Disposal process for sulfide-free black liquors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

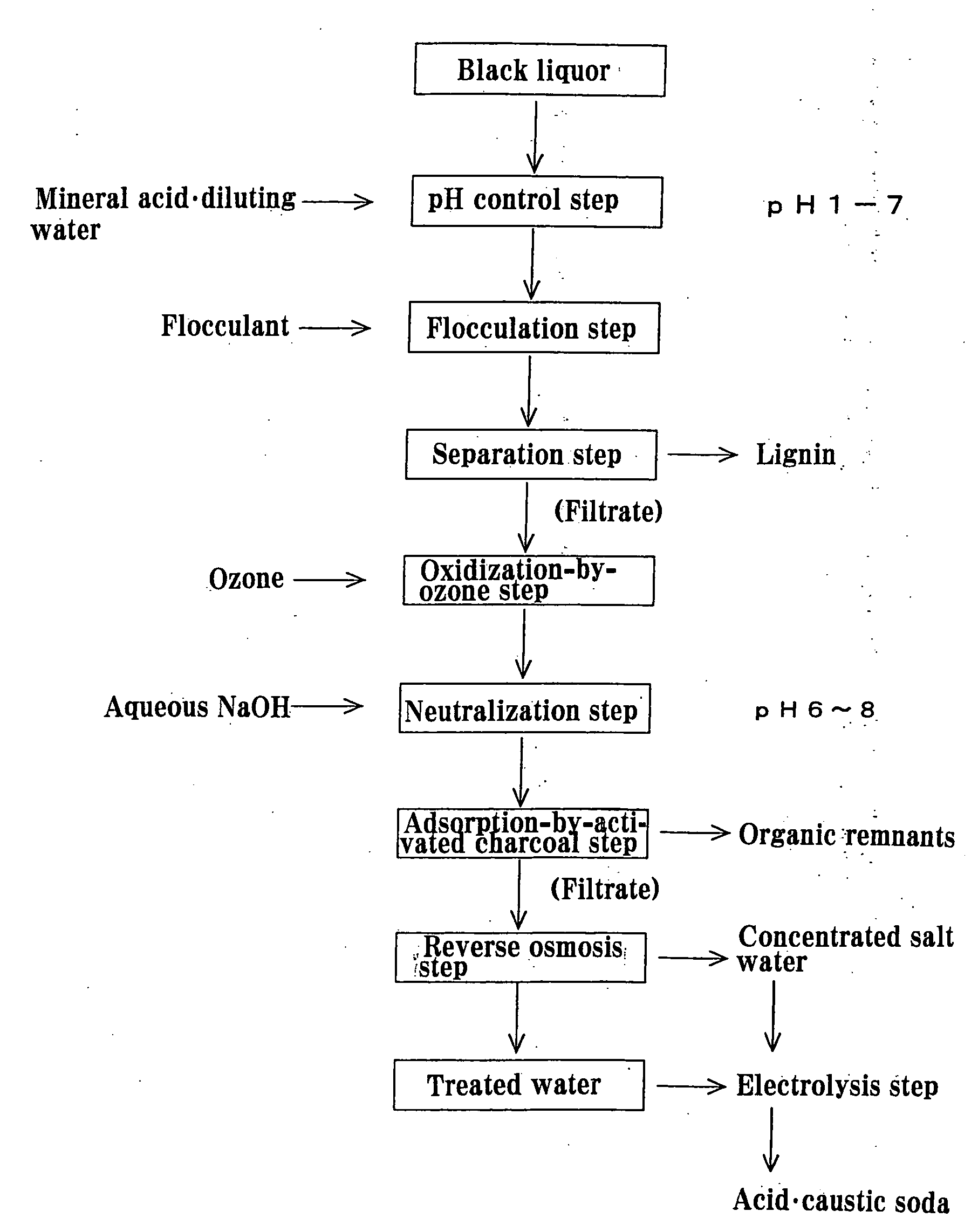

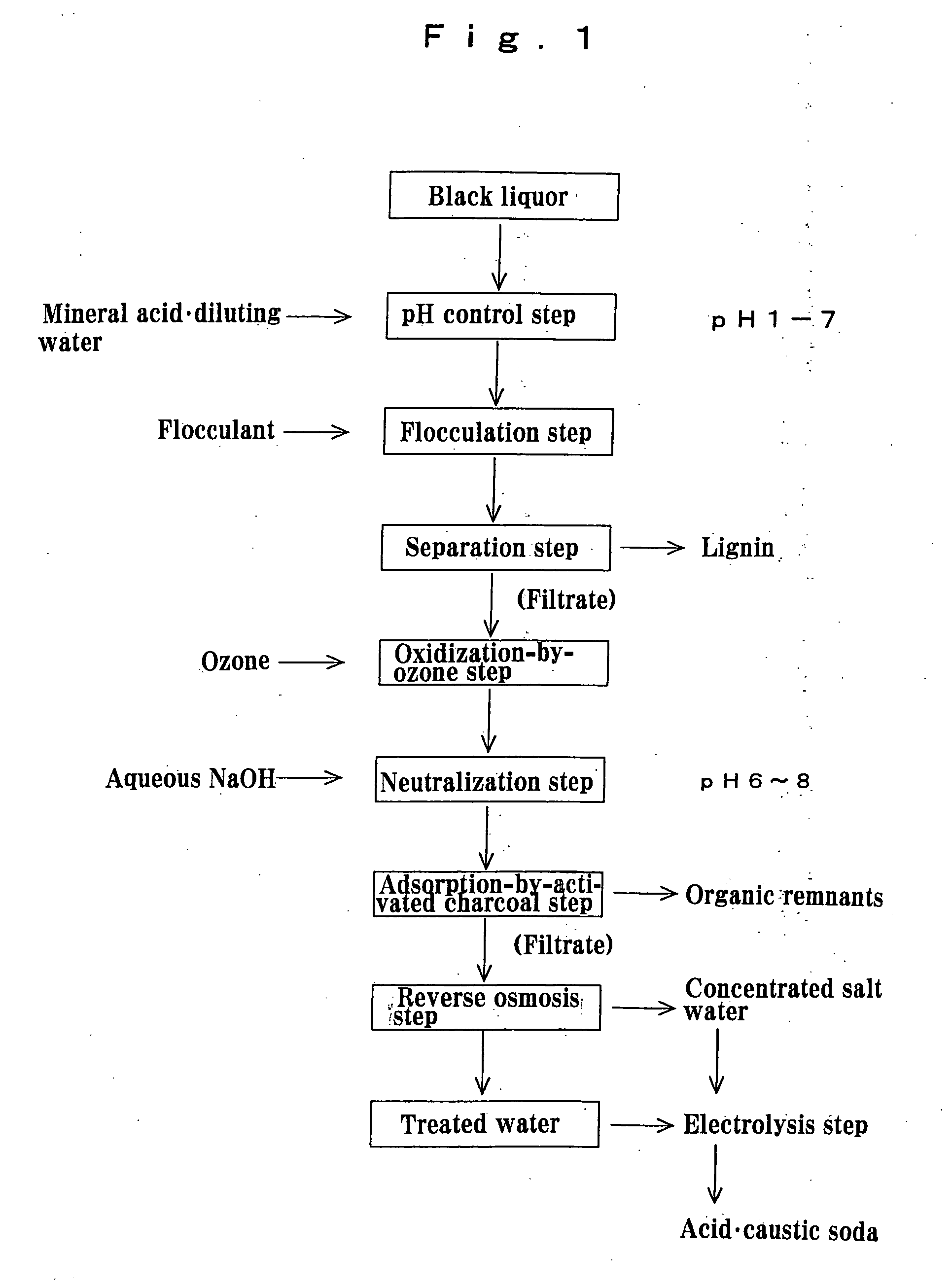

[0063]The present invention is now explained with reference to the flowchart of FIG. 1.

[0064]As the black liquor, a sulfides-free black liquor discharged out of the pulp digestion step is used.

[0065]The black liquor suited for the inventive disposal is a black liquor discharged out of the process set forth in Japanese Patent Application No. 2007-006159-Patent Publication 1, i.e., the pulp-making process in which chips are partially oxidized with dilute nitric acid, and then digested with dilute caustic soda. More specifically, that black liquor is free of sulfides, and contains lignin in a concentration of a few % by weight or less.

[0066]Note here that a black liquor occurring with the kraft method where the incorporation of sulfides is unavoidable cannot be applied to the invention, because the sulfides are oxidized into sulfur that in turn clings and sticks to disposal equipment, rendering it difficult to run.

[0067]In the pH control step the mineral acid and, if necessary, dilutin...

example 2

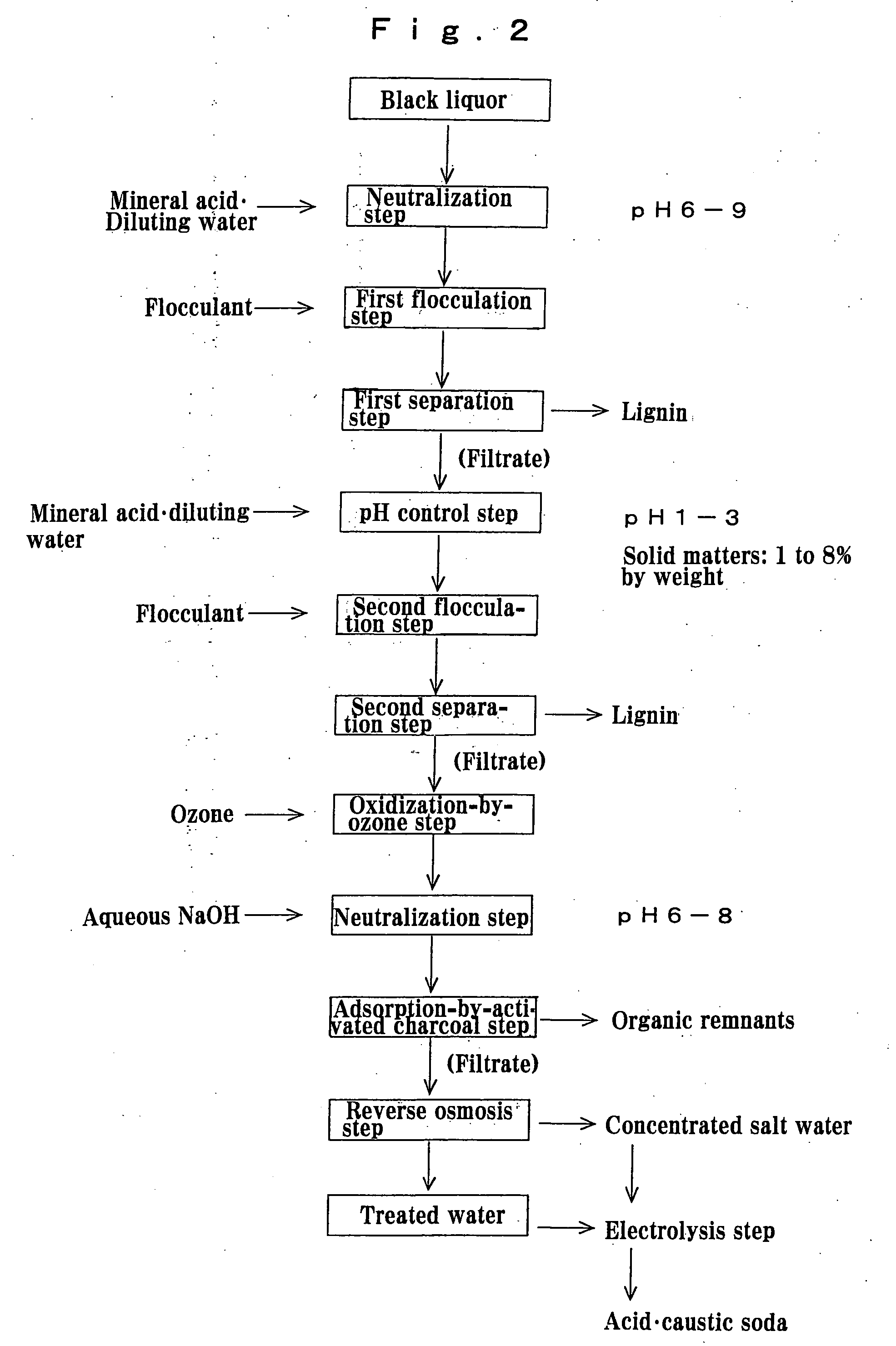

[0088]Another example of the invention is now explained with reference to the flowchart of the invention of FIG. 2.

[0089]Example 2 is the same as Example 1 in that the sulfide-free black liquor discharged out of the pulp digestion step is used.

[0090]In the neutralizing step a mineral acid and, if necessary, diluting water is added to the black liquor to control its pH to 6 to 9. The mineral acid used here may include hydrochloric acid, and sulfuric acid. Note here that nitric acid is not preferable because it tends to give rise to NOx in the later steps. As the concentration of solid matters (total remnants after evaporation) is lower, the rate of collection of organic matters during flocculation grows high, but as that concentration is all too low, disposal efficiency goes worse because the liquor amount grows large. Dilution should thus be carried out such that the solid matters are kept at 1 to 8% by weight in the later pH control step.

[0091]In the first flocculation step, stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

| Hydrophilicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com