a discharge of the remaining gas. Then the frequency of the supply voltage will increase and a small reactive current only will remain to flow through the resonance circuit.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

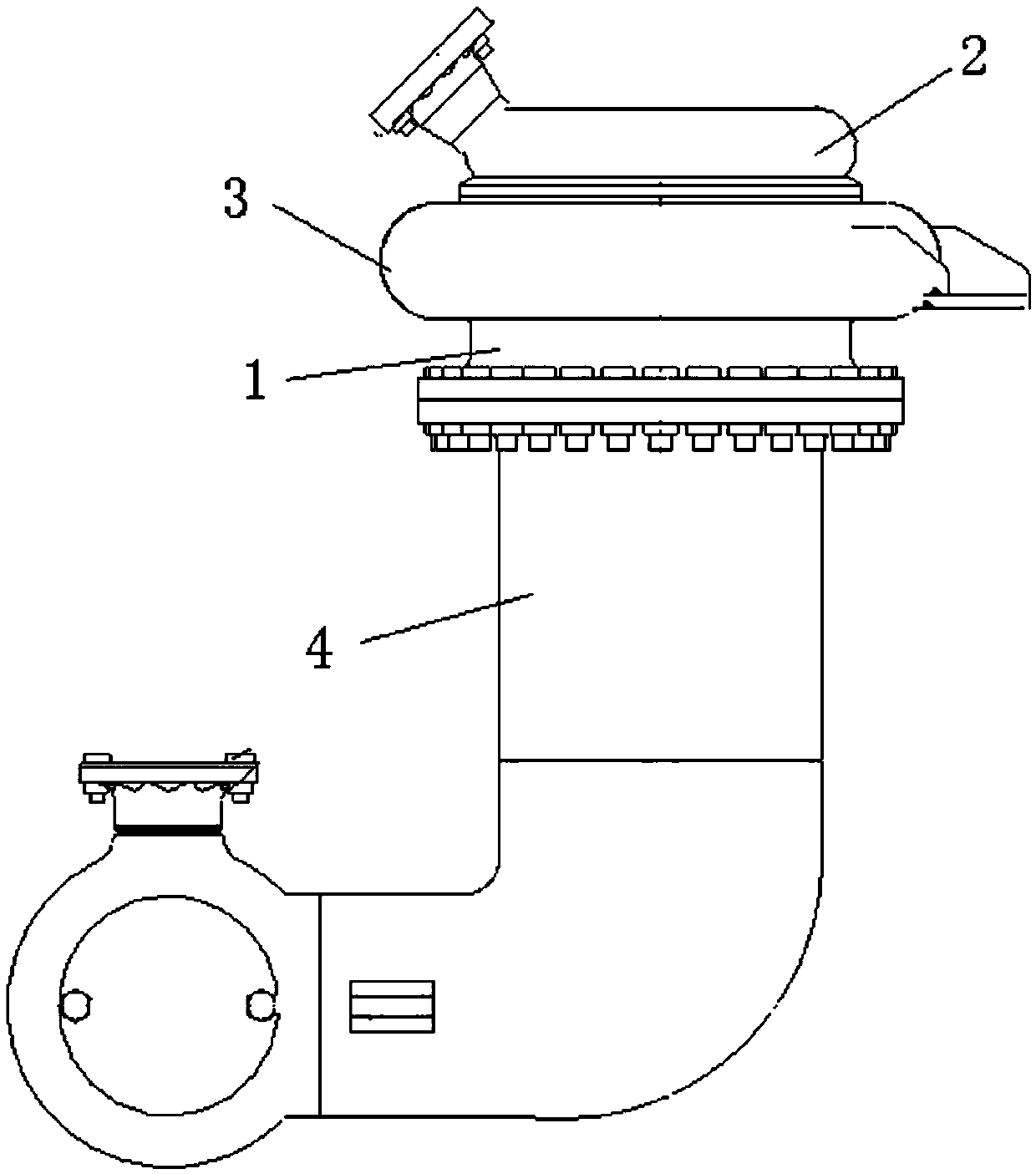

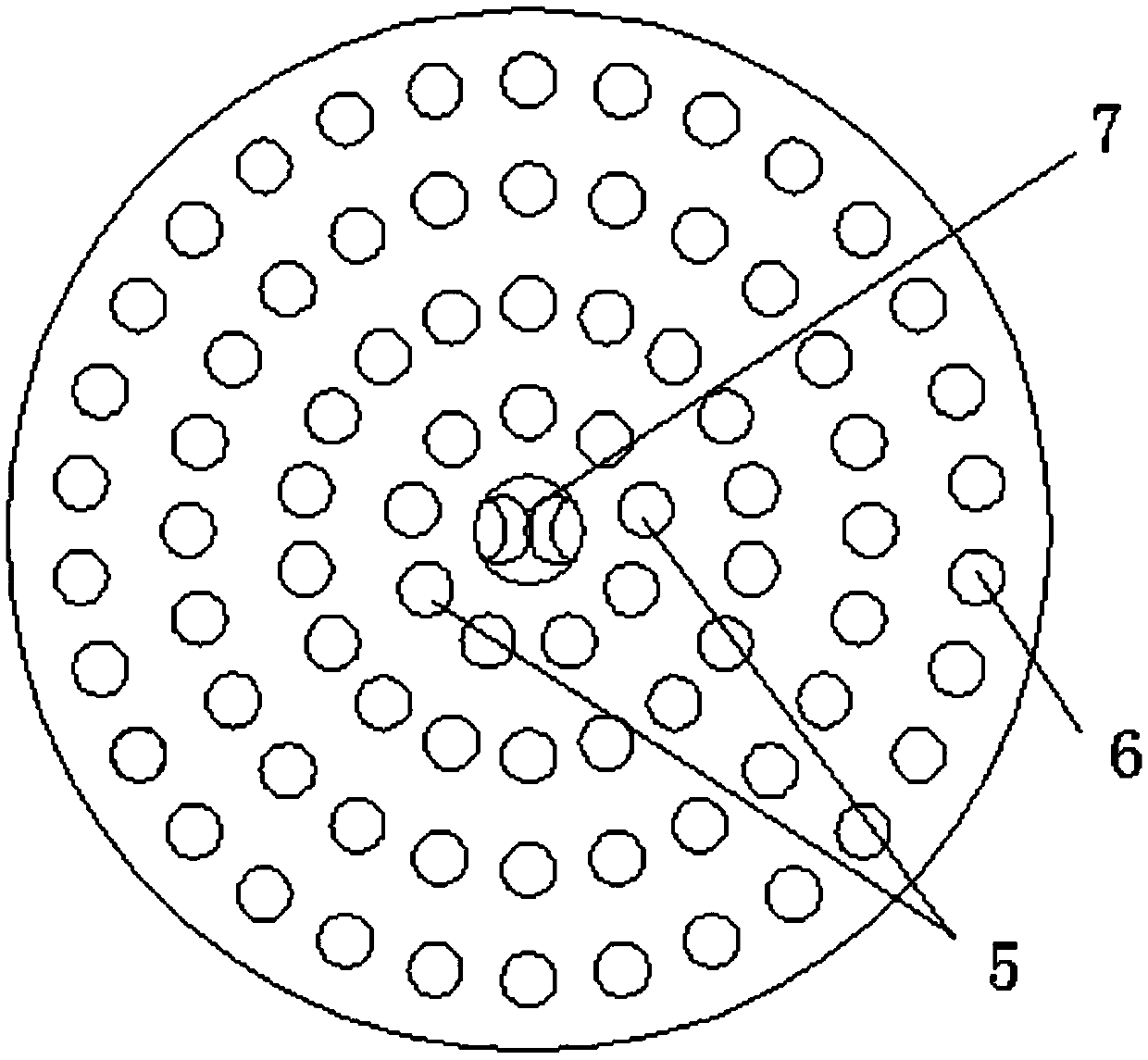

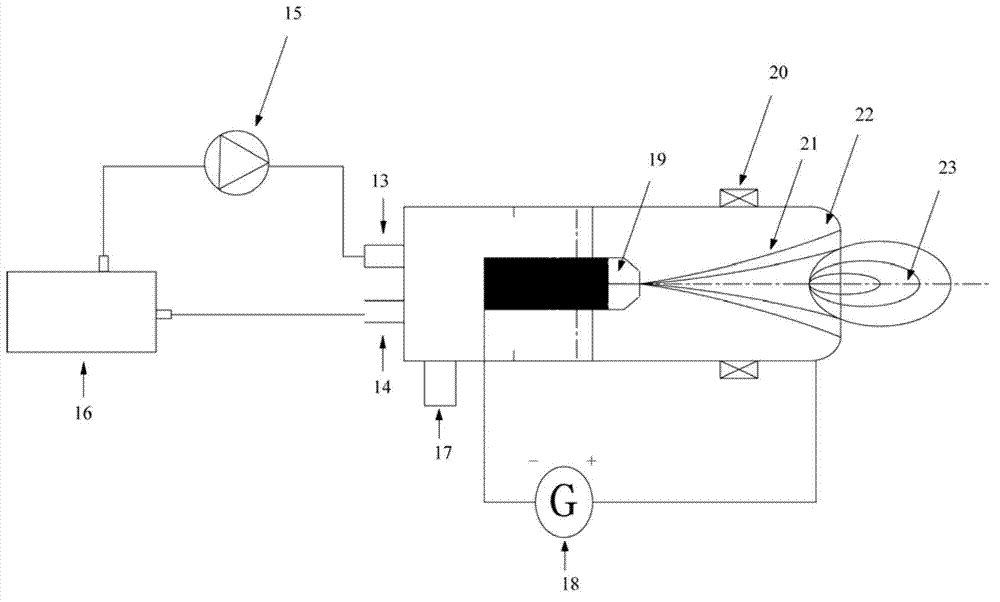

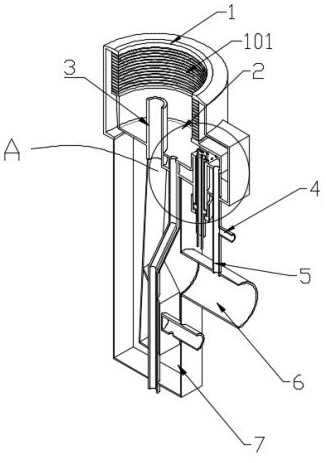

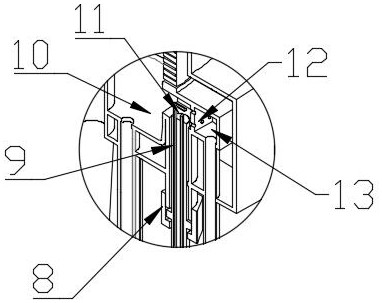

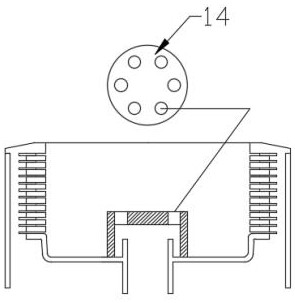

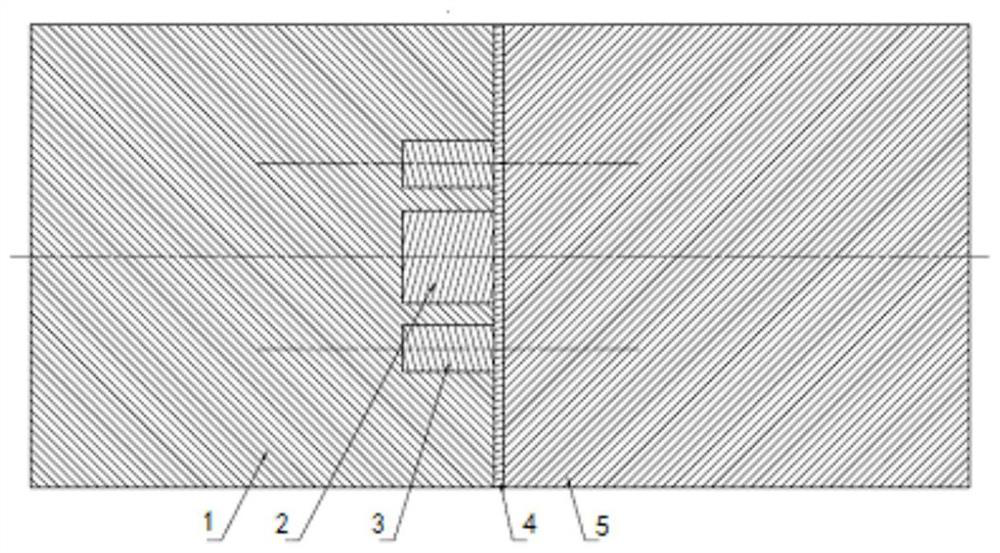

A gas generating device

ActiveCN106196171BSolve the shortcoming of short ignition delay timeShorten ignition delayContinuous combustion chamberNuclear engineeringIgnition delay

The invention provides a fuel gas generating device. The fuel gas generating device comprises an injector (1), an oxidizing agent collector (2), a fuel collector (3) and a body (4), wherein the oxidizing agent collector (2) and the fuel collector (3) are arranged on the injector (1) which is connected to the body (4); an oxidizing agent and fuel enter the injector (1) respectively through the circular ring-shaped oxidizing agent collector (2) and the fuel collector (3), then are atomized by double coaxial nozzles (5) and coaxial direct-flow type nozzles (6) in the injector (1) and finally are burned; and products generated after burning enter the body (4). The fuel gas generating device solves the problems of long ignition delay time, low ignition reliability and uneven fuel gas outlet temperature, shortens ignition delay and improves ignition reliability and evenness of fuel gas outlet temperature from structural design.

Owner:BEIJING AEROSPACE PROPULSION INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![A method for the efficient catalytic decomposition of ammonium perchlorate based on the energetic complex [mn(bto)(h2o)2]n A method for the efficient catalytic decomposition of ammonium perchlorate based on the energetic complex [mn(bto)(h2o)2]n](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/6893d8e2-b381-4737-b2d5-e4e0d386cf0b/HDA0001006800100000011.png)

![A method for the efficient catalytic decomposition of ammonium perchlorate based on the energetic complex [mn(bto)(h2o)2]n A method for the efficient catalytic decomposition of ammonium perchlorate based on the energetic complex [mn(bto)(h2o)2]n](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/6893d8e2-b381-4737-b2d5-e4e0d386cf0b/HDA0001006800100000012.png)