Biodiesel motor fule additive composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] This invention is in one aspect directed to a biodiesel fuel additive comprising: (a) a detergent component which is selected from the group consisting of (i) the reaction product of a substituted hydrocarbon and an amino compound, (ii) a polybutylamine or polyisobutylamine; and (b) a fuel conditioner component comprising a polar oxygenated hydrocarbon compound and an oxygenated compatibilizing agent.

[0021] Another aspect of the present invention is directed to a biodiesel fuel additive comprising (a) a fuel conditioner component comprising a polar oxygenated hydrocarbon compound and an oxygenated compatibilizing agent.

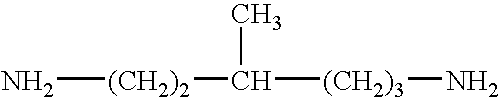

[0022] If the reaction product detergent component is employed, the substituted hydrocarbon reactant used to prepare the reaction product is of the formula

R1-x (I)

wherein R1 is a hydrocarbyl radical having a molecular weight in the range of about 150 to about 10,000, preferably a polyalkylene radical having a molecular weight in the range of about 400 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com